Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Improves wrinkle recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

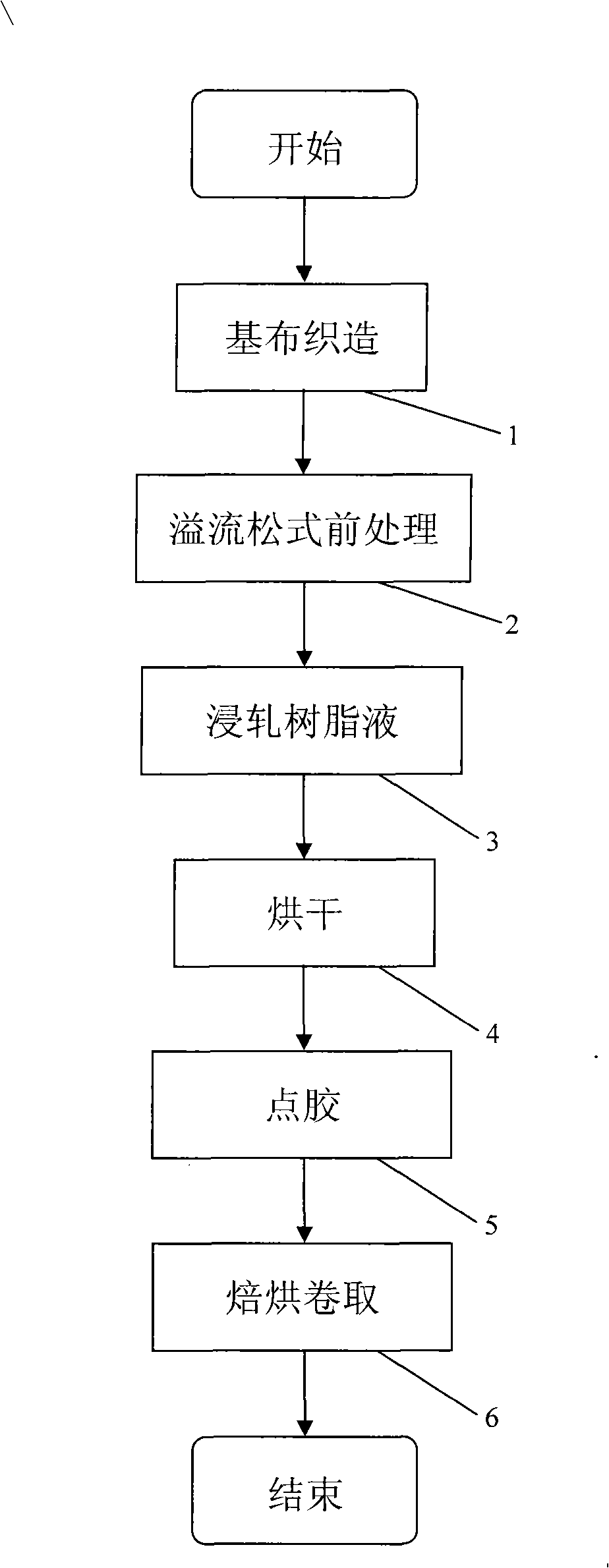

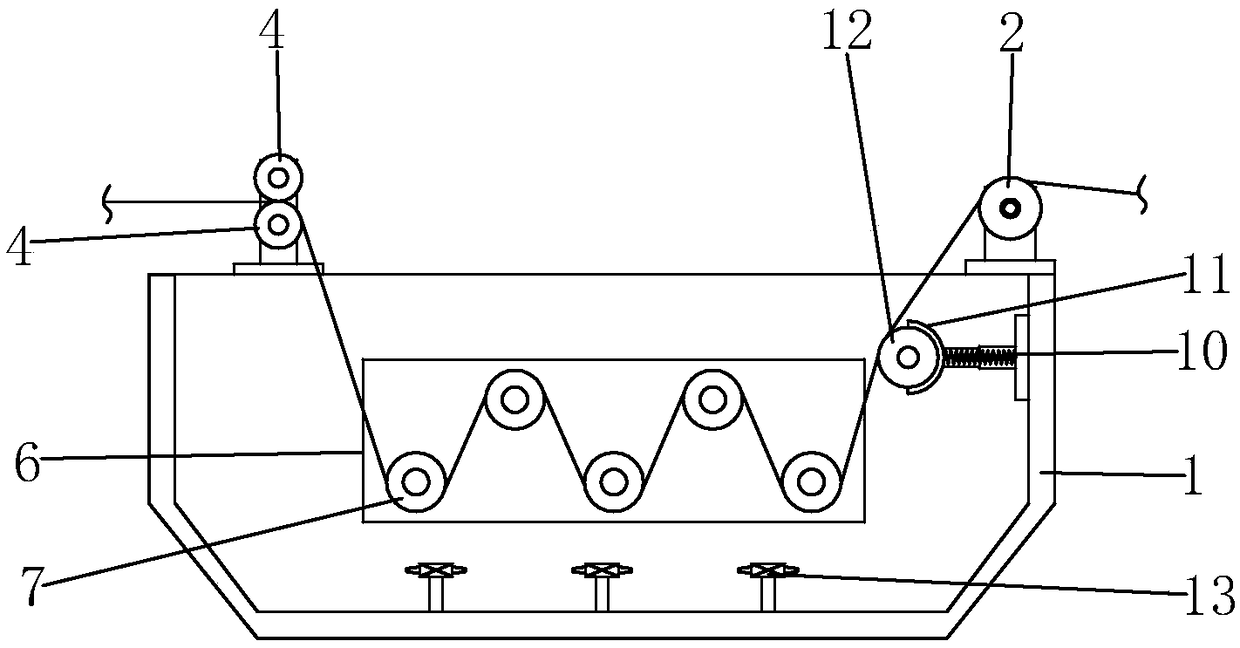

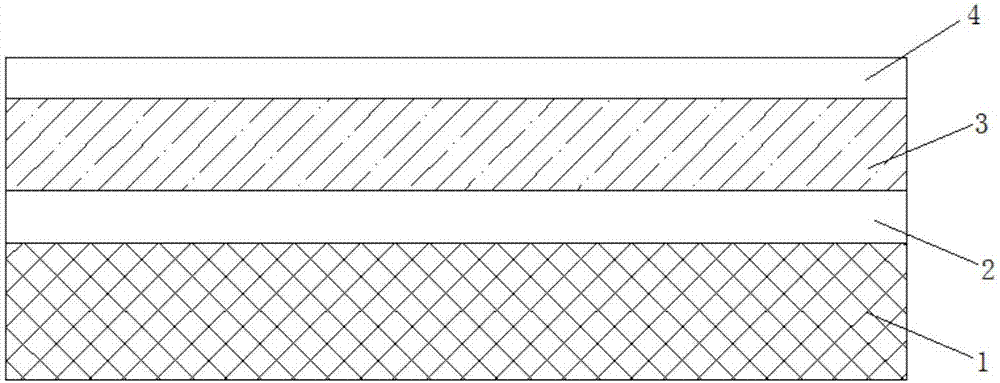

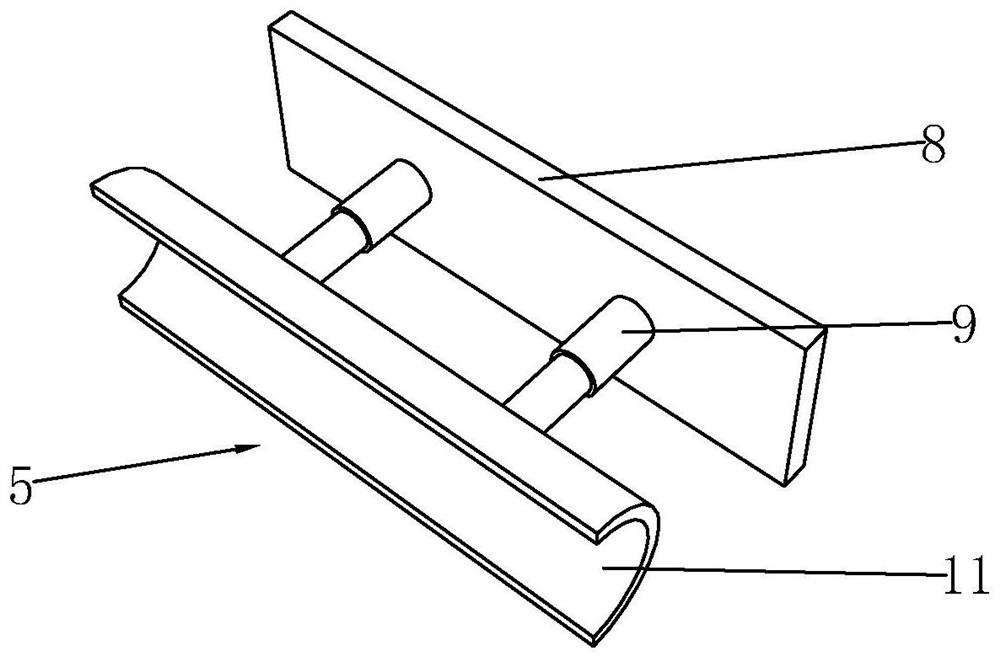

Manufacturing technique of crease-shedding uniforms lining

InactiveCN101288507AImprove deformation recovery performanceImproves wrinkle recoveryGarmentsVegetal fibresFiberPolyamide

The invention discloses a technique for manufacturing anti-wrinkle liner of suits. The technique comprises the processes of weaving base fabric, overflow and loose pre-treatment, immersing in resin liquid and rolling, drying, gluing, baking, coiling and so on. The technique adopts environment-friendly resin liquid with high quality for twice-immersing and twice-rolling treatment which causes the resin liquid to sufficiently permeate into fibers and to become uniformly cross-linking, leads the treated fabric to obtain good anti-wrinkle recoverability and solid hand feeling. Nylon polyamine hotmelt adhesive is used for double-dot coating, which is characterized by strong adhesion fastness, having good drapability after being bonded with the fabric and excellent anti-wrinkle property when in use. The lining cloth has soft hand feeling and good anti-wrinkle property. Suits made from the lining cloth have the advantages of fullness and being docile. The anti-wrinkle property and sizing property after washing are better than any other ordinary adhesive lining cloth. The lining cloth is mainly used for wash-and-wear suits and career wears.

