A fluorine-free water-repellent and antifouling finishing agent and its preparation method and application

A fluorine-free water-repellent and finishing agent technology, applied in anti-coloring pollution/anti-fouling fibers, fiber treatment, shrink-proof fibers, etc., can solve the problems of no anti-fouling and finishing agents that cannot achieve super water repellency, etc. Achieving ease of implementation, maintaining feel and breathability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

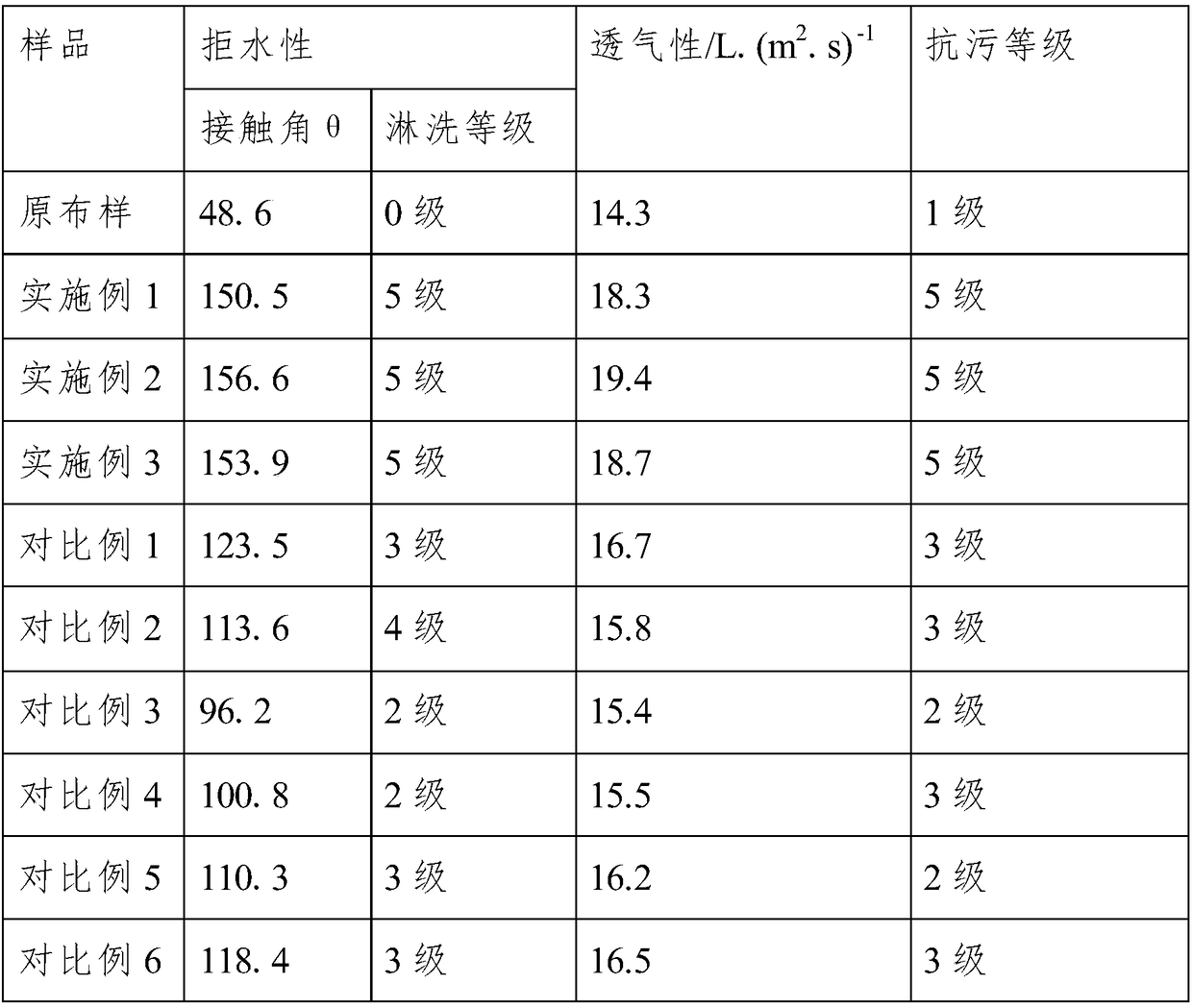

[0029] Example 1. A fluorine-free water-repellent and antifouling finishing agent

[0030] The fluorine-free water-repellent and antifouling finishing agent described in Example 1 of the present invention includes system A and system B, the weight ratio of system A and system B in the finishing agent is 1:0.7, and the system A is composed of 0.3% chitosan oligosaccharide , water-based polyurethane 8% and the balance of water, the system B is modified nano-silica sol.

[0031] Preparation:

[0032] ⅰ) Preparation of system A: dissolving chitosan and water-based polyurethane in water, and mixing uniformly to obtain system A;

[0033] ii) Preparation of system B:

[0034] S1. Dilute the water glass with a modulus n of 2 with distilled water until the silicon content of the solution is 4wt%, to obtain a water glass solution; in the state of stirring at a speed of 10ml / min, press the water glass solution: mixed solution = 1:1 Add the above-mentioned water glass solution dropwise...

Embodiment 2

[0038] Example 2, a fluorine-free water-repellent and antifouling finishing agent

[0039] The fluorine-free water-repellent and antifouling finishing agent described in Example 2 of the present invention includes system A and system B, the weight ratio of system A and system B in the finishing agent is 1:0.6, and the system A is composed of 0.8% chitosan oligosaccharide , water-based polyurethane 6% and the balance of water, the system B is modified nano-silica sol.

[0040] Preparation:

[0041] ⅰ) Preparation of system A: dissolving chitosan and water-based polyurethane in water, and mixing uniformly to obtain system A;

[0042] ii) Preparation of system B:

[0043] S1. Dilute the water glass with a modulus n of 2 with distilled water until the silicon content of the solution is 4wt%, to obtain a water glass solution; in the state of stirring at a speed of 10ml / min, press the water glass solution: mixed solution = 1:1 Add the above-mentioned water glass solution dropwise...

Embodiment 3

[0047] Example 3. A fluorine-free water-repellent and antifouling finishing agent

[0048] The fluorine-free water-repellent and antifouling finishing agent described in Example 3 of the present invention includes system A and system B, and the weight ratio of system A to system B in the finishing agent is 1:0.8, and the system A is composed of 1% chitosan oligosaccharide , water-based polyurethane 10% and the balance of water, the system B is modified nano-silica sol.

[0049] The preparation method refers to Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com