Spider silk protein/polylactic acid composite nano fibre yarn and preparation method thereof

A composite nanofiber, spider silk protein technology, applied in fiber processing, filament/thread forming, cellulose/protein conjugated rayon, etc., can solve the problem of unable to obtain yarn, achieve uniformity improvement, diameter Reduced, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

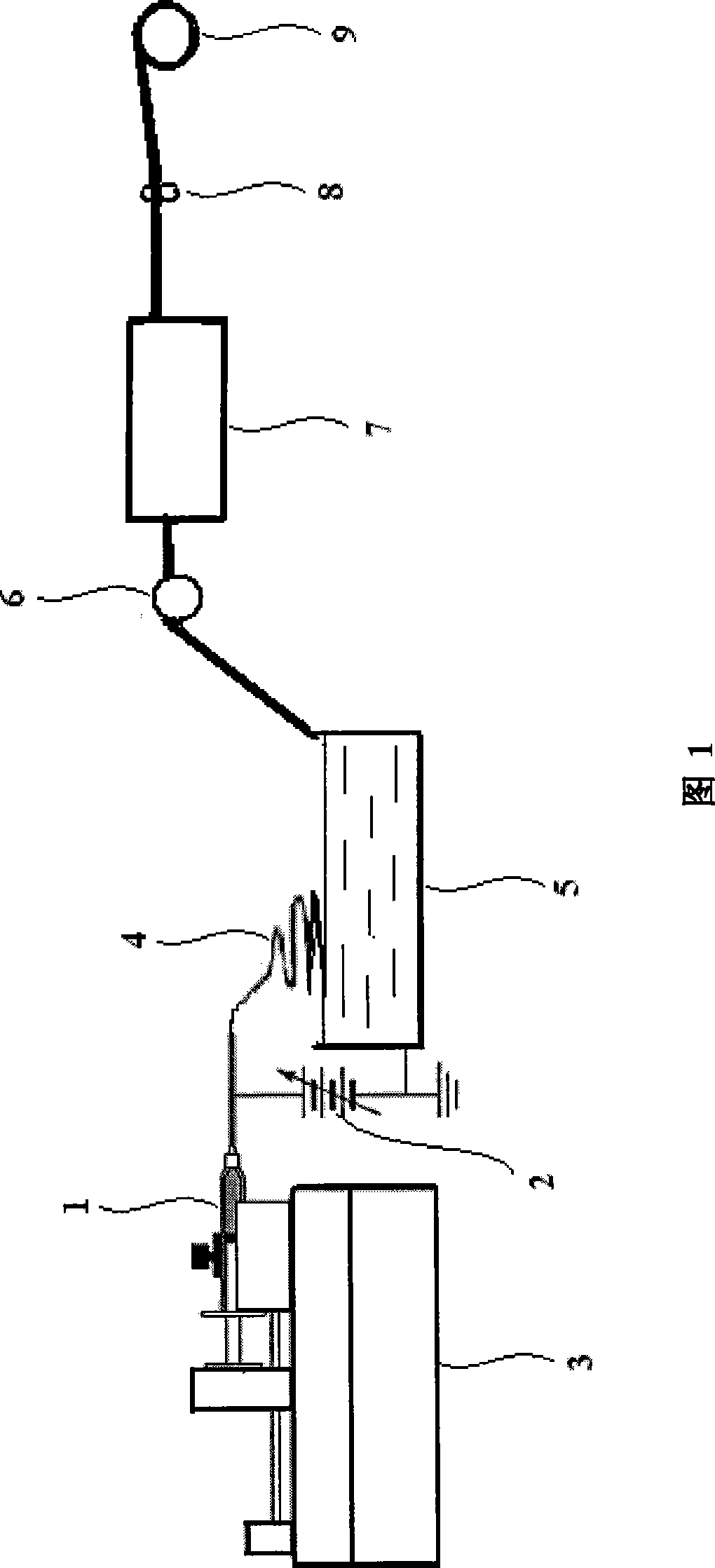

Method used

Image

Examples

Embodiment 1

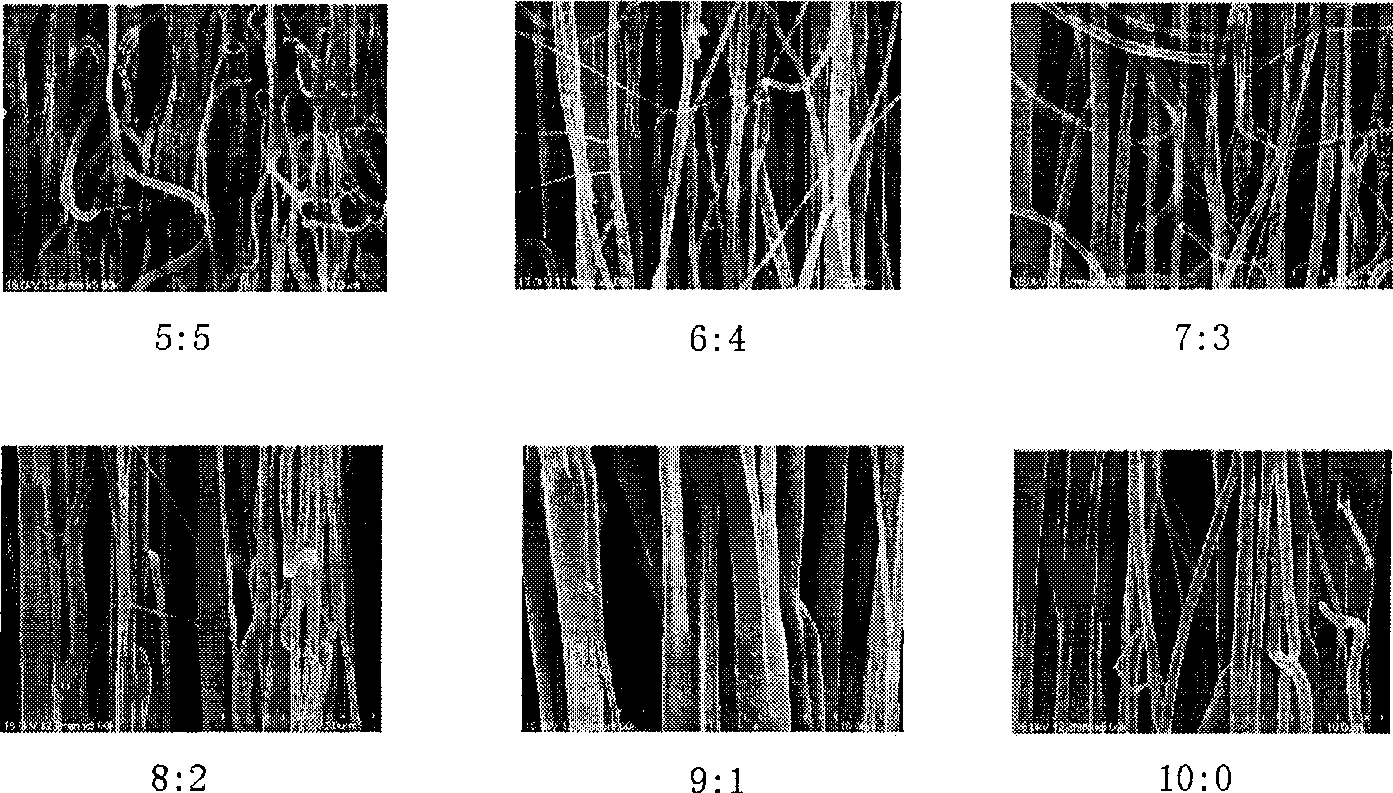

[0032] The preparation of different ratios of spider silk protein / polylactic acid composite nanofiber yarns comprises the following steps:

[0033] (1) Preparation of spinning solution: Dissolve pure and dry polylactic acid (PLA) in 99% hexafluoroisopropanol (HFIP) at room temperature, and after fully stirring and dissolving, a 9% by mass percentage is obtained. PLA solution; the tiger's bird spider silk is dissolved in 99% hexafluoroisopropanol solution, after being fully stirred and filtered with a metal filter, a 1% spider silk protein solution with a mass percentage of 1% is obtained, and then the two solutions are mixed Mix evenly according to a certain weight ratio to obtain spinning solution;

[0034] (2) Preparation of bath liquid: Dissolve the commercially available hydrophilic silicone softener of model KGF-903 produced by Nantong Chongchuan Keguang New Material Research Institute in deionized water to prepare a bath liquid with a mass percentage of 0.2% ;

[0035]...

