A self-dulling water-based transfer aluminum coating

A self-extinguishing, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of heavy pollution, strong odor, cumbersome process, etc., and achieve the effect of reducing the cost of use, convenient production and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

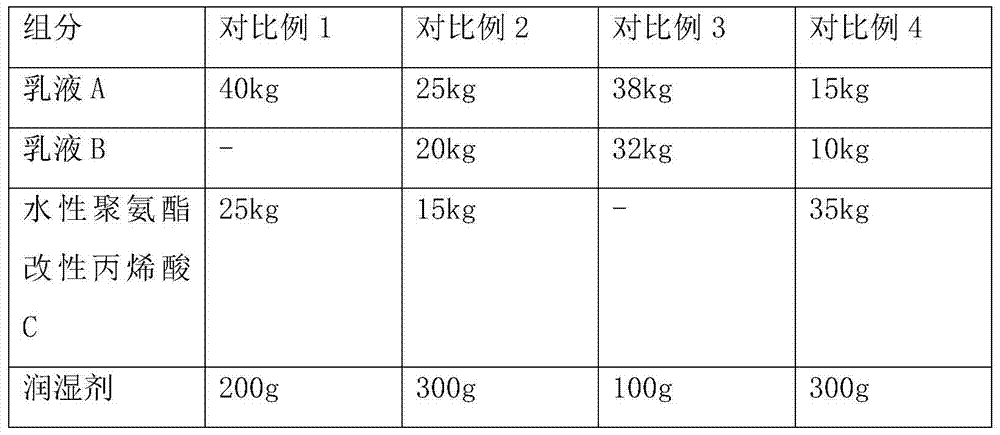

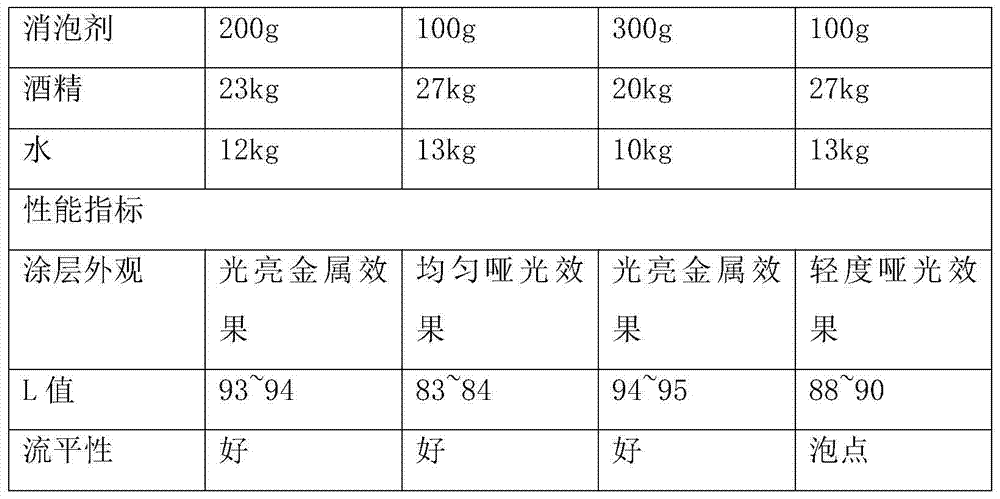

Embodiment 1

[0029] A method for preparing self-dulling water-based transfer aluminized coating, the method comprises the following processing steps:

[0030] (1) 35 kilograms of water-based polyurethane emulsion A, 5 kilograms of water-based polyurethane emulsion B, and 25 kilograms of water-based polyurethane modified acrylic acid C are dropped into the reactor successively, and stirred at a slow speed for 0.5 hour;

[0031] (2) Keep stirring and drop into the reaction kettle after premixing 12 kilograms of water and 23 kilograms of ethanol, and stir for 0.5 hour;

[0032] (3) After mixing evenly, slowly put 200g of wetting agent into the reaction kettle and stir at high speed for 10-15 minutes;

[0033] (4) After mixing evenly, slowly put 200g of defoamer into the reaction kettle and stir at high speed for 20-30 minutes.

[0034] 100.4 kilograms of final gained coatings, solid content 22%. Control coating dry weight 1.4g / m 2 , The coating has good leveling property, no orange peel an...

Embodiment 2

[0036] A method for preparing self-dulling water-based transfer aluminized coating, the method comprises the following processing steps:

[0037] (1) 30 kilograms of water-based polyurethane emulsion A, 15 kilograms of water-based polyurethane emulsion B, and 15 kilograms of water-based polyurethane modified acrylic acid C are dropped into the reactor successively, and stirred at a slow speed for 0.5 hour;

[0038] (2) Keep stirring and drop into the reactor after premixing 13 kilograms of water and 27 kilograms of ethanol, and stir for 0.5 hour;

[0039] (3) After mixing evenly, slowly put 300g of wetting agent into the reaction kettle, and stir at high speed for 10-15 minutes;

[0040] (4) After mixing evenly, slowly put 100g of defoamer into the reaction kettle and stir at high speed for 20-30 minutes.

[0041] 100.4 kilograms of final gained coatings, solid content 20%. Control coating dry weight 1.4g / m 2 , The coating has good leveling property, no orange peel and no b...

Embodiment 3

[0043] A method for preparing self-dulling water-based transfer aluminized coating, the method comprises the following processing steps:

[0044] (1) 35 kilograms of water-based polyurethane emulsion A, 30 kilograms of water-based polyurethane emulsion B, and 5 kilograms of water-based polyurethane modified acrylic acid C are dropped into the reactor successively, and stirred at a slow speed for 0.5 hour;

[0045] (2) Keep stirring and drop into the reactor after premixing 10 kilograms of water and 20 kilograms of ethanol, and stir for 0.5 hour;

[0046] (3) After mixing evenly, slowly put 100g of wetting agent into the reaction kettle and stir at high speed for 10-15 minutes;

[0047] (4) After mixing evenly, slowly put 300g of defoamer into the reaction kettle and stir at high speed for 20-30 minutes.

[0048] 100.4 kilograms of final gained coatings, solid content 22%. Control coating dry weight 1.4g / m 2 , The coating has good leveling property, no orange peel and no bub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com