Preparation method and application of cationic modifier TCTAC

A cationic modifier, deionized water technology, applied in plant fibers, fiber treatment, fibers affecting crease behavior, etc., can solve the problems of rare antibacterial and anti-wrinkle cotton fabrics and lack of application research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

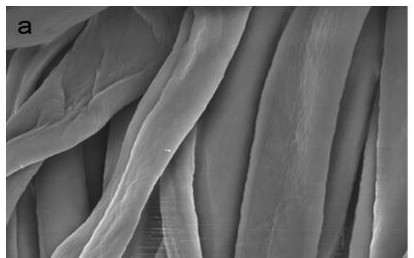

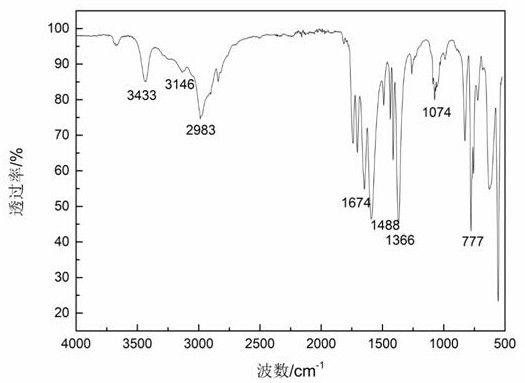

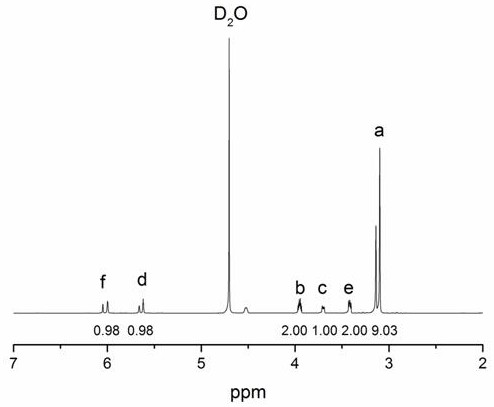

Image

Examples

Embodiment 1

[0036] 1) Preparation of cationic modifier TCTAC:

[0037] 1. Weigh 0.01 mol of 2,3-epoxyhydroxypropyltrimethylammonium chloride (EPTAC) and 20 mL of deionized water, dissolve them in a round bottom flask and stir for 20 min, and then add constant pressure to the round bottom flask Slowly add 0.01 mol ammonia solution dropwise into the funnel, and stir at 80°C for 12 h. After the reaction, filter with suction to obtain 1-amino-3-hydroxypropyltrimethylammonium chloride (ACTAC).

[0038] 2. Weigh 0.01 mol of cyanuric chloride and 40 mL of acetone to dissolve in a three-neck flask and stir for 20 min. Dissolve 0.01 mol of 1-amino-3-hydroxypropyltrimethylammonium chloride in 20 mL of deionized water and constant The pressure funnel was slowly dropped into the three-necked flask, the temperature of the system was maintained at 0 °C, and the pH value of the entire reaction system was adjusted to 6-7 with a sodium carbonate solution with a concentration of 0.1 g / L, and the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com