Coating for carbon-free paper with developer layer and use thereof

A technology of carbonless copy paper and color developer, applied in paper coatings, pigmented coatings, papermaking, etc., can solve the problems of high surface tension, poor paint running performance, high viscosity, etc., and achieve low dynamic surface tension and good coating effect , the effect of uniform coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8, comparative Embodiment 1

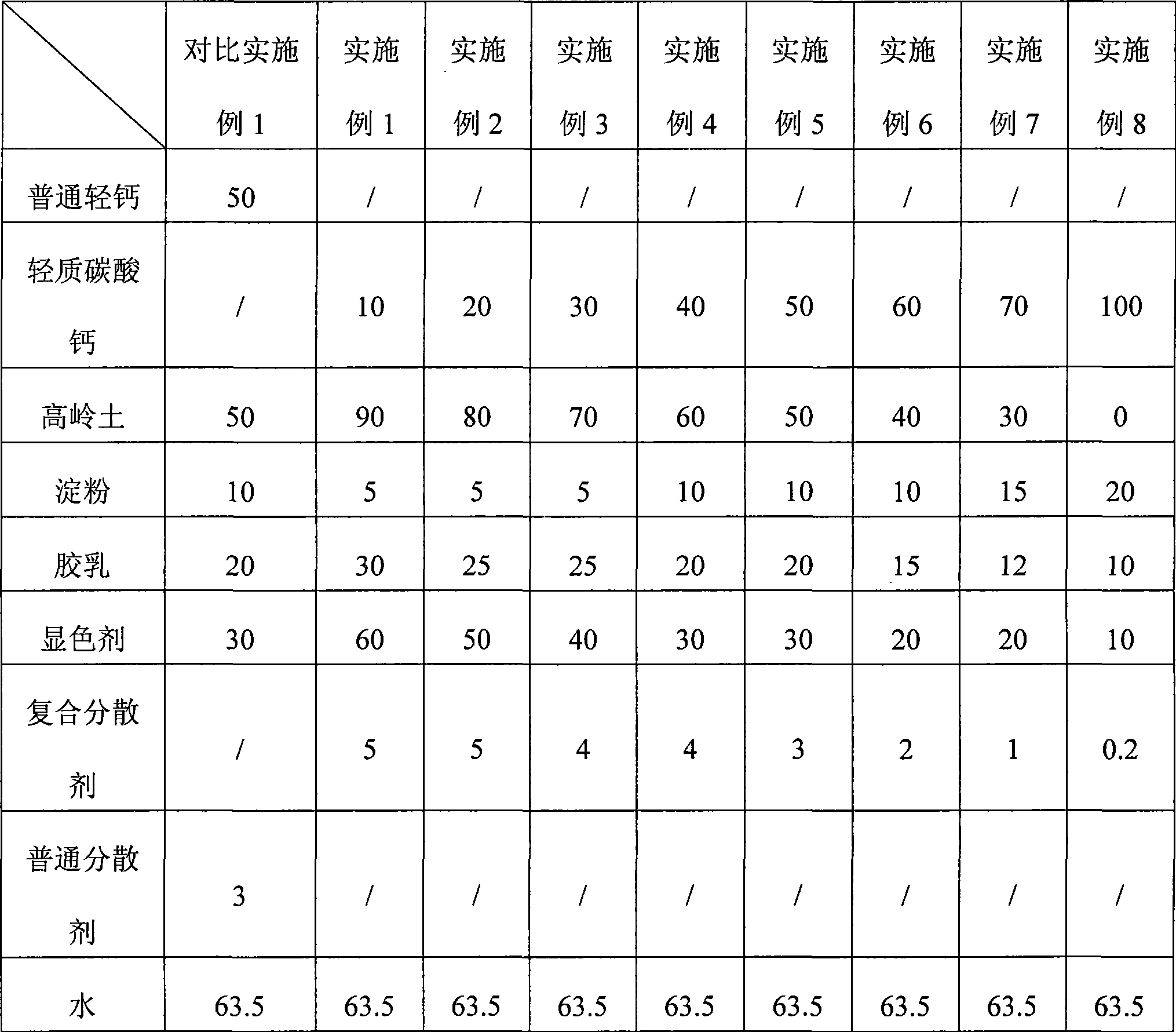

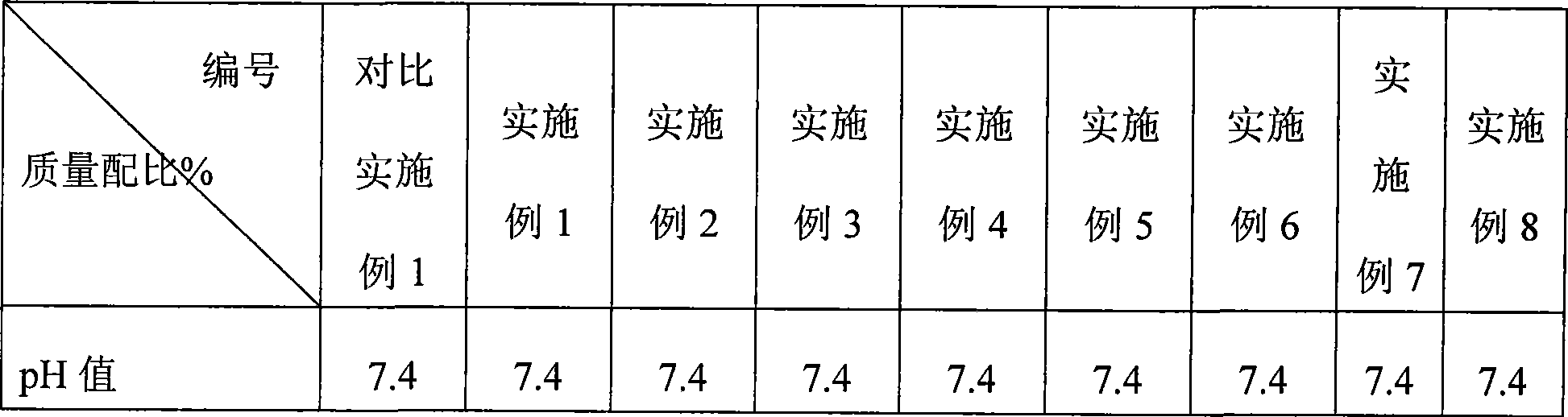

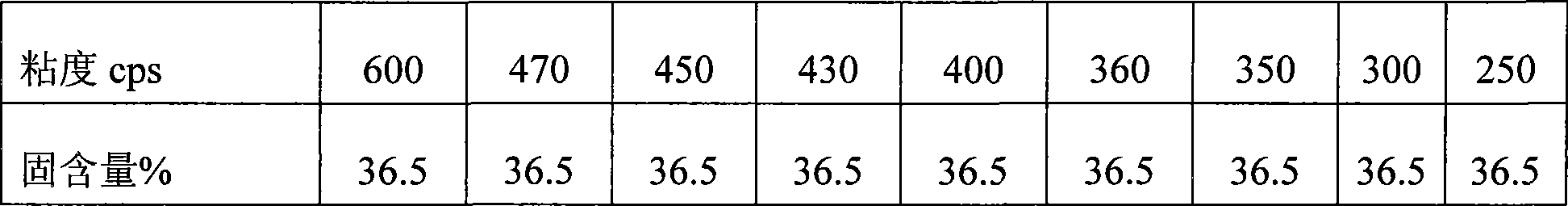

[0036] The coating formula is shown in Table 1, all are mass proportioning %

[0037]

[0038] Among them: light calcium carbonate is special light calcium for carbonless copy paper produced by Shanghai Dongsheng New Material Co., Ltd. with the brand name DS-CFPCC;

[0039] The latex is the propylbenzene latex of the brand name DA-SA821 produced by Shanghai Dongsheng New Material Co., Ltd.;

[0040] The composite dispersant is compounded by sodium polyacrylate (the product produced by Shanghai Dongsheng New Material Co., Ltd. with the brand name DS-FS551) with a solid content of 42%, sodium hexametaphosphate and sodium tripolyphosphate. The mass ratio is 6:2:2; the kaolin is the kaolin produced by the U.S. Huber Engineered Materials company (Huber Engineering Materials Company) and is Polygloss90;

[0041] The starch is the cassava modified starch of HQ-2 provided by Beihai Haoxing Trading Co., Ltd.;

[0042] The color developer is the resin color developer of Ruifeng Che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com