Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Low linear expansion coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curable resin composition, curable resin composition tablet, molded body, semiconductor package, semiconductor component and light emitting diode

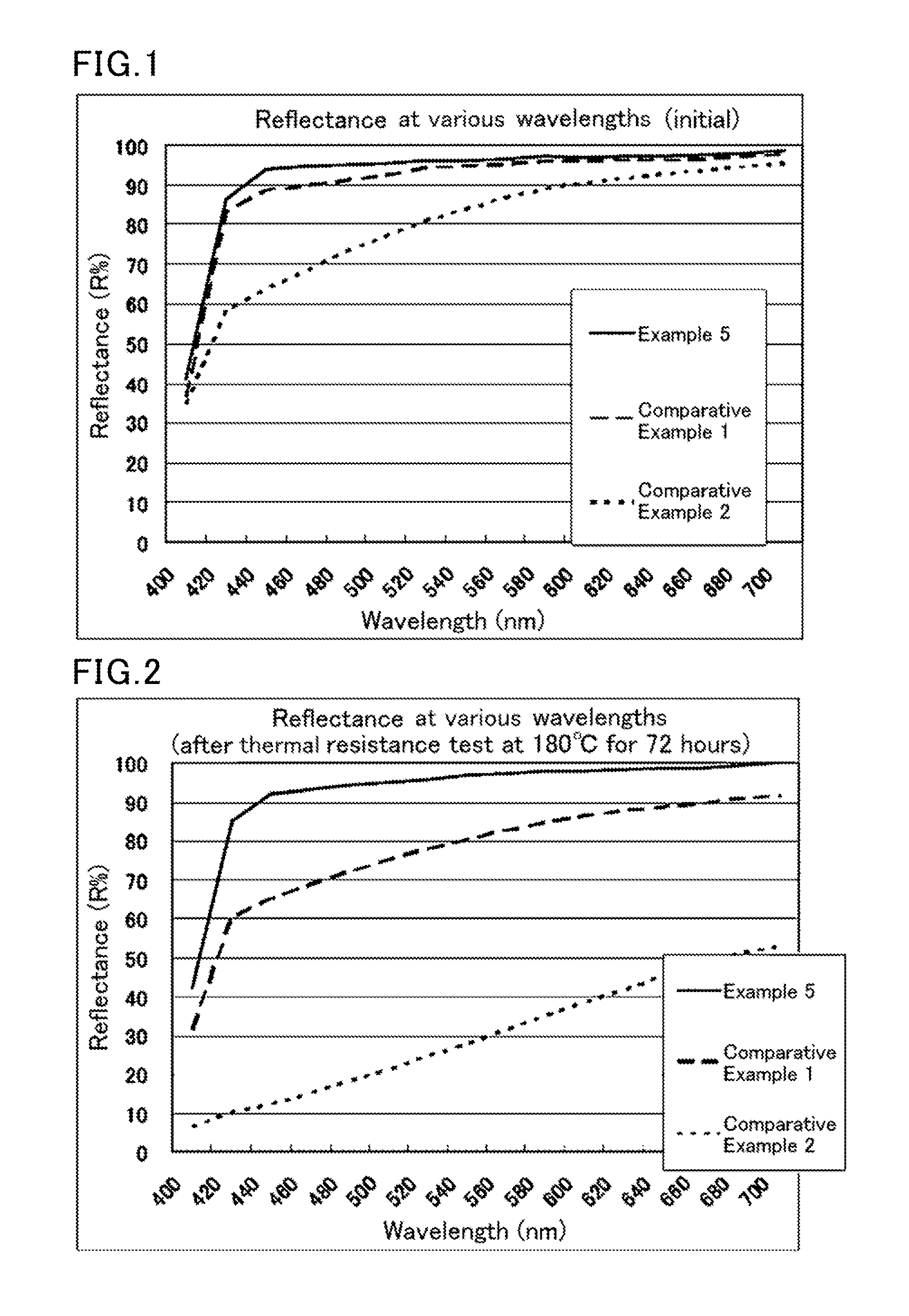

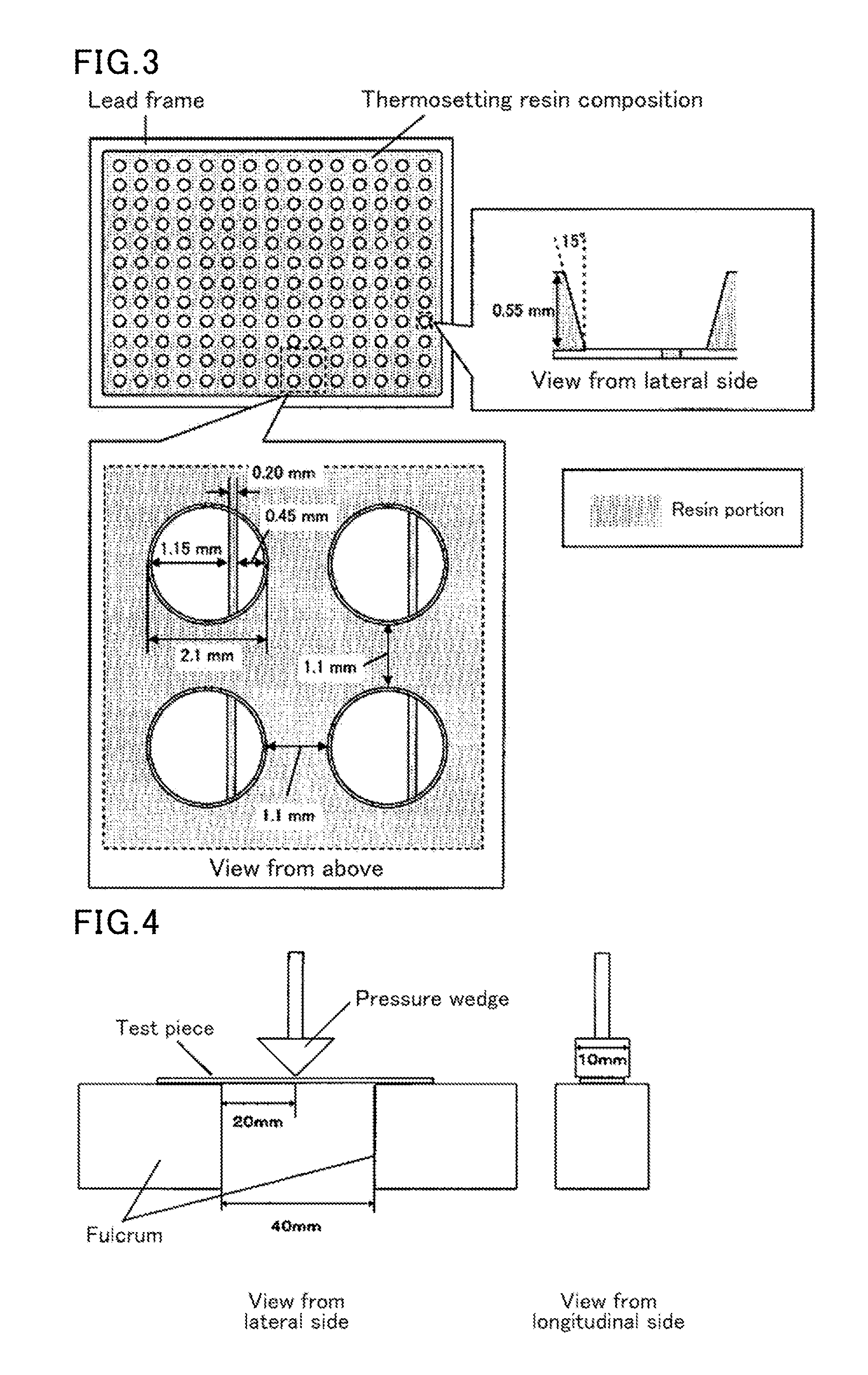

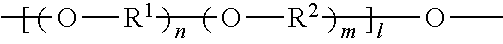

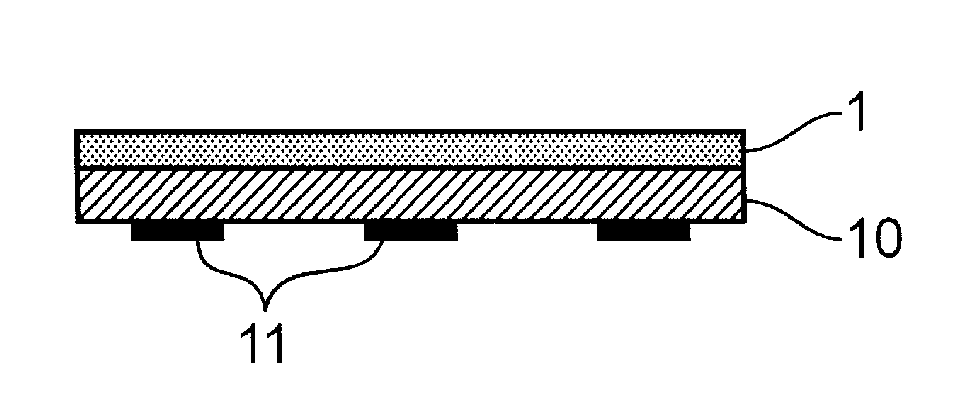

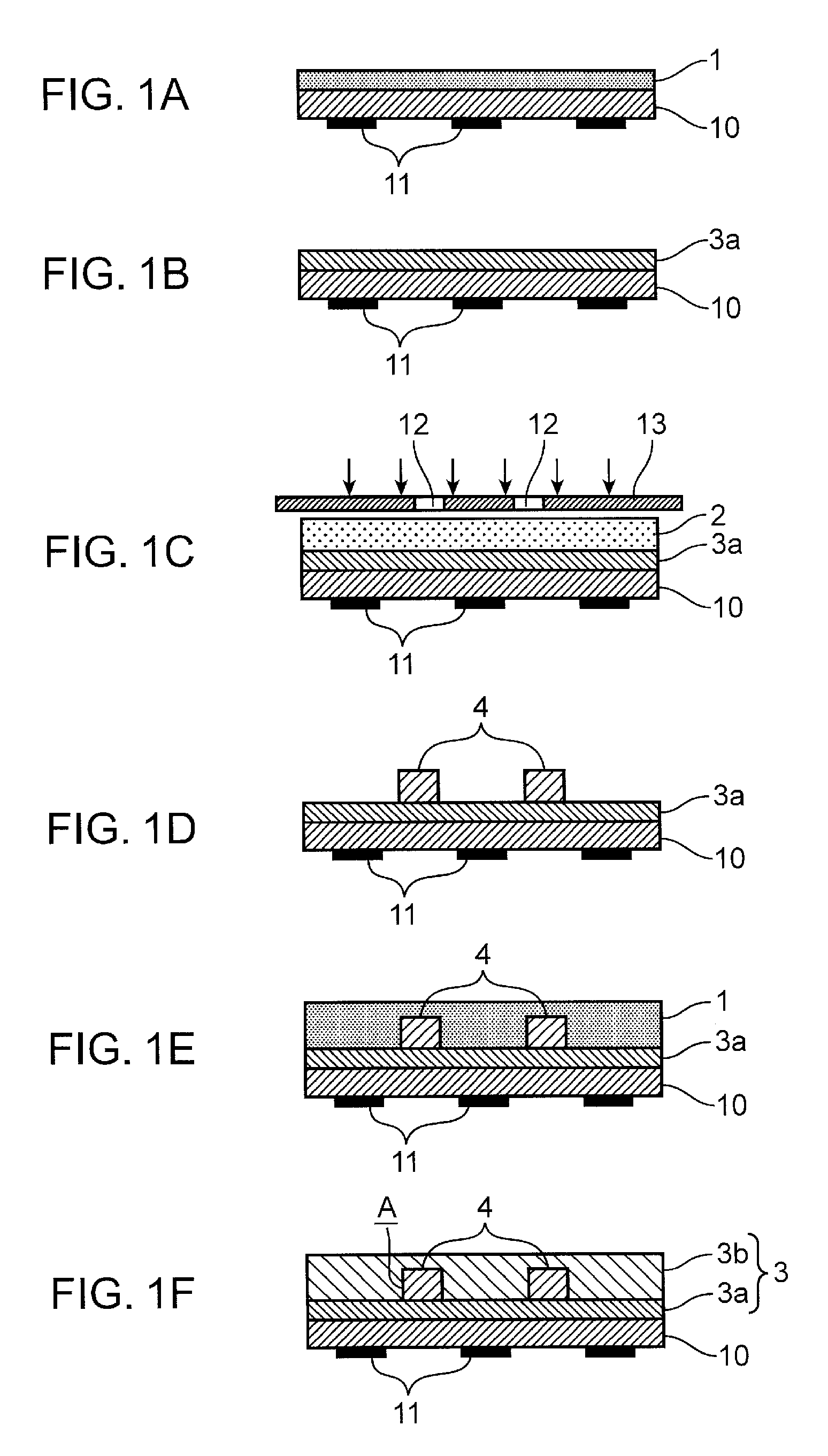

ActiveUS20130082369A1Low coefficient of linear expansionReduce warpageFibre treatmentSemiconductor/solid-state device detailsChemical compoundSemiconductor package

The present invention aims to provide a curable resin composition which gives a cured product having a low linear expansion coefficient. The curable resin composition of the present invention contains, as essential components, (A) an organic compound having at least two carbon-carbon double bonds reactive with SiH groups per molecule, (B) a compound containing at least two SiH groups per molecule, (C) a hydrosilylation catalyst, (D) a silicone compound having at least one carbon-carbon double bond reactive with a SiH group per molecule, and (E) an inorganic filler.

Owner:KANEKA CORP

Alkali-free glass substrate, method for producing it and liquid crystal display panel

ActiveUS20090176640A1High Young 's modulusLow linear expansion coefficientGlass rolling apparatusNon-linear opticsAlkali freeYoung's modulus

To provide an alkali-free glass substrate, which has a high Young's modulus, a low linear expansion coefficient, a high strain point and a low density, does not devitrify in the float forming process and is excellent in acid resistance.An alkali-free glass substrate, which contains neither alkali component nor BaO and consists essentially of, as represented by mol % based on oxide, from 57.0 to 65.0% of SiO2, from 10.0 to 12.0% of Al2O3, from 6.0 to 9.0% of B2O3, from 5.0 to 10.0% of MgO, from 5.0 to 10.0% of CaO and from 2.5 to 5.5% of SrO, provided that MgO+CaO+SrO is from 16.0 to 19.0%, MgO / (MgO+CaO+SrO)≧0.40, and B2O3 / (SiO2+Al2O3+B2O3)≦0.12; wherein Young's modulus ≧75 GPa; the linear expansion coefficient at from 50 to 350° C. is from 30×10−7 / ° C. to 40×10−7 / ° C.; the strain point ≧640° C.; the temperature T2 (the viscosity η satisfies log η=2)≦1,620° C.; the temperature T4 (the viscosity η satisfies log η=4)≦1,245° C.; the devitrification temperature ≦T4; and weight loss per unit area is at most 0.6 mg / cm2, when immersed in 0.1N HCl at 90° C. for 20 hours.