Owner:严华荣

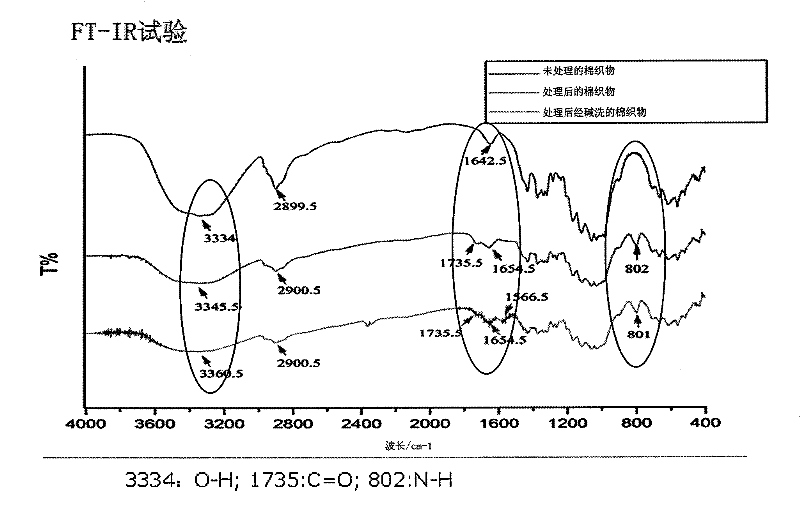

Biological enzyme process antibacterial and anti-wrinkle finishing method of silk fabric

InactiveCN102677475AHigh catalytic efficiencyReduce dosageBiochemical fibre treatmentAnimal fibresCooking & bakingCatalytic oxidation

The invention discloses a biological enzyme process antibacterial and anti-wrinkle finishing method of a silk fabric, belongs to the field of a textile biotechnology, and aims to overcome the defects of high baking temperature, high probability of damage of silk fibers and reduced whiteness in real silk antibacterial and anti-wrinkle treatment of the conventional chemical method and realize enzyme-promoted antibacterial and anti-wrinkle functional modification of a real silk fabric. According to the method, a chitosan natural finishing agent with a primary amine structure is grafted to the surface of the silk fiber by utilizing the catalytic oxidation effect of tyrosinase, so that the antibacterial and anti-wrinkle effects of the silk fabric are improved. The process flow comprises the following steps of: pre-treating the silk fabric; catalyzing grafting modification treatment of chitosan by the tyrosinase; washing; and drying. Through the silk fabric treated by the invention, the antibacterial performance is improved, the wrinkle recovery performance is improved, and the mechanical property and the dyeing performance of the fabric are also improved. Compared with the conventional chemical method, the method has the advantages of adoption of the tyrosinase process for catalysis of the antibacterial and anti-wrinkle treatment process of the real silk, low energy consumption, high efficiency, less pollution and contribution to environmental protection.

Owner:FOSHAN CITY HANHAI YANBU SISTER FLOWER UNDERWEAR

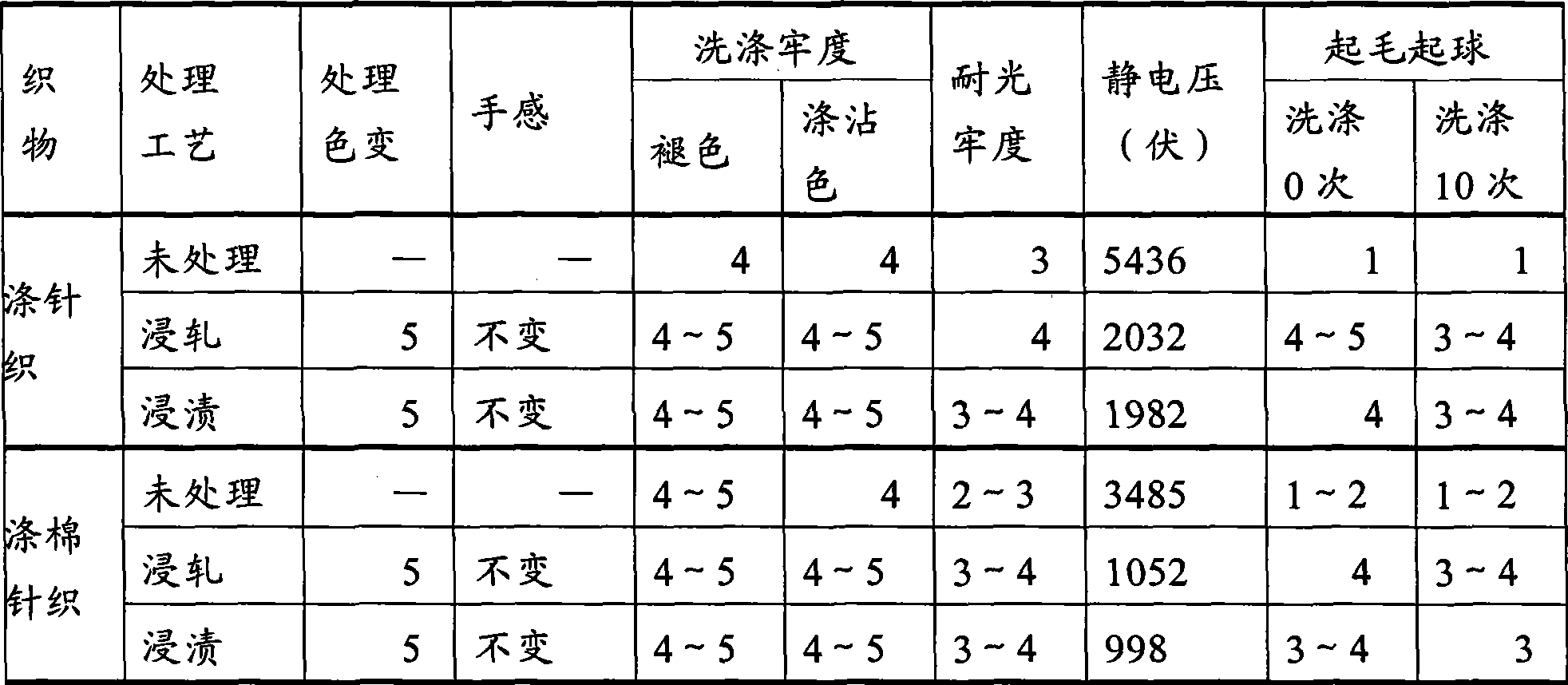

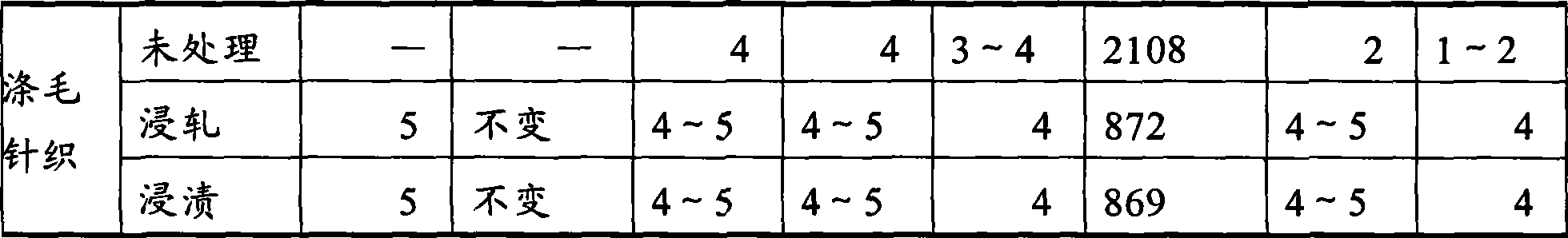

Anti-fuzzing and anti-pilling finishing agent for fabric

The invention relates to an auxiliary agent in the printing and dyeing industry, in particular to a surface finishing auxiliary agent for fabric. An anti-pilling finishing agent for the fabric is nonionic macromolecular polymer, and is characterized in that the anti-pilling finishing agent for the fabric is formed by copolymerizing 10 to 20 portions of high-hydro silicone oil, 30 to 50 portions of polyurethane prepolymer and 30 to 50 portions of polypropylene ester copolymer under the conditions of catalyst and heating; and the portion is weight portion. The fabric anti-pilling finishing agent is suitable for various fibers and fabrics; and in particular, polyester fabric treated by the anti-pilling finishing agent has basically unchanged tone and handfeel, improves the fastness to washing and light fastness, greatly improves the antistatic performance, has certain dust resistance and obviously improves the anti-pilling performance.

Owner:上海德桑精细化工有限公司

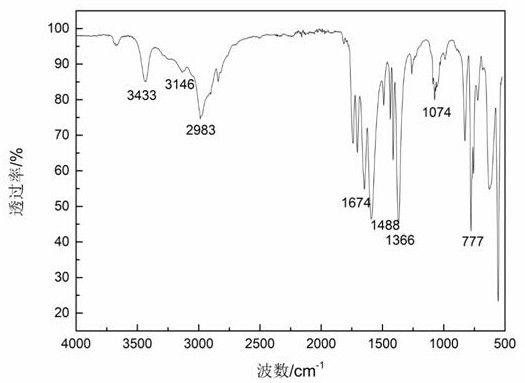

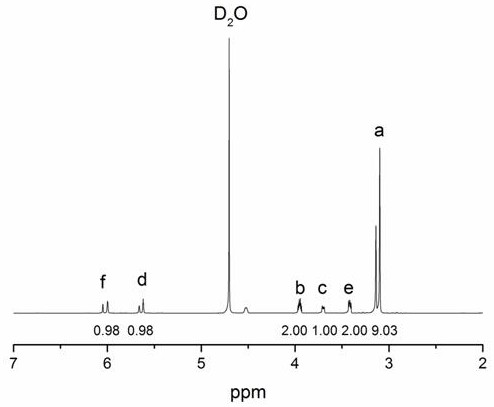

Hyperbranched anti-crease finishing agent as well as preparation method and application thereof

ActiveCN105442320AThe operation process is simple and convenientComposition is easy to controlWrinkle resistant fibresTextile printerCarboxylic group

The invention discloses a hyperbranched anti-crease finishing agent as well as a preparation method and an application thereof and belongs to the field of textile printing and dyeing. A hydrophobic monomer and a monomer containing adjacent carboxylic groups are taken as comonomers, a branched macromolecule is polymerized under the action of an initiator and a branched monomer, a reactive group is introduced to the structure of the branched macromolecule, and the anti-crease finishing agent is synthesized. According to the preparation method and the application, conditions are mild, and the operation is simple and convenient. The anti-crease finishing agent has excellent performance, formaldehyde is not released in production and application processes, a phosphorus-containing catalyst is not needed to add or only a minute quantity of the phosphorus-containing catalyst is needed to add, and the environment is protected.

Owner:JIANGNAN UNIV

Fibroin-polyurethane composite finishing agent and preparation method thereof

InactiveCN104233814AGood moisture absorption and air permeabilityImprove adsorption capacityAnimals/human peptidesAnimal fibresMoistureMaterials science

The invention discloses a fibroin-polyurethane composite finishing agent which comprises the following components in parts by weight: 5-10 parts of fibroin finishing liquid, 7-15 parts of waterborne polyurethane, 1-3 parts of a catalyst, 2-5 parts of a softer, 2-5 parts of a penetrant and 1-5 parts of a crosslinker. The invention further discloses a preparation method of the finishing agent. The finishing agent prepared by the method can increase the wrinkle recovery angle of a silk fabric and enables the silk fabric to keep flat, and also can endow the silk fabric with a soft hand feel and good luster and enables the silk fabric to have the water absorptivity, moisture absorptivity and moisture releasability as well as excellent hand feel of natural real silk; moreover, the finishing agent is nontoxic, harmless to a human body and favorable for environmental protection.