Embodiment 2

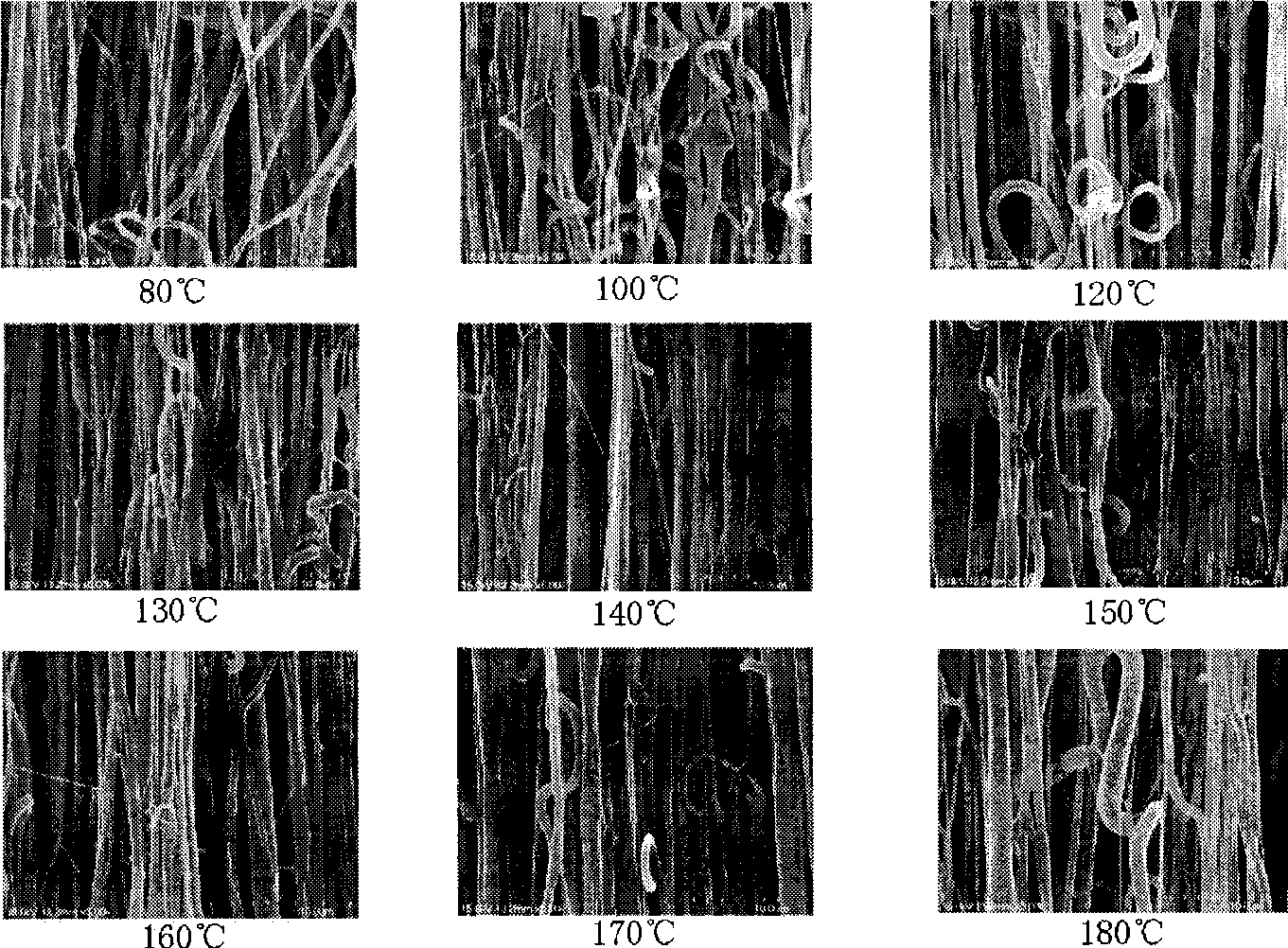

[0045] The preparation of the spider silk protein / polylactic acid composite nanofiber yarn under different heating zone temperatures comprises the following steps:

[0046] (1) Preparation of spinning solution: Dissolve pure and dry polylactic acid (PLA) in 99% hexafluoroisopropanol (HFIP) at room temperature, and after fully stirring and dissolving, a 9% by mass percentage is obtained. PLA solution; the tiger's bird spider silk is dissolved in 99% hexafluoroisopropanol solution, after being fully stirred and filtered with a metal filter, a 1% spider silk protein solution with a mass percentage of 1% is obtained, and then the two solutions are mixed Mix evenly at a weight ratio of 7:3 to obtain a spinning solution;

[0047] (2) Preparation of bath liquid: Dissolve the commercially available hydrophilic silicone softener of model KGF-903 produced by Nantong Chongchuan Keguang New Material Research Institute in deionized water to prepare a bath liquid with a mass percentage of 0...

Embodiment 3

[0056] The preparation of spider silk protein / polylactic acid composite nanofiber yarn comprises the following steps:

[0057] (1) Preparation of spinning solution: Dissolve pure and dry polylactic acid (PLA) in 99% hexafluoroisopropanol (HFIP) at room temperature, and after fully stirring and dissolving, a 9% by mass percentage is obtained. PLA solution; the tiger's bird tarantula silk is dissolved in 99% hexafluoroisopropanol solution, fully stirred and filtered with a metal filter to obtain a 0.8% spider silk protein solution by mass percentage, and then the two solutions are mixed Mix evenly at a weight ratio of 7:3 to obtain a spinning solution;

[0058] (2) Preparation of bath liquid: Dissolve the commercially available hydrophilic silicone softener of model KGF-903 produced by Nantong Chongchuan Keguang New Material Research Institute in deionized water to prepare a bath liquid with a mass percentage of 0.4% ;

[0059] (3) adopting the electrospinning method, adding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com