A kind of preparation method of pearlescent pigment

A pearlescent pigment and solution technology, applied in inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of poor film stability and difficulty in obtaining uniform color, and achieve the effect of film stability and uniform hue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

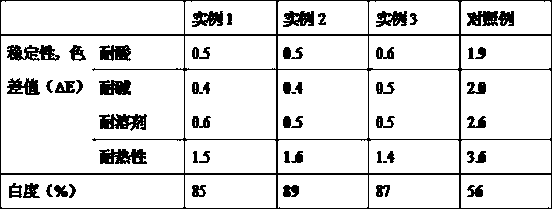

Examples

preparation example Construction

[0022] The preparation method of sulfuric acid titanyl acid solution: put titanyl sulfate, 1.3mol / L sulfuric acid solution and water into the container according to the mass ratio of 4~6:3~5:15~20, stir at 400r / min for 20~25min, That's it.

[0023] The preparation method of pearlescent pigment of the present invention, comprises the steps:

[0024] (1) According to the mass ratio of 1:3, take mica powder and 1.8mol / L hydrochloric acid in a container and mix evenly, keep warm at 70-80°C for 1-2 hours, filter while it is hot, and collect the filter residue, according to the mass ratio of 1:2 ~4, mix the filter residue with 1.2mol / L hydrogen peroxide evenly, heat at 85~90℃ for 55~65min, cool to room temperature, filter, collect the filtrate, wash the filtrate with water until there is no chloride ion in the filtrate, wash the The final filtrate is dried at 100°C for 4 to 5 hours, and the dried matter is collected;

[0025] (2) According to the mass ratio of 4~6:1:0.4~0.8:2~4, p...

example 1

[0030] Mica powder (manufacturer: Guangdong Yufeng Powder Material Co., Ltd.; bulk density: 2.6 g / cm 3 ; Whiteness: 96; Fineness: the average particle size is 10.5±0.5μm).

[0031] Choice of surfactant: triethanolamine oleate.

[0032] The preparation method of sulfuric acid titanyl acid solution: put titanyl sulfate, 1.3mol / L sulfuric acid solution and water into a container at a mass ratio of 4:3:15, and stir at 400r / min for 25min.

[0033] The preparation method of pearlescent pigment of the present invention, comprises the steps:

[0034] (1) According to the mass ratio of 1:3, take mica powder and 1.8mol / L hydrochloric acid in a container and mix evenly, keep warm at 80°C for 2 hours, filter while it is hot, collect the filter residue, and mix the filter residue with Mix 1.2mol / L hydrogen peroxide evenly, heat at 90°C for 65 minutes, cool to room temperature, filter, collect the filtrate, wash the filtrate with water until there is no chloride ion in the filtrate, and ...

example 2

[0040] Mica powder (manufacturer: Guangdong Yufeng Powder Material Co., Ltd.; bulk density: 2.6 g / cm 3 ; Whiteness: 96; Fineness: the average particle size is 10.5±0.5μm).

[0041] Choice of surfactant: fatty amine polyoxyethylene ether.

[0042] The preparation method of sulfuric acid titanyl acid solution: put titanyl sulfate, 1.3mol / L sulfuric acid solution and water into a container at a mass ratio of 4:3:15, and stir at 400r / min for 25min.

[0043] The preparation method of pearlescent pigment of the present invention, comprises the steps:

[0044] (1) According to the mass ratio of 1:3, take mica powder and 1.8mol / L hydrochloric acid in a container and mix evenly, keep warm at 70°C for 1 hour, filter while it is hot, and collect the filter residue, according to the mass ratio of 1:2, mix the filter residue with Mix 1.2mol / L hydrogen peroxide evenly, heat at 85°C for 55 minutes, cool to room temperature, filter, collect the filtrate, wash the filtrate with water until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com