Owner:SUZHOU INSILK CO LTD

Method for processing yarn-dyed four-side stretch fabric garment

ActiveCN109097974AClear organizationImprove cohesionLiquid/gas/vapor removalBiochemical treatment with enzymes/microorganismsYarnEngineering

The invention discloses a method for processing a yarn-dyed four-side stretch fabric garment. The method comprises the following steps: (a) alkali soaking; (b) biological enzyme polishing; (c) dyeing;(d) air drying; (e) sizing; (f) weaving; (g) desizing; (h) scouring and bleaching; (i) padding; (j) drying; (k) finishing; and (l) pre-shrinking. The method is simple in process, saves energy and reduces consumption and is easy to control, and an obtained fabric is soft and comfortable in touch and has a fine and soft gloss, good non-ironing property, anti-wrinkle performance and anti-pilling performance and dimensional stability.

Owner:盛泰智造集团股份有限公司

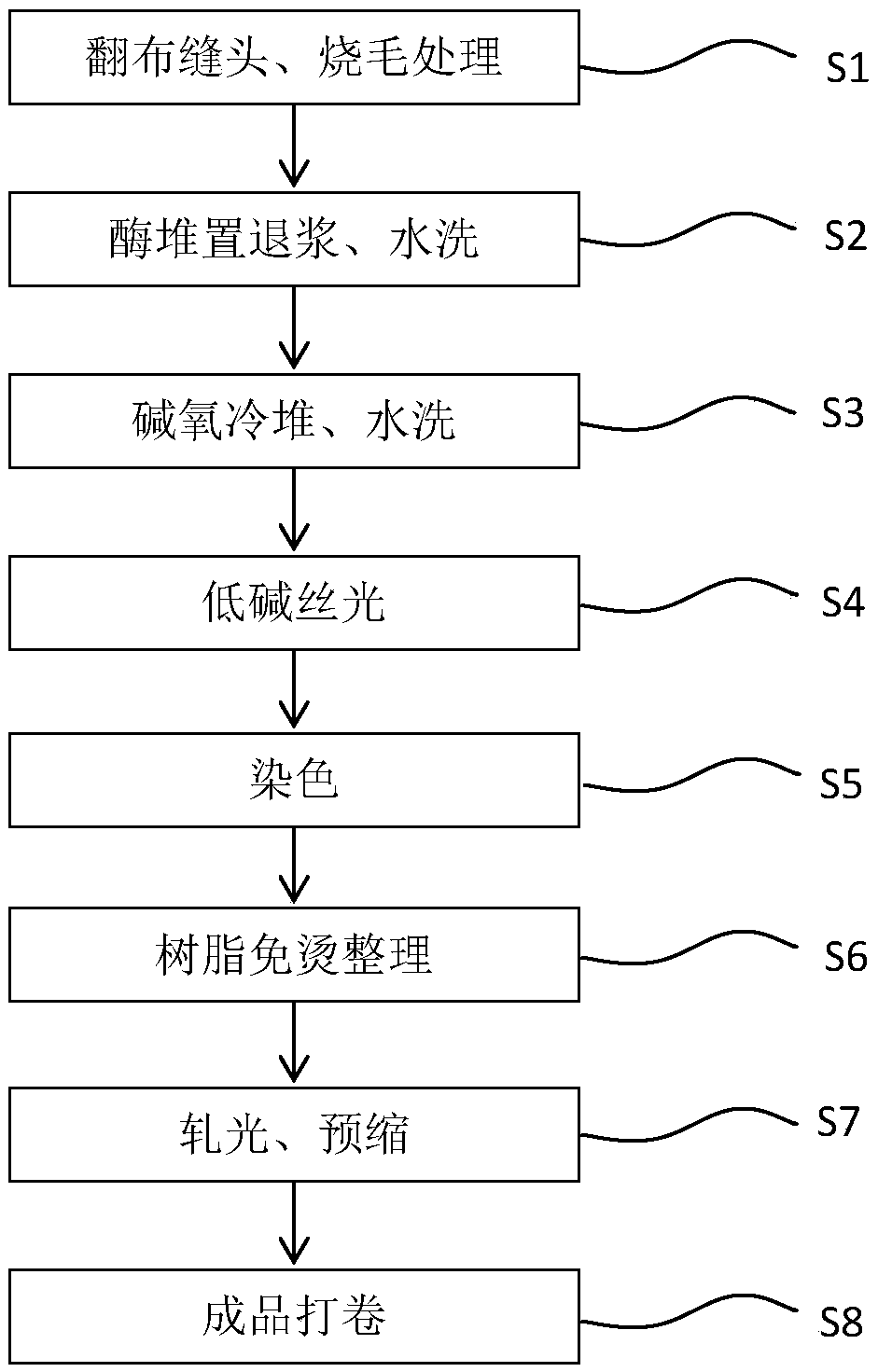

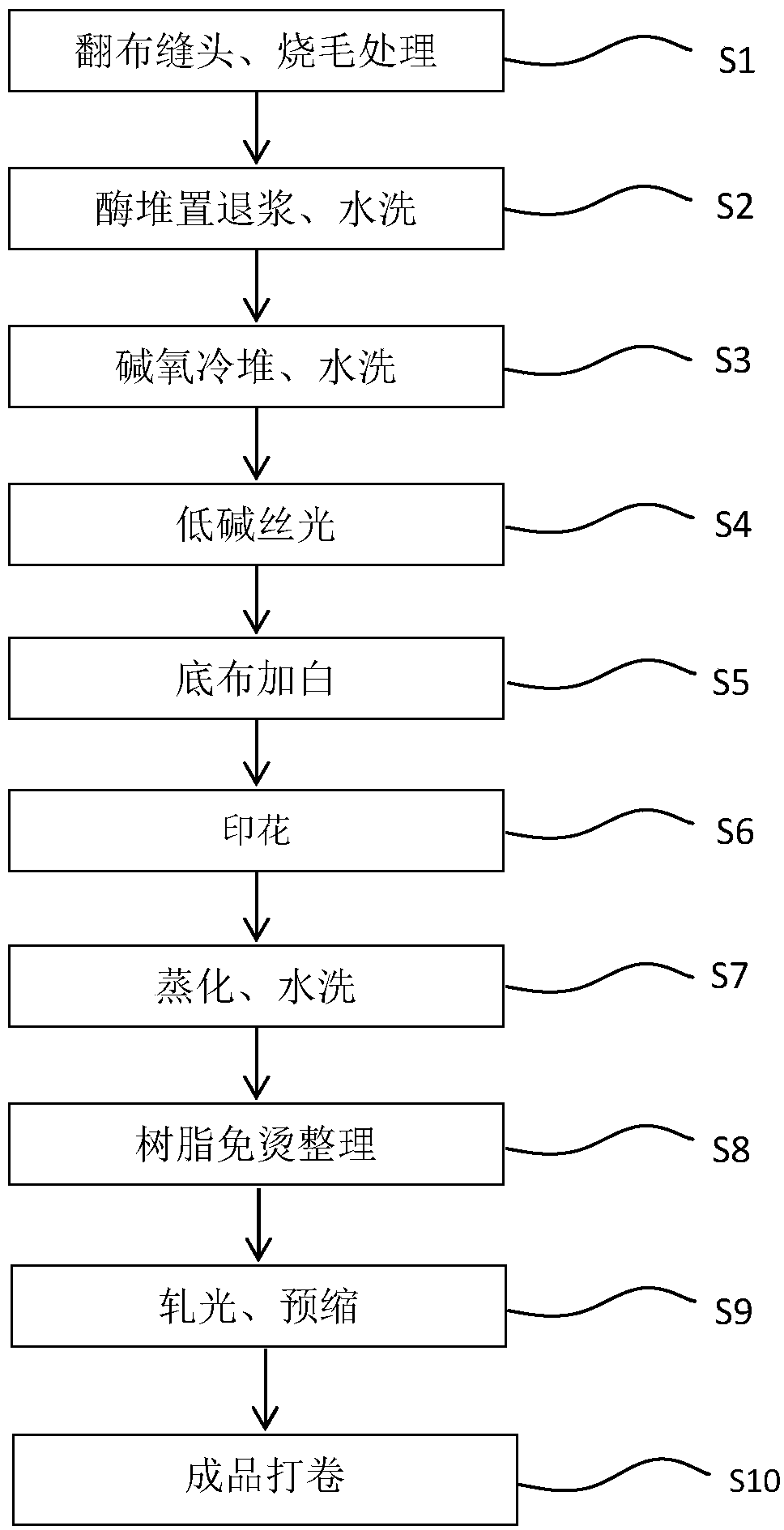

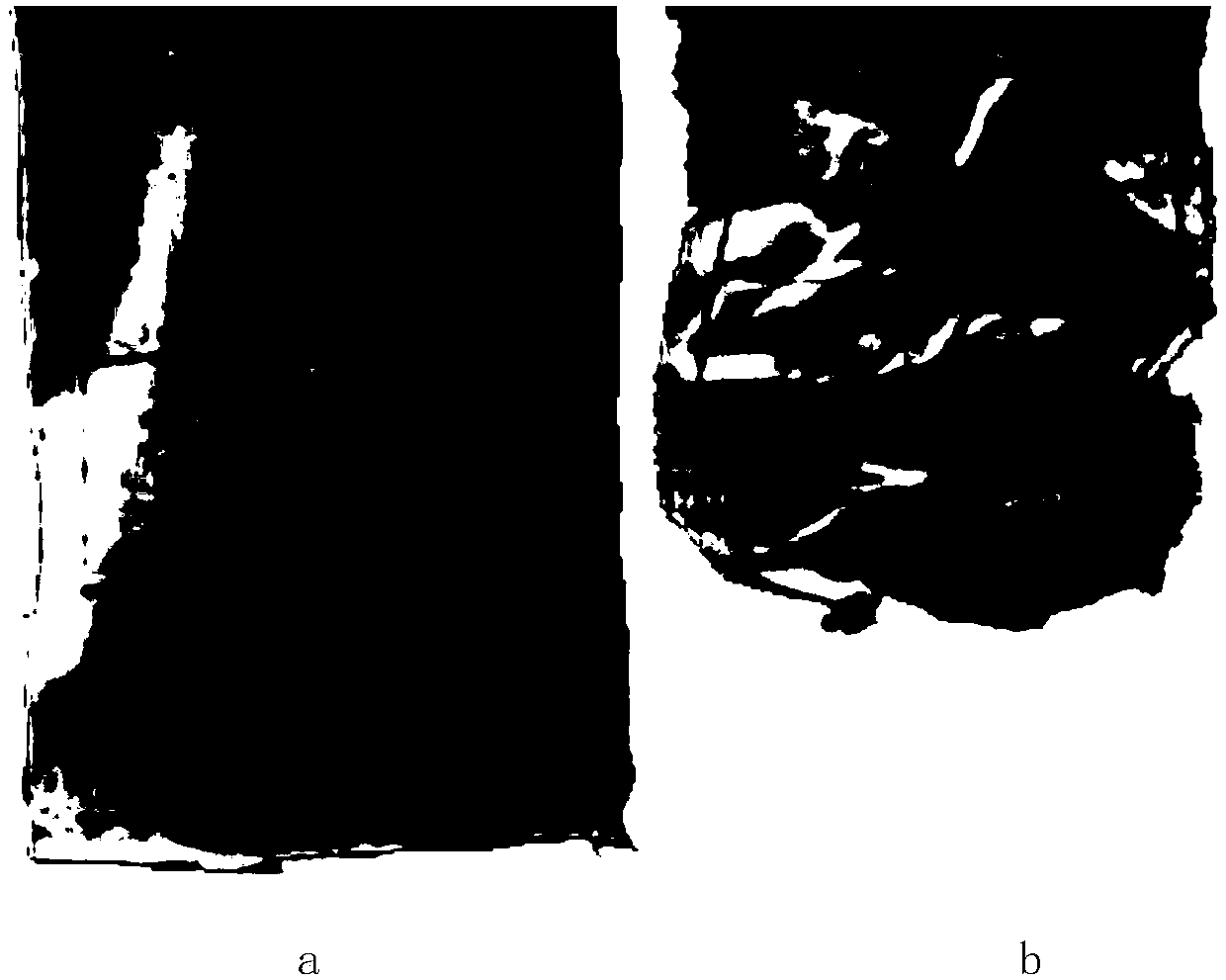

Processing method for improving washability of lyocell standard fiber fabric

InactiveCN109853218AImprove washing resistanceHigh glossMercerising of indefinite length fabricsSucessive textile treatmentsFiberEngineering

