Antistatic agent for dacron textile and preparation method of antistatic agent

A technology of polyester fabric and antistatic agent, applied in the field of antistatic agent and its synthesis, can solve the problems of poor solubility, limited use, and insoluble of hyperbranched polyester, and achieve improved washing resistance, little influence on hand feeling, and chemical resistance. Easy to modify effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

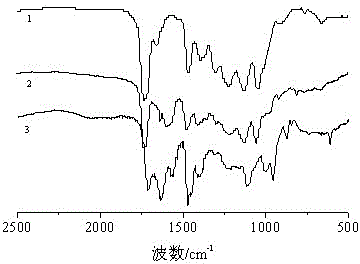

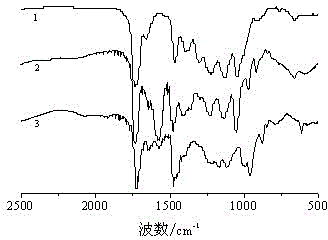

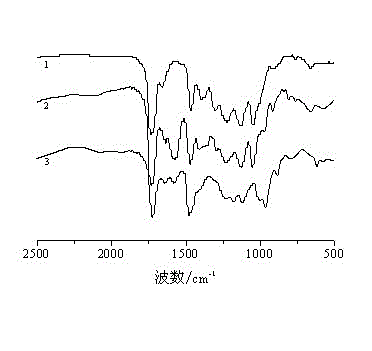

Image

Examples

Embodiment 1

[0030] 1. Add 10.50g (0.005mol) hyperbranched polyester Boltorn H20 into the reaction vessel, heat it to a molten state, turn on the electric stirrer and condensing reflux device, add 0.04g hydroquinone, then add 2.88g (0.040mol ) acrylic acid and 11.00 g toluene.

[0031] 2. Control the temperature at 100°C. When the system forms a homogeneous solution, add 0.06g p-toluenesulfonic acid, reflux for 1 hour, and then cool in an ice-water bath.

[0032] 3. Dissolve the obtained product in 18.90g of N,N-dimethylformamide, add 0.30g of solid sodium hydroxide, and slowly add 6.06g (0.040mol) of glycidyltrimethylammonium chloride dropwise under constant stirring, The reaction was carried out at 50°C for 24 hours, and the solid sodium hydroxide was removed by suction filtration under reduced pressure.

[0033] 4. Remove and recover the solvent. Vacuumize to 0.10Mpa at 70°C and treat for 0.5 hours to remove and recover N,N-dimethylformamide to obtain modified hyperbranched polyester....

Embodiment 2

[0041] 1. Add 10.5g (0.005mol) of hyperbranched polyester into the reaction vessel, heat it to a molten state at 120°C, use an electric stirrer and a condensation reflux device, add 0.04g of hydroquinone, and then add 3.46g (0.048 mol) of acrylic acid and 13.00 g of toluene.

[0042] 2. Control the temperature at 105°C. When the system forms a homogeneous solution, add 0.08g p-toluenesulfonic acid, reflux for 1 hour, and then cool in an ice-water bath.

[0043] 3. Dissolve the obtained product in 19.00g N, N-dimethylformamide, add 0.20g solid sodium hydroxide, and slowly add 4.85g (0.032mol) glycidyltrimethylammonium chloride dropwise under constant stirring, React at 45°C for 24 hours. The solid was removed by suction filtration under reduced pressure.

[0044] 4. Remove and recover the solvent. Vacuumize to 0.10Mpa at 65°C and treat for 1 hour to remove and recover N,N-dimethylformamide to obtain modified hyperbranched polyester.

[0045] 5. Dissolve the modified hyperbr...

Embodiment 3

[0052] 1. Add 10.5g (0.005mol) of hyperbranched polyester into the reaction vessel, heat it to a molten state at 120°C, turn on the electric stirrer and the condensation reflux device, add 0.04g of hydroquinone, and then add 4.32g ( 0.060 mol) of acrylic acid and 13.00 g of toluene.

[0053] 2. Control the temperature at 110°C. When the system forms a homogeneous solution, add 0.08g p-toluenesulfonic acid, reflux for 1 hour, and then cool in an ice-water bath.

[0054] 3. Dissolve the obtained product in 18.80g of N,N-dimethylformamide, add 0.20g of solid sodium hydroxide, and slowly add 4.55g (0.030mol) of glycidyltrimethylammonium chloride dropwise under constant stirring, 50 ℃ should be 24 hours. The solid was removed by suction filtration under reduced pressure.

[0055] 4. Remove and recover the solvent. Vacuumize to 0.10Mpa at 70°C and treat for 0.5 hours to remove and recover N,N-dimethylformamide to obtain modified hyperbranched polyester.

[0056] 5. Dissolve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com