Synthesis method and application of formaldehyde-free acid dye fixing agent

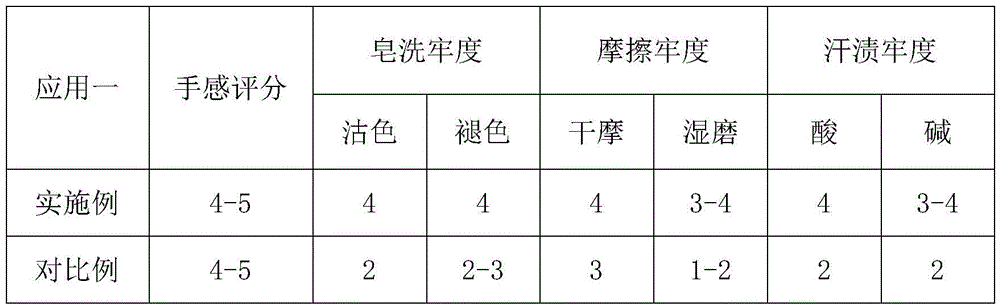

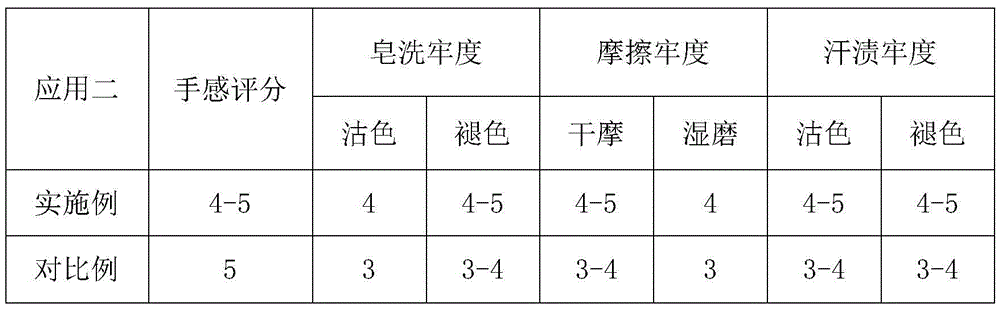

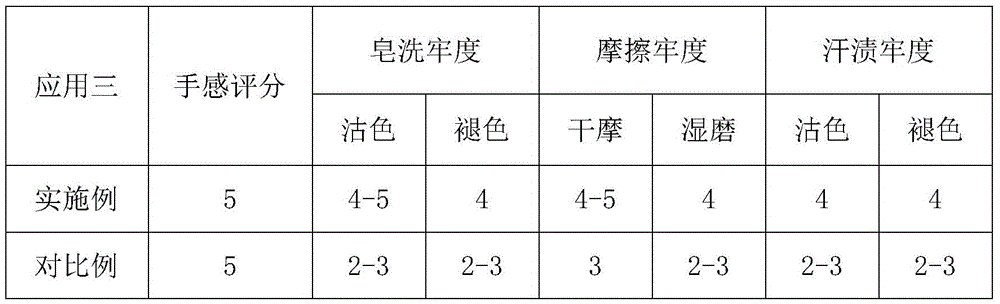

A technology of acid dyes and synthesis methods, applied in dyeing, textile and papermaking, etc., can solve the problem of insufficient color fixing effect of polyester fibers and silk fabrics, poor wet ironing fastness and chlorine immersion fastness, affecting fabrics. Color light and hand feel, etc., to achieve the effect of promoting industrialization, improving fastness to friction and perspiration, and improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for synthesizing formaldehyde-free acid dye fixing agent, using acrylic acid, 2-naphthol, 2-acrylamide-2-methylpropanesulfonic acid as raw materials, ammonium acetate as initiator, and nickel chloride as catalyst. It includes the following steps:

[0041] Add 12 times the weight of acrylic acid to the acrylic acid and mix the mixture uniformly and raise the temperature to 15°C, add nickel chloride (the addition amount is 0.1% of the weight of acrylic acid) and mix uniformly, keep the temperature for 3 hours;

[0042] Add 2-naphthol and 2-acrylamide-2-methylpropanesulfonic acid solids so that the mass concentrations of 2-naphthol and 2-acrylamide-2-methylpropanesulfonic acid are 15% and 20% respectively, and mix Reflux and heat for 3h after homogenization;

[0043] Slowly add ammonium acetate aqueous solution (mass concentration of 20%) so that the ammonium acetate concentration is 0.4%, and the temperature of the water bath is 60°C and the reaction is stirred at low ...

Embodiment 2

[0046] A method for synthesizing formaldehyde-free acid dye fixing agent, using acrylic acid, 2-naphthol, 2-acrylamide-2-methylpropanesulfonic acid as raw materials, ammonium acetate as initiator, and nickel chloride as catalyst. It includes the following steps:

[0047] Add 13 times the weight of acrylic acid to the acrylic acid and mix the mixture uniformly and raise the temperature to 20°C, add nickel chloride (addition amount is 0.3% of the acrylic acid weight) and mix uniformly, keep it warm and stand for 5h;

[0048] Add 2-naphthol and 2-acrylamide-2-methylpropanesulfonic acid solids so that the mass concentrations of 2-naphthol and 2-acrylamide-2-methylpropanesulfonic acid are 20% and 22% respectively, and mix Reflux and heat for 4h after homogenization;

[0049] Slowly add ammonium acetate aqueous solution (with a mass concentration of 25%) to make the mass concentration of ammonium acetate 0.7%, and the temperature of the water bath is 65°C with low-speed stirring for 14 ho...

Embodiment 3

[0052] A method for synthesizing formaldehyde-free acid dye fixing agent, using acrylic acid, 2-naphthol, 2-acrylamide-2-methylpropanesulfonic acid as raw materials, ammonium acetate as initiator, and nickel chloride as catalyst. It includes the following steps:

[0053] Add 12 times the weight of acrylic acid to the acrylic acid and mix it evenly and heat it up to 20°C, add nickel chloride (additional amount is 0.1% of the weight of acrylic acid) and mix it evenly, keep it warm and stand for 5 hours;

[0054] Add 2-naphthol and 2-acrylamide-2-methylpropanesulfonic acid solids so that the mass concentrations of 2-naphthol and 2-acrylamide-2-methylpropanesulfonic acid are 15% and 22% respectively, and mix Reflux and heat for 3h after homogenization;

[0055] Slowly add ammonium acetate aqueous solution (with a mass concentration of 25%) so that the mass concentration of ammonium acetate is 0.4%, and the temperature of the water bath is 65°C with low-speed stirring for 12 hours;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com