The invention relates to a processing method for improving the washability of a lyocell standard fiber fabric. The technological process comprises the following steps of cloth turning for end stitching, singeing treatment, enzyme stacking desizing, washing, alkali-oxygen cold stacking, washing, low-alkali mercerizing, dyeing or printing, ironing-free resin finishing, calendering, pre-shrinking andfinished product rolling; by controlling the whole processing technology and adding the steps of low-alkali mercerizing and ironing-free resin finishing, the water resistance of the lyocell standardfabric is improved. According to the processing method, the defects are overcome that existing lyocell standard fiber fabrics in the prior art are low in washability, the smoothness of fabric surfacesis poor after the fabrics are normally washed by machines several times, fluff is likely to be generated, and the hand feeling is hard. According to the processing method, the washability of the lyocell standard fiber fabric is improved, correspondingly the lyocell standard fiber fabric can be normally washed by a machine, the washing requirement of the lyocell standard fiber fabric is lowered, the high smoothness of the fabric surface of the lyocell standard fiber fabric can still be maintained after the lyocell standard fiber fabric is washed by the machine several times, and the lyocell standard fiber fabric has good luster and a great hand feeling.

Owner:江苏豪申家纺布艺科技有限公司

Preparation method of antibacterial anti-wrinkle linen-cotton fabric

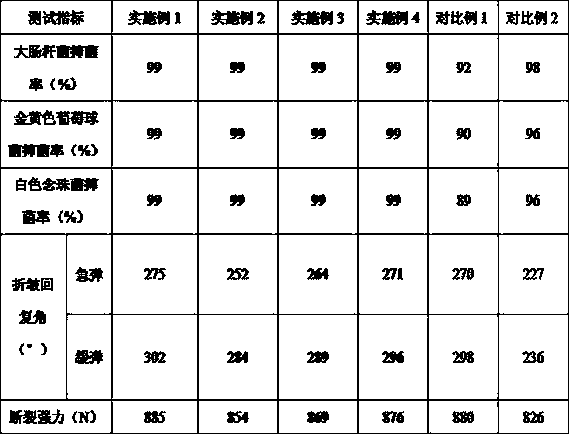

InactiveCN109295706AIncrease elasticityImproves wrinkle recoveryBiochemical fibre treatmentWrinkle resistant fibresAntimony trioxidePolyphenol

The invention provides a preparation method of antibacterial anti-wrinkle linen-cotton fabric. The method comprises the following steps: (1) ultrasonically treating the linen-cotton fabric with an aqueous solution of triethanolamine; (2) preparing amino-modified silver nanoparticles; (3) modifying 2,3-epoxypropyltrimethyl ammonium chloride by a carbodiimide solution, then crosslinking with the amino-modified silver nanoparticles, aminated graphene, and chitosan, and drying the materials; and (4) adding a dried product obtained in the step (3), tea polyphenol, malic acid, tartaric acid, tripolymaleic acid, nano TiO2, antimony trioxide, an osmotic agent, and fibroin to an aqueous solution of ethanol to prepare a finishing agent, and performing dip padding on the fabric to obtain the antibacterial anti-wrinkle linen-cotton fabric. The linen-cotton fabric prepared by the invention has good inhibition effect on Escherichia coli, Staphylococcus aureus and Candida albicans, and has good anti-wrinkle performance. Therefore, the fabric made by the invention has broad application prospects as the antibacterial anti-wrinkle fabric.

Owner:SUZHOU INST OF TRADE & COMMERCE

Anti-wrinkle finishing process of silk fabric

The invention discloses an anti-wrinkle finishing process of a silk fabric, which relates to the technical field of anti-wrinkle finishing of fabrics. The anti-wrinkle finishing process comprises the following steps of preparing an anti-wrinkle finishing agent from the components of olefin acid oligomer, formic acid, a catalyst, an organic silicone softening agent and water; under the conditions that the bath ratio is 1:(25-30) and the temperature is 20-30 DEG C, carrying out immersion and rolling for twice on the silk fabric in finishing liquor containing the anti-wrinkle finishing agent with the take-up rate being 85%-90%; prebaking the immersed and rolled silk fabric for 3-5 minutes, then baking the fabric for 1-2 minutes at the temperature of 140-150 DEG C, washing by hot water at the temperature of 40-50 DEG C and water at the temperature of 20-25 DEG C, drying at the temperature of 70-80 DEG C to obtain the finished silk fabric. The anti-wrinkle finishing process disclosed by the invention has the advantages that the raw materials of the anti-wrinkle finishing agent are low in price, do not contain formaldehyde, and has economic and environment-friendly effects; the anti-wrinkle finishing process is simple and easy to operate; the finished silk fabric has good anti-wrinkle recovery performance, a high retention rate and good anti-wrinkle performance.

Owner:SUZHOU SANHE KAITAI COLORED THREAD WEAVING CO LTD

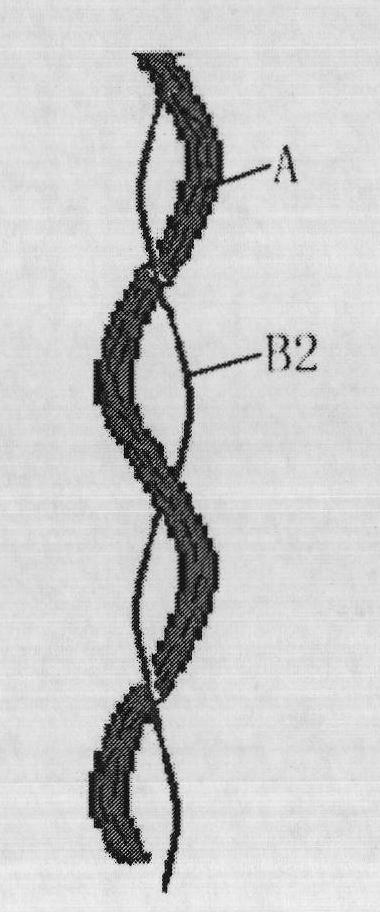

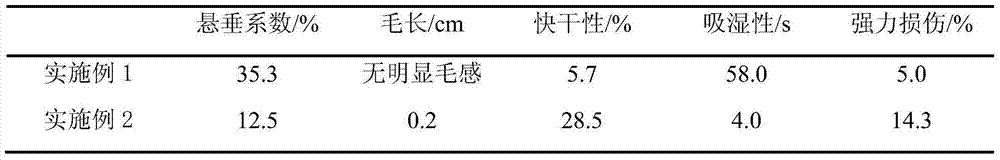

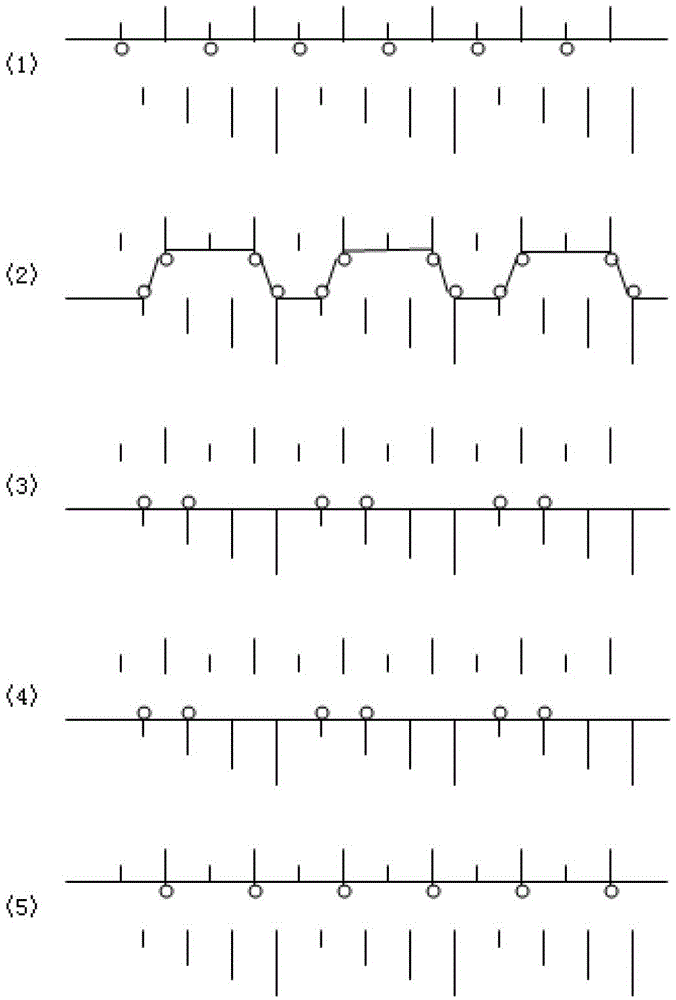

Wool fabric with strapping structure yarns and preparation method thereof

The invention discloses a wool fabric with strapping structure yarns and a preparation method thereof. The wool fabric is characterized in that the yarns in the wool fabric are strapping structure yarns which are formed by strapping fine-denier chemical fiber filaments on wool yarns, wherein the wool yarn does not have twist degree or has the twist degree which is less than or equal to 50% of that of the yarn at the same fineness, and the fine-denier chemical fiber filaments are strapped on the wool yarns by the twist degree of 300-1000 T / m. The wool fabric has the advantages of soft feeling, low tendency to generate hairiness, and the like. The fine-denier chemical fiber filament has elasticity, thereby obviously enhancing the elongation capacity and fold restorability of the wool fabric.

