Anti-wrinkle finishing process for natural silk fabric

A technology for silk fabrics and anti-wrinkle finishing, which is applied in fiber treatment, animal fibers, textiles and papermaking, etc. It can solve the problems affecting the feel and hydrophilicity of silk fabrics, and achieve excellent hydrophilicity and handfeel and good wrinkle recovery performance , the effect of good strong retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

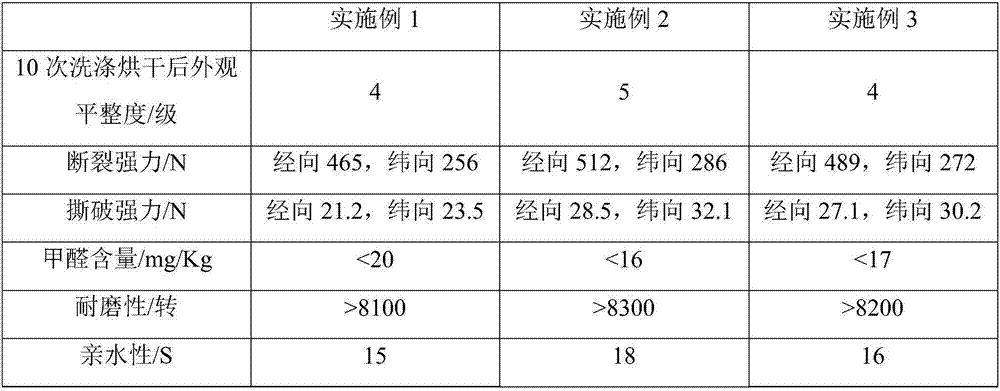

Examples

Embodiment 1

[0021] A kind of silk fabric anti-wrinkle finishing process, described process comprises the following steps:

[0022] (1) The real silk fabric is mixed with a mass concentration of 10g / L sodium sulfite aqueous solution, and reacted for 2 hours under normal temperature conditions. After the reaction is completed, it is repeatedly washed with deionized water and dried naturally;

[0023] (2) Soak the silk fabric treated in step (1) in phosphate buffer for 24 hours, take it out and dry it at a constant temperature of 55°C;

[0024] (3) Add water-soluble polyurethane, chitosan and deionized water to the Erlenmeyer flask, and add hydrochloric acid dropwise to make the pH value of the solution 1.5, place it in a water bath at 30°C, and shake vigorously for 12 minutes;

[0025] (4) Add softener, strong protective agent, catalyst and penetrating agent to the system in step (3), and stir and mix evenly under the condition of 40° C. to prepare anti-wrinkle finishing solution;

[0026]...

Embodiment 2

[0036] A kind of silk fabric anti-wrinkle finishing process, described process comprises the following steps:

[0037] (1) The real silk fabric is mixed with a mass concentration of 12g / L sodium sulfite aqueous solution, and reacted for 3.5 hours under normal temperature conditions. After the reaction is completed, it is repeatedly washed with deionized water and dried naturally;

[0038] (2) Soak the silk fabric treated in step (1) in phosphate buffer for 36 hours, take it out and dry it at a constant temperature of 55°C;

[0039] (3) Add water-soluble polyurethane, chitosan and deionized water into the Erlenmeyer flask, and dropwise add hydrochloric acid to make the pH value of the solution 2.0, place it in a water bath at 36°C, and shake vigorously for 18 minutes;

[0040] (4) Add softener, strong protective agent, catalyst and penetrating agent to the system in step (3), and stir and mix evenly under the condition of 45° C. to prepare anti-wrinkle finishing solution;

[0...

Embodiment 3

[0051] A kind of silk fabric anti-wrinkle finishing process, described process comprises the following steps:

[0052] (1) The real silk fabric is mixed with a mass concentration of 15g / L sodium sulfite aqueous solution, and reacted for 5 hours under normal temperature conditions. After the reaction is completed, it is repeatedly washed with deionized water and dried naturally;

[0053] (2) Soak the silk fabric treated in step (1) in phosphate buffer for 48 hours, take it out and dry it at a constant temperature of 55°C;

[0054] (3) Add water-soluble polyurethane, chitosan and deionized water to the Erlenmeyer flask, and add hydrochloric acid dropwise to make the pH value of the solution 2.2, place it in a water bath at 45°C, and shake vigorously for 20 minutes;

[0055] (4) Add softener, strong protective agent, catalyst and penetrating agent to the system in step (3), and stir and mix evenly under the condition of 50° C. to prepare anti-wrinkle finishing solution;

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com