Multilayer steel truss fragmented reverse hoisting construction method in arc-shaped frame

A steel truss, multi-level technology, applied in the direction of construction, building structure, building materials, etc., can solve the problems of steel truss lifting difficulties, large volume of three-dimensional crossing operations, hoisting operations, etc., to reduce high-altitude assembly and welding operations less volume, fewer three-dimensional intersection operations, and reduced mechanical shifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

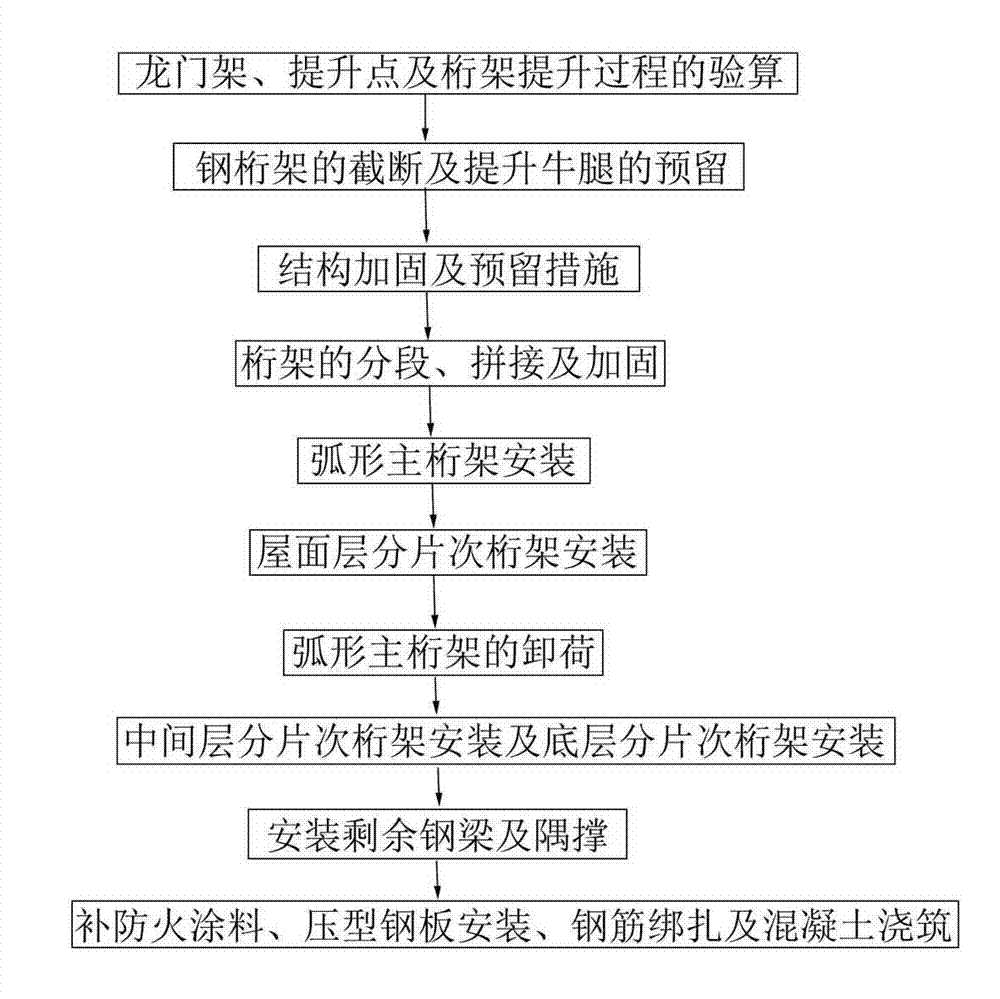

[0145] Embodiment one, Nantong Nengda Building construction project, refer to the attached figure 2

[0146] Project overview, Nengda Building construction project, project investment 226 million, construction area 119,998 square meters, the steel truss structure above the podium 2-18 to 2-23 axis lecture hall is a large-span multi-level spatial structure system, complex structure, Large components, heavy weight and high height. The project was constructed by Jiangsu Nantong No.6 Construction Group Co., Ltd. The hoisting of the steel structure began in September 2012 and ended in November 2012.

[0147] Application situation, there are 6 steel structure trusses in this project. There are many high-altitude operations during installation, and the construction is difficult. Only by adopting a reasonable installation plan can the construction period, safety, quality, and economy be guaranteed. After analysis and discussion, the lifting order of the steel trusses is a...