Owner:ASAHI GLASS CO LTD

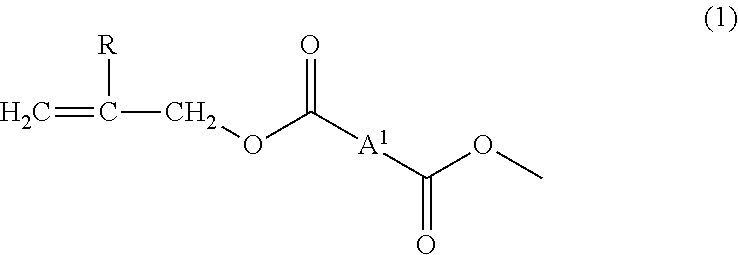

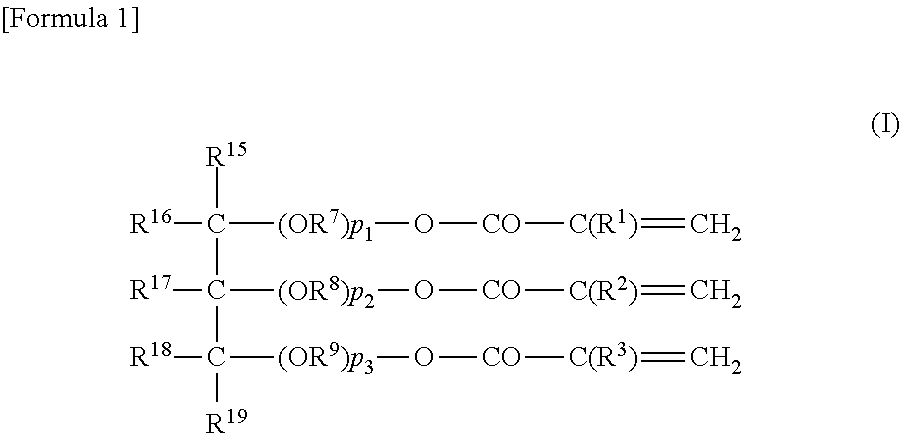

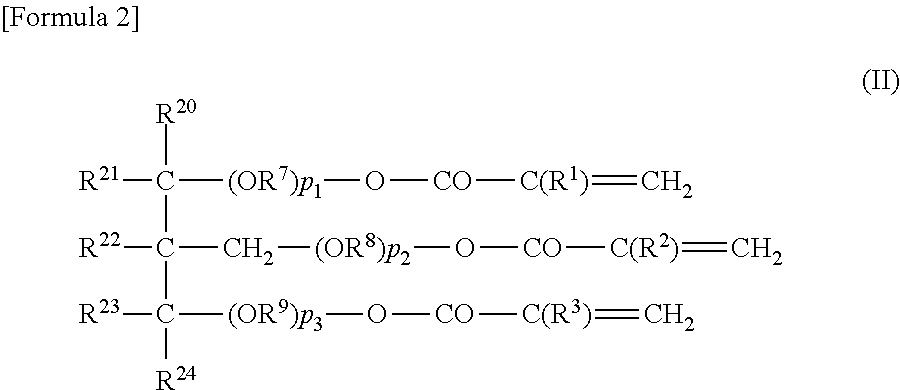

Vinyl Polymer Powder, Curable Resin Composition and Cured Product

InactiveUS20140296437A1Good dispersionTurn fasterSemiconductor/solid-state device detailsSynthetic resin layered productsCrack resistanceGlass transition

A vinyl polymer powder, a curable resin composition containing the vinyl polymer powder and a curable resin, and a cured product obtained by curing the curable resin composition are provided. The vinyl polymer powder contains a vinyl polymer of which the glass transition temperature is 120° C. or higher and the mass average molecular weight is 100,000 or more, has excellent dispersibility in the curable resin composition, and rapidly turns the curable resin composition into a gel state by heating at a predetermined temperature in a short time. Further, the vinyl polymer powder decreases the linear expansion coefficient of the obtained cured product, and improves the crack resistance.

Owner:MITSUBISHI RAYON CO LTD

Silica sol and silica-containing epoxy resin composition

ActiveUS20160068664A1Lower emission rateSmall moisture absorption coefficientOther chemical processesSilicon compoundsEpoxySilica particle

The silica sol of the invention contains silica particles having a mean primary particle size of 20 to 100 nm and which has a silica particle size / mean primary particle size ratio, determined through dynamic light scattering, of 3.0 or less, wherein the silica particles are surface-treated with an organic silane compound and have an α-ray emission rate of 0.005 counts / cm2·hr or less and a moisture absorption coefficient, determined after allowing the silica particles to stand for 48 hours at 23° C. and a relative humidity of 50 RH %, of 0.5 mass % or lower.

Owner:NISSAN CHEM IND LTD

Alkali-free glass substrate, method for producing it and liquid crystal display panel

ActiveUS7754631B2High Young 's modulusLow linear expansion coefficientGlass rolling apparatusNon-linear opticsAlkali freeYoung's modulus

To provide an alkali-free glass substrate, which has a high Young's modulus, a low linear expansion coefficient, a high strain point and a low density, does not devitrify in the float forming process and is excellent in acid resistance.An alkali-free glass substrate, which contains neither alkali component nor BaO and consists essentially of, as represented by mol % based on oxide, from 57.0 to 65.0% of SiO2, from 10.0 to 12.0% of Al2O3, from 6.0 to 9.0% of B2O3, from 5.0 to 10.0% of MgO, from 5.0 to 10.0% of CaO and from 2.5 to 5.5% of SrO, provided that MgO+CaO+SrO is from 16.0 to 19.0%, MgO / (MgO+CaO+SrO)≧0.40, and B2O3 / (SiO2+Al2O3+B2O3)≦0.12; wherein Young's modulus ≧75 GPa; the linear expansion coefficient at from 50 to 350° C. is from 30×10−7 / ° C. to 40×10−7 / ° C.; the strain point ≧640° C.; the temperature T2 (the viscosity η satisfies log η=2)≦1,620° C.; the temperature T4 (the viscosity η satisfies log η=4)≦1,245° C.; the devitrification temperature ≦T4; and weight loss per unit area is at most 0.6 mg / cm2, when immersed in 0.1N HCl at 90° C. for 20 hours.

Owner:ASAHI GLASS CO LTD

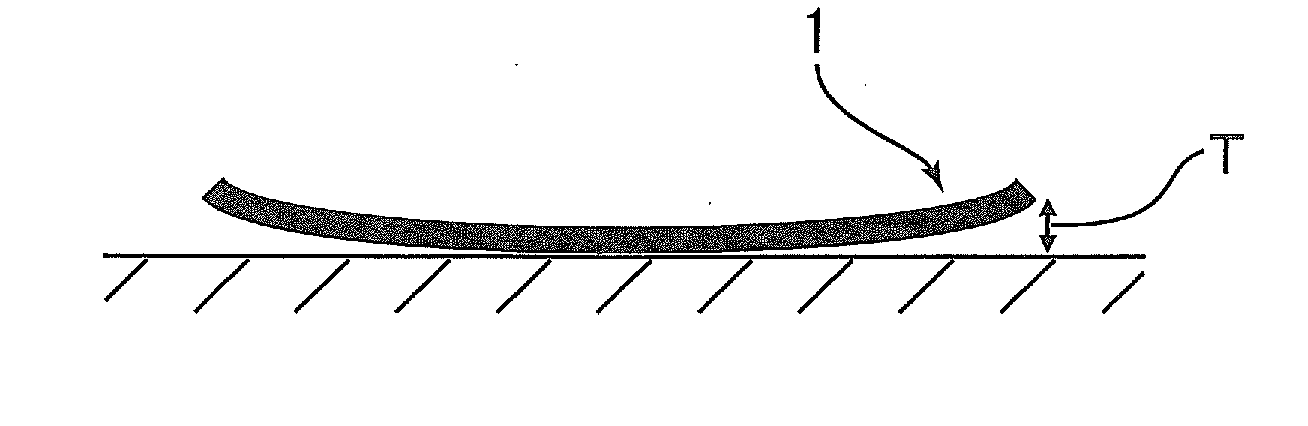

Transparent film, transparent electro-conductive laminate, and touch panel, solar cell, and display device using the same

ActiveUS20140224318A1Improve thermal shock resistanceImprove heat resistanceSynthetic resin layered productsPhotovoltaic energy generationTouch panelNitrogen atmosphere

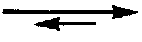

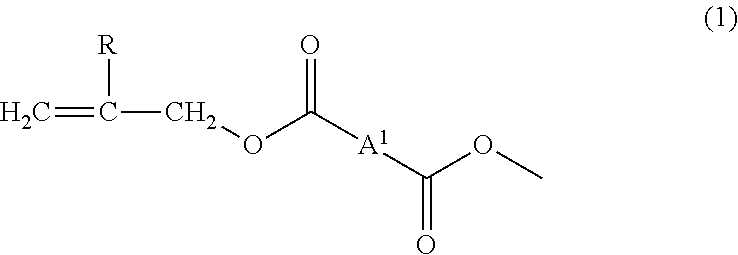

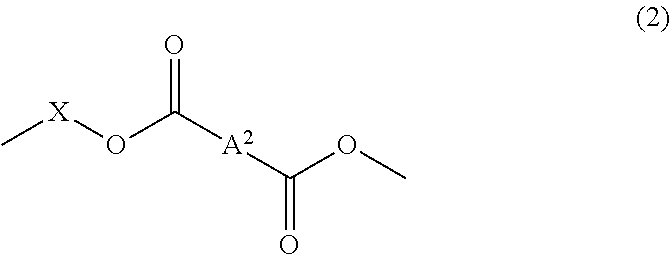

A transparent electro-conductive laminate comprising:a substrate film made of a polyimide; anda thin film made of an electro-conductive material and stacked on the substrate film, whereinthe polyimide is a polyimidecontaining at least one repeating unit represented by the following general formula (1):[in the formula (1), R1, R2, and R3 each independently represent one selected from the group consisting of a hydrogen atom, alkyl groups having 1 to 10 carbon atoms, and a fluorine atom, R4 represents an aryl group having 6 to 40 carbon atoms, and n represents an integer of 0 to 12],having a glass transition temperature of 350° C. to 450° C., andhaving a linear expansion coefficient of 30 ppm / ° C. or less, the linear expansion coefficient being determined by measuring change in length under a nitrogen atmosphere and under a condition of a rate of temperature rise of 5° C. / minute in a temperature range from 50° C. to 200° C.

Owner:JX NIPPON OIL & ENERGY CORP

Transparent Substrate

InactiveUS20130184380A1Low coefficient of linear expansionHigh light transmittanceCosmetic preparationsImpression capsMoisture permeabilityOptical transmittance

The present invention provides a formed article, or more specifically a transparent substrate, which effectively utilizes a natural stuff and which has a low linear expansion coefficient, a high light transmittance and an appropriate level of moisture permeability. The transparent substrate includes at least an oxidized polysaccharide and has a linear expansion coefficient of 50 ppm / ° C. or less at 30-150° C. and a light transmittance of 70% or more at 660 nm. Its manufacturing method includes an oxidation process in which cellulose reacts with TEMPO or its derivatives as a catalyst to be oxidized in water under the presence of a co-oxidant, along with a fiberizing process in which the oxidized cellulose is fiberized in water to form a cellulose fiber, and a substrate-forming process in which a transparent substrate is formed from a cellulose dispersion liquid containing the cellulose fiber.

Owner:TOPPAN PRINTING CO LTD

Polyimide and alicyclic tetracarboxylic dianhydride used for producing the same

A polyimide containing at least one of repeating units represented by the following general formulae (1) and (2):wherein the formulae (1) and (2), R1, R2, and R3 each independently represents a hydrogen atom or the like, R4 represents an aryl group having 6 to 40 carbon atoms, and n represents an integer of 0 to 12, wherein a total amount of the repeating units represented by the general formulae (1) and (2) is 90% by mole or more relative to all repeating units.

Owner:JX NIPPON OIL & ENERGY CORP

Hardenable epoxy resin composition

InactiveUS20100190899A1High glass transition temperatureLow linear expansion coefficientSpecial tyresPrinted circuitsEpoxyPolyamide

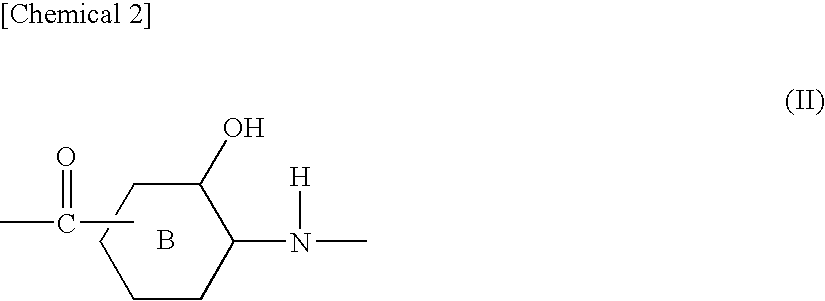

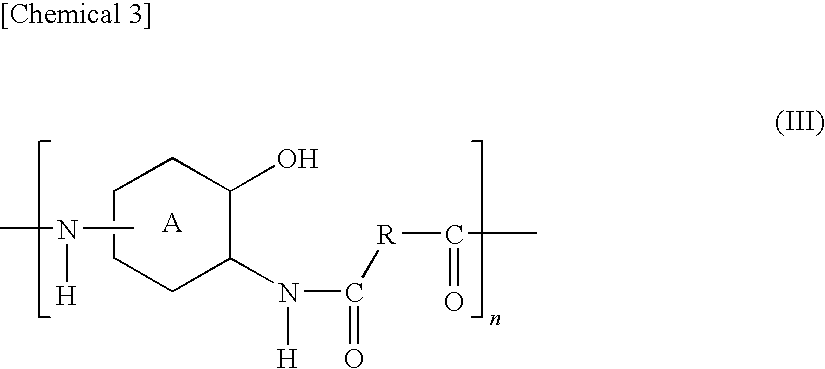

The epoxy resin composition of the present invention is characterized in that a polyamide compound having a moiety derived from a hydroxyl substituted aromatic amine having a phenolic hydroxyl group adjacent to an amino group is used as an epoxy resin hardener.