Owner:JIANGSU JIANLU WOOLEN +3

Polyester peach velvet fabric processing method

InactiveCN104746263ASoft lusterGood air permeabilityHeating/cooling textile fabricsMercerisingPolyesterChemistry

The invention discloses a polyester peach velvet fabric processing method, comprising the steps: desizing, mercerizing, alkali peeling, air washing, sizing, sanding with carbon brush, preshrinking and plaiting; the desizing step adopts a dewaxing agent to remove an oiling agent on the surface of a fabric; the alkali concentration in the mercerizing step is 170-220 g / L and the turning speed is 50-70 m / min; in the alkali peeling step, the dosage of caustic soda is 5g / L, the processing time is 1h and the peeling rate is controlled to be 5%; in the air washing step, the rotating speed of a fan is 2,200 rpm and the processing time is 30min; in the sizing step, the temperature is controlled to be 170 DEG C, the fabric is soaked with a nano hydroscopic and fast dry finishing agent, and the hygroscopicity of the fabric is improved; the polyester peach velvet fabric produced by adopting the method touches soft and light and is fluffy and fine, smooth and elastic; in addition, the hydroscopic and fast dry feature is given to the fabric, so that the wet and cold feelings of the fabric after moisture absorption are eliminated and the wearing comfort is improved.

Owner:张家港市金陵纺织有限公司

Preparation method and application method of after-finishing solution for fabrics

InactiveCN110685161AImproves wrinkle recoveryWon't releaseWrinkle resistant fibresVegetal fibresPolymer sciencePolyol

The invention relates to a preparation method and an application method of an after-finishing solution for fabrics. The preparation method includes: in protection of nitrogen, adding polyhydric alcohols, catalysts, diisocyanate and chain extenders into a four-neck flask to react to generate polyurethane prepolymer, adding a neutralizer for neutralizing, adding organic silicon for modification, andfinally adding deionized water for emulsification, so as to obtain cationic organic silicon modified waterborne polyurethane; compounding the cationic organic silicon modified waterborne polyurethanewith an anti-crease finishing agent to obtain the after-finishing solution for fabrics. The application method includes soaking the fabrics in the after-finishing solution for fabrics, subjecting thefabrics to the process of dip dyeing twice and rolling twice, and then drying and baking the fabrics sequentially. Since the cationic organic silicon modified waterborne polyurethane and the anti-crease finishing agent are compounded, cotton fiber internal cross-linking and deposition on surface or in gap of fabric weave are achieved simultaneously, and under the synergistic reaction of the internal cross-linking and the film forming by surface deposition, the crease recovery of the fabrics is improved while strength loss is kept at a low level.

Owner:JIANGNAN UNIV +1

Projector curtain and preparation method thereof

InactiveCN107419538AImprove adhesionImprove wash resistanceStain/soil resistant fibresLiquid surface applicatorsUltraviolet lightsFire retardant

The invention provides a projector curtain and a preparation method thereof. The projector curtain is prepared through thermocompression of a basic bottom layer, an adhesion layer and a light reflecting layer and coating of an organosilicon protecting layer, wherein the basic bottom layer is multiaxial woven fabric layer soaked in a first soaking solution; the first soaking solution is resin composition, and the resin composition is prepared from, in parts by weight, 100 parts of polyurethane resin, 0.2-0.8 parts of a catalyst, 15-25 parts of an impregnating compound, 0.2-0.8 parts of a coupling agent, 0.5-1.5 parts of an ultraviolet light absorber, 1-10 parts of a flame retardant, 10-30 parts of a defoaming agent, 10-30 parts of an organosilicon fabric finishing agent and 30-40 parts of a curing agent. The projector curtain is resistant to dirt, anti-bacterial, crease-resistant and good in winkle recovery performance, and the technical problems that existing curtains easily crease and are difficult to recover and not resistant to dirt, the viewing effect is affected and the service life is short are solved.

Owner:WEINAN NORMAL UNIV

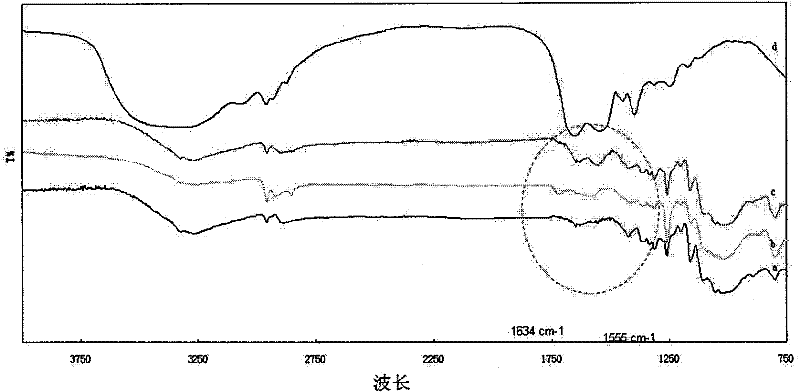

Method for dyeing and anti-crease finishing of silk based coupling reaction

ActiveCN108824021AAchieve connectionTo achieve the purpose of anti-wrinkle finishingWrinkle resistant fibresDyeing processCooking & bakingRecovery performance

The invention discloses a method for dyeing and anti-crease finishing of silk based on a coupling reaction, and belongs to the technical field of textile chemistry. In the invention, an aromatic diamine compound is diazotized, and the diazotized aromatic diamine compound and a phenolic hydroxyl group-containing tyrosine side group in silk fiber macromolecules undergo a coupling reaction to make the silk fabric dyed and improve the anti-crease recovery performance to achieve the anti-crease finishing. The method concretely includes the following steps: (1) diazotization of the aromatic diaminecompound; (2) impregnation of the silk fabric in an alkali lye; (3) coupling coloration of the silk fabric; and (4) water washing and drying post-treatment. Compared with methods for anti-crease finishing of the silk fabric resin by silk dyeing using high temperature boiling dyeing and a high temperature baking process, the method disclosed in the invention has the advantages of less damages to the silk fiber, short process flow, and good dyeing fastness of the fabric.

