Anti-fuzzing and anti-pilling finishing agent for fabric

An anti-pilling, finishing agent technology, applied in the direction of fiber treatment, textile and papermaking, fiber type, etc., to reduce the tendency of pilling, increase dimensional stability, and good anti-pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

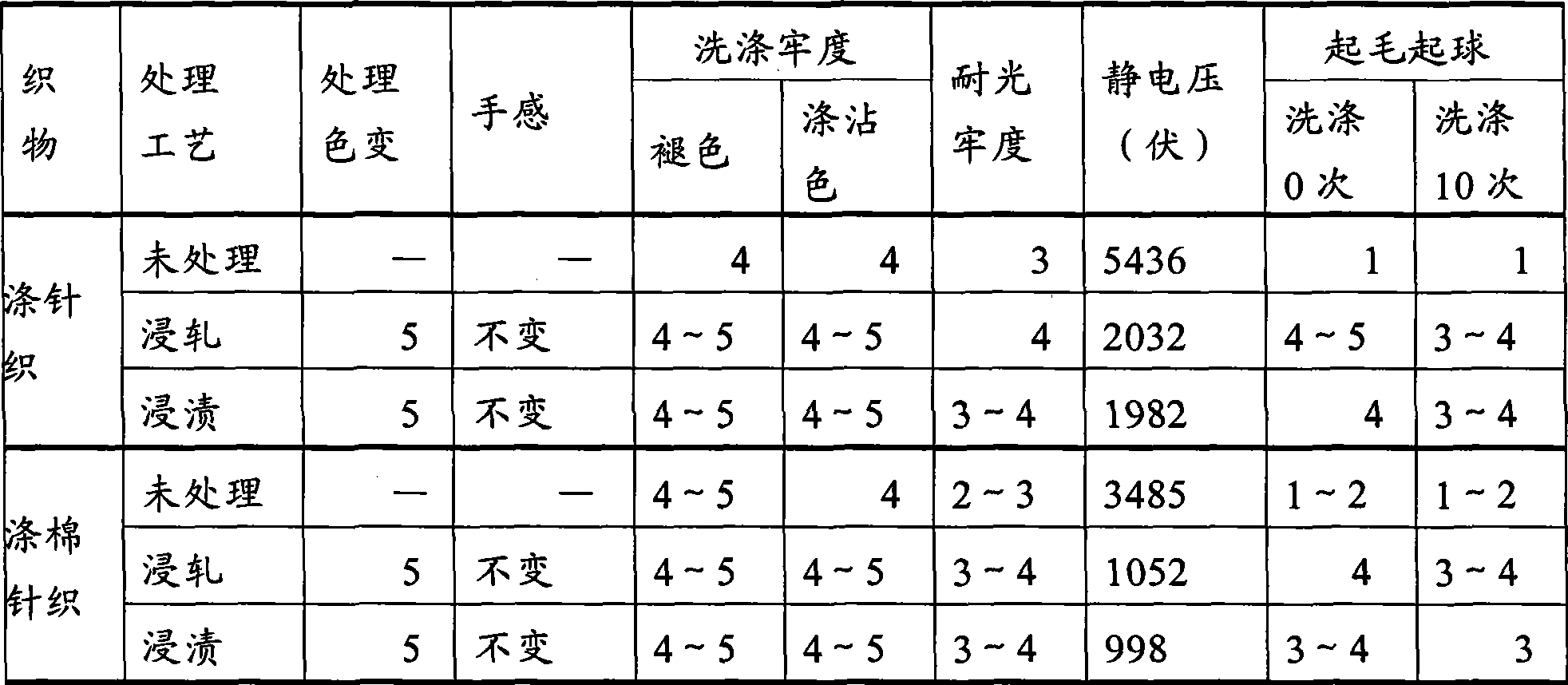

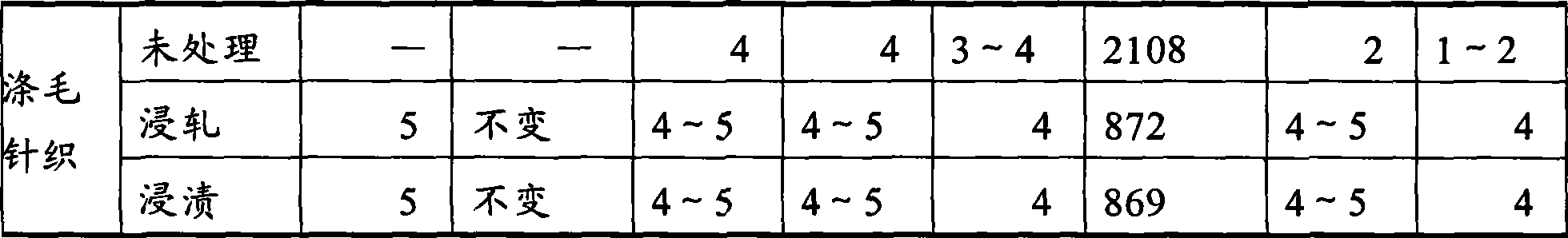

Examples

Embodiment Construction

[0026] A fabric anti-pilling finishing agent, which is a non-ionic high molecular polymer, the fabric anti-pilling, ball finishing agent is composed of:

[0027] 10-20 parts of high hydrogen-containing silicone oil, hydrogen content: 1.0%-1.8%;

[0028] 30-50 parts of polyurethane prepolymer, the degree of polymerization is: 2000-5500;

[0029] 30-50 parts of polypropylene ester copolymers, such as acrylic acid and acrylamide copolymers,

[0030] It is formed by copolymerization under the conditions of catalyst and heating; the catalyst is an organotin catalyst, and its dosage is 0.5-2 parts, and the said parts are parts by weight.

[0031] In the fabric anti-pilling finishing agent, the pH value of the dyed fabric wet rubbing fastness improving agent is 6-7.

[0032] Such as high hydrogen-containing silicone oil: polyurethane prepolymer: acrylic acid and acrylamide copolymer: organotin catalyst according to the ratio of 0.3:1:1:0.02 to prepare the anti-pilling finishing age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com