Owner:ADEKA CORP

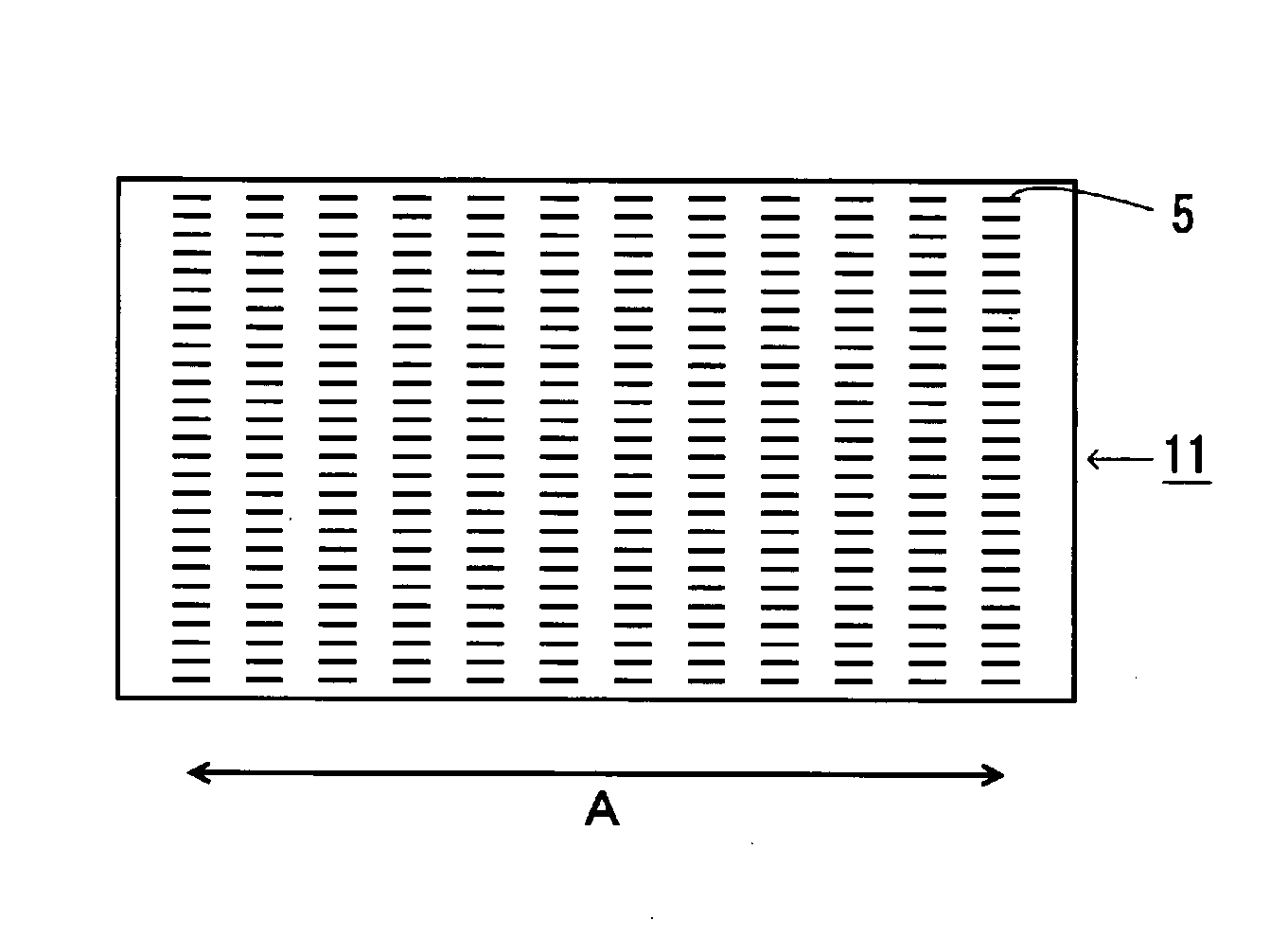

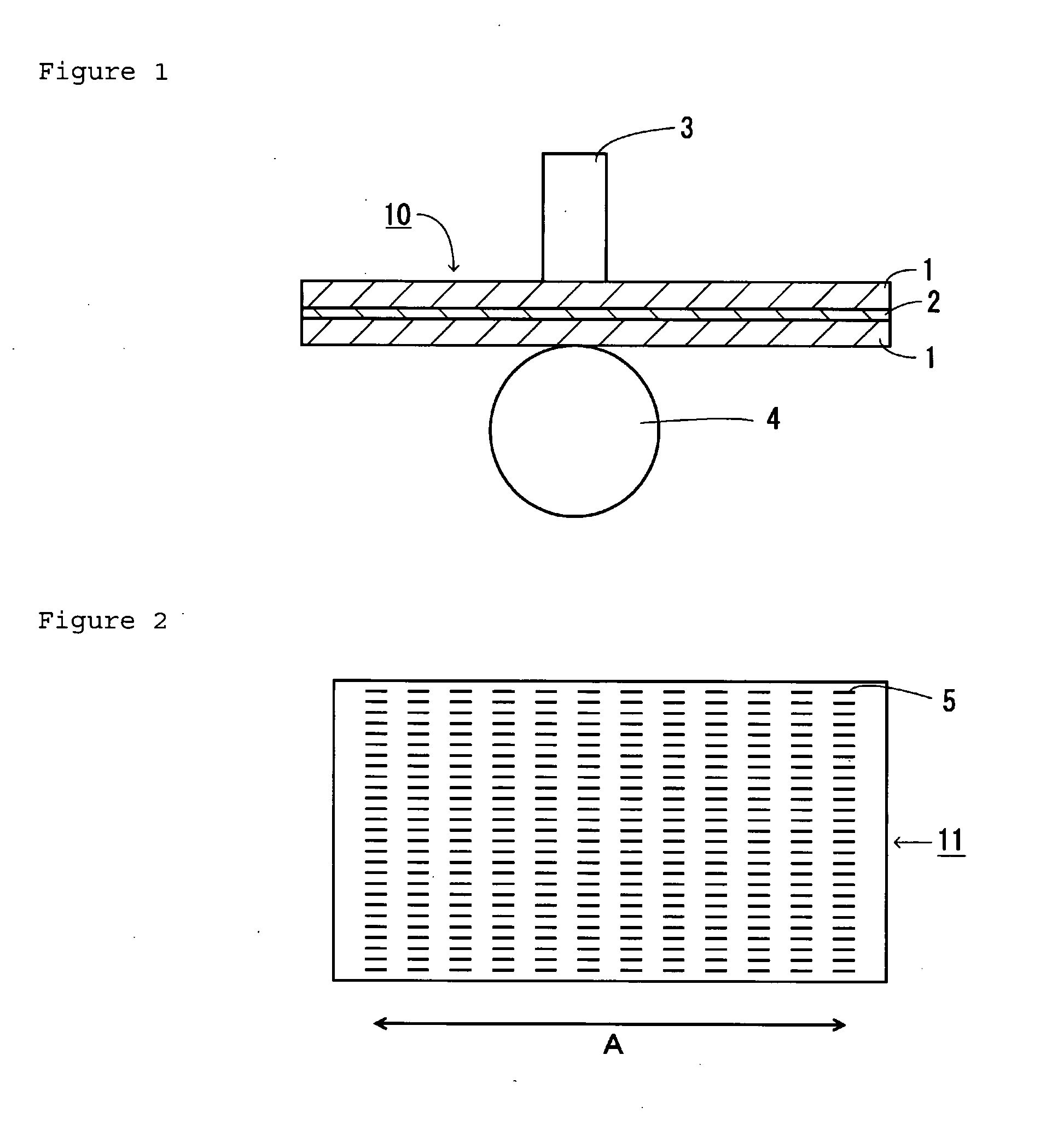

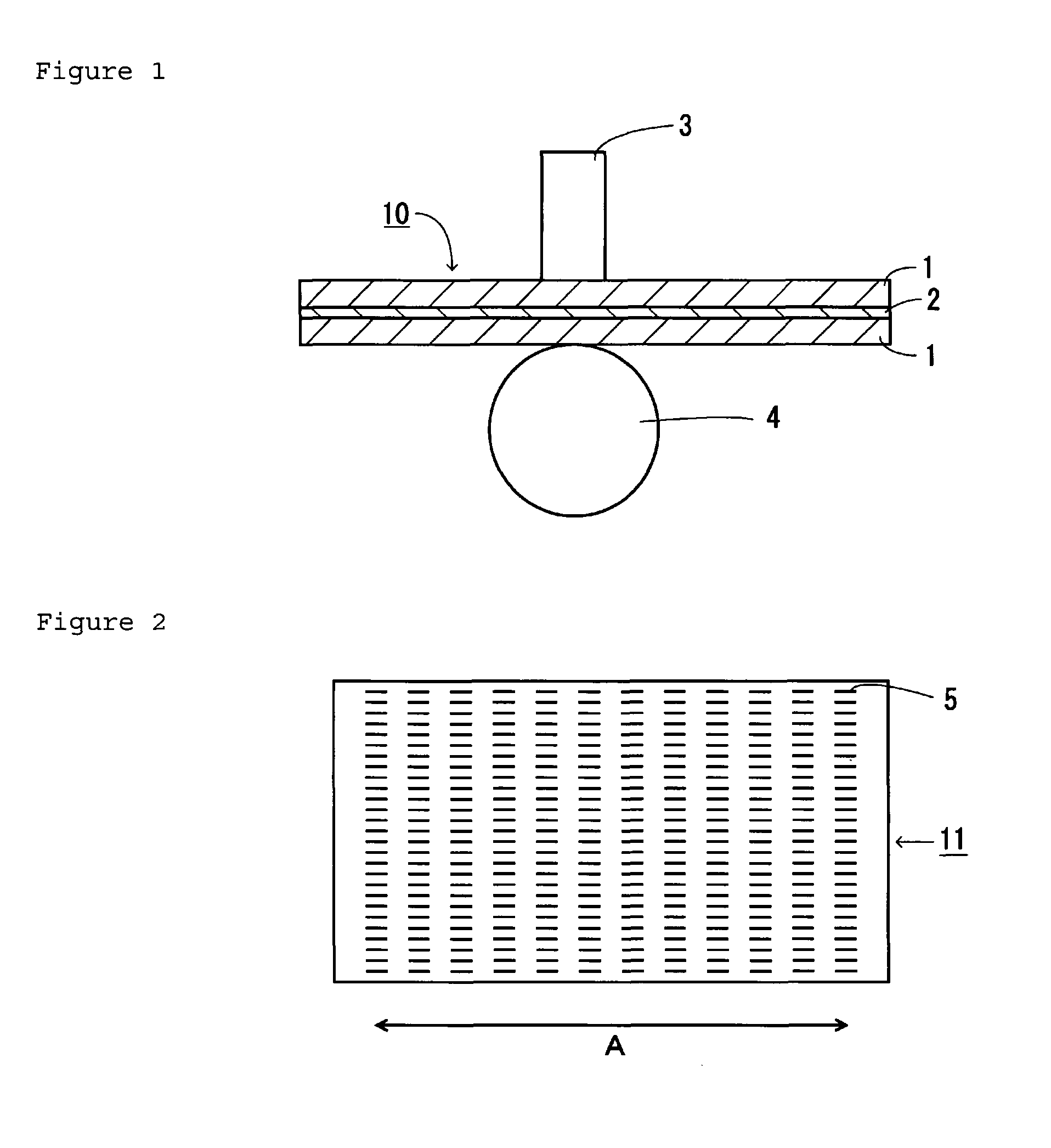

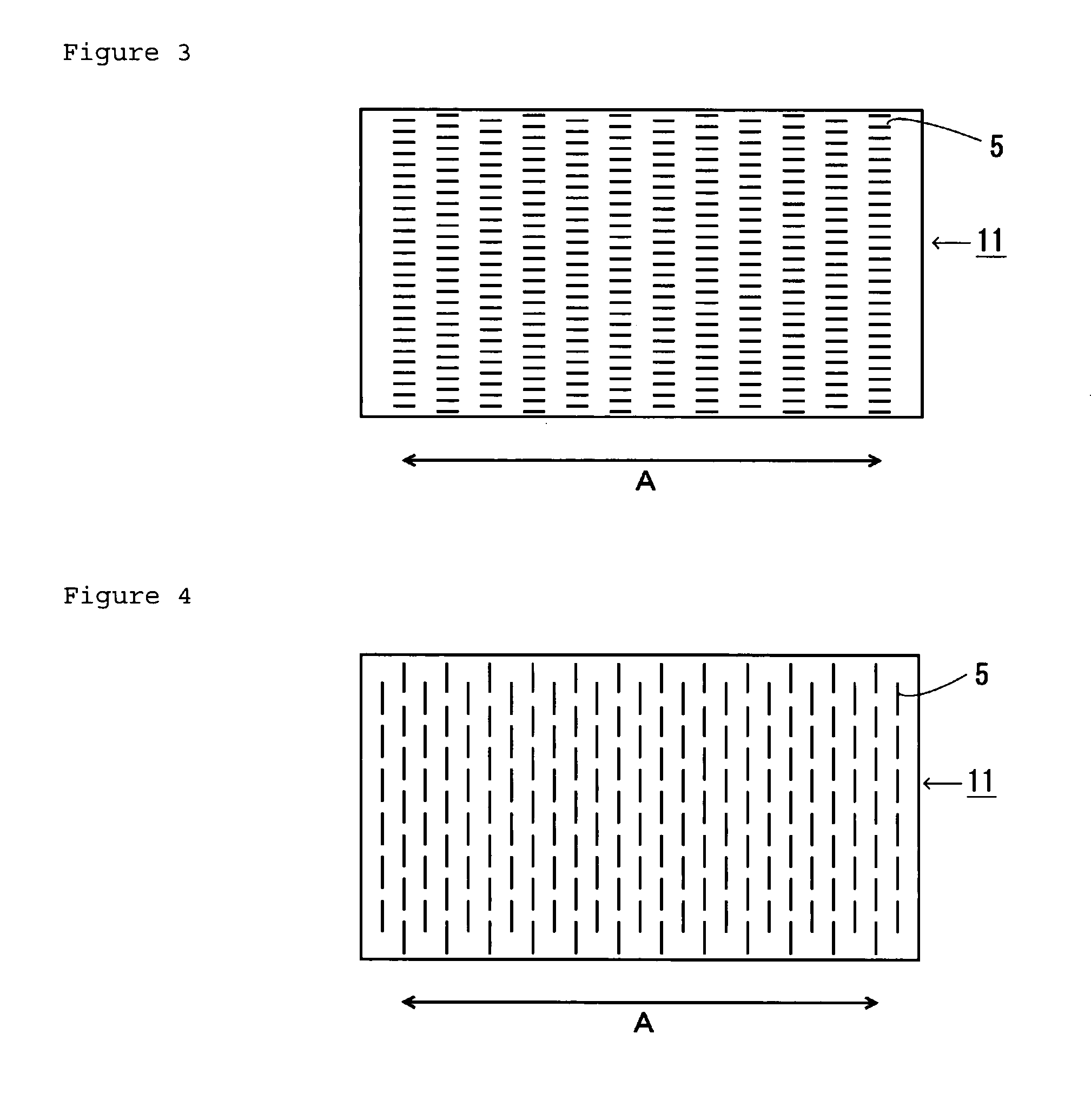

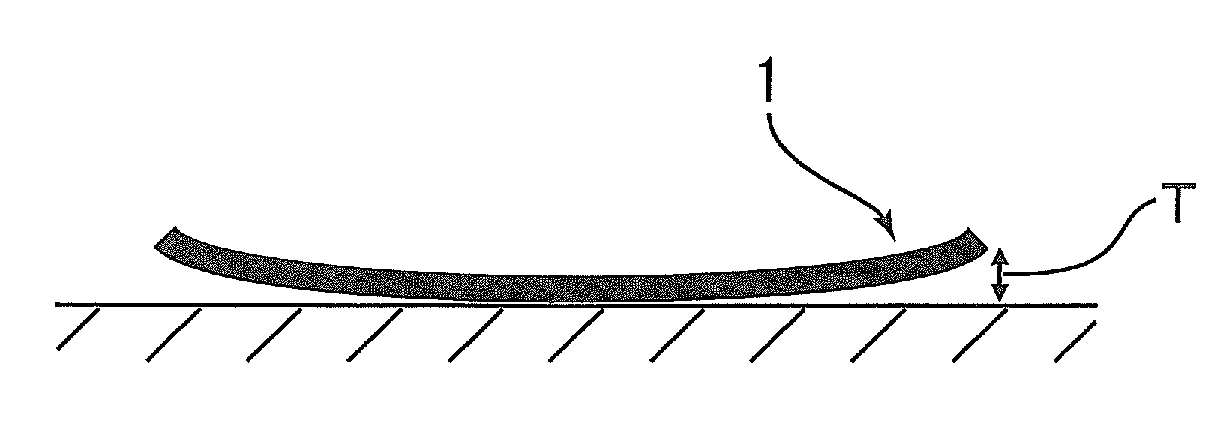

Process for Producing Oriented Thermoplastic Polyester Resin Sheet, and Laminate-Molded Body

ActiveUS20080182472A1Modulus improvementIncrease resistanceCeramic shaping apparatusCoatingsVitrificationProduction rate

The present invention provides a process for producing an oriented thermoplastic polyester resin sheet which is excellent in tensile strength, tencile modulas and heat resistance, and a light laminate-molded body using the same, which has a low linear expansion coefficient and is excellent in impact resistance, durability, easiness of handling, productivity, and others. A process for producing an oriented thermoplastic polyester resin sheet, which includes: pultrusion-drawing a thermoplastic polyester resin sheet in an amorphous state at a temperature from the glass transition temperature of the thermoplastic polyester resin−20° C. to the glass transition temperature of the thermoplastic polyester resin+20° C.; and then drawing the resultant uniaxially at a temperature higher than the temperature for the pultrusion-drawing. A laminate-molded body, wherein a thermoplastic resin layer is laminated on each of the surfaces of the resultant oriented thermoplastic polyester resin sheet.

Owner:SEKISUI CHEM CO LTD

Curable resin composition, curable resin composition tablet, molded body, semiconductor package, semiconductor component and light emitting diode

ActiveUS20150188008A1Low linear expansion coefficientReduce warpageSemiconductor/solid-state device detailsSolid-state devicesSimple Organic CompoundsChemical compound

The present invention aims to provide a curable resin composition which gives a cured product having a low linear expansion coefficient. The curable resin composition of the present invention contains, as essential components, (A) an organic compound having at least two carbon-carbon double bonds reactive with SiH groups per molecule, (B) a compound containing at least two SiH groups per molecule, (C) a hydrosilylation catalyst, (D) a silicone compound having at least one carbon-carbon double bond reactive with a SiH group per molecule, and (E) an inorganic filler.