Owner:JIANGNAN UNIV

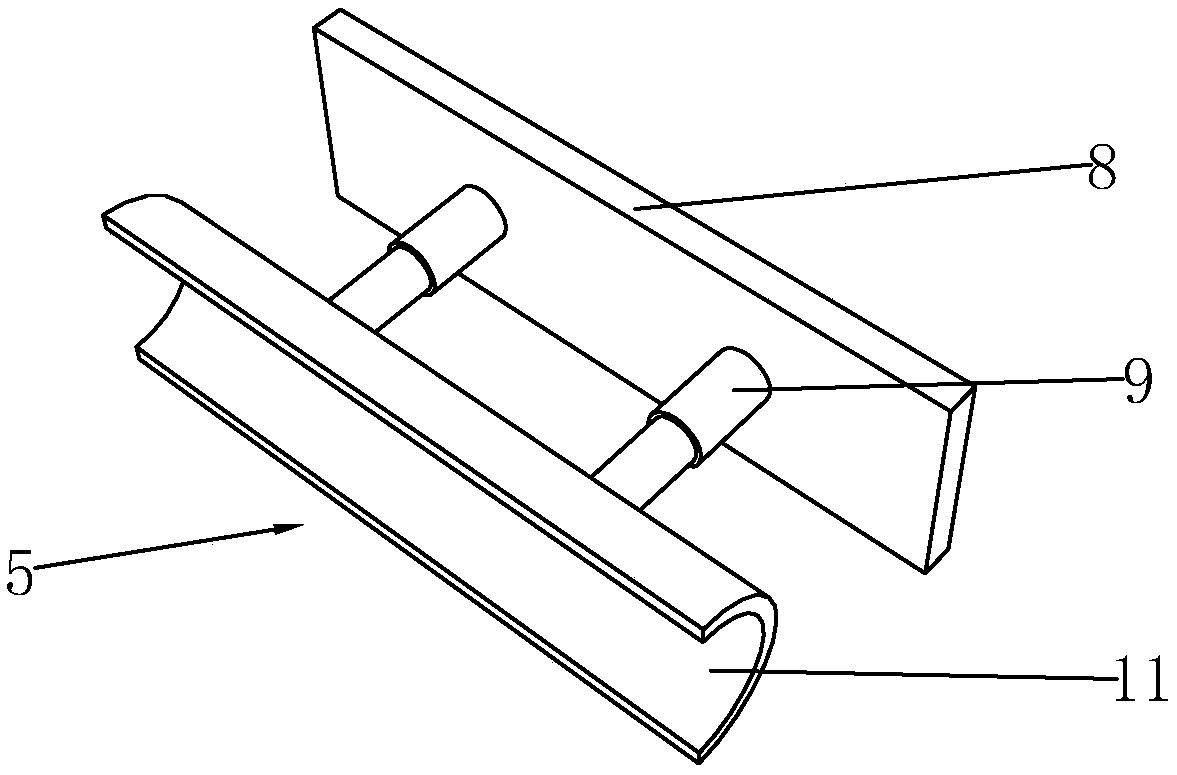

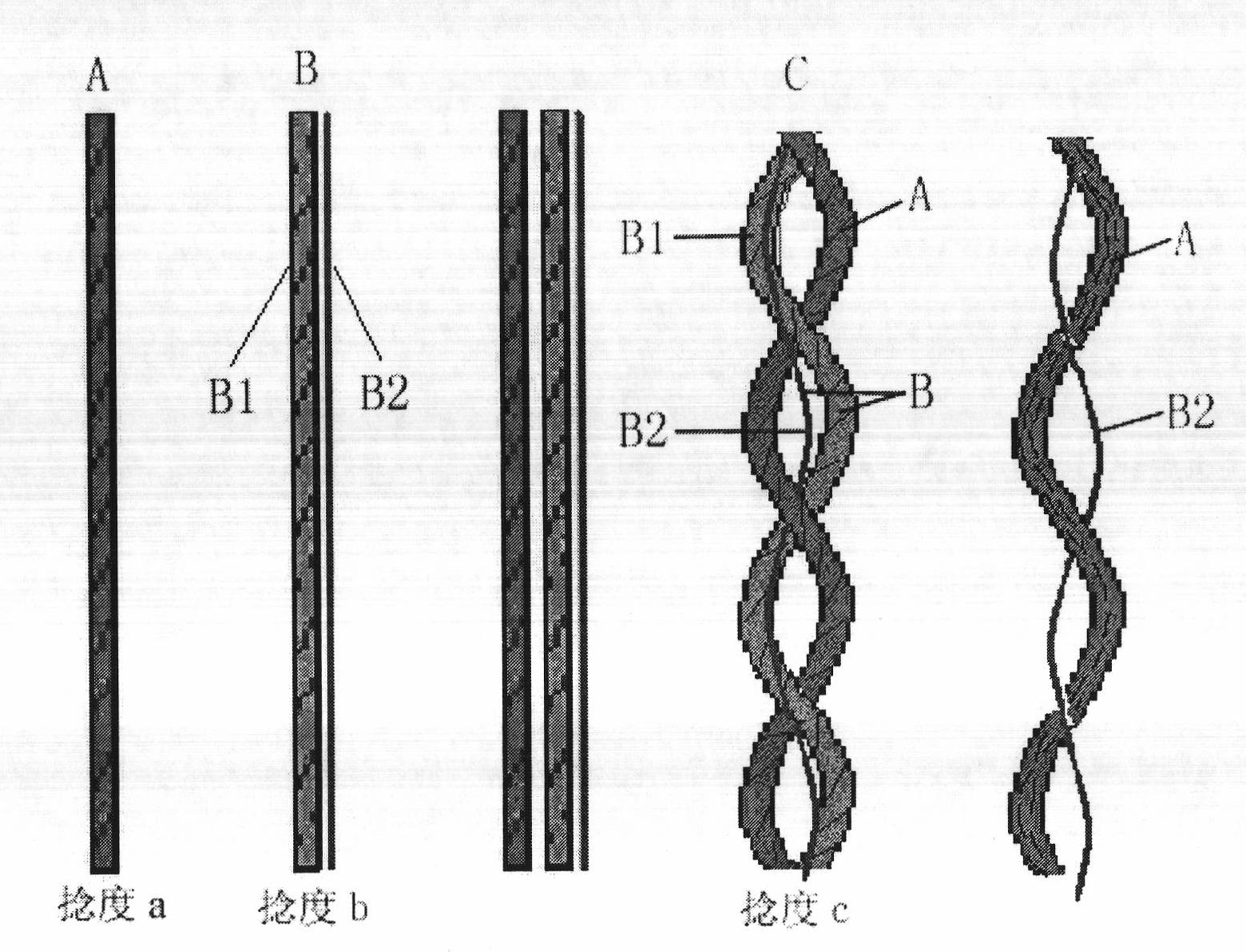

Elastic fasciated yarn resistant to electromagnetic radiation and fabric obtained by weaving same

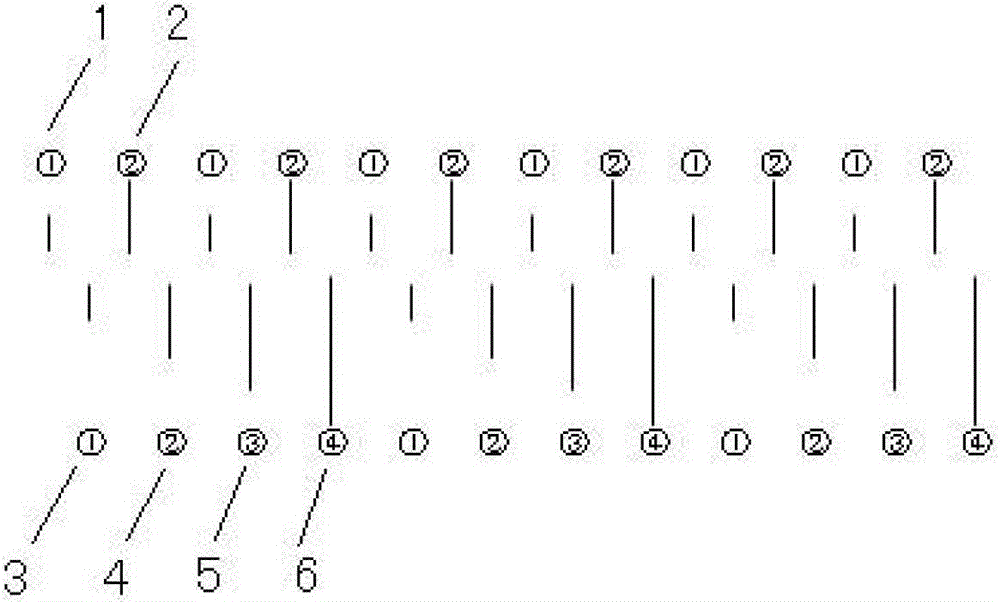

ActiveCN107475845AIncrease elasticityImproves wrinkle recoveryWeft knittingFilament/thread formingMetal filamentElectromagnetic shielding

The invention relates to an elastic fasciated yarn resistant to electromagnetic radiation and fabric obtained by weaving the same. The core yarn of the elastic fasciated yarn is made of an elastic fiber filament, wherein the outer wrapping yarn is made of conductive polyester / metal filament fasciated yarn, the core yarn of the conductive polyester / metal filament fasciated yarn is made of a metal filament, and the outer wrapping yarn is made of a conductive polyester fiber filament. The fabric obtained by weaving the elastic fasciated yarn resistant to the electromagnetic radiation has a transverse elongation of 70-120%, a transverse recovery of 96-100%, a longitudinal extension of 95-130%, a longitudinal recovery of 95-100%, a creasy recovery angle of 300-330 degrees, the flatness of appearance of 4-5 grade and an electromagnetic shielding value of up to 7-27 dB against 1.5 GHz electromagnetic waves. According to the elastic fasciated yarn resistant to the electromagnetic radiation and the fabric obtained by weaving the same, the elastic fiber filament is adopted as the core yarn, and the conductive polyester / metal filament is adopted as the outer wrapping yarn, and therefore the fabric obtained by weaving the elastic fasciated yarn resistant to the electromagnetic radiation not only is high in shape retention, but also has two effects of reflection and absorption of the electromagnetic waves at the same time, so that the shielding effectiveness of the fabric against the electromagnetic waves is improved.

Owner:DONGHUA UNIV

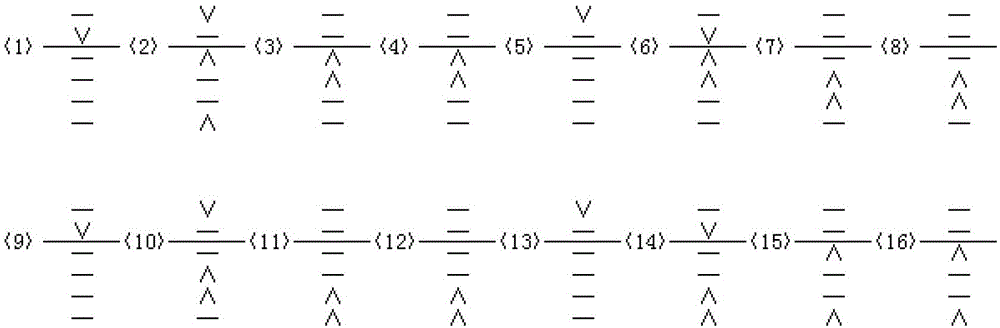

Preparation method of anti-wrinkle real silk fabrics in hollow structure

InactiveCN103014972AImproves wrinkle recoveryElasticWeft knittingWarp knittingFiberRecovery performance

The invention relates to a preparation method of anti-wrinkle real silk fabrics in a hollow structure. According to the preparation method, centre yarns and cocoon silks in a moist state in a reeling silk bath are coated together, water soluble fibers of the centre yarns in core covering silks are dissolved through refining, and the manufacture of hollow real silk is completed at the reeling silk stage. The preparation method has the advantages that the production cost is low, the process is simple, the hollow real silk has the elasticity, the anti-wrinkle recovery performance of the real silk is enhanced, the anti-wrinkle performance of finished products is high, the wrinkling cannot be generated after washing, and the wide application can be realized.

Owner:JIANGSU HUAJIA SILK +1

Nursing and felt proofing finishing method for wool fabric with ultraviolet radiation based on keratin oligopeptides, polypeptides or keratin macro-molecules

InactiveCN107541928AEasy to prepareSimple finishing processPhysical treatmentPeptide preparation methodsKeratinOligopeptide

The invention relates to a nursing and felt proofing finishing method for wool fabric with ultraviolet radiation based on keratin oligopeptides, polypeptides or keratin macro-molecules. A biochemicalmethod is used for extracting keratin oligopeptides, polypeptides or keratin macro-molecules from animal fibre, and a heterogenous protein cross-linking agent is used for carrying out a reaction in order to prepare reaction type keratin finishing liquid; the liquid is applied on wool fabric by sprinkling and dipping; after the fabric is dehydrated and spin-dried, and ultraviolet radiation and nature drying are carried out in order to realize an application of keratin oligopeptides, polypeptides or keratin macro-molecules to nursing and felt proofing finishing of wool fabric. The finishing process is simple and easy to operate with low energy consumption and little pollution, and does not have obvious influences on appearance of the wool fabric; the wool fabric treated by the nursing and felt proofing finishing method has good size stability, crease recovery performance, and improved breaking strength and elasticity.

Owner:JIAXING UNIV

Cotton fabric delayed baking non-ironing finishing process

ActiveCN113235292AGood storage stabilityReduced stabilitySolvent-treatmentSucessive textile treatmentsIndustrial engineeringLiquid ammonia

The invention relates to the technical field of textile after-finishing, in particular to a cotton fabric delayed baking non-ironing finishing process. The cotton fabric delayed baking non-ironing finishing process comprises the following steps of singeing, desizing, liquid ammonia treatment, mercerizing, liquid ammonia treatment and after-baking finishing. According to the method, the stability of the delayed baking sensitized fabric in delayed baking is remarkably improved, the problem caused by slow reaction in the storage process of the delayed baking sensitized fabric is solved, and the product quality can be improved.

Owner:JIANGNAN UNIV +1

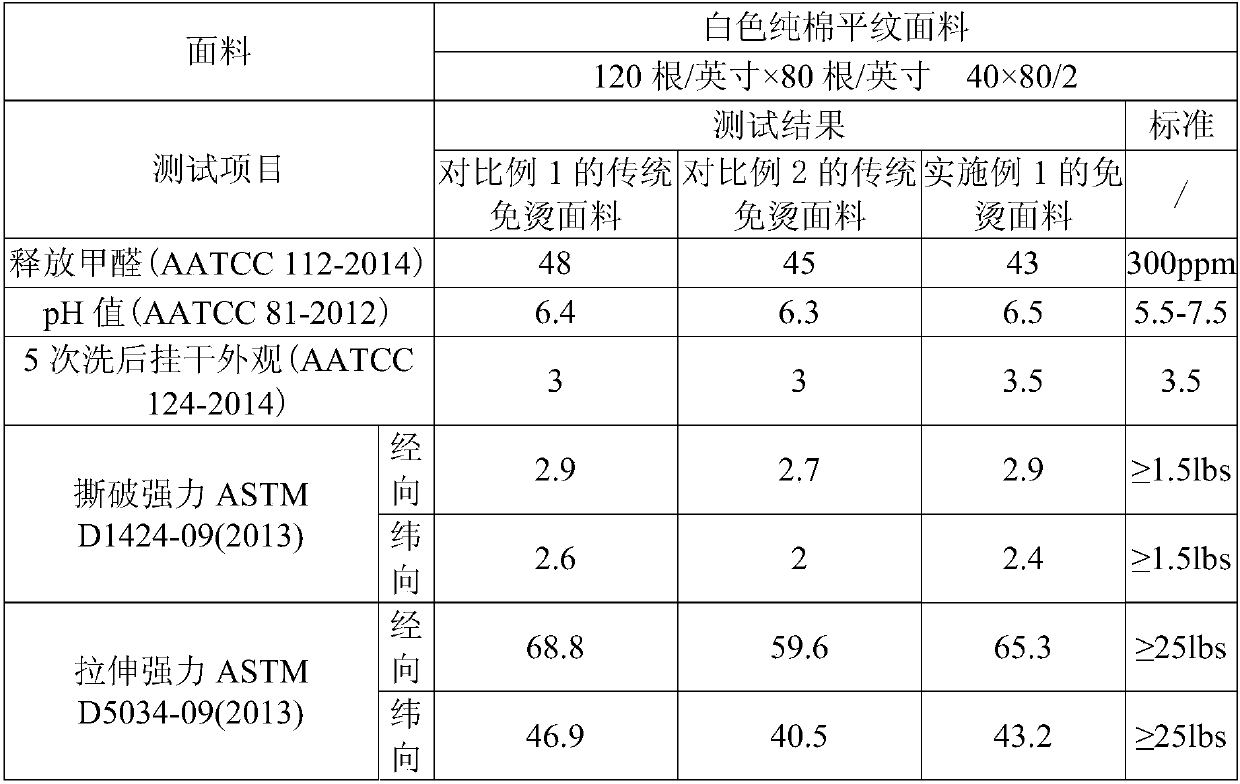

Non-ironing fabric with high hang-dry appearance and manufacturing method thereof

