Preparation method of antibacterial anti-wrinkle linen-cotton fabric

A fabric, cotton and linen technology, applied in the field of preparation of antibacterial and anti-wrinkle cotton and linen fabrics, can solve the problems of poor antibacterial and anti-wrinkle effects, achieve good inhibition effect, wide application prospects, and improved anti-wrinkle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

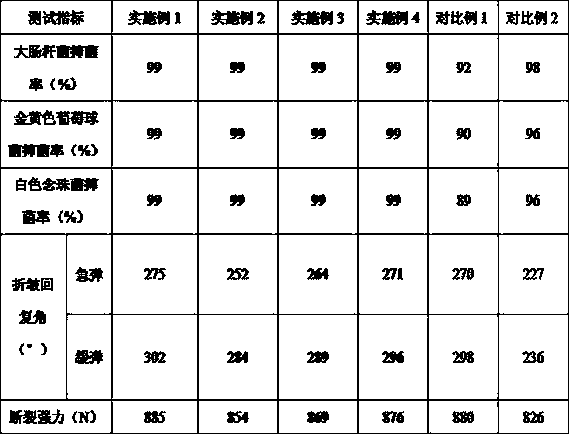

Examples

Embodiment 1

[0019] A preparation method of antibacterial wrinkle-resistant cotton and linen fabric, comprising the following steps:

[0020] (1) Add cotton and linen fabrics to 20wt% triethanolamine aqueous solution for ultrasonic treatment, the treatment temperature is 40°C, the treatment time is 3h, the ultrasonic frequency is 65Hz, and then the cotton and linen fabrics are ultrasonically machine washed with deionized water After 23 minutes, shake and dry the fabric for later use;

[0021] (2) Prepare 50nM silver nanoparticles dispersed in 0.01M pH7.4 PBS buffer, add PEG400 modified with thiol and amino groups at both ends, so that the concentration of PEG is 2M, shake and mix at room temperature for 40min, then Centrifuge it at 4000r / min for 8min, remove the supernatant, resuspend the precipitated particles with an equal volume of PBS buffer, and disperse the precipitated particles under ultrasonic conditions to prepare amino-modified silver nanoparticles;

[0022] (3) Dissolve 40 par...

Embodiment 2

[0026] A preparation method of antibacterial wrinkle-resistant cotton and linen fabric, comprising the following steps:

[0027] (1) Add cotton and linen fabrics to a triethanolamine aqueous solution with a mass fraction of 10wt% for ultrasonic treatment. The treatment temperature is 30°C, the treatment time is 2 hours, and the ultrasonic frequency is 50Hz. Then, the cotton and linen fabrics are ultrasonically machine washed with deionized water After 15 minutes, the fabric is shaken and dried for later use;

[0028] (2) Prepare 50nM silver nanoparticles dispersed in 0.01M pH7.4 PBS buffer, add PEG400 modified with thiol and amino groups at both ends, so that the concentration of PEG is 1M, shake and mix at room temperature for 30min, then Centrifuge it at 3000r / min for 5min, remove the supernatant, resuspend the precipitated particles with an equal volume of PBS buffer, and disperse the precipitated particles under ultrasonic conditions to prepare amino-modified silver nanopa...

Embodiment 3

[0033] A preparation method of antibacterial wrinkle-resistant cotton and linen fabric, comprising the following steps:

[0034] (1) Add cotton and linen fabrics to a triethanolamine aqueous solution with a mass fraction of 15wt% for ultrasonic treatment. The treatment temperature is 35°C, the treatment time is 2.5h, and the ultrasonic frequency is 60Hz. Then, the cotton and linen fabrics are treated with a deionized water ultrasonic machine. Wash for 20 minutes, shake and dry the fabric for later use;

[0035] (2) Prepare 50nM silver nanoparticles dispersed in 0.01M pH7.4 PBS buffer, add PEG400 modified with thiol and amino groups at both ends, so that the concentration of PEG is 1.5M, shake and mix at room temperature for 35min, Then it was centrifuged at 3500r / min for 6min, the supernatant was removed, the precipitated particles were resuspended with an equal volume of PBS buffer, and the precipitated particles were dispersed under ultrasonic conditions to obtain amino-modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com