Owner:KANEKA CORP

Transparent film, transparent electro-conductive laminate, and touch panel, solar cell, and display device using the same

ActiveUS9768328B2Improve thermal shock resistanceImprove heat resistancePhotovoltaic energy generationThin material handlingDisplay deviceConductive materials

A transparent electro-conductive laminate comprising:a substrate film made of a polyimide; anda thin film made of an electro-conductive material and stacked on the substrate film, whereinthe polyimide is a polyimidecontaining at least one repeating unit represented by the following general formula (1):[in the formula (1), R1, R2, and R3 each independently represent one selected from the group consisting of a hydrogen atom, alkyl groups having 1 to 10 carbon atoms, and a fluorine atom, R4 represents an aryl group having 6 to 40 carbon atoms, and n represents an integer of 0 to 12],having a glass transition temperature of 350° C. to 450° C., andhaving a linear expansion coefficient of 30 ppm / ° C. or less, the linear expansion coefficient being determined by measuring change in length under a nitrogen atmosphere and under a condition of a rate of temperature rise of 5° C. / minute in a temperature range from 50° C. to 200° C.

Owner:JX NIPPON OIL & ENERGY CORP

Polyimide and alicyclic tetracarboxylic dianhydride used for producing the same

A polyimide containing at least one of repeating units represented by the following general formulae (1) and (2):wherein the formulae (1) and (2), R1, R2, and R3 each independently represents a hydrogen atom or the like, R4 represents an aryl group having 6 to 40 carbon atoms, and n represents an integer of 0 to 12, wherein a total amount of the repeating units represented by the general formulae (1) and (2) is 90% by mole or more relative to all repeating units.

Owner:JX NIPPON OIL & ENERGY CORP

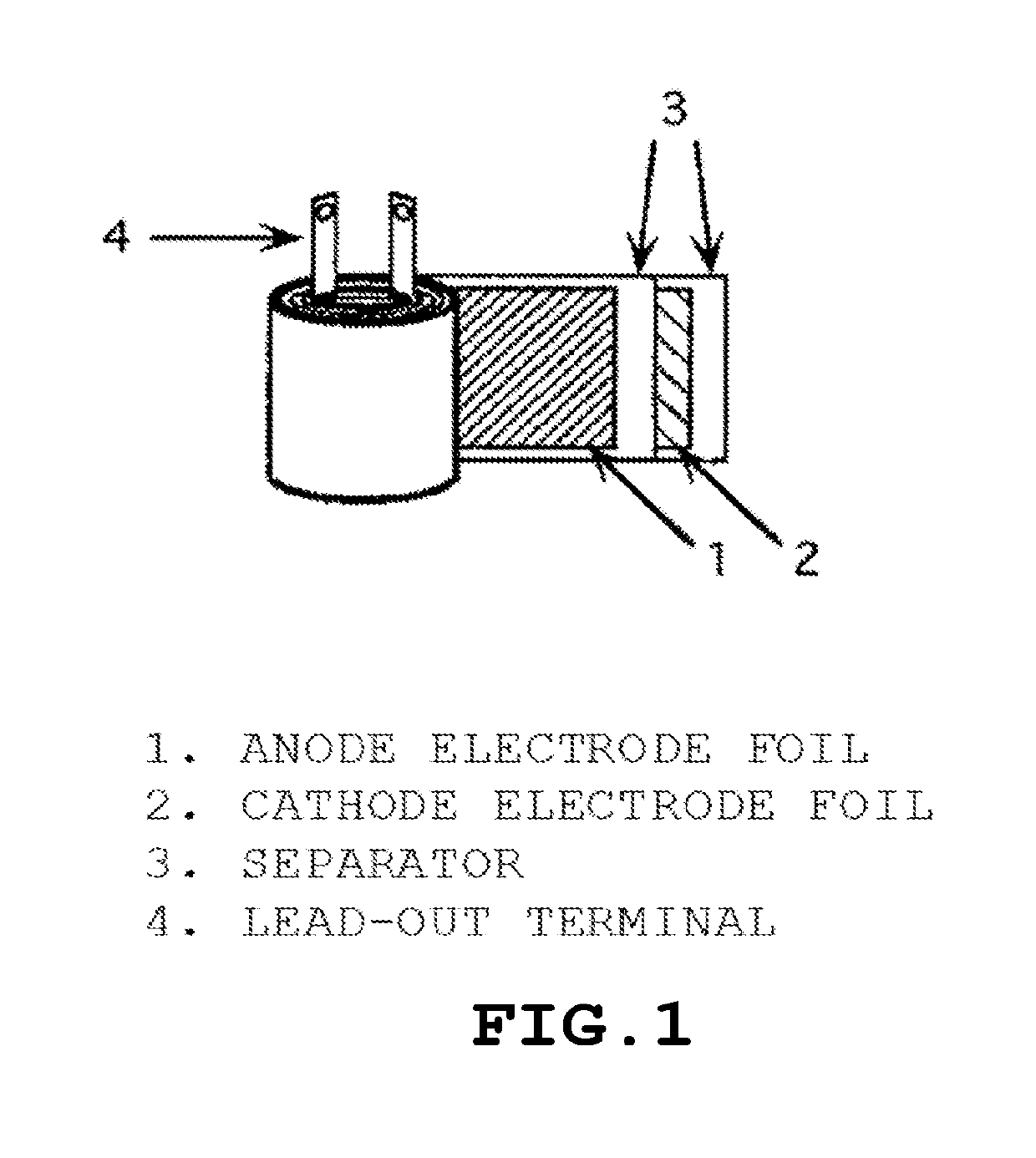

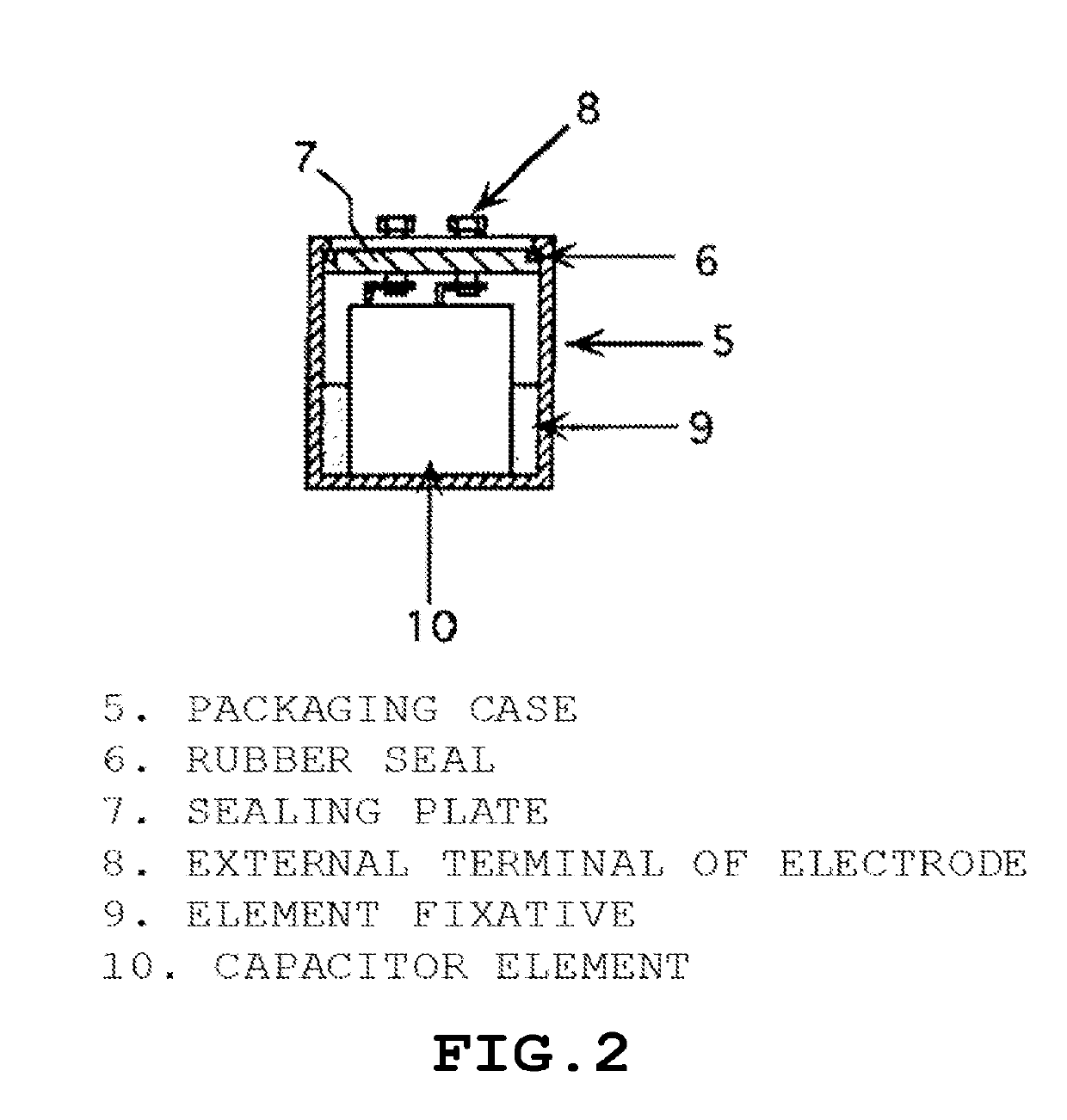

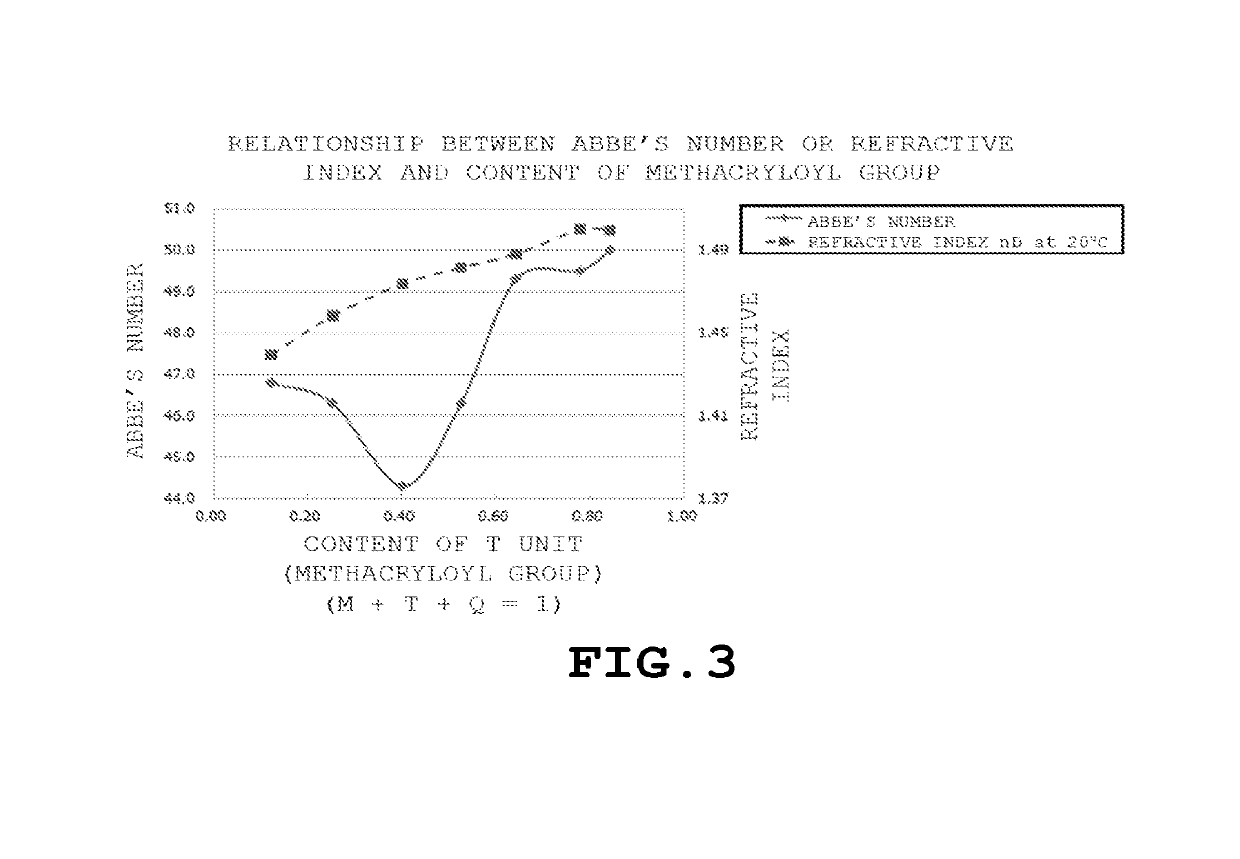

Polyorganosiloxane, polyorganosiloxane composition, cured product, polyorganosiloxane-containing electrolytic solution for electrolytic capacitor, and electrolytic capacitor using same

ActiveUS20190292320A1Reduction in linear expansion coefficientLarge effect on viscosityElectrolytic capacitorsElectrolysisAlkoxy group

Provided are a polyorganosiloxane high in elasticity, high in strength and the like. The polyorganosiloxane is a polyorganosiloxane including an M unit (R1R2R3SiO1 / 2) at a content of 10% by mol or more relative to the total of silicon and a T unit (R6SiO3 / 2) at a content of 80% by mol or less relative to the total of silicon, the polyorganosiloxane having an alkoxy group bound and a reactive functional group bound to silicon, wherein the polyorganosiloxane has the alkoxy group bound at a content of 0.07 to 4% by weight based on the total weight of the polyorganosiloxane and has 3 to 12 of the reactive functional groups bound on a number basis per a molecular weight of 1000 of the polyorganosiloxane, and the weight loss of the polyorganosiloxane in heating at 110° C. under a reduced pressure of 0.15 torr for 2 hours is 5% by weight or less.

