Hydrophilic strong base resistant color fixing agent and preparation method thereof

A technology of strong alkali resistance and color-fixing agent, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of large influence of fabric color change, decline of color-fixing effect, and general color-fixing effect, so as to improve the color fastness of fabrics, Reduce the generation of floating color, color fixing effect and excellent effect of alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

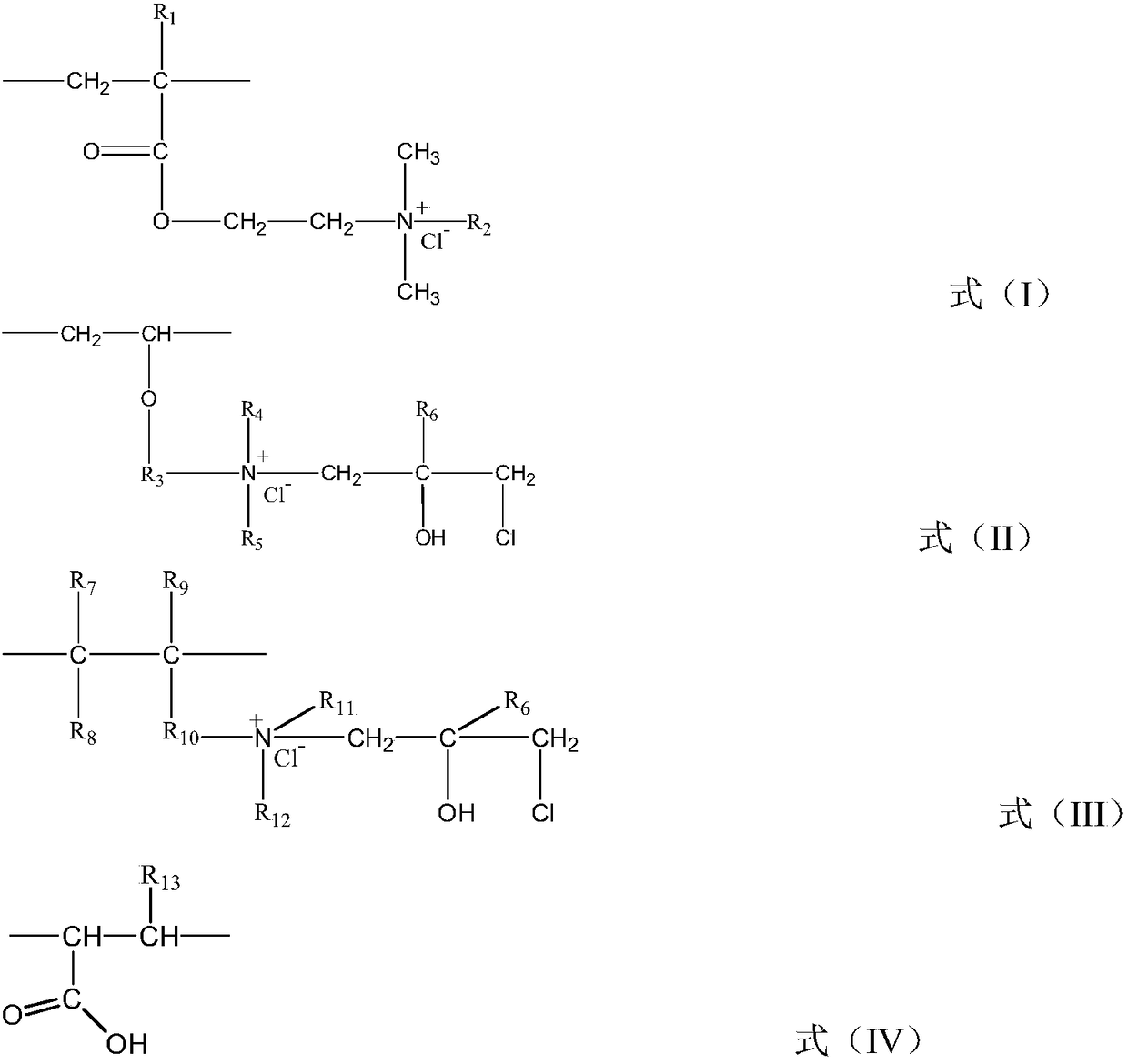

[0054] In a preferred embodiment of the present invention, the present invention provides a preparation method of the above-mentioned hydrophilic and strong alkali-resistant fixing agent, the method comprising the following steps:

