Bamboo fiber garment fabric with anti-bacteria function

A technology of antibacterial effect and bamboo fiber, applied in the field of fabrics, can solve the problems of low added value, single function and low grade, and achieve the effect of novel functional design, uniform dyeing and high added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

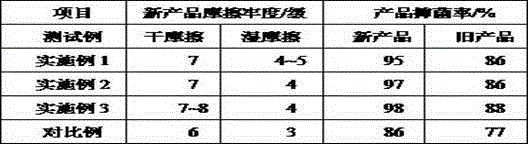

Examples

Embodiment 1

[0031] A kind of bamboo fiber clothing fabric with antibacterial effect is obtained by the raw material blending of following weight ratio:

[0032] Bamboo fiber 95%

[0033] Hemp Fiber 1.7%

[0035] Soy protein fiber 1.2%

[0036] Silver fiber 0.3%

[0037] Carbonized cotton bactericidal fiber 0.4%.

[0038] A kind of preparation method of the bamboo fiber garment fabric with bacteriostasis, comprises the steps:

[0039] (1) Blending bamboo fiber, hemp fiber, aloe fiber, soybean protein fiber, silver fiber and carbonized cotton sterilizing fiber according to the ratio in the formula to obtain a blended product;

[0040] (2) Dissolve chitosan in 2% acetic acid solution at a concentration of 0.5%, sonicate until it is completely dissolved without air bubbles, soak the blended product in the chitosan solution for 30 minutes, take it out and dry it;

[0041] (3) Immerse the blended fabric in the compound enzyme preparation, the dosage is 0.8% o...

Embodiment 2

[0050] A kind of bamboo fiber clothing fabric with antibacterial effect is obtained by the raw material blending of following weight ratio:

[0051] Bamboo fiber 95%

[0052] Hemp Fiber 1.7%

[0054] Soy protein fiber 1.2%

[0055] Silver fiber 0.3%

[0056] Carbonized cotton bactericidal fiber 0.4%.

[0057] A kind of preparation method of the bamboo fiber garment fabric with bacteriostasis, comprises the steps:

[0058] (1) Blending bamboo fiber, hemp fiber, aloe fiber, soybean protein fiber, silver fiber and carbonized cotton sterilizing fiber according to the ratio in the formula to obtain a blended product;

[0059] (2) Dissolve chitosan in 2% acetic acid solution at a concentration of 0.5%, sonicate until it is completely dissolved without air bubbles, soak the blended product in the chitosan solution for 33 minutes, take it out and dry it;

[0060] (3) Soak the blended fabric in the compound enzyme preparation, the dosage is 1% owf, p...

Embodiment 3

[0069] A kind of bamboo fiber clothing fabric with antibacterial effect is obtained by the raw material blending of following weight ratio:

[0070] Bamboo fiber 95%

[0071] Hemp Fiber 1.7%

[0073] Soy protein fiber 1.2%

[0074] Silver fiber 0.3%

[0075] Carbonized cotton bactericidal fiber 0.4%.

[0076] A kind of preparation method of the bamboo fiber garment fabric with bacteriostasis, comprises the steps:

[0077] (1) Blending bamboo fiber, hemp fiber, aloe fiber, soybean protein fiber, silver fiber and carbonized cotton sterilizing fiber according to the ratio in the formula to obtain a blended product;

[0078] (2) Dissolve chitosan in 2% acetic acid solution at a concentration of 0.5%, sonicate until it is completely dissolved without air bubbles, soak the blended product in the chitosan solution for 35 minutes, take it out and dry it;

[0079] (3) Immerse the blended fabric in the compound enzyme preparation, the dosage is 0.8~1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com