Owner:MITSUBISHI CHEM CORP

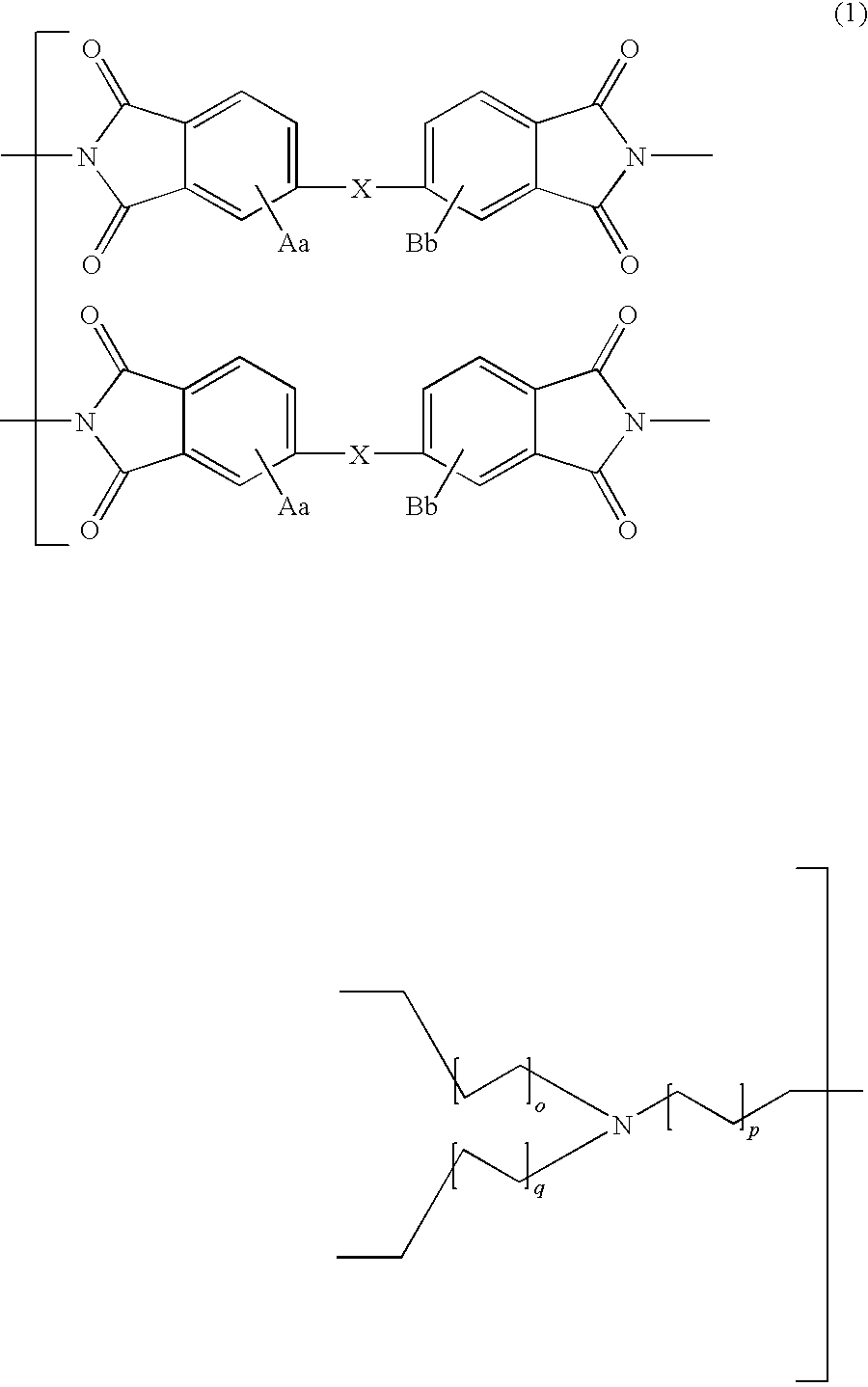

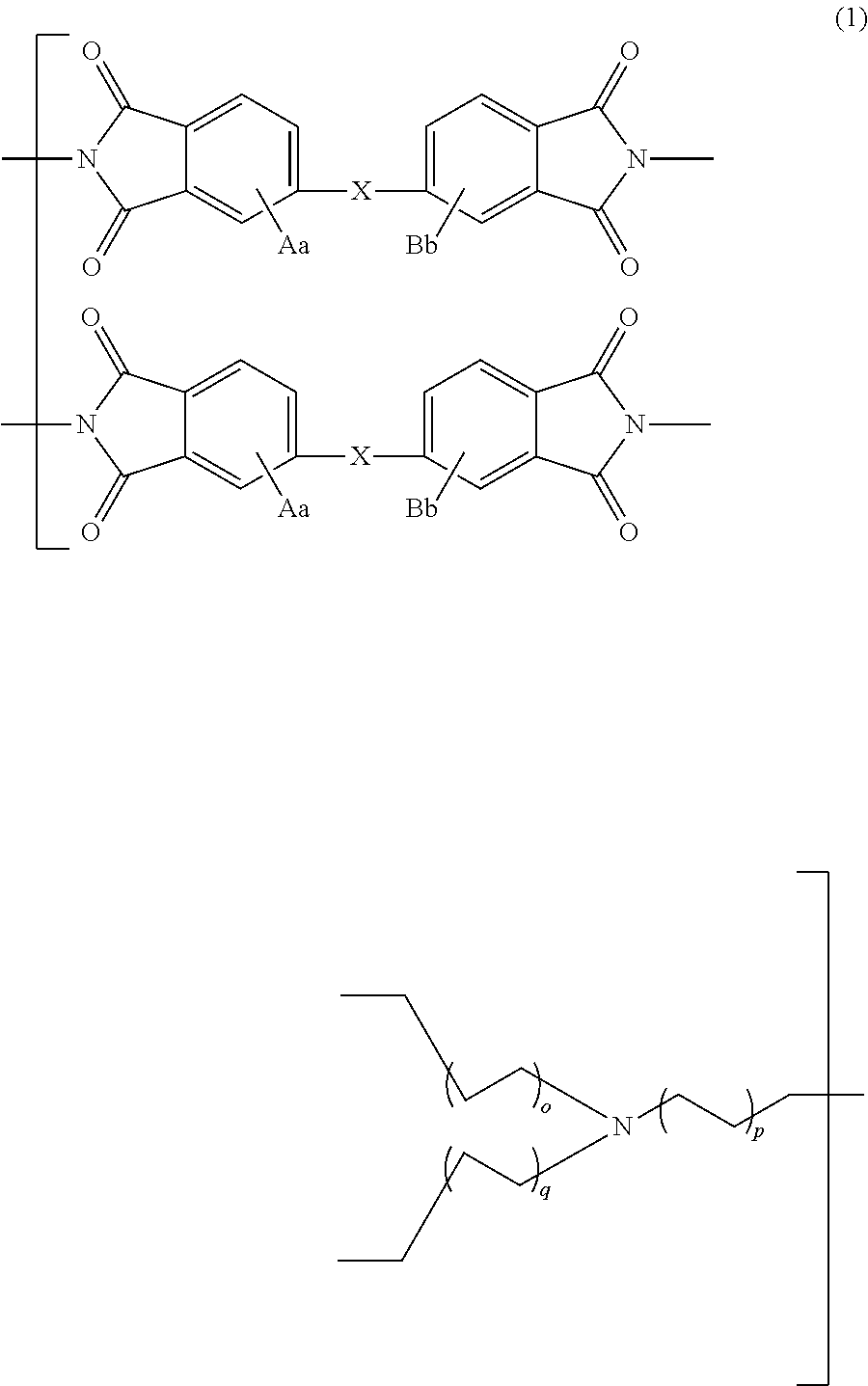

Polyimide compound, preparation method therefor, and optical film and optical waveguide produced by employing the compound

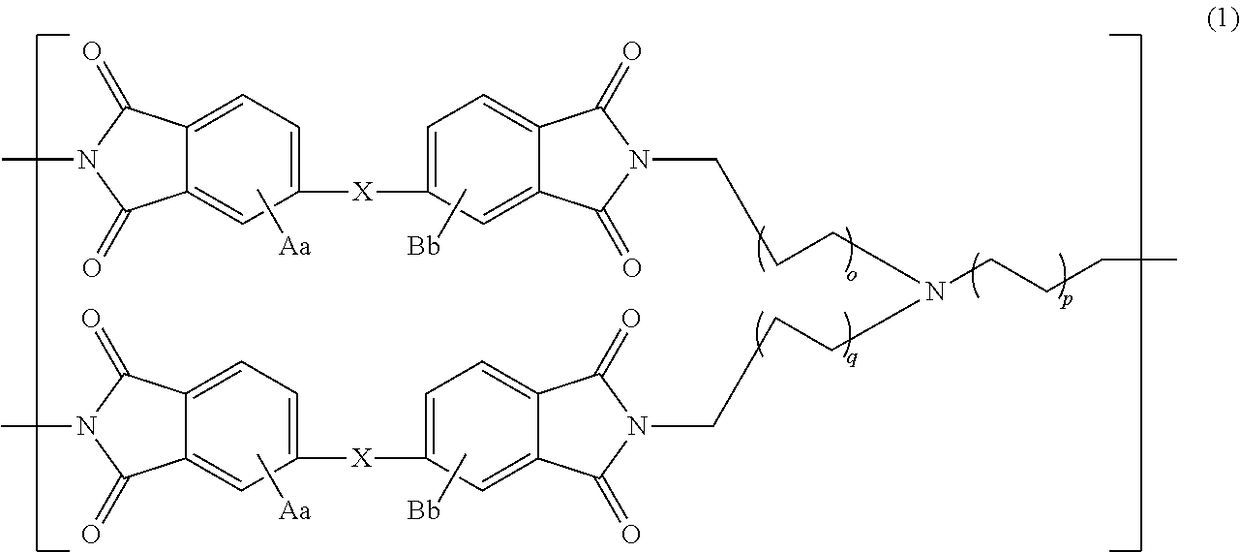

ActiveUS20100322586A1Reduces linear expansion coefficientLow linear expansion coefficientOrganic chemistryOptical waveguide light guideCompound aAryl

A novel polyimide compound which has a low linear expansion coefficient and permits film formation by a spin coating method or the like, a preparation method for the polyimide compound, and an optical film and an optical waveguide produced by employing the compound. The polyimide compound has a structural unit represented by the following general formula (1):wherein X is a covalent single bond, —CH2—, —C(CF3)2— or —CR(R′)— (wherein R and R′, which may be the same or different, are each a C1 to C6 alkyl group or an aryl group); A and B, which may be the same or different, are substituents each selected from a hydroxyl group, a halogen group and a C1 to C4 alkyl group; a and b, which are the numbers of the substituents A and B, respectively, are each an integer of 0 to 2; and o, p and q are each an integer of 1 to 5.

Owner:NITTO DENKO CORP

Resin composition for optical waveguide, dry film, optical waveguide, and photoelectric composite wiring board using same

ActiveUS9005740B2High transparencyLow linear expansion coefficientDecorative surface effectsDuplicating/marking methodsEpoxyOpto electronic

Provided are a resin composition which offers both high transparency and a low linear expansion coefficient and can be used as a material for a dry film, and also a dry film obtained from this composition, an optical waveguide, and a photoelectric composite wiring board. The resin composition for an optical waveguide includes: (A) an epoxy resin constituted by a solid epoxy resin with one or less hydroxyl group in a molecule, and a liquid epoxy resin with one or less hydroxyl group in a molecule; (B) a curing agent with one or less hydroxyl group in a molecule; and (C) a nanosize silica sol, and contains no compound including two or more hydroxyl groups in a molecule as a resin component.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

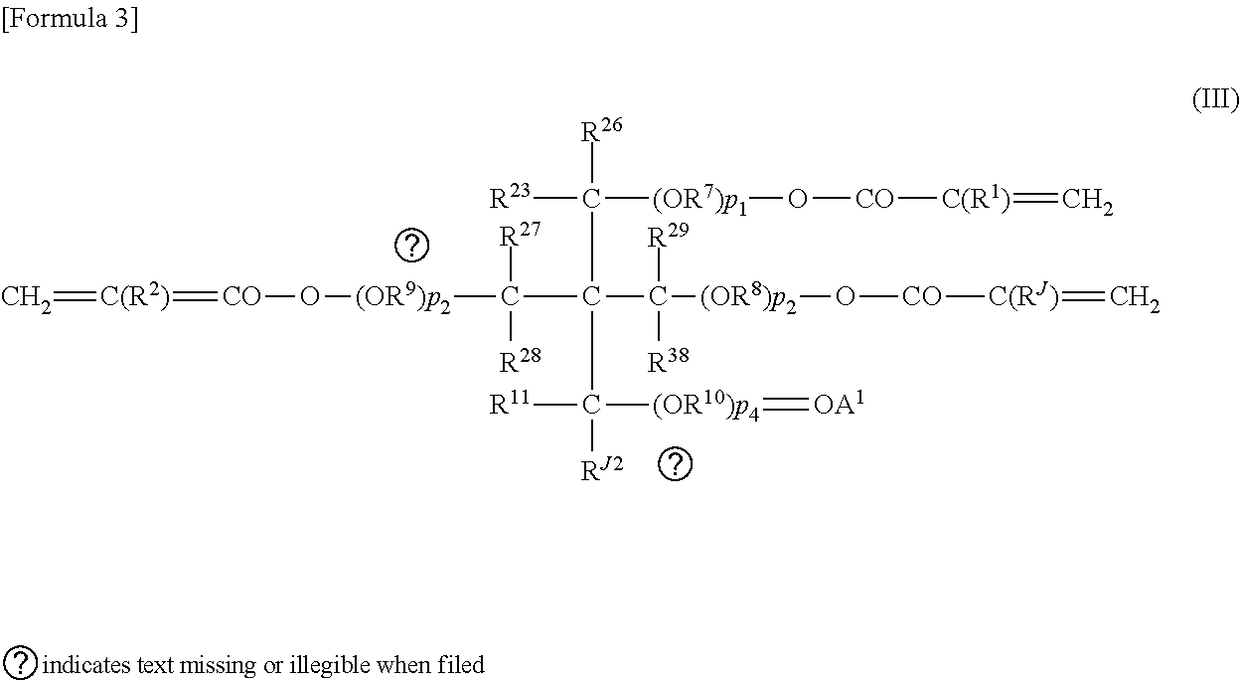

Curable composition, transparent heat-resistant material, and use thereof

The present invention provides a curable composition, which contains a crosslinking aid (B) containing three or more allyl groups in the molecule in an amount of 1 to 50 parts by mass, polyfunctional (meth)acrylic compound (C) in an amount of 5 to 50 parts by mass, and photopolymerization initiator (D1) and / or thermal polymerization initiator (D2) in an amount of 0.1 to 10 parts by mass, respectively, as a polymerization initiator (D) to 100 parts by mass of allyl group-terminated allyl ester oligomer (A);wherein the crosslinking aid (B) containing allyl group is a compound containing three or more allyl groups in a molecule;wherein the content of impurities derived from the crosslinking aid (B) in the curable composition is less than 0.1 mass %;wherein the content of the (meth)acrylic compound containing a hydroxyl group in a molecule (C1) in the curable composition is 0.5 to 30 mass %.

Owner:RESONAC CORP

Transparent substrate

ActiveUS20140228487A1Low linear expansion coefficientHigh light transmittanceImpression capsPolarising elementsMoisture permeabilityTransmittance

The present invention provides a formed article, or more specifically a transparent substrate, which effectively utilizes a natural stuff and which has a low linear expansion coefficient, a high light transmittance and an appropriate level of moisture permeability. The transparent substrate includes at least an oxidized polysaccharide and has a linear expansion coefficient of 50 ppm / ° C. or less at 30-150° C. and a light transmittance of 70% or more at 660 nm. Its manufacturing method includes an oxidation process in which cellulose reacts with TEMPO or its derivatives as a catalyst to be oxidized in water under the presence of a co-oxidant, along with a fiberizing process in which the oxidized cellulose is fiberized in water to form a cellulose fiber, and a substrate-forming process in which a transparent substrate is formed from a cellulose dispersion liquid containing the cellulose fiber.