Embodiment 2

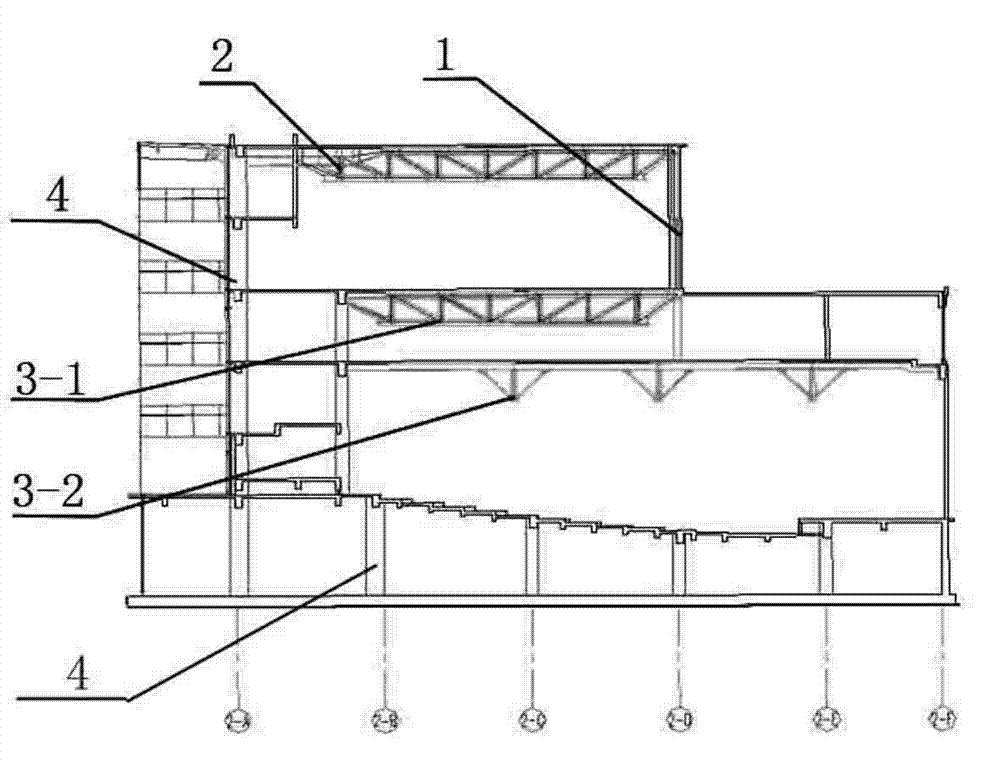

[0150] Embodiment 2, Keyu Information Industry Building

[0151]Project overview, Shanxi Keyu Industrial Co., Ltd. has a land area of 56,000 square meters and a total construction area of 116,000 square meters. The project is a main office building with 24 floors above ground, and an annex building with 3 floors above ground, with a single-story basement, which has functions such as scientific research, office, conference, and exhibition. The curved frame conference room in the annex building is designed as a three-story steel structure with a span of 36 meters, with a curved main truss (span 35.6 m, center line height of upper and lower chords 8.360 m, weight 80.5T), roof secondary truss (truss height 1.8 m, length 16.2 m, weight 36T), the middle level truss (span 34.2m, the height of the center line of the upper and lower chords is 2m), and the bottom level truss (span 32.8m, the height of the center line of the upper and lower chords is 2m), forming a three-level tru...

Embodiment 3

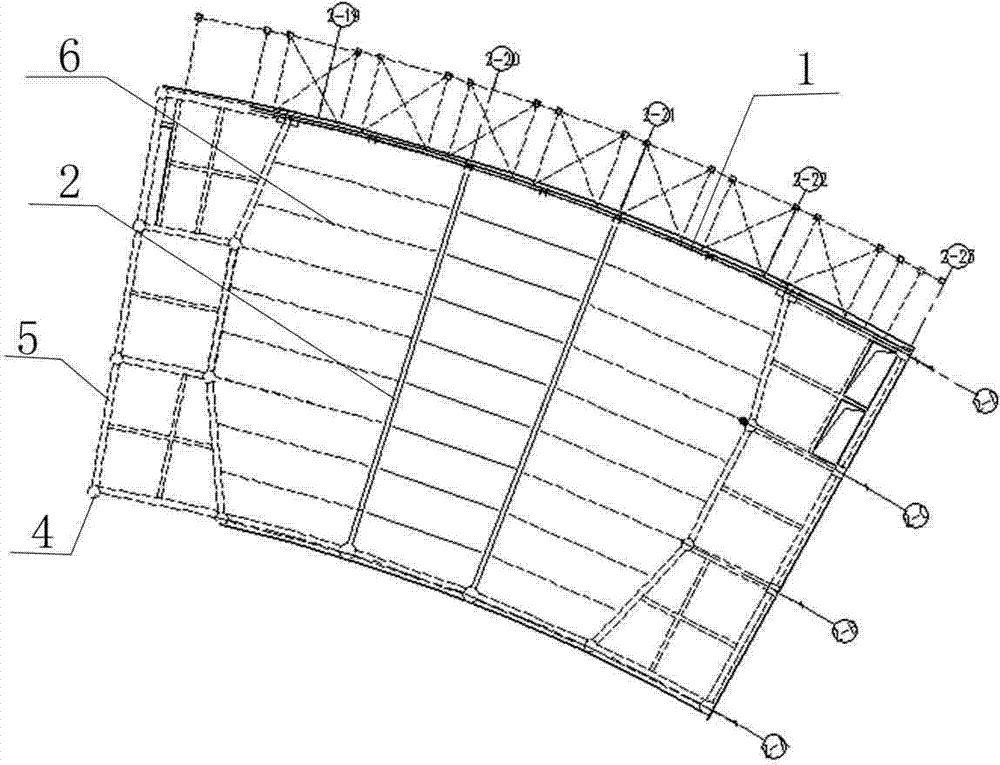

[0153] Embodiment 3, Fengshangfeng Business Complex Building

[0154] Project overview, Fengshangfeng commercial complex building project, two basement floors (partly three floors) are garages, the first to sixth floors above ground are podiums, and above the podiums are business buildings, of which the arc-shaped frame auditorium of the podium (the first basement The steel structure trusses from floor to roof) mainly have five parts: arc-shaped main truss (span 40.2m, centerline height of upper and lower chords 16.40m) passing through the second to sixth floors, roof secondary truss (truss height 2.1m, length 22.5m) , the middle layer (third and fifth floors) secondary truss (span 34.2m, centerline height of upper and lower chords 2m), the bottom layer (second floor) secondary truss (span 34.2m, height of upper and lower chord centerlines 2m), forming a four-layer truss . The project was constructed by Jiangsu Nantong No.6 Construction Group Co., Ltd. The hoisting of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com