Polyester peach velvet fabric processing method

A peach skin and fabric technology, which is applied in the processing field of polyester peach skin fabric, can solve the problems of poor antistatic performance, low moisture absorption performance, cold and hard hand feeling, etc., and achieves strong moisture conductivity, soft luster and good wrinkle recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

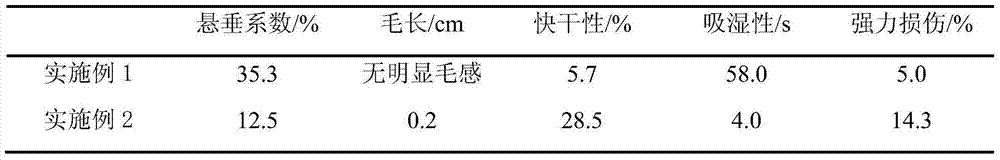

Examples

Embodiment 1

[0013] Material: 160x9075DX75D full polyester yarn-dyed fabric, fabric width 57 / 58”

[0014] The steps include: desizing → mercerizing → shaping → pre-shrinking → code cloth.

[0015] In the desizing process, use 5g / L of high-efficiency wax remover, 3g / L of penetrating agent, 70m / min of vehicle speed, stack at 55°C for 30min, then wash 2 compartments at 85°C and 3 compartments at 55°C;

[0016] In the mercerizing process, the alkali concentration is 175g / L, the vehicle speed is 50m / min, and the door width of the middle vehicle is 148cm;

[0017] In the shaping process, the temperature is 170°C, the vehicle speed is 45m / min, the amount of nano moisture-absorbing and quick-drying finishing agent is 40g / L, and the door width is 147cm;

[0018] Pre-shrinking process, the shrinkage rate is 0.5%.

Embodiment 2

[0020] Material: 160x9075DX75D full polyester yarn-dyed fabric, fabric width 57 / 58”

[0021] The steps include: desizing → mercerizing → alkali weight reduction → air washing → shaping → carbon brush sanding → pre-shrinking → code cloth.

[0022] In the desizing process, use 5g / L of high-efficiency wax remover, 3g / L of penetrating agent, 70m / min of vehicle speed, stack at 55°C for 30min, then wash 2 compartments at 85°C and 3 compartments at 55°C;

[0023] In the mercerizing process, the alkali concentration is 175g / L, the vehicle speed is 50m / min, and the height is 148cm;

[0024] In the alkali reduction process, the amount of caustic soda is 7g / L, the treatment time is 1h, the temperature is 60°C, and the reduction rate is controlled at 5.0%.

[0025] In the air washing process, the fan speed is 2200 / min, and the processing time is 40 minutes.

[0026] In the shaping process, the temperature is 170°C, the vehicle speed is 45m / min, the dosage of nano moisture-absorbing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com