Wool fabric with strapping structure yarns and preparation method thereof

A technology of wool fabric and yarn, applied in the field of wool fabric with bundled structure yarn and its preparation, to achieve the effect of improving elongation and wrinkle recovery ability, not easy to hairiness, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

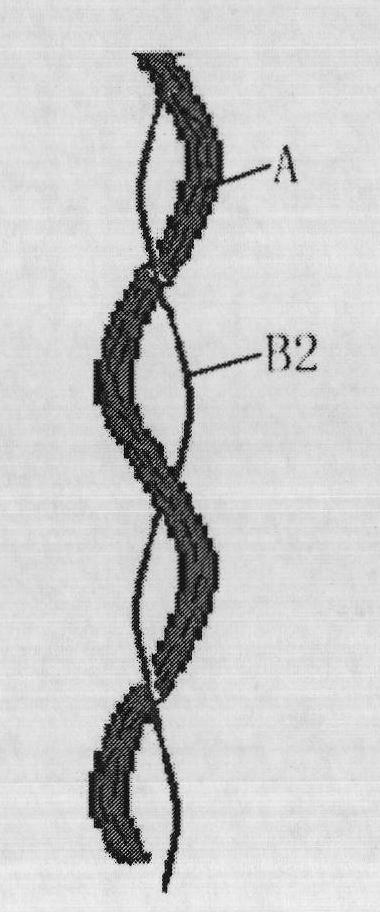

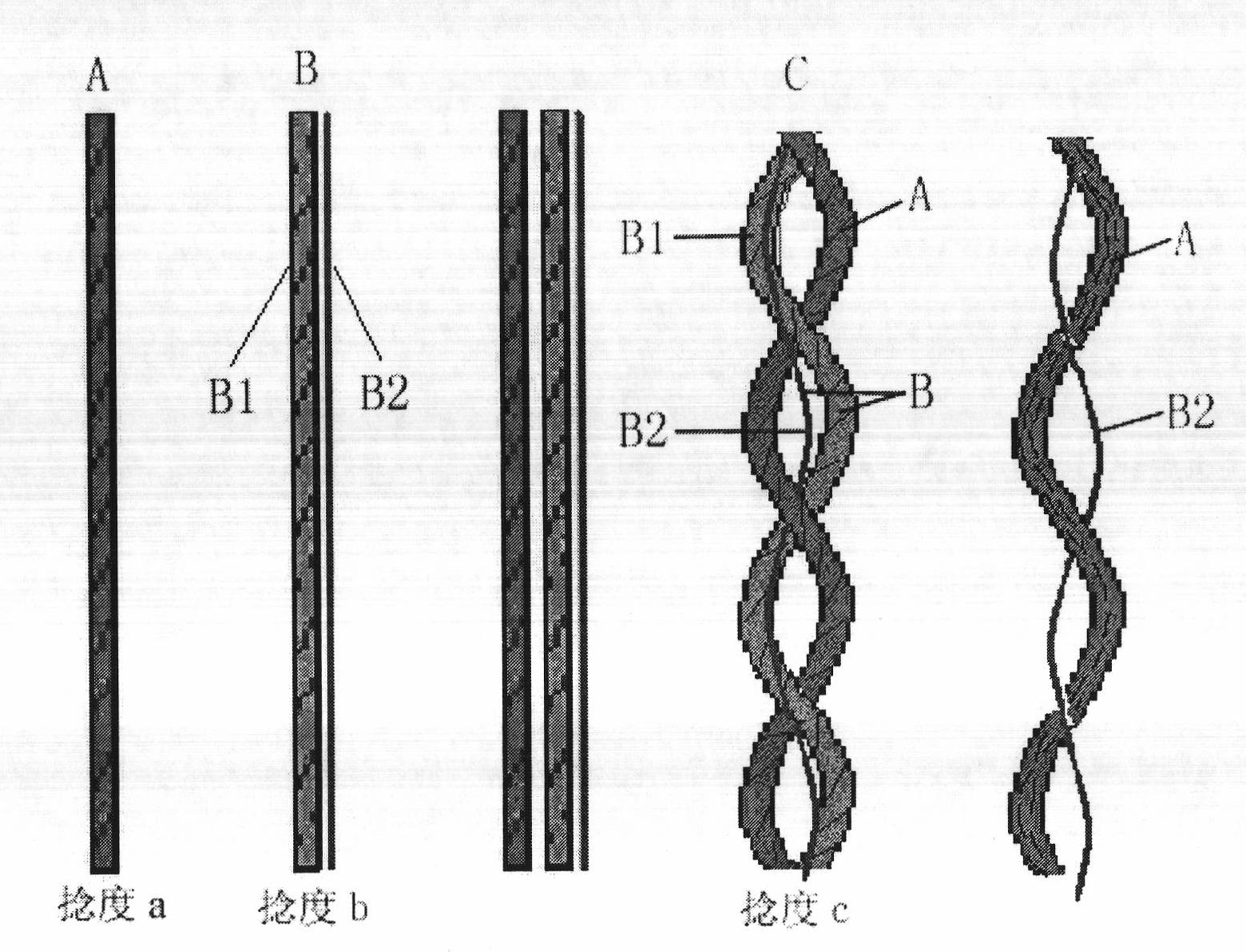

[0032] figure 2 It is a schematic diagram of the preparation method of the wool fabric of the present invention. As shown in the figure, firstly, the primary twist a is applied to the pure or blended wool yarn A, and the twist direction can be Z direction or S direction; and the water-soluble vinylon B1 is combined with a fine-denier chemical fiber filament B2 to form a sliver B , the sliver B can be untwisted, or the initial twist b is applied, and the twist direction is the same as that of the wool yarn A; then the wool yarn A and the sliver B are paralleled on the double twister, and then reverse twisted on the two-for-one twister , the double-twisted twist applied by reverse twisting is c, thus obtaining the woolen double-twisted yarn C; then using the woolen double-twisted yarn C to make a gray cloth through a weaving process; dyeing and finishing the gained gray cloth, and The fiber removal process is set in the dyeing and finishing process; after the water-soluble vin...

Embodiment 1

[0035] Embodiment 1: prepare low-twisted woolen fabric by wool / polyester blended yarn

[0036] In order to use thicker wool to achieve a better feel and provide good elasticity, 64 wool tops are used to spin wool / polyester 70 / 3034Nm yarn, twist 550 twist / m, Z direction (wool yarn A), using 85℃ water-soluble 14.6tex water-soluble vinylon yarn and a 50dtex / 24fPTT filament, twist 400 twists / m, Z direction (sliver B). Wool yarn A and sliver B are combined by doubling machine, and then 400 twists are added by two-for-one twisting machine in S direction, thus making wool yarn double-twisted yarn C. Place it naturally for 24 hours to set the twist and then carry out warping, weft winding and arrow loom weaving. After the gray fabric is made, it is firstly de-dimensionalized in an overflow dyeing machine at a bath ratio of 1:30 at 90°C×25min, and then Conventional wet and dry finishing. In the setting process, a large warp and weft tension is applied so that no wrinkles appear on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com