Method for preparing hydroxylated sulfonated castor oil borate

A technology for hydroxylation of sulfonated castor oil and sulfonated castor oil, which is applied in chemical instruments and methods, organic chemistry, compounds containing elements of Group 3/13 of the periodic table, etc. , sulfonated castor oil esters have limited water solubility and emulsifying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

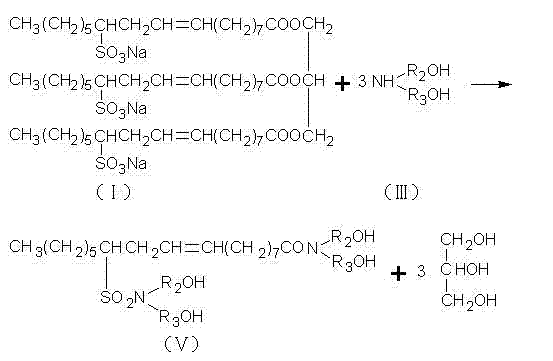

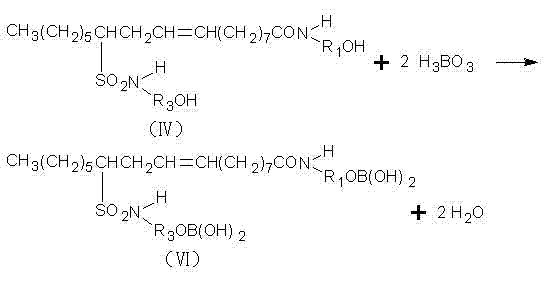

Method used

Image

Examples

Embodiment 1

[0017] Add 350 grams of 70% sulfonated castor oil ester and 80 grams of monoethanolamine into a three-necked flask equipped with a stirring device, a reflux condensing device and a thermometer, heat with microwaves, and carry out hydroxylation reaction at 130°C to 140°C for 3 to 4 hours. Then slowly lower the temperature to about 80°C, react under constant temperature and reduced pressure for 2-3 hours, and further distill off glycerin and water under reduced pressure to obtain the intermediate product hydroxylated sulfonated castor oil; add 23 grams of boric acid to the three-necked bottle, After carrying out the esterification reaction at ℃ for 3-5 hours, stop the reaction to obtain hydroxylated sulfonated castor oil borate.

Embodiment 2

[0019] Add 170 kg of 70% sulfonated castor oil ester and 63 kg of diethanolamine into a reaction kettle equipped with a stirring device, a reflux condensing device and a thermometer, heat with microwaves, and carry out hydroxylation reaction at 140°C to 150°C for 4 h, then slowly Slowly lower the temperature to about 80°C, react under constant temperature and reduced pressure for 2-3 hours, and further distill off glycerin and water under reduced pressure to obtain the intermediate product hydroxylated sulfonated castor oil; After 3-5 hours of esterification reaction, stop the reaction to obtain hydroxylated sulfonated castor oil borate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com