Owner:TOPPAN PRINTING CO LTD

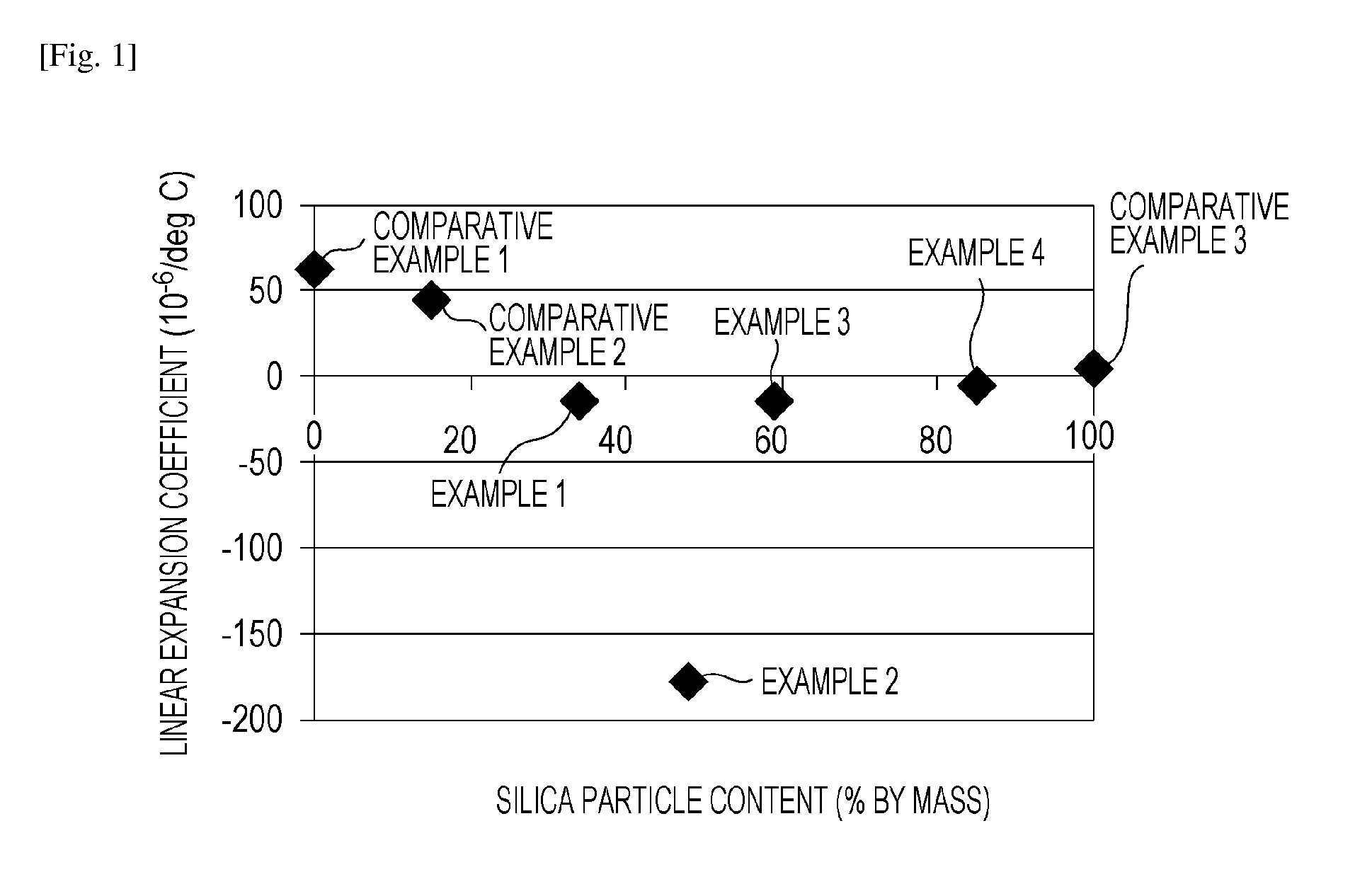

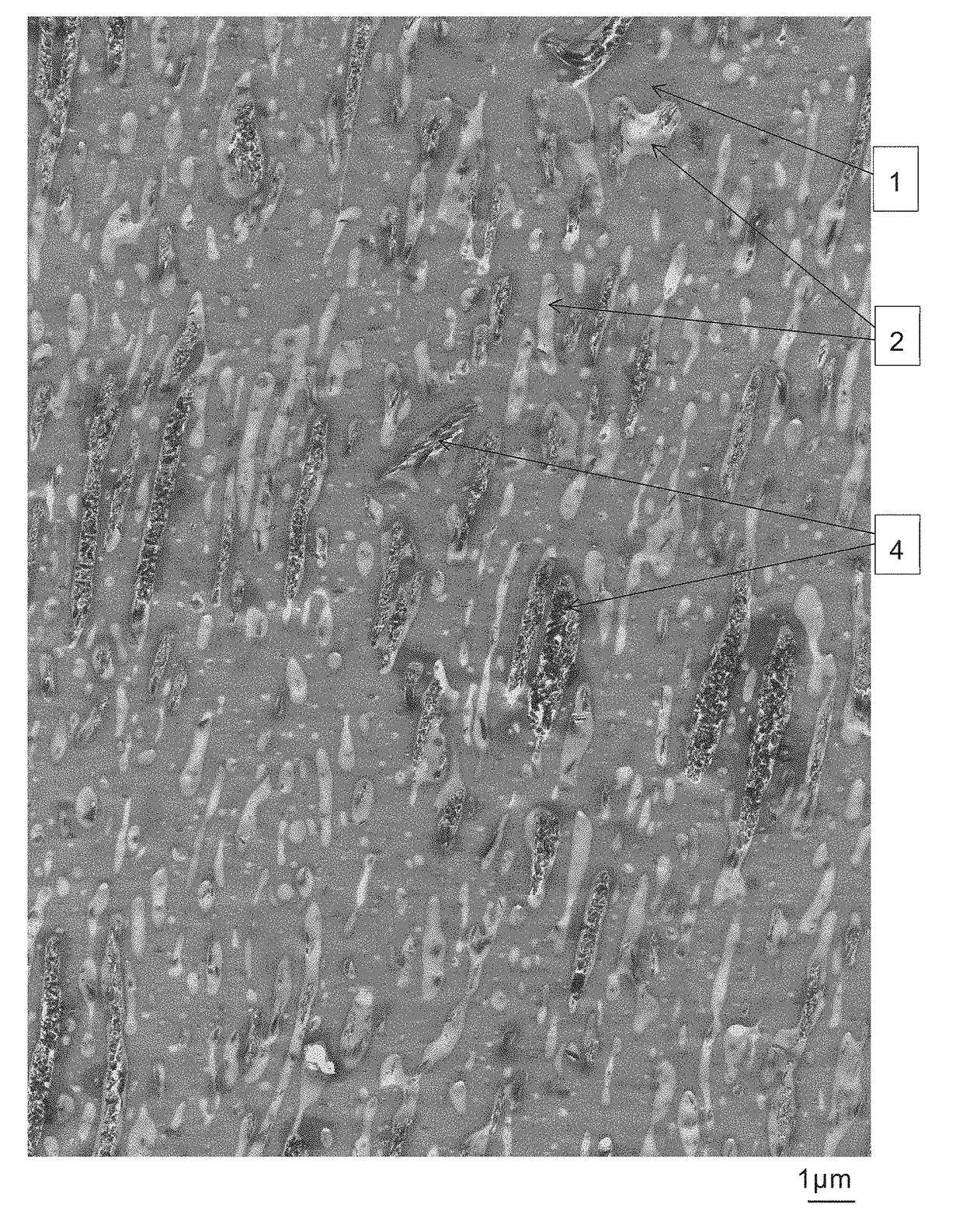

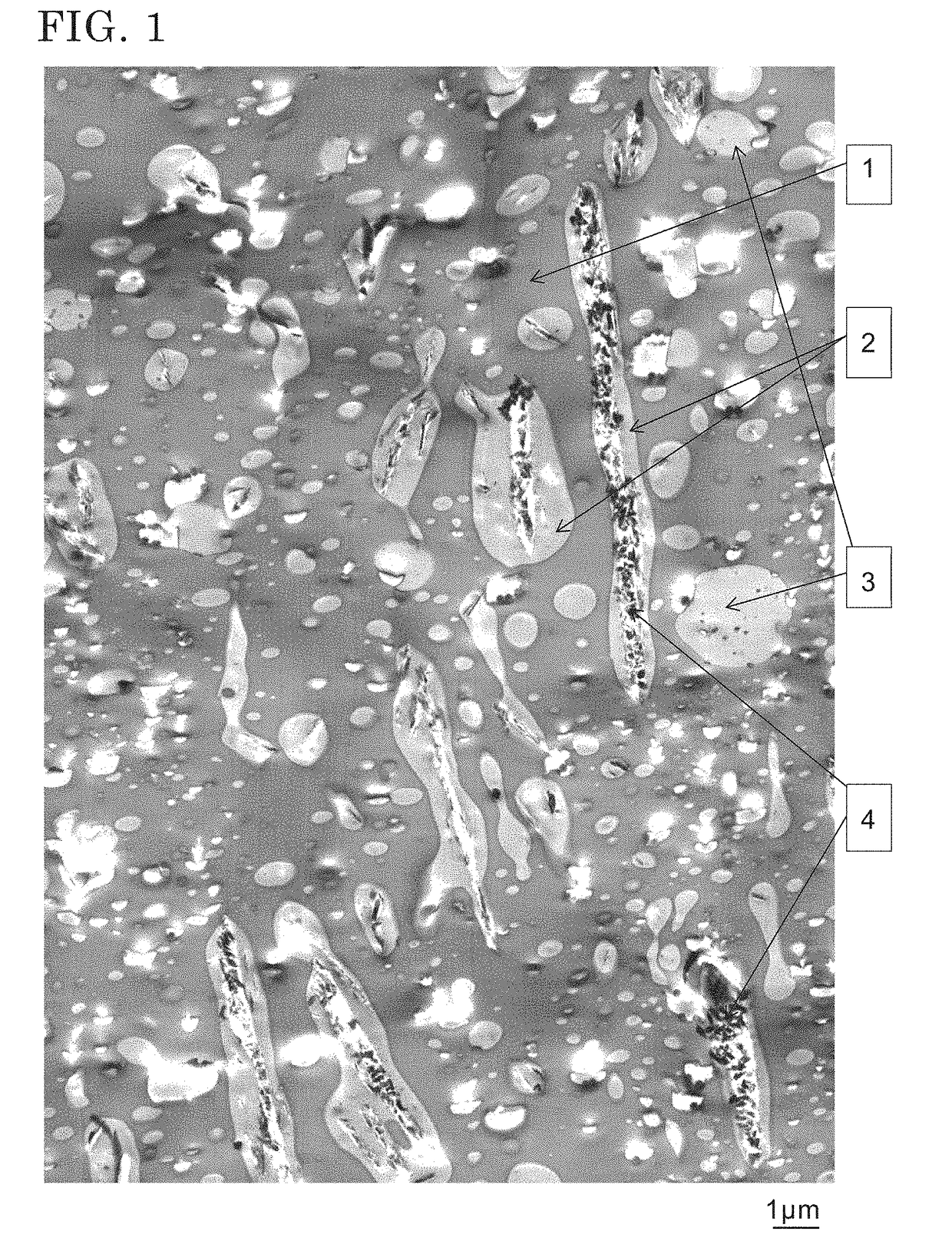

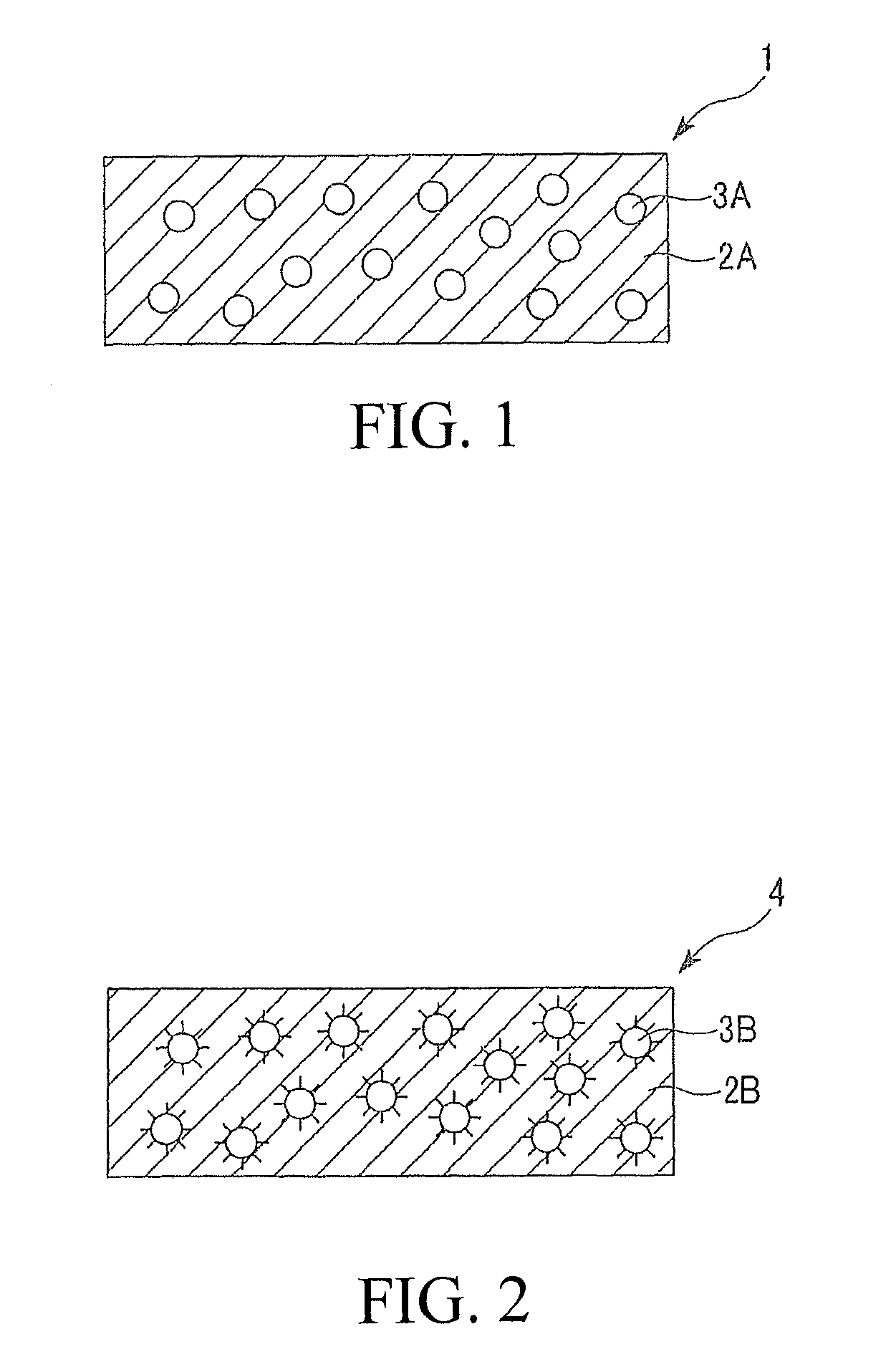

Molded article and method of producing the same

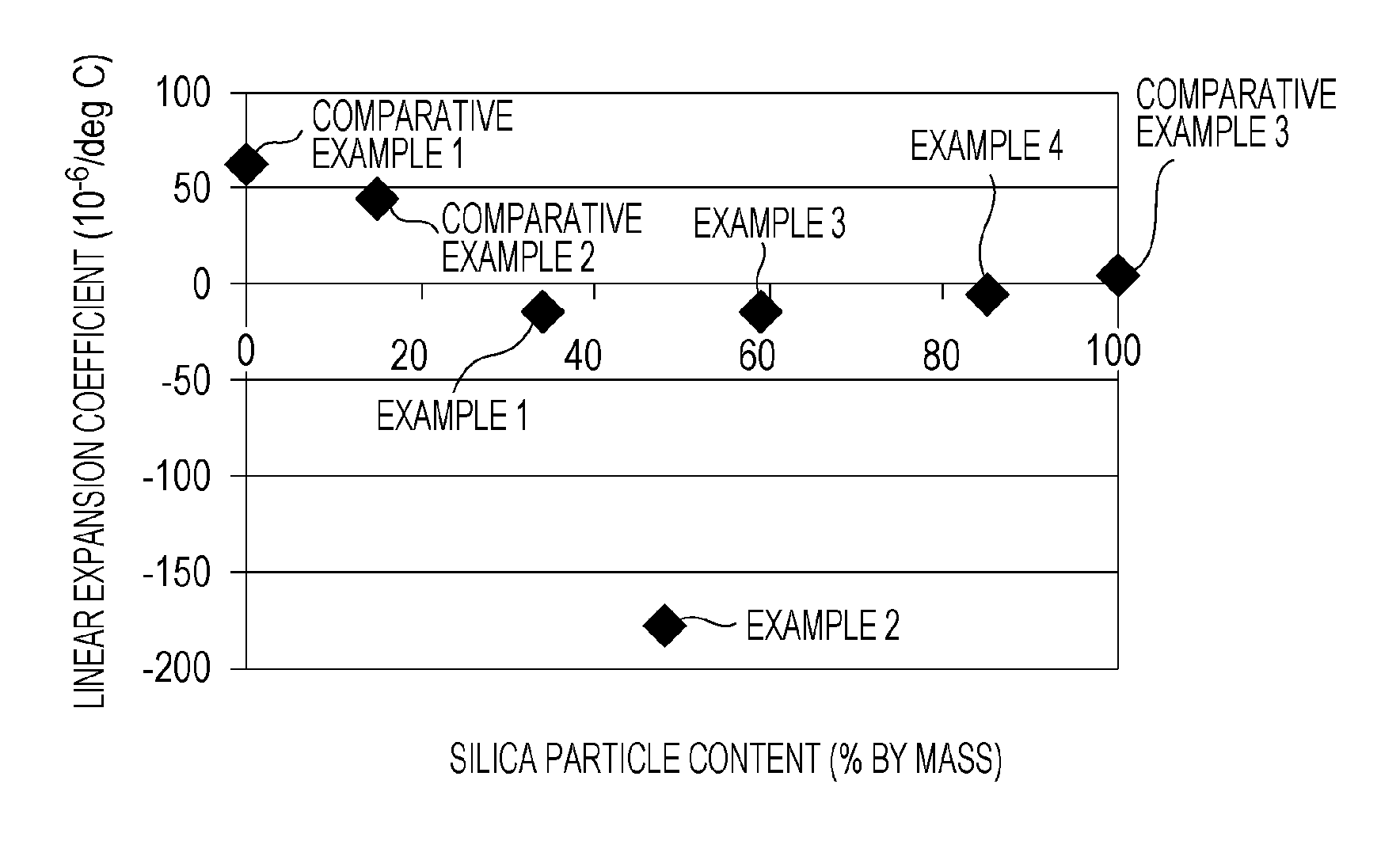

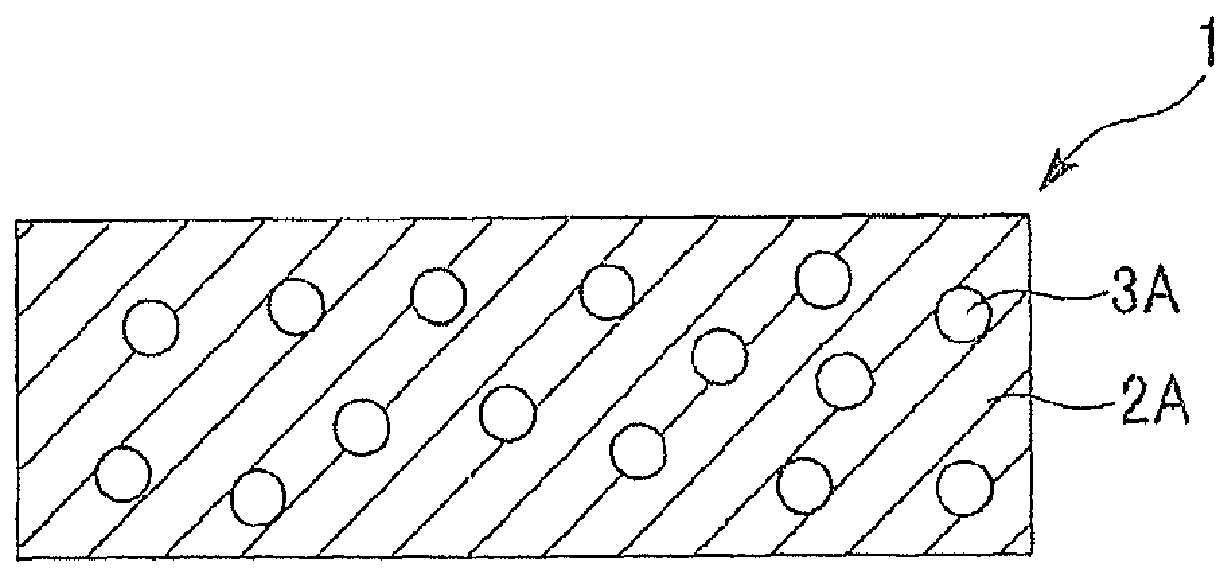

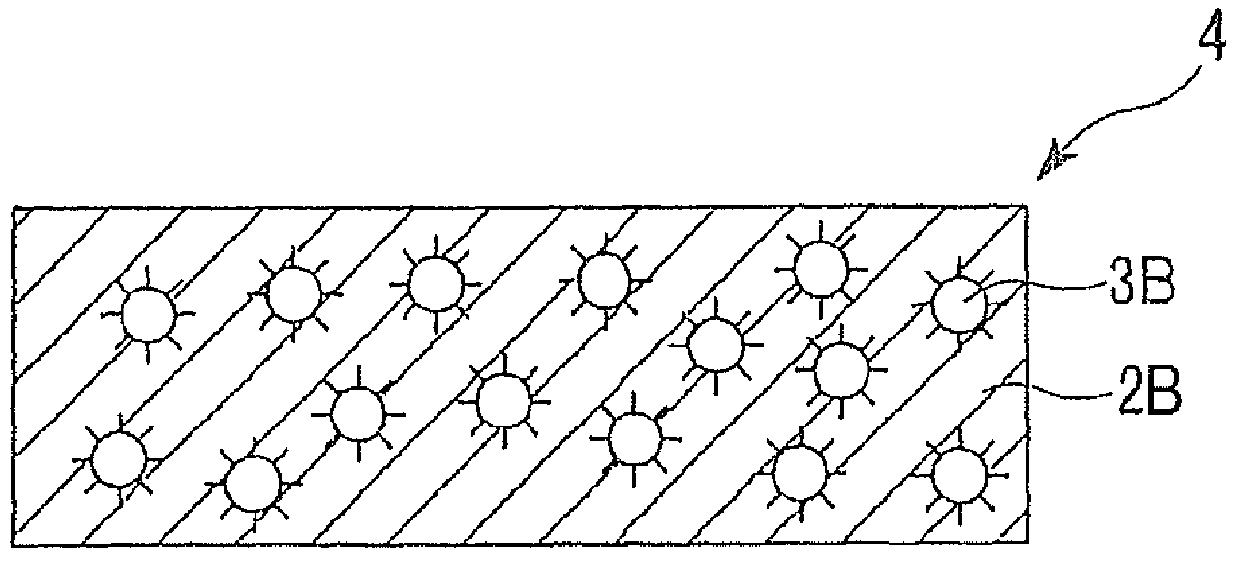

ActiveUS20150111988A1Low coefficient of linear expansionLow linear expansion coefficientMaterial nanotechnologySilica particlePolymer science

The present invention relates to a molded article exhibiting a low linear expansion coefficient and a method of producing the molded article. The molded article is molded from a resin composition containing at least a thermoplastic cyclic olefin resin and silica particles surface-modified with amino functional groups and having a number average particle diameter of primary particles of 10 nm or more and 50 nm or less. The resin composition contains the silica particles in an amount of 34% by mass or more and 85% by mass or less.

Owner:CANON KK

Polycarbonate resin composition having excellent thermal decomposition resistance

ActiveUS20180155543A1Improve heat resistanceLow linear expansion coefficientWeighing by removing componentPolyester resinPolycarbonate

Provided is a polycarbonate resin composition containing 1-20 parts by weight of an amorphous thermoplastic resin having a glass transition temperature of not lower than 110° C., and 1-50 parts by weight of plate-shaped fillers having a number average major axis length of 0.5-45 μm, with respect to 100 parts by weight of a matrix resin component containing 35-95 wt % of a polycarbonate resin and 5-65 wt % of a thermoplastic polyester resin.

Owner:KANEKA CORP

Molding method and molded article of fluoropolymer with multilayered particulate structure

ActiveUS8158260B2Excellent chemical liquid resistance and gas impermeabilityLow linear expansion coefficientSynthetic resin layered productsCork mechanical workingParticulatesPolymer science

Owner:THE CHEMOURS CO FC LLC +1

Polycarbonate resin composition having excellent thermal decomposition resistance

ActiveUS10344162B2Improve heat resistanceLow linear expansion coefficientWeighing by removing componentVitrificationPolyester resin

Provided is a polycarbonate resin composition containing 1-20 parts by weight of an amorphous thermoplastic resin having a glass transition temperature of not lower than 110° C., and 1-50 parts by weight of plate-shaped fillers having a number average major axis length of 0.5-45 μm, with respect to 100 parts by weight of a matrix resin component containing 35-95 wt % of a polycarbonate resin and 5-65 wt % of a thermoplastic polyester resin.