ActiveCN110219172AImprove moisture wrinkle resistanceImproves wrinkle recovery performanceSucessive textile treatmentsWrinkle resistant fibresBuffering agentEngineering

The invention provides non-ironing fabric with a high hang-dry appearance and a manufacturing method thereof. The manufacturing method includes padding the fabric in non-ironing finishing liquid, andstoring the padded fabric in an environment with the temperature of 28-40 DEG C and the humidity of 20-70% for 6-15 hours, wherein the non-ironing finishing liquid comprises a resin crosslinking agentand an acid-base buffering agent; performing steaming treatment at 80-150 DEG C for 2-8 minutes to obtain the non-ironing fabric with the high hang-dry appearance. The non-ironing fabric produced bythe manufacturing method has the high hang-dry appearance under the condition of enough power.

Owner:GUANGDONG ESQUEL TEXTILES

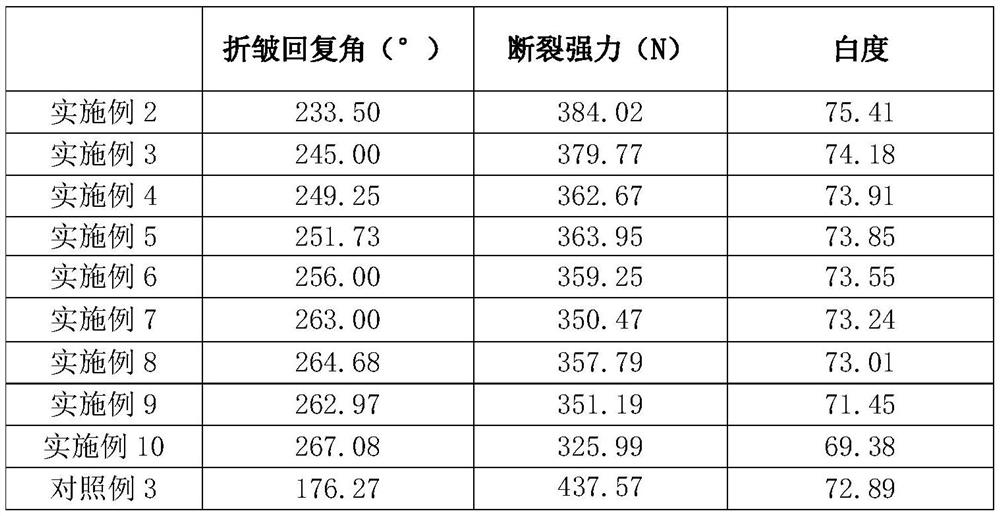

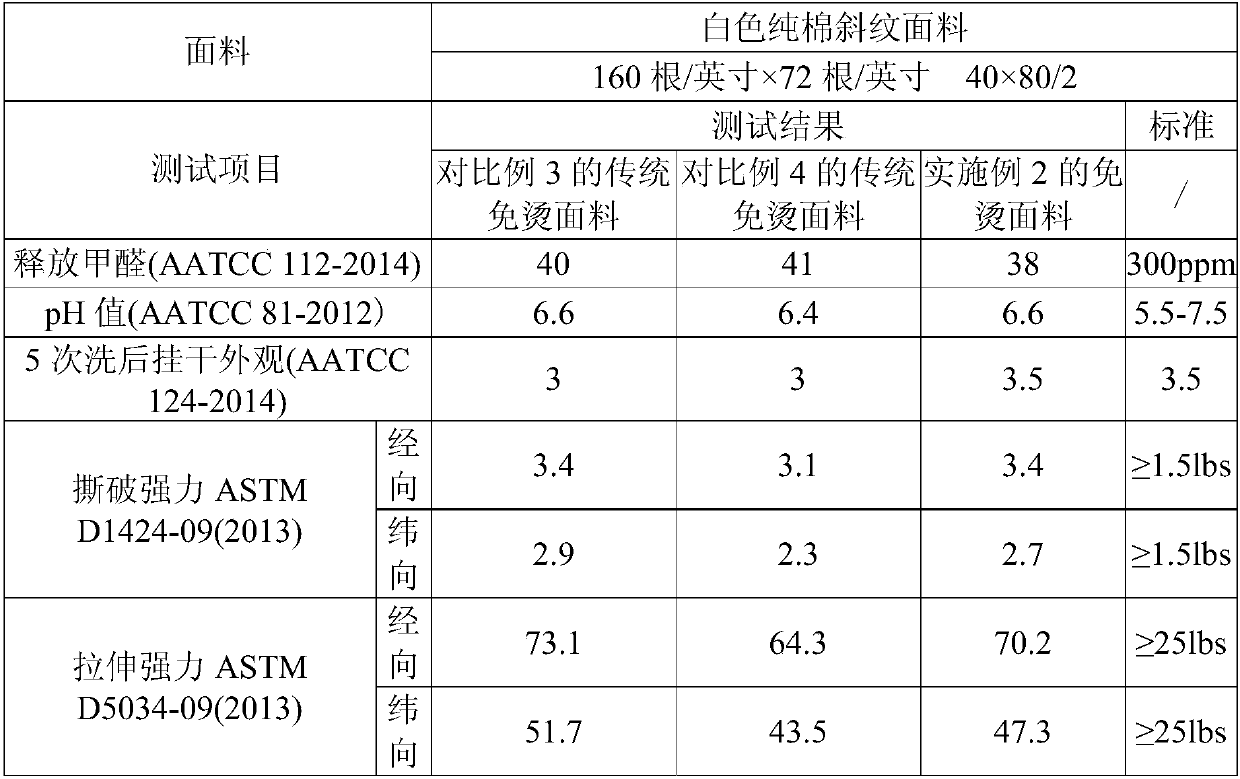

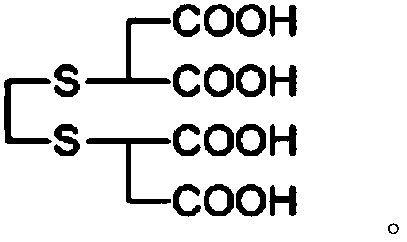

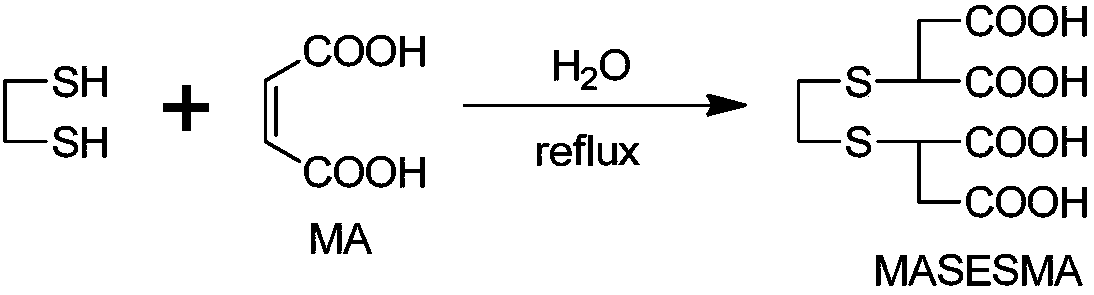

Tetracarboxylic acid for non-iron finishing and preparation and application of tetracarboxylic acid

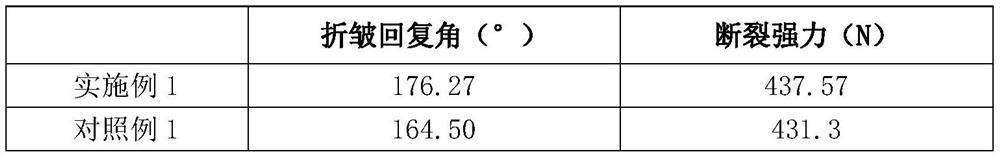

InactiveCN109440457AImproves wrinkle recoveryGood strong retentionWrinkle resistant fibresVegetal fibresBreaking strengthRecovery performance

The invention relates to tetracarboxylic acid for non-iron finishing and preparation and application of the tetracarboxylic acid. The tetracarboxylic acid is prepared by steps: dissolving diacid intowater, adding dithioglycol and a catalyst I, and performing heating reaction, cooling and suction filtration to obtain tetracarboxylic acid. An application process includes steps: dissolving the tetracarboxylic acid into water, adding a catalyst II to obtain finishing liquid, soaking a cotton fabric into the finishing liquid, performing twice dipping and twice padding, drying and calcining to obtain a non-iron fabric. The non-iron fabric is excellent in crease recovery performance and high in break strength retention rate, the problem of break strength decline of fabrics and BTCA expensivenessin current polybasic carboxylic acid crease-resistant finishing are evidently improved, and a promising application prospect and market prospect can be achieved.

Owner:DONGHUA UNIV +1

Hygroscopic and sweat releasing knitted fabric with shape memory function and processing method thereof

Owner:SHANGHAI JIALE

Anti-fuzzing and anti-pilling finishing agent for fabric

The invention relates to an auxiliary agent in the printing and dyeing industry, in particular to a surface finishing auxiliary agent for fabric. An anti-pilling finishing agent for the fabric is nonionic macromolecular polymer, and is characterized in that the anti-pilling finishing agent for the fabric is formed by copolymerizing 10 to 20 portions of high-hydro silicone oil, 30 to 50 portions of polyurethane prepolymer and 30 to 50 portions of polypropylene ester copolymer under the conditions of catalyst and heating; and the portion is weight portion. The fabric anti-pilling finishing agent is suitable for various fibers and fabrics; and in particular, polyester fabric treated by the anti-pilling finishing agent has basically unchanged tone and handfeel, improves the fastness to washing and light fastness, greatly improves the antistatic performance, has certain dust resistance and obviously improves the anti-pilling performance.

