Method for preparing warm composite woven fabric

A fabric and weaving technology, applied in the field of clothing fabrics, can solve the problems of inability to reduce heat loss, single function, unsatisfactory thermal insulation effect, etc., and achieve the effect of soft luster, comfortable hand feeling, and enhanced thermal insulation and fluffiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

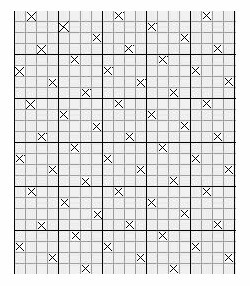

[0033] see figure 1 , see figure 1 , figure 1 It is a structural schematic diagram of the thermal fabric in the prior art. Depend on figure 1 It can be seen that the thermal fabric in the prior art is formed by interweaving one group of warp yarns 1 and one group of table weft 2 according to the number of one upper and seven lower wefts as 5, that is, a single-layer satin weave structure.

Embodiment 2

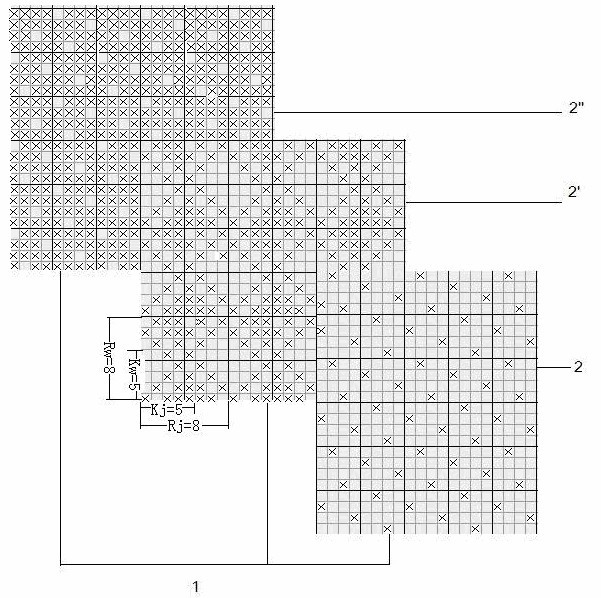

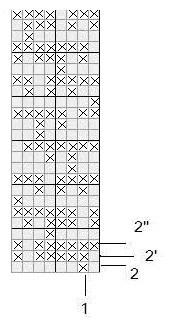

[0034] Example 2: see Figure 2~Figure 3 , figure 2 It is a structural schematic diagram of the woven composite thermal fabric of the present invention. image 3 It is the overall structure diagram of the woven composite thermal fabric of the present invention. Depend on figure 2 with image 3 It can be seen that the preparation method of the woven composite thermal fabric of the present invention is formed by overlapping and interweaving one group of warp yarns 1 and three groups of weft yarns, wherein the three groups of weft yarns are respectively the outer weft 2, the middle weft 2' and the inner weft 2' ', surface latitude 2: middle latitude 2': inner latitude 2'' = 1:1:1 arrangement; by figure 2 It can be seen that: warp 1 and surface weft 2 are interwoven with 5 flying wefts to form 8 pieces of satin with 5 flying wefts as the surface layer, and warp 1 and inner weft 2" are interwoven with 5 flying wefts at 1 upper and 7 lower wefts. 8 pieces of satin with 5 fly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com