Owner:KANEKA CORP

Process for producing oriented thermoplastic polyester resin sheet, and laminate-molded body

ActiveUS8617445B2Modulus improvementIncrease resistanceCeramic shaping apparatusCoatingsProduction rateVitrification

Owner:SEKISUI CHEM CO LTD

Polyimide compound, preparation method therefor, and optical film and optical waveguide produced by employing the compound

ActiveUS8470959B2Reduces linear expansion coefficientLow linear expansion coefficientOrganic chemistryOptical waveguide light guideWaveguideStructural unit

A novel polyimide compound which has a low linear expansion coefficient and permits film formation by a spin coating method or the like, a preparation method for the polyimide compound, and an optical film and an optical waveguide produced by employing the compound. The polyimide compound has a structural unit represented by the following general formula (1):wherein X is a covalent single bond, —CH2—, —C(CF3)2— or —CR(R′)— (wherein R and R′, which may be the same or different, are each a C1 to C6 alkyl group or an aryl group); A and B, which may be the same or different, are substituents each selected from a hydroxyl group, a halogen group and a C1 to C4 alkyl group; a and b, which are the numbers of the substituents A and B, respectively, are each an integer of 0 to 2; and o, p and q are each an integer of 1 to 5.

Owner:NITTO DENKO CORP

Silica sol and silica-containing epoxy resin composition

The silica sol of the invention contains silica particles having a mean primary particle size of 20 to 100 nm and which has a silica particle size / mean primary particle size ratio, determined through dynamic light scattering, of 3.0 or less, wherein the silica particles are surface-treated with an organic silane compound and have an α-ray emission rate of 0.005 counts / cm2·hr or less and a moisture absorption coefficient, determined after allowing the silica particles to stand for 48 hours at 23° C. and a relative humidity of 50 RH %, of 0.5 mass % or lower.

Owner:NISSAN CHEM IND LTD

Molded article and method of producing the same

The present invention relates to a molded article exhibiting a low linear expansion coefficient and a method of producing the molded article. The molded article is molded from a resin composition containing at least a thermoplastic cyclic olefin resin and silica particles surface-modified with amino functional groups and having a number average particle diameter of primary particles of 10 nm or more and 50 nm or less. The resin composition contains the silica particles in an amount of 34% by mass or more and 85% by mass or less.