Owner:上海德桑精细化工有限公司

Preparation method and application of cationic modifier TCTAC

ActiveCN113373691ATest mechanical propertiesTest stabilityBiochemical fibre treatmentWrinkle resistant fibresCyanuric chlorideAnti bacterial

The invention discloses a preparation method and application of a cationic modifier TCTAC, and relates to the technical field of anti-wrinkle and antibacterial finishing of cotton fabrics. The preparation method comprises the following steps of dissolving 2,3-epoxy hydroxypropyl trimethyl ammonium chloride in deionized water, dropwise adding ammonia water, heating and stirring for a reaction, and dissolving in deionized water to form a 1-amino-3-hydroxypropyl trimethyl ammonium chloride aqueous solution; and dissolving cyanuric chloride in acetone, dropwise adding the 1-amino-3-hydroxypropyl trimethyl ammonium chloride aqueous solution, adjusting the pH value to 6-7 by using a sodium carbonate aqueous solution, stirring for a reaction until the reaction is finished, performing salting-out purification and drying to obtain the cationic modifier TCTAC. According to the method, the synthesis period is short, the yield is high, the novel cationic modifier is synthesized, the cationic modifier can be used for carrying out anti-wrinkle / antibacterial dual-function treatment on a cotton fabric, and relative slippage among fibers can be effectively inhibited, so that the wrinkle recovery capability is improved, and the cotton fabric with excellent dry and wet wrinkle resistance can be obtained.

Owner:JIANGSU LIANFA TEXTILE +1

A non-ironing processing method for yarn-dyed four-way stretch fabric garments

ActiveCN109097974BClear organizationImprove cohesionLiquid/gas/vapor removalBiochemical treatment with enzymes/microorganismsYarnProcess engineering

Owner:盛泰智造集团股份有限公司

Smoothing conditioning method for wool fabric

InactiveCN106065529AImprove surface smoothnessImproves wrinkle recoveryYarnDiffusion analysisEngineeringSurface smoothness

The invention relates to a smoothing conditioning method for wool fabric. By the smoothing conditioning method for wool fabric, surface smoothness of fabric can be raised, and fabric crease restorability can be improved. Meanwhile, a water-absorption testing method is simple and practical, and test results are fast and timely. By the method for water absorption testing, the testing can be completed within a short period of time, and water-absorbing fabric production and technology guarantees are assisted for enterprises. The testing cost is low. By the method for testing, no professional detection equipment is required.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

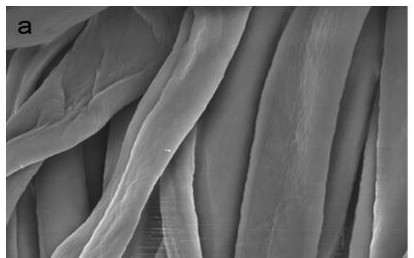

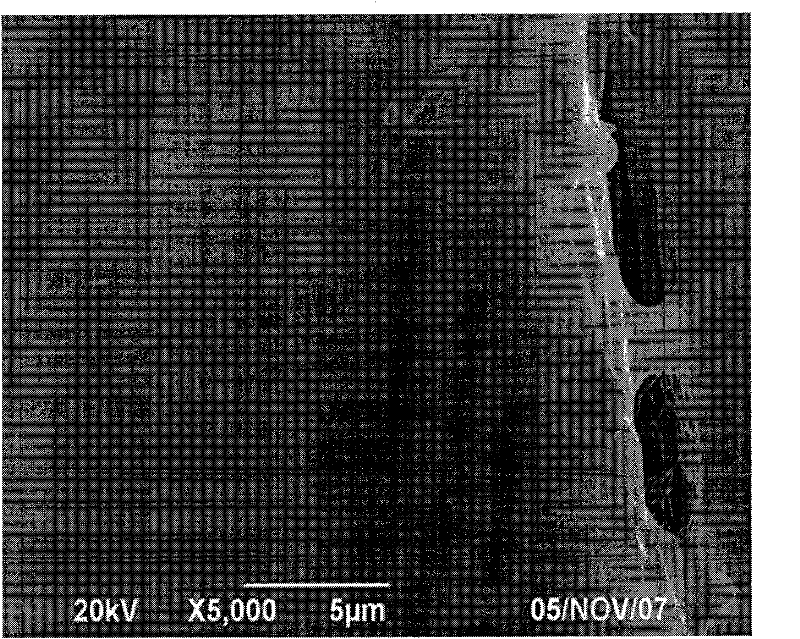

Function textile with nanometer composite structure produced by nanometer protein material and method of preparation

InactiveCN101684616BMeet friendly requestsImproves UV protectionMaterial nanotechnologyLight resistant fibresProtein materialsNanotechnology

A method for producing function textile with nanometer composite structure by nanometer protein material comprises the following three steps: S1.nanometer protein material accumulating on the surface of the cotton fabric, S2.nanometer protein material diffusing into the cotton fabric, S3.nanometer protein material cross-linking with the cotton fabric. The solution and the dealing technique used in each step are all different. The function textile with nanometer compound structure obtained by the method has improved crease resistance. The tear strength of the function textile does not decreaseand the content of formaldehyde does not increase. Furthermore the producing technique meets the requirement to be friendly to the environment.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

Cotton fabric treatment process based on liquid ammonia and mercerizing combined finishing

ActiveCN113373684AImprove performanceEasy to takeMercerising of indefinite length fabricsDry-cleaning apparatus for textilesPulp and paper industryOrganic chemistry

The invention relates to the technical field of textile after-finishing, in particular to a cotton fabric treatment process based on liquid ammonia and mercerizing combined finishing. The cotton fabric treatment process based on liquid ammonia and mercerizing combined finishing comprises the following steps of singeing, desizing, liquid ammonia treatment, mercerizing, liquid ammonia treatment, tentering and preshrinking. The comprehensive physical and mechanical properties of the wrinkle recovery angle and the breaking strength of the cotton fabric are improved, and meanwhile, the hand feeling style of the cotton fabric is further improved. The cotton fabric treatment process based on liquid ammonia and mercerizing combined finishing is relatively simple and feasible, and is suitable for industrial large-scale production.

Owner:JIANGNAN UNIV

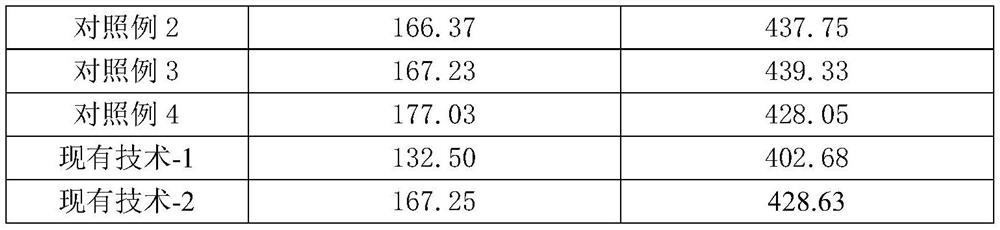

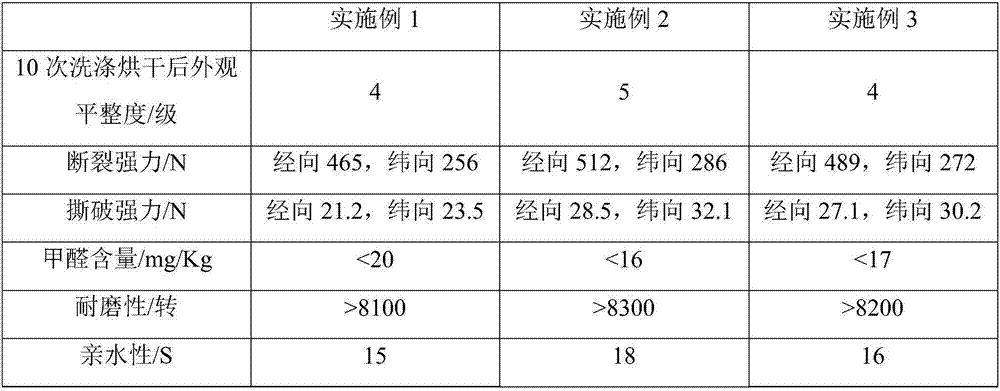

Anti-wrinkle finishing process for natural silk fabric

The invention discloses an anti-wrinkle finishing process for a natural silk fabric. The process comprises the steps of pretreatment of the natural silk fabric, preparation of an anti-wrinkle finishing solution, anti-wrinkle finishing and the like. The natural silk fabric obtained by finishing in the process disclosed by the invention has the advantages of good wrinkle recovering property, strength retention rate as well as excellent hydrophilcity and hand feeling; wear resistance of the natural silk fabric obtained by finishing in the process is improved.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

Preparation method for crease-resistant shrinkproof silk woven fabric

InactiveCN108914574AImprove wrinkle resistanceHigh resilienceWrinkle resistant fibresShrinking resistant fibresWrinkle skinEthylene urea

The invention provides a preparation method for a crease-resistant shrinkproof silk woven fabric. The preparation method comprises the following steps: treating the fabric with a sodium hydroxide solution at first, immersing the fabric in a DMF solution of trimethylolpropane triacrylate; grafting dimethyl dihydroxy ethylene urea and otcamethylcyclotetrasiloxane onto the surface of the fabric; andthen treating the grafted fabric with an ethanol solution containing succinic anhydride-modified nanometer silica, sodium dichloroisocyanurate, modified fluoroalkyl polyether modified polysiloxanes, chitosan, silk fibroin and sodium alginate so as to obtain the crease-resistant shrinkproof silk woven fabric. Test results show that the wrinkle recovery angle of the treated fabric is as high as 298degrees, improved by one time or more compared with untreated fabrics, so the treated fabric has good wrinkle recovery performance; the fabric of the invention has breaking strength reduced to 857 N and break strength retention rate of 91.4%; thus, the fabric of the invention has greater advantages in crease resistance than the untreated fabric.

Owner:苏州织圣丝绸科技中心

Anti-felting finishing method of wool fabric

InactiveCN107881778AGood dimensional stabilityImproves wrinkle recoveryWrinkle resistant fibresGrip property fibresBreaking strengthRecovery performance

The invention discloses an anti-felting finishing method of wool fabric. Firstly, the wool fabric is put in hot water to be pre-boiled after the water content of the wool fabric is kept at 30% with aspray method, and roll compacting is performed at 130-140 DEG C; the wool fabric coated with a finishing liquid is dried in a drying room; finally, oscillatory drying is performed and secondary dryingis performed. The invention provides the anti-felting finishing method of the wool fabric. With the adoption of the method, the process procedures are simple; the anti-felting wool fabric finished with the method has good dimensional stability and crease recovery performance, the breaking strength and the softness of the wool fabric can be improved, and the brightness of colored fabric is improved.

Owner:SUZHOU EMBROIDERY COLORFUL WORLD EMBROIDERY CRAFT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com