Natural dye fixing agent and preparation method thereof

A technology of natural dyes and color-fixing agents, applied in the direction of dyeing, textile and papermaking, etc., can solve problems such as affecting the fading of dyes, and achieve the effect of improving color fastness and strong affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Preparation of natural dye fixing agent

[0050] Step 1), add 106 kilograms of dimethyl diallyl ammonium chloride, 5.7 kilograms of monoallylamine, 63 kilograms of deionized water in the reactor, heat up to 90 DEG C, dropwise add ammonium persulfate aqueous solution (0.07 kilograms per Ammonium sulfate was dissolved in 1.33 kg of deionized water), and the dropwise addition was completed in 3 hours, and then kept at 90° C. for 6 hours, and ended.

[0051] Step 2), add 37 kg of epichlorohydrin and 64.5 kg of deionized water into the reactor, add 6 kg of ethylenediamine dropwise, during which the temperature is controlled not to be higher than 70°C, after the dropwise addition is completed, continue to keep warm at 70°C for 3 hours, and end .

[0052] In step 3), mix the products in step 1) and step 2), stir evenly, then raise the temperature to 50° C., keep the temperature for 4 hours, and end.

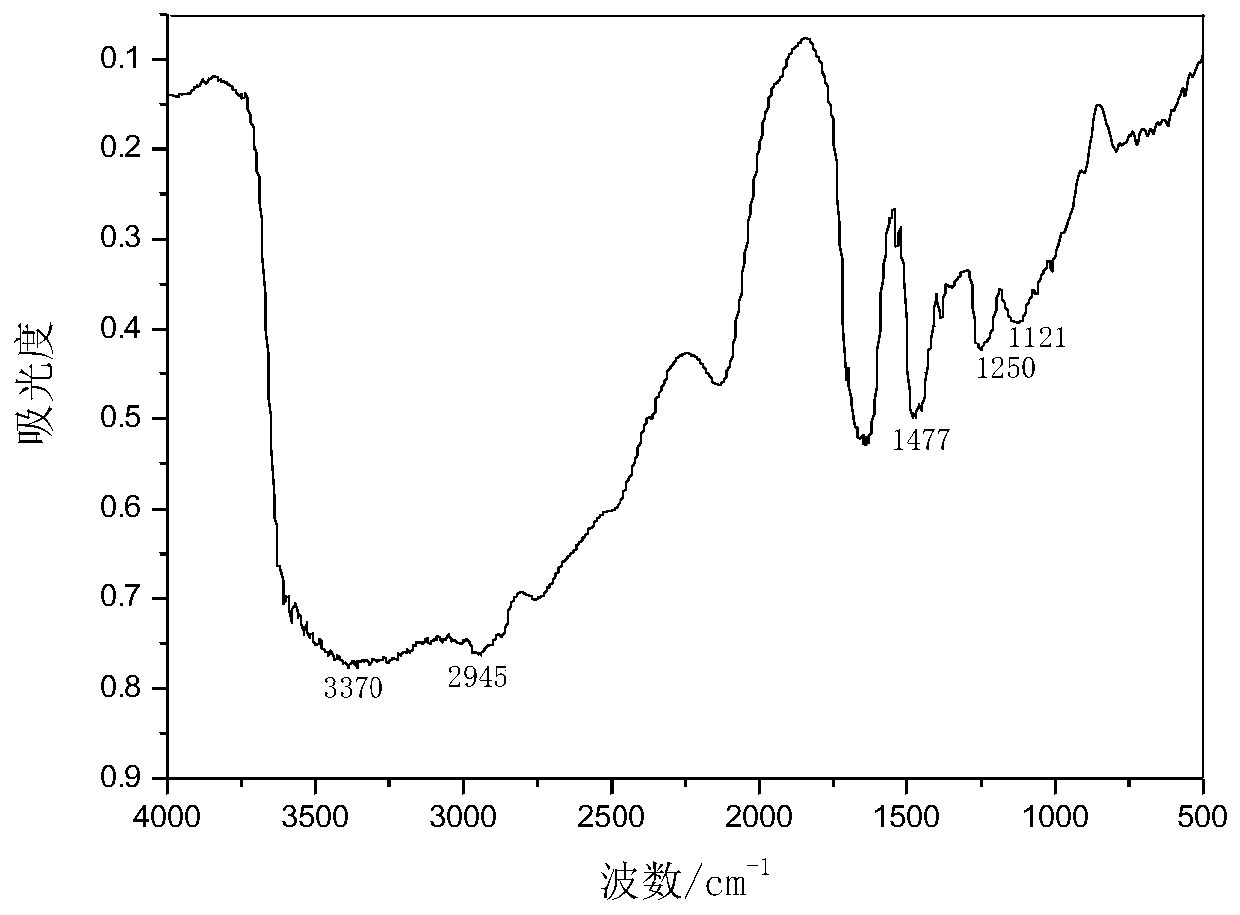

[0053] The molecular structure of the above-mentioned synthetic natural d...

Embodiment 2

[0061] 1. Preparation of natural dye fixing agent

[0062] Step 1), add 53.3 kilograms of dimethyl diallylammonium chloride, 9.7 kilograms of diallylamine, 20.4 kilograms of deionized water in the reactor, raise the temperature to 60 DEG C, dropwise add ammonium persulfate aqueous solution (0.09 kilograms per Ammonium sulfate was dissolved in 0.81 kg of deionized water), and the dropwise addition was completed in 4 hours, and then kept at 60° C. for 8 hours, and ended.

[0063] Step 2), add 37 kg of epichlorohydrin and 43 kg of deionized water into the reactor, add 6 kg of ethylenediamine dropwise, during which the temperature is controlled not to be higher than 60°C, after the dropwise addition is completed, continue to keep warm at 60°C for 2 hours, and end .

[0064] In step 3), mix the products in step 1) and step 2), stir evenly, then raise the temperature to 60° C., keep the temperature for 3 hours, and end.

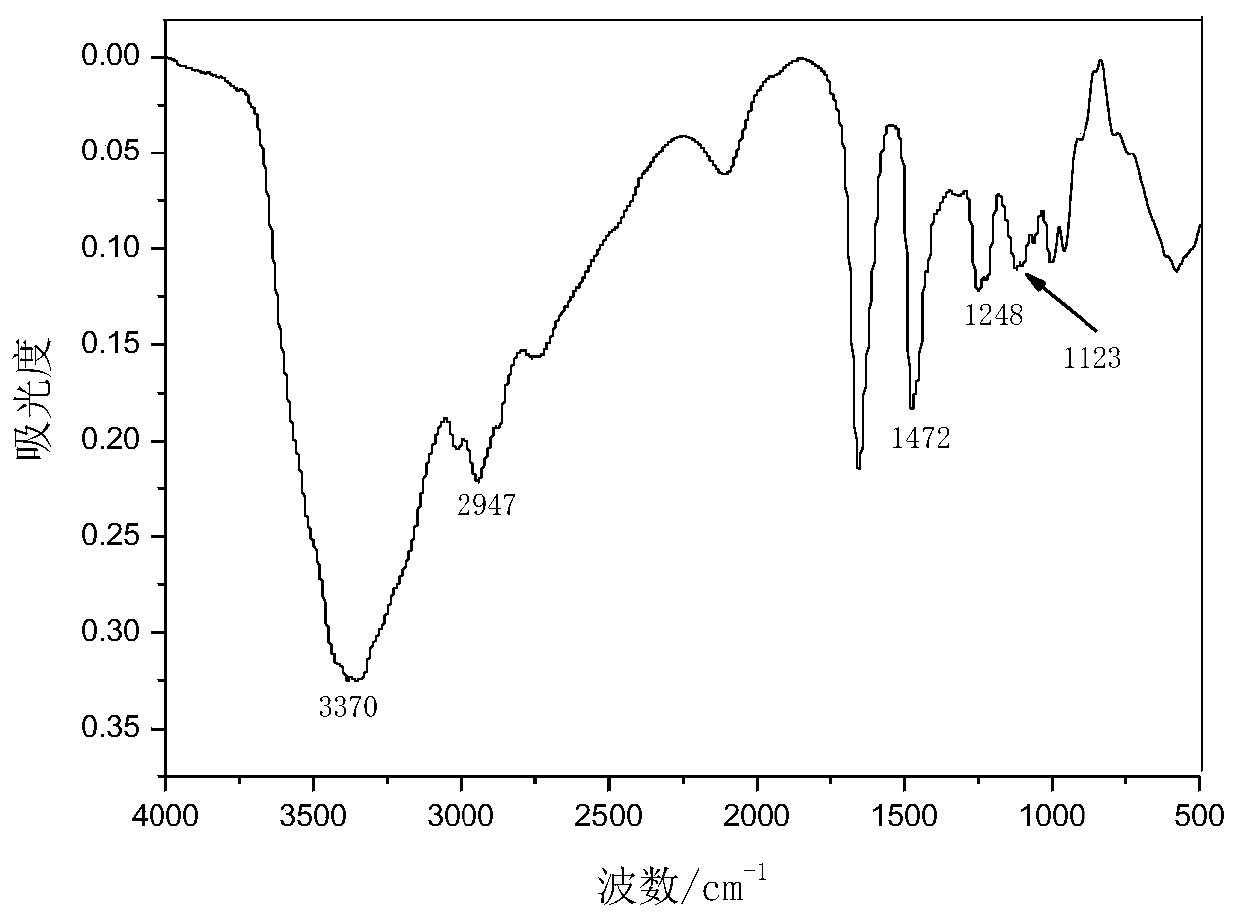

[0065] The above-mentioned synthetic natural dye fixing age...

Embodiment 3

[0073] 1. Preparation of natural dye fixing agent

[0074] Step 1), add 80 kilograms of dimethyl diallylammonium chloride, 9.7 kilograms of diallylamine, 156 kilograms of deionized water in the reactor, raise the temperature to 70 DEG C, dropwise add aqueous solution of ammonium persulfate (0.23 kilograms of over Ammonium sulfate was dissolved in 0.23 kg of deionized water), and the dropwise addition was completed in 5 hours, and then kept at 70° C. for 7 hours, and ended.

[0075] Step 2), add 37 kg of epichlorohydrin and 100 kg of deionized water into the reactor, add 6 kg of ethylenediamine dropwise, during which the temperature is controlled not to be higher than 80°C, after the dropwise addition is completed, continue to keep warm at 80°C for 1 hour, and end .

[0076] In step 3), mix the products in step 1) and step 2), stir evenly, then raise the temperature to 70° C., keep the temperature for 2 hours, and end.

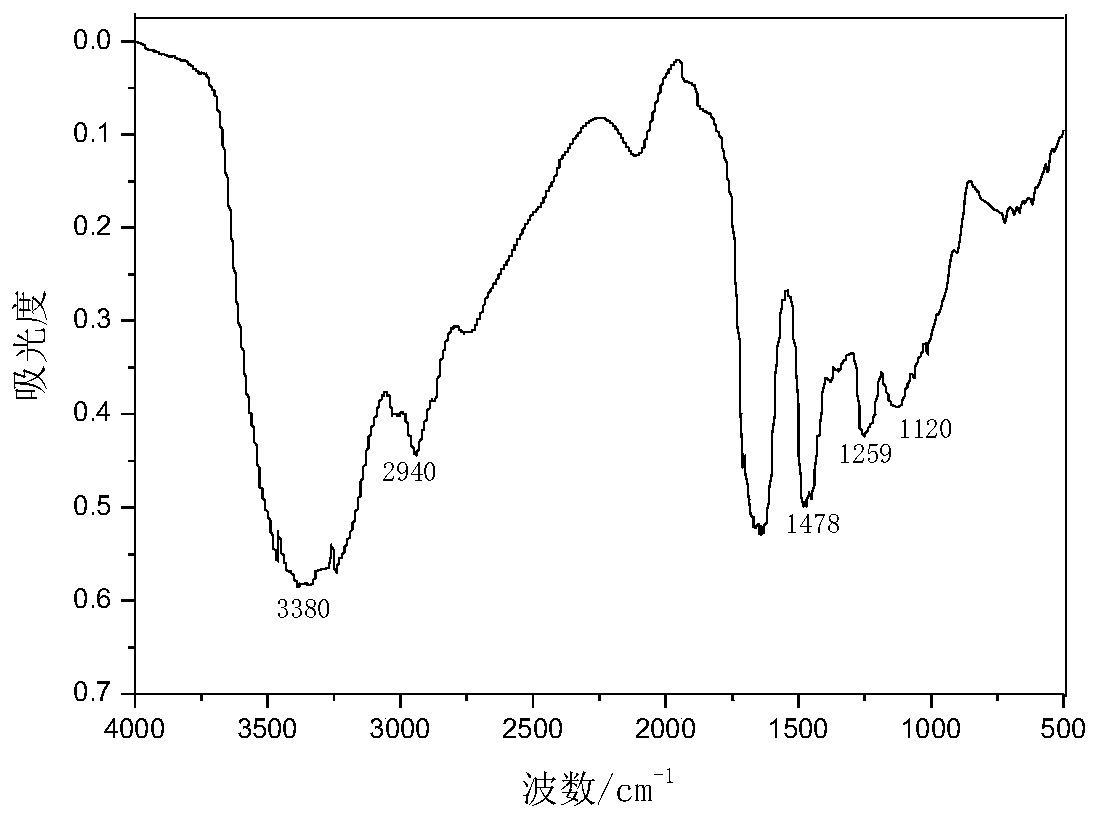

[0077] The above-mentioned synthetic natural dye fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com