Owner:CANON KK

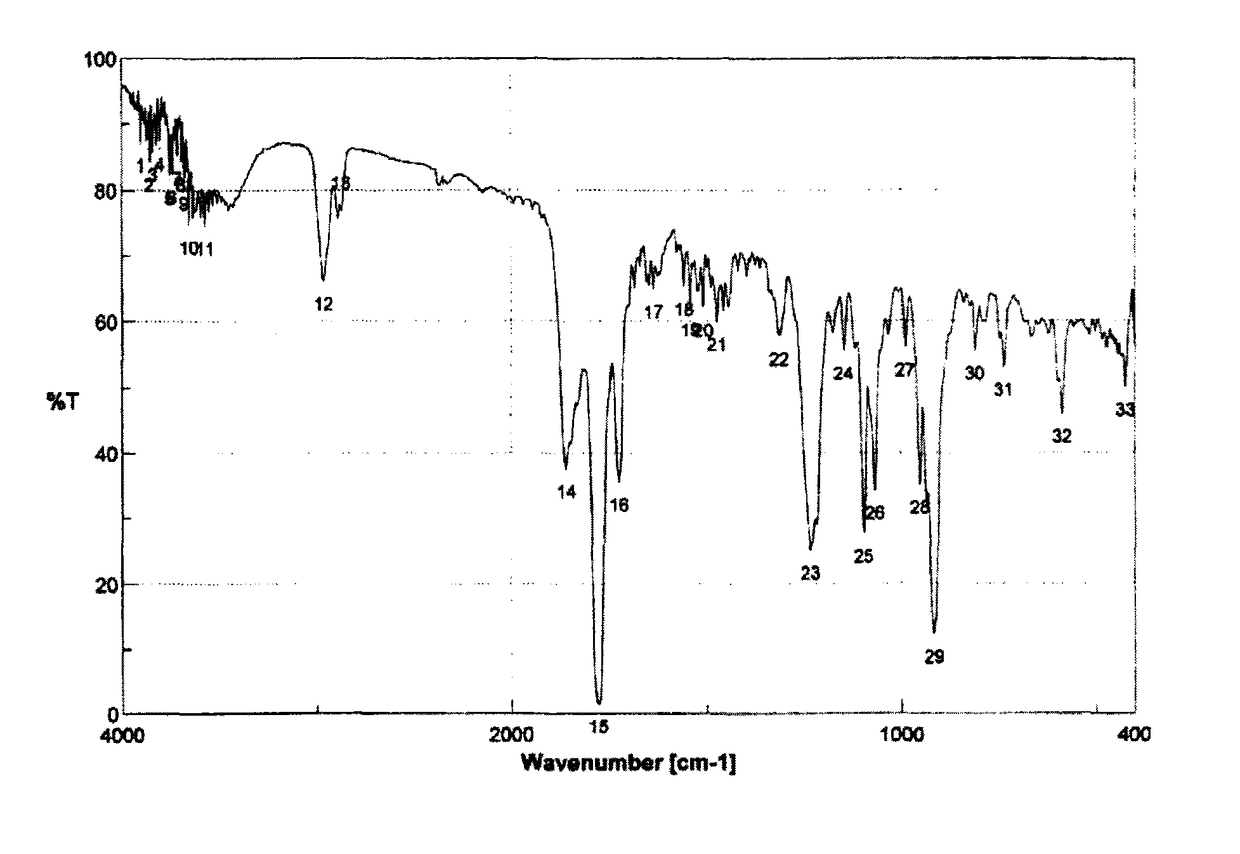

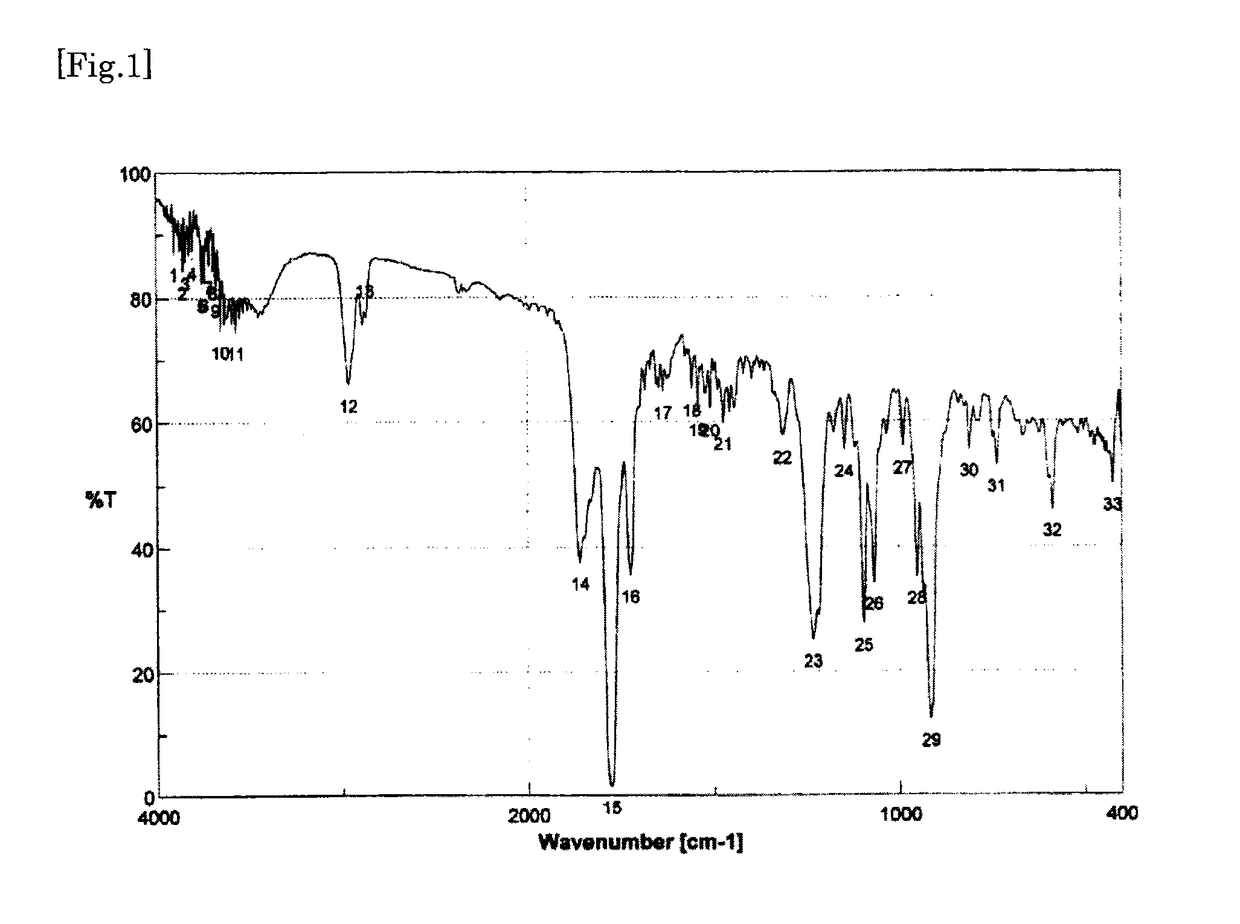

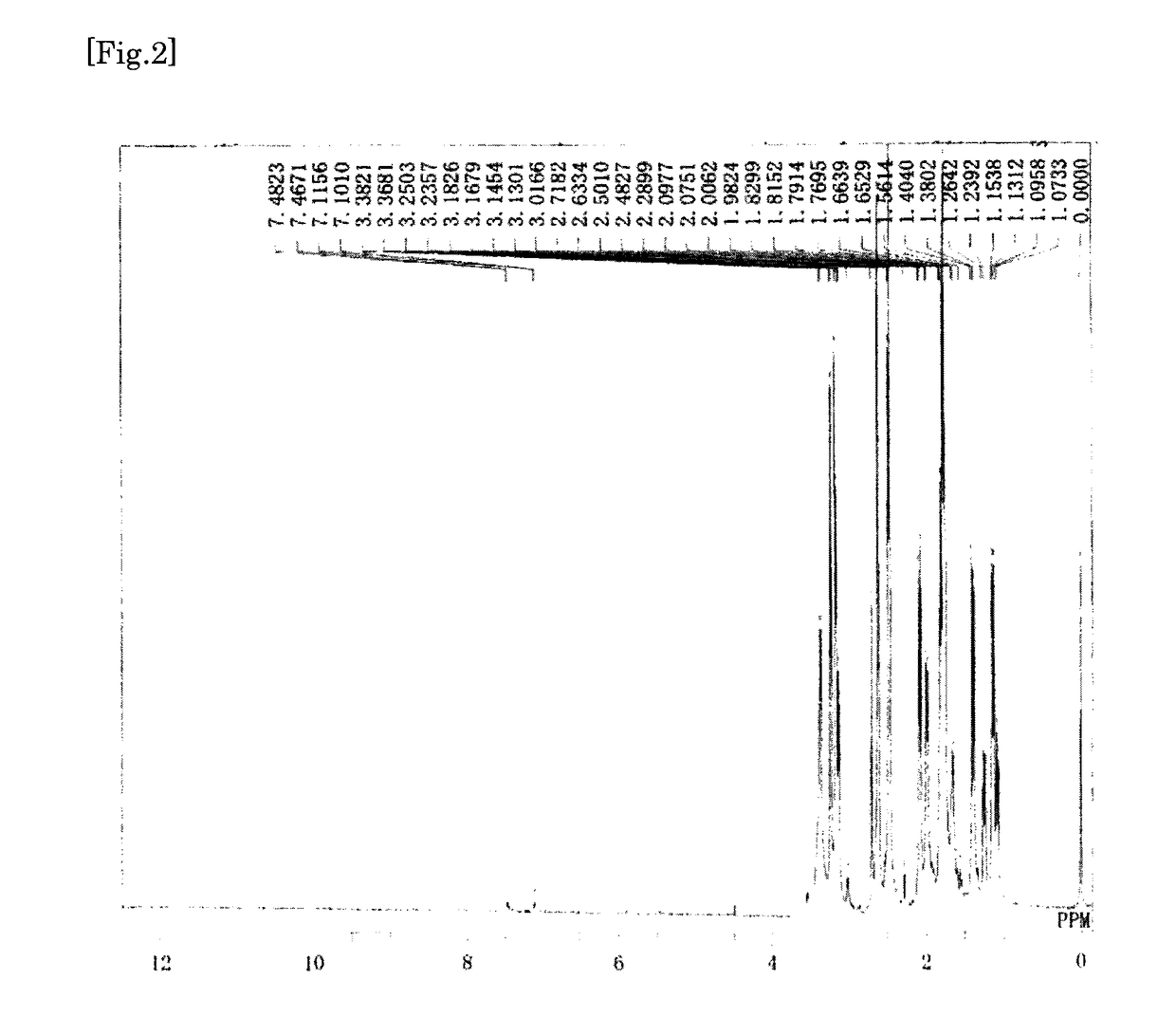

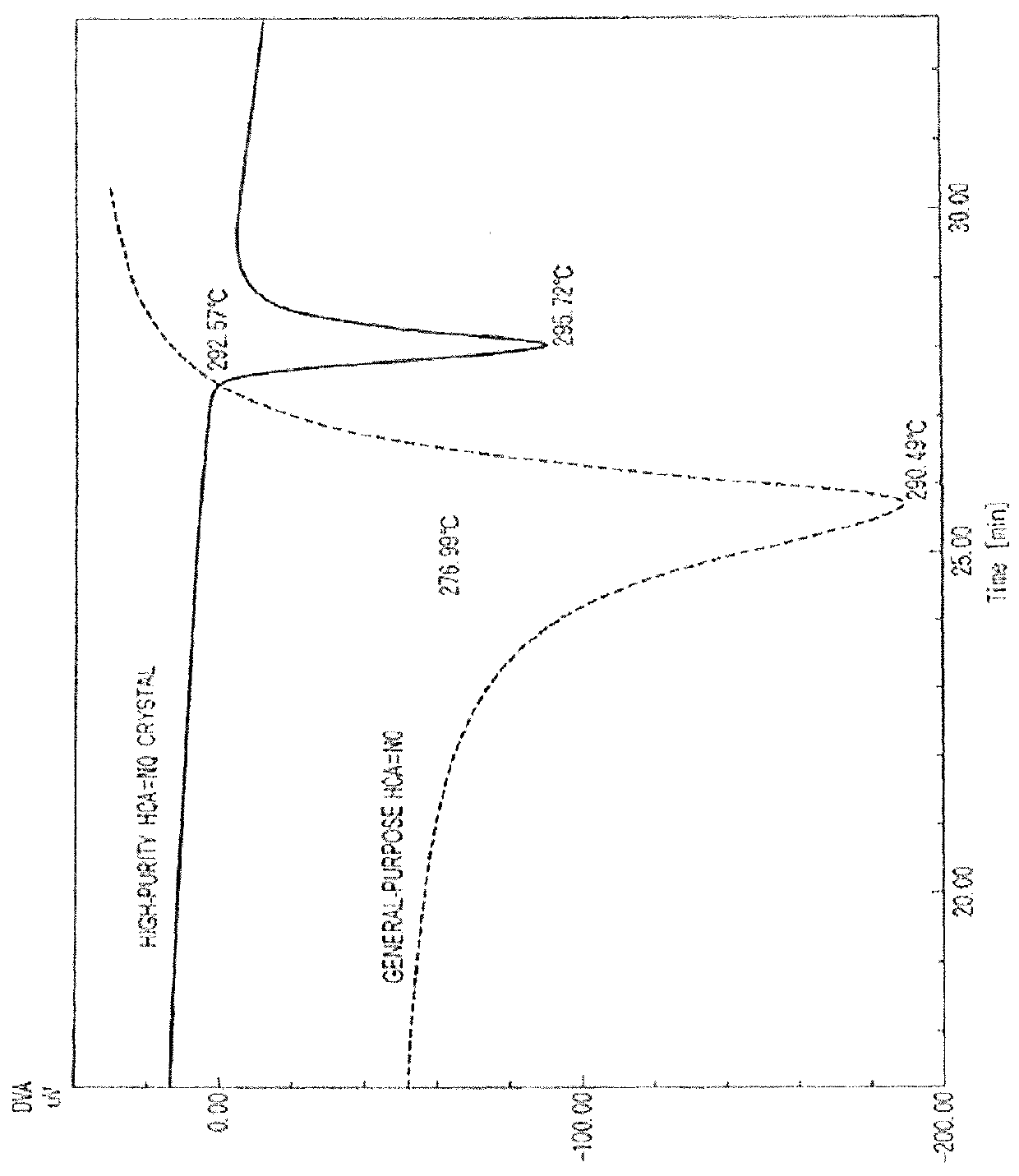

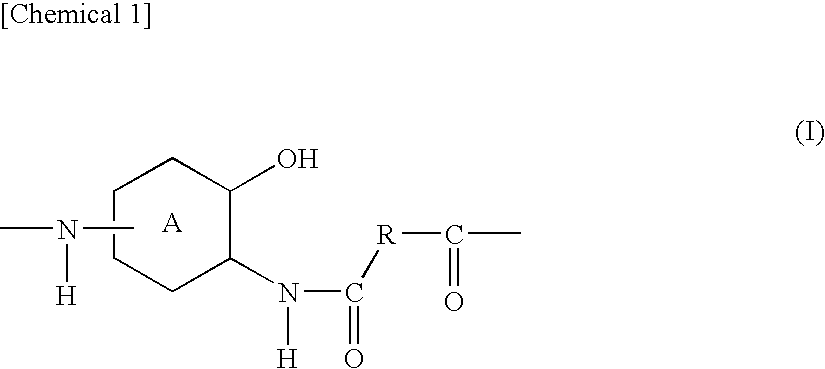

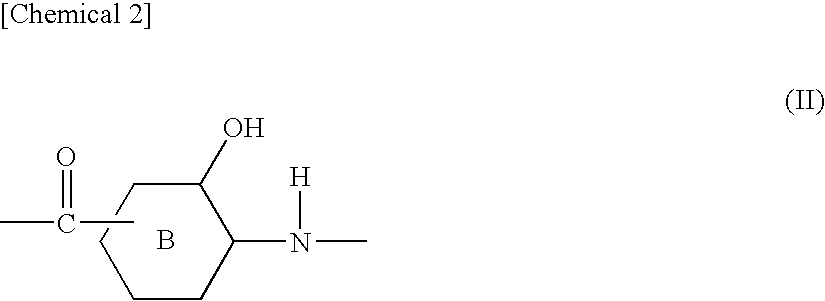

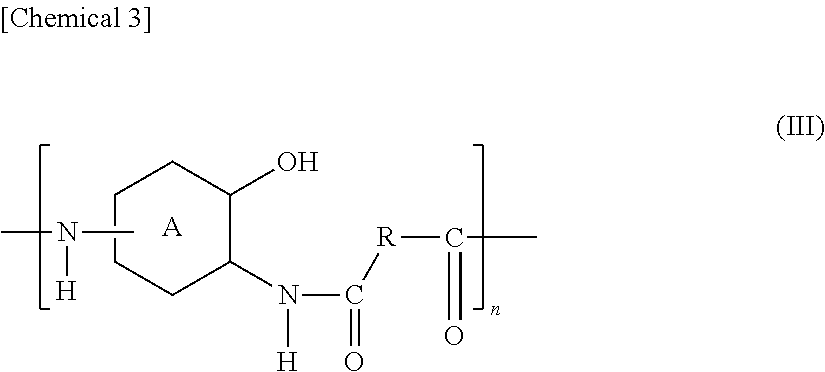

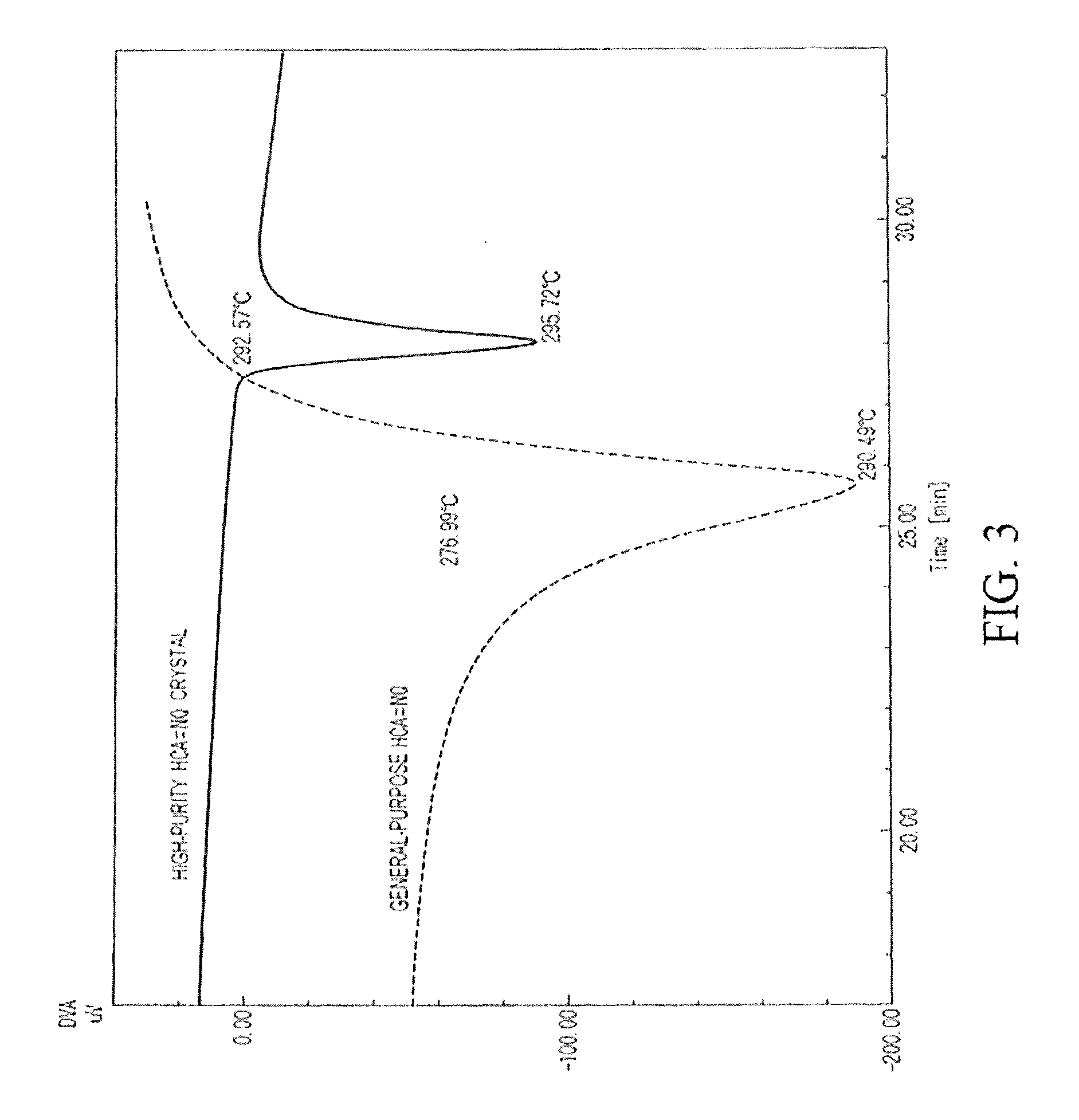

High melting point flame retardant crystal and method for manufacturing the same, epoxy resin composition containing the flame retardant, and prepreg and flame retardant laminate using the composition

ActiveUS20130053473A1Excellent heat resistance reliabilityImprove high temperature reliabilityPlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsEpoxyCyclohexanone

Owner:SANKO CO LTD

Hardenable epoxy resin composition

InactiveUS8426504B2High glass transition temperatureLow linear expansion coefficientSpecial tyresPrinted circuitsEpoxyPolyamide

The epoxy resin composition of the present invention is characterized in that a polyamide compound having a moiety derived from a hydroxyl substituted aromatic amine having a phenolic hydroxyl group adjacent to an amino group is used as an epoxy resin hardener.

Owner:ADEKA CORP

Curable resin composition, curable resin molded article, cured product, laminate, complex, and multi-layer printed circuit board

InactiveUS20180355184A1Low coefficient of linear expansionImprove heat resistanceSynthetic resin layered productsPrinted circuit aspectsHeat resistancePrinted circuit board

[Problem] To provide a curable resin composition which has a low linear expansion coefficient and high heat resistance, which can form a cured product in which the occurrence of void defects and the like is suppressed, and with which the toughness or a molded article can be maintained. [Solution] A curable resin composition comprising an epoxy compound (A), an epoxy curing agent (B), an inorganic filter (C), and a compound (D) including at least three ethylenically unsaturated bonds, wherein the ratio of the inorganic filler (C) in a non-volatile component exceeds 50 mass %.

Owner:INTEL CORP

High melting point flame retardant crystal and method for manufacturing the same, epoxy resin composition containing the flame retardant, and prepreg and flame retardant laminate using the composition

ActiveUS9371438B2Improve reliabilityIncrease resistancePlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsCyclohexanoneEpoxy

Owner:SANKO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com