Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Lower emission rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

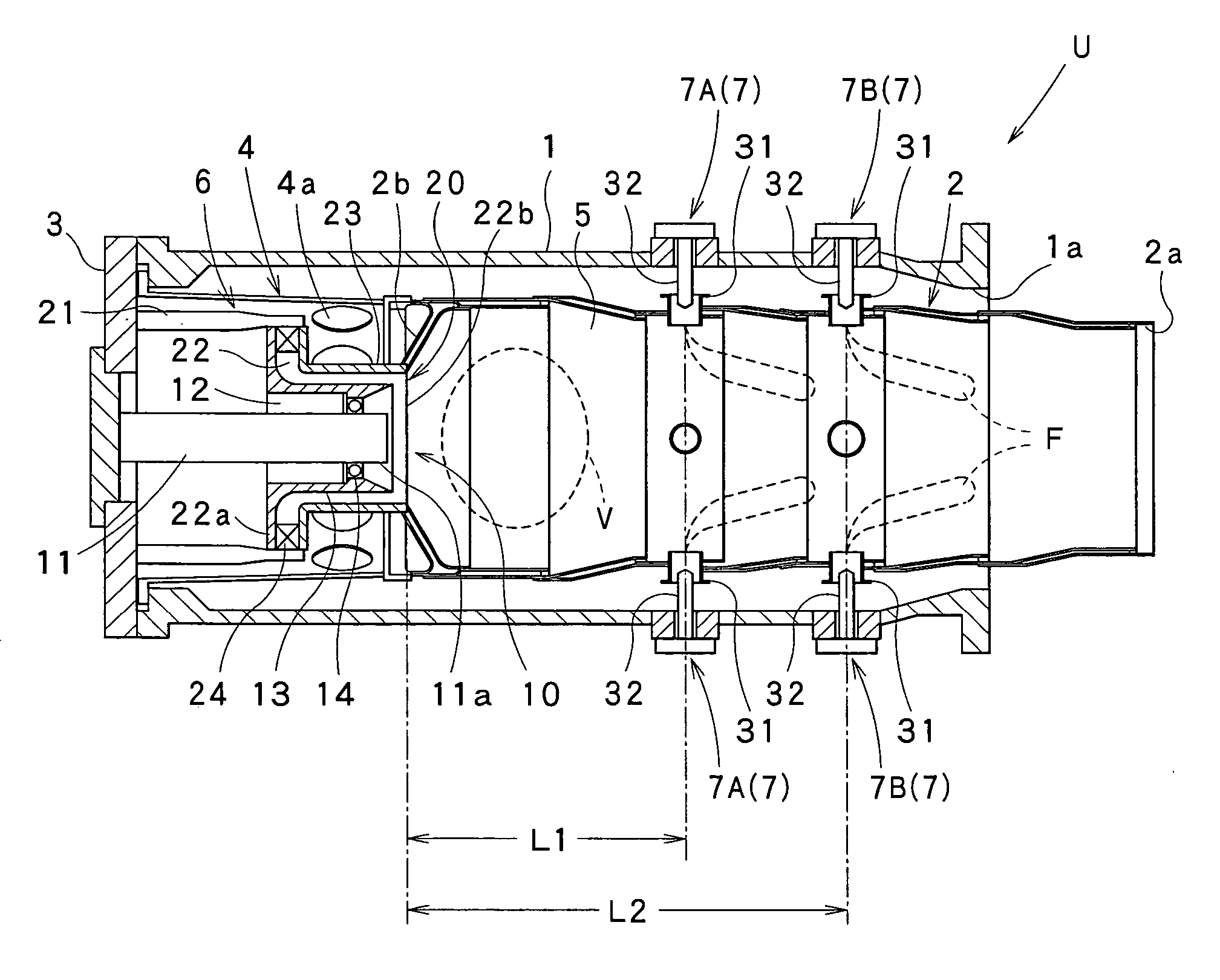

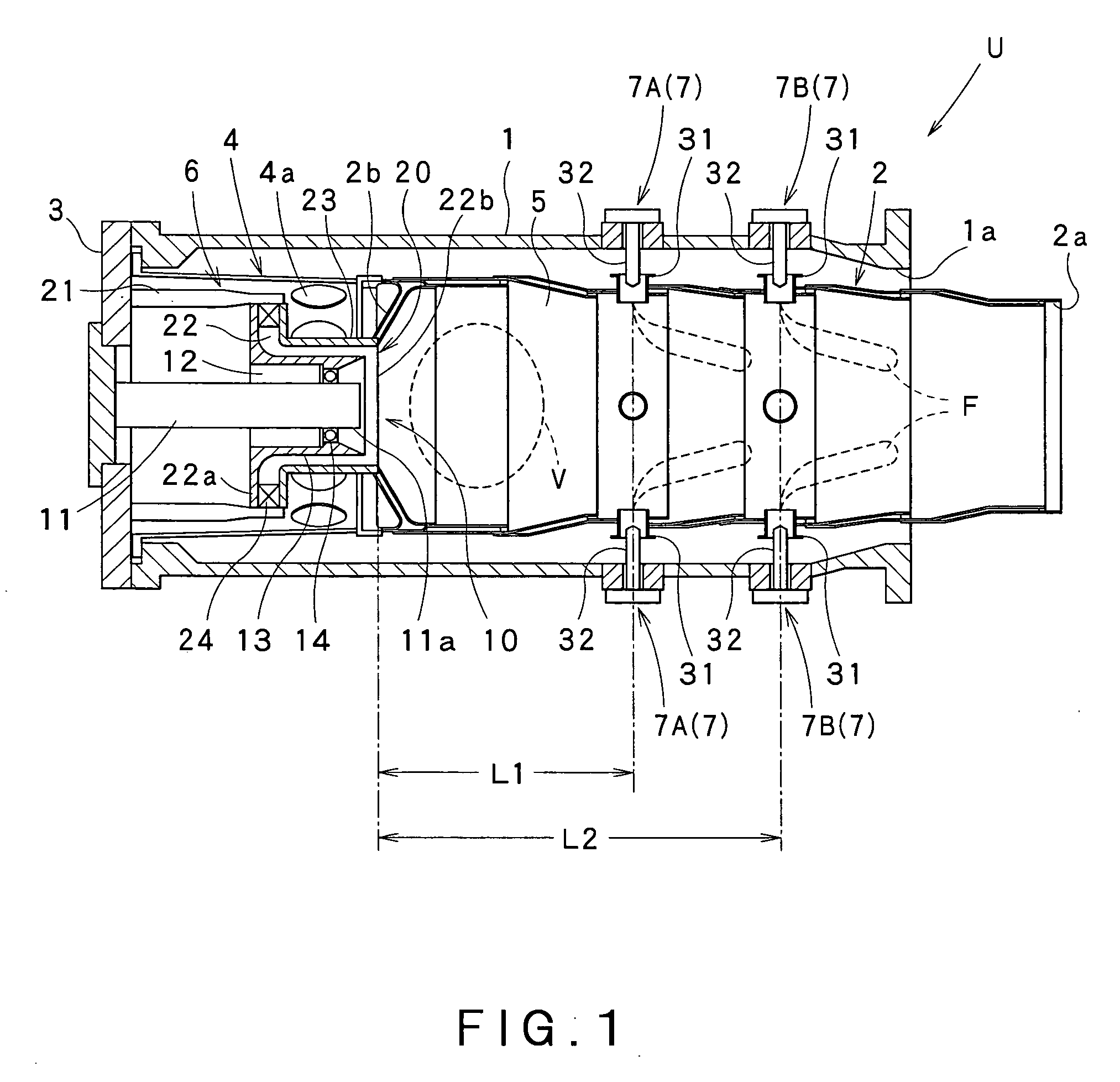

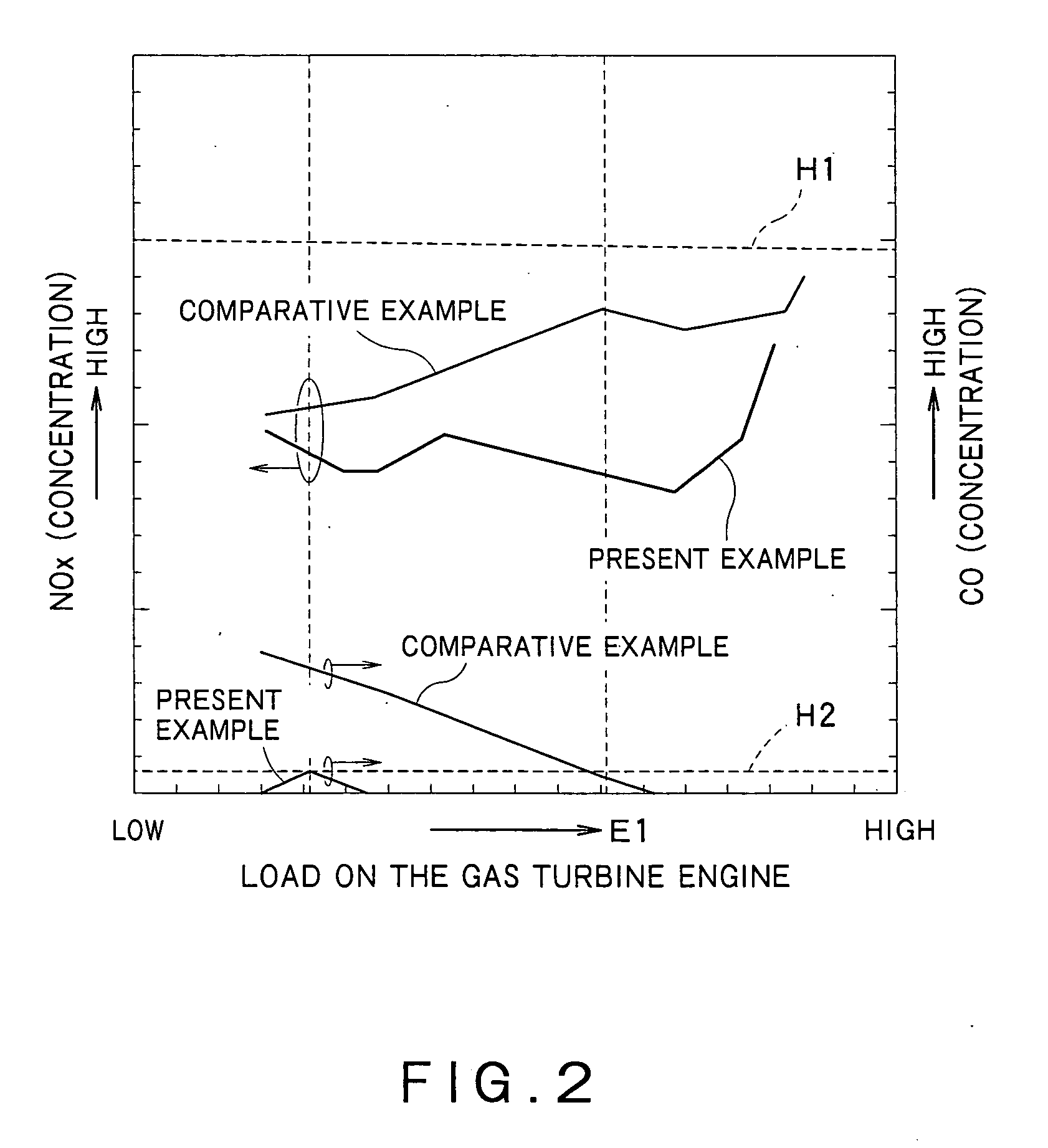

Combustor for gas turbine engine

InactiveUS20070089419A1Reduce the amount requiredStable combustionContinuous combustion chamberGas turbine plantsFuel supplyGas turbines

A combustor for a gas turbine engine of a lean premixed combustion type, includes: a fuel jetting device configured to jet a premixed fuel into a combustion chamber so that the premixed fuel burns in a premixed combustion zone which is formed in the combustion chamber; and an additive fuel supply unit disposed downstream of the premixed combustion zone so as to additionally supply fuel into the combustion chamber. The additive fuel supply unit includes first and second additive fuel supply devices disposed in a two-stage arrangement such that the second additive fuel supply device is positioned downstream of the first additive fuel supply device.

Owner:KAWASAKI HEAVY IND LTD

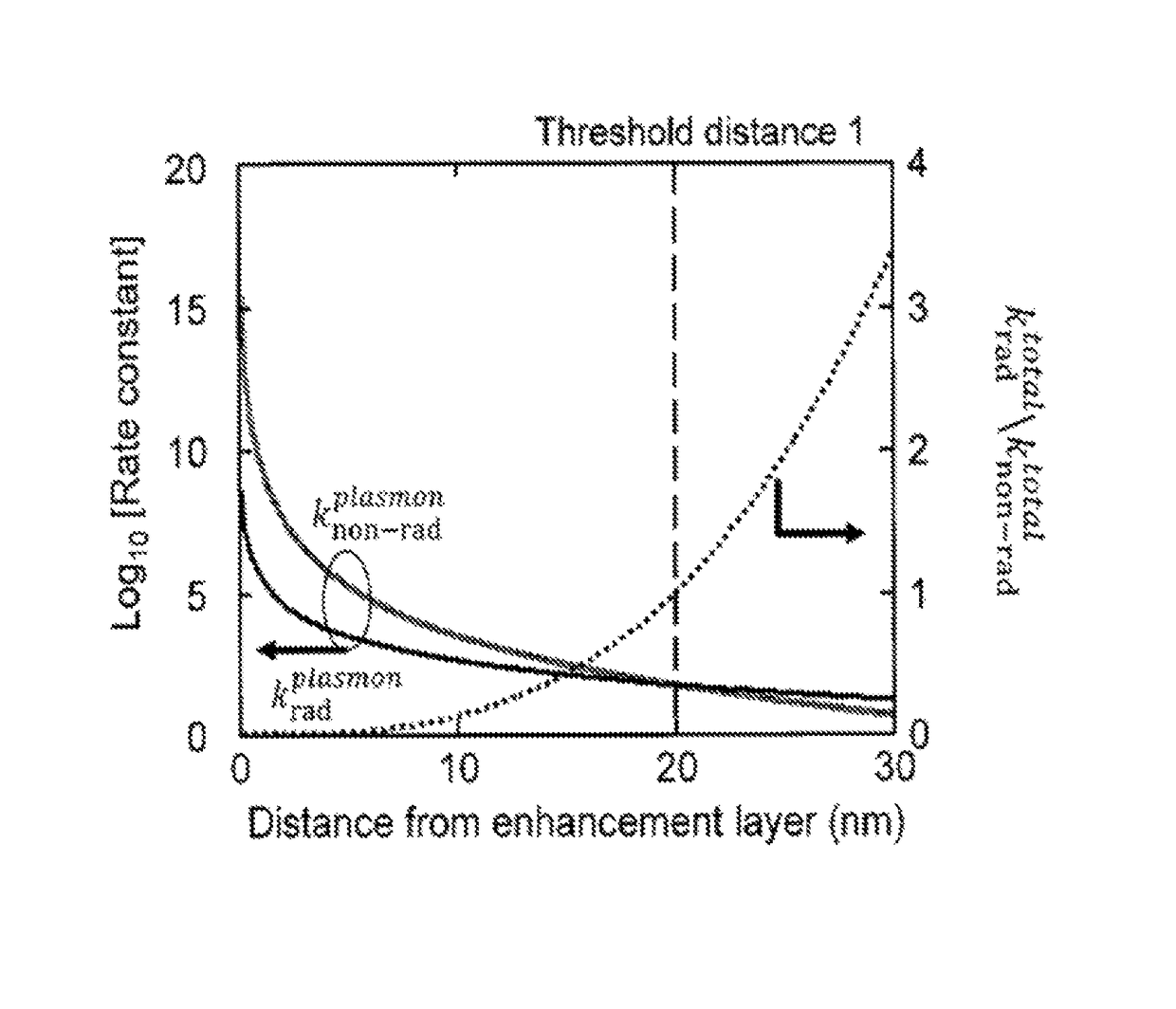

