Polycationic formaldehyde-free color fixing agent and preparation method thereof

A polycation and color-fixing agent technology, applied in the field of textile auxiliaries, can solve the problems of epichlorohydrin being highly toxic, causing great harm to the human body, restricting the industrialization process of formaldehyde-free color-fixing agents, etc., and achieving strong color-fixing power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

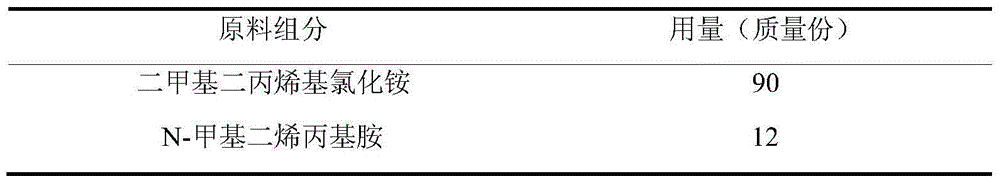

[0033] The ratio of each raw material is as follows:

[0034]

[0035]

[0036]The temperature of the polymerization reaction was 70°C; 60 minutes after the start of the polymerization reaction, the remaining monomer solution and initiator solution were added dropwise for 1 hour, and the temperature was lowered to terminate the polymerization reaction after 4 hours after the dropwise addition was completed.

Embodiment 2

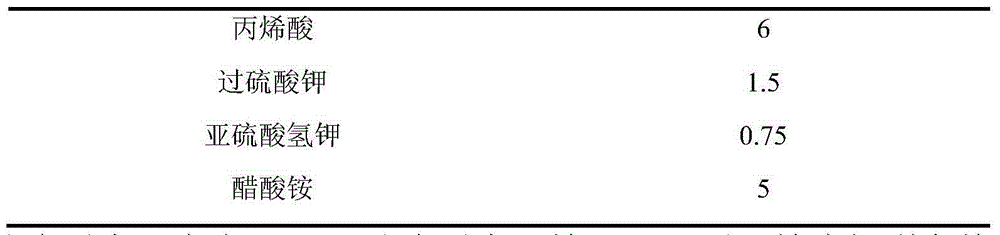

[0038] The ratio of each raw material is as follows:

[0039]

[0040] The temperature of the polymerization reaction was 80°C; 30 minutes after the start of the polymerization reaction, the remaining monomer solution and initiator solution were added dropwise for 2.5 hours, and the temperature was lowered to terminate the polymerization reaction after 3 hours after the completion of the dropwise addition.

Embodiment 3

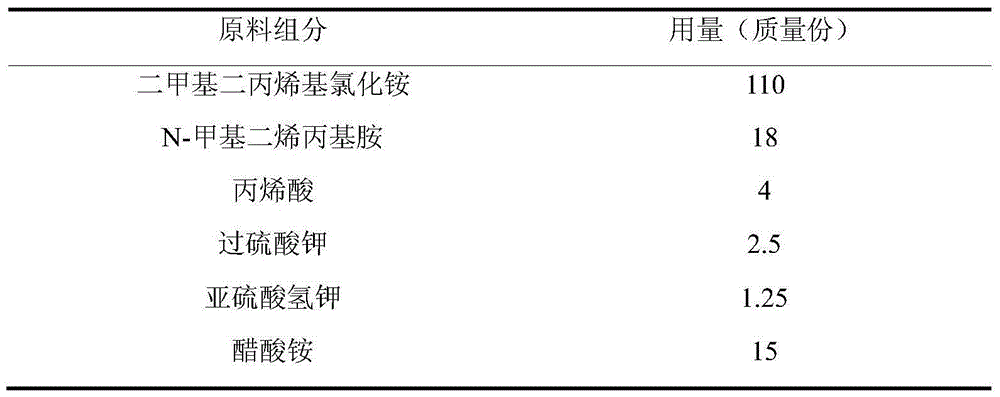

[0042] The ratio of each raw material is as follows:

[0043]

[0044] The temperature of the polymerization reaction was 75°C; 45 minutes after the start of the polymerization reaction, the remaining monomer solution and initiator solution were added dropwise for 105 minutes, and 210 minutes after the completion of the dropwise addition, the temperature was lowered to terminate the polymerization reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com