Preparation method of anti-clay concrete admixture

A concrete admixture and admixture technology are applied in the preparation of clay-resistant concrete admixtures and the field of concrete admixture preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of an anti-clay concrete admixture, comprising the preparation of polyether-based glycidyl ether and the preparation of an anti-clay admixture, specifically comprising the following steps,

[0040] (1), preparation of polyether-based glycidyl ether

[0041] Firstly, the polyhydroxy initiator, alkylene oxide and catalyst are reacted under certain temperature and pressure conditions to make polyether polyol; then continue to add epichlorohydrin and react under certain temperature and pressure conditions to obtain polyether Glycidyl ether;

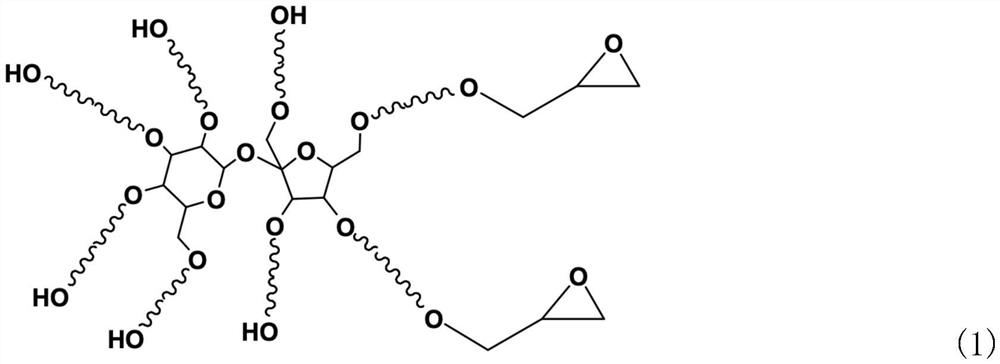

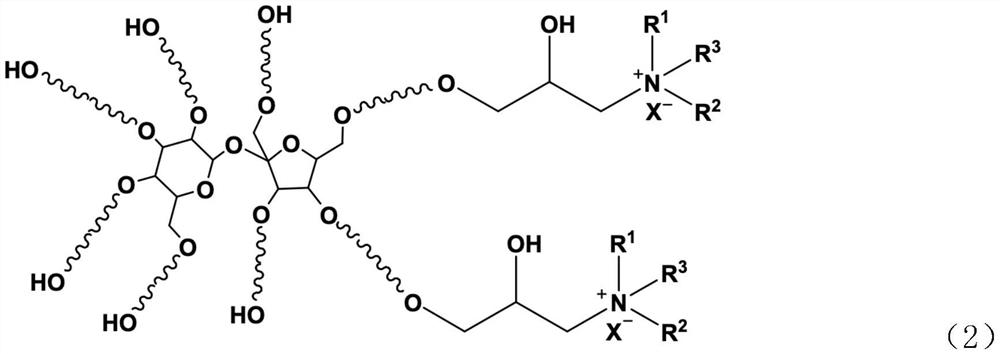

[0042] One of the structural formulas of the polyether-based glycidyl ether described in the above step (1) is shown in the following formula (1),

[0043]

[0044] in," "Represents polyether segment;

[0045] The synthesis process of the polyether-based glycidyl ether described in the above-mentioned step (1) is: in the airtight reaction kettle, add polyhydroxy initiator, polyethylene glycol monomethyl ethe...

Embodiment 1

[0069] Weigh 100.0 parts of sorbitol, 10.0 parts of polyethylene glycol monomethyl ether (Mn=400) as a solvent, and 0.15 parts of sodium hydroxide as a catalyst, and put them into a closed reaction kettle, replace with nitrogen for 3 times, then raise the temperature to 100°C, and pass them in sequence 1210.0 parts of ethylene oxide, 63.7 parts of propylene oxide, the reaction temperature is controlled between 100 ~ 130 ° C, the reaction pressure is controlled between 0.0 ~ 0.4 MPa, after the feeding is completed, the reaction is kept for 0.5 h ~ 1.0 h, and then the temperature is lowered to At 50°C, under the condition of -0.1MPa, the volatile components were distilled off under reduced pressure to obtain polyether polyol. The molecular weight of polyether polyol was 2450 by the hydroxyl value method.

[0070] Add 43.9 parts of sodium hydroxide to the above reaction kettle, replace with nitrogen for 3 times, then raise the temperature to 50°C, gradually add 122.0 parts of epic...

Embodiment 2

[0073] Weigh 100.0 parts of glycerol, 0.0 parts of polyethylene glycol monomethyl ether (Mn=400) as a solvent, and 0.2 parts of potassium hydroxide as a catalyst, put them into a closed reaction kettle, replace with nitrogen for 3 times, then raise the temperature to 100°C, and pass through Add 1,787.0 parts of ethylene oxide, 160.8 parts of glycidol, and 126.1 parts of isopropyl glycidyl ether. The reaction temperature is controlled between 100 and 130°C, and the reaction pressure is controlled between 0.0 and 0.4 MPa. 0.5h to 1.0h, then lower the temperature to 50°C, and distill off the volatile components under reduced pressure at -0.1MPa to obtain polyether polyol. The molecular weight of polyether polyol is 1986 according to the hydroxyl value method.

[0074] Add 121.7 parts of potassium hydroxide to the above reaction kettle, replace with nitrogen for 3 times, then raise the temperature to 60°C, gradually add 241.3 parts of epichlorohydrin, the pressure of the reaction k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com