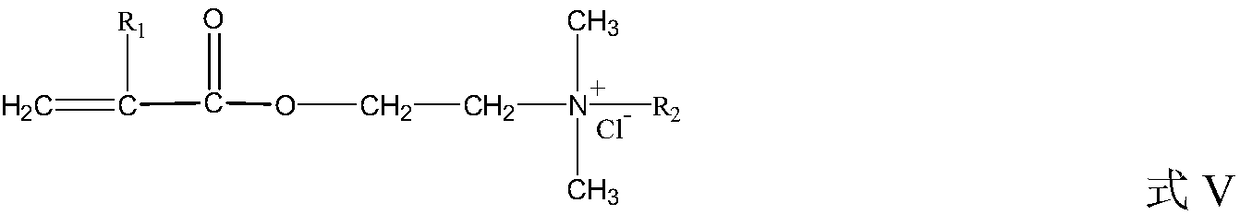

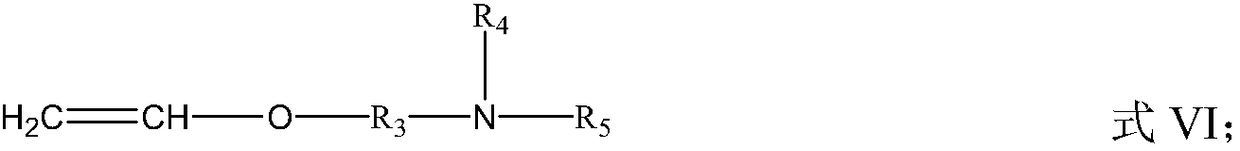

[0055] 1) A (meth)acryloyloxy quaternary ammonium salt cationic monomer represented by a mole of formula (V), b mole of vinyl ether monomer containing an amine group represented by formula (VI), and c mole of formula (VII) The enamine monomer, d mole of the unsaturated carboxylic acid monomer represented by formula (VIII), and water (preferably deionized water) are added to the reactor and stirred. It is preferable to stir at 40-80°C for 10-20 minutes. In the above-mentioned monomer mixture, it is preferable to optionally add 10-25% by mass of an acid agent and 20-60% by mass of water based on the total weight of the monomers. The aforementioned acid agent is preferably a strong acid, more preferably a strong inorganic acid such as hydrochloric acid ...

Embodiment 1

[0079] In a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, 30g of acryloyloxyethyl trimethylammonium chloride (80%; M=193.67; n=0.1239mol), 8g 2-(diethyl) Amine) ethanol vinyl ether (M=143; n=0.05594mol), 4.6g N-ethylmethacrylamine (M=99.17; n=0.04638mol), 10g crotonic acid (M=86.09; n=0.1162mol) ), 11g hydrochloric acid (37%; M=36.46; n=0.1116mol) and 26.4g deionized water, after stirring at 60℃ for 10min, start dripping 1% ammonium persulfate aqueous solution, 1.5h dripping is over, the temperature is raised to 80℃ , Keep for 2.5h, then lower the temperature to 40℃, adjust the pH to 7-8 with NaOH, add 10g epichlorohydrin (M=92.52; n=0.1081mol) dropwise, the dripping ends for 1.5h, keep for 3h. Get hydrophilic and alkali-resistant fixing agent 1. The application effect is shown in Table 1 and Table 2. The weight average molecular weight of the hydrophilic strong alkali-resistant fixing agent 1 is 35,000.

Embodiment 2

[0081] In a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, 37g methacryloxyethyl trimethylammonium chloride (75%; M=207.7; n=0.1336mol), 10g 2-(two Ethylamine) ethanol vinyl ether (M=143; n=0.6993mol), 5g N-methyl-2-methylallylamine (M=85.15; n=0.05872mol), 8g crotonic acid (M= 86.09; n = 0.09293 mol), 12 g hydrochloric acid (37%; M = 36.46; n = 0.1218 mol), and 16 g deionized water, stirred at 70°C for 10 minutes, and then started to add 1% ammonium persulfate aqueous solution, and the 1 hour addition was over. Warm up to 75°C, keep it for 3h, then lower the temperature to 50°C, adjust the pH to 7-8 with NaOH, add 12g epichlorohydrin (M=92.52; n=0.1297mol) dropwise, finish the 2h dropping, keep it for 2.5h . Get hydrophilic and alkali-resistant fixing agent 2. The application effect is shown in Table 1 and Table 2. The weight average molecular weight of the hydrophilic strong alkali-resistant color fixing agent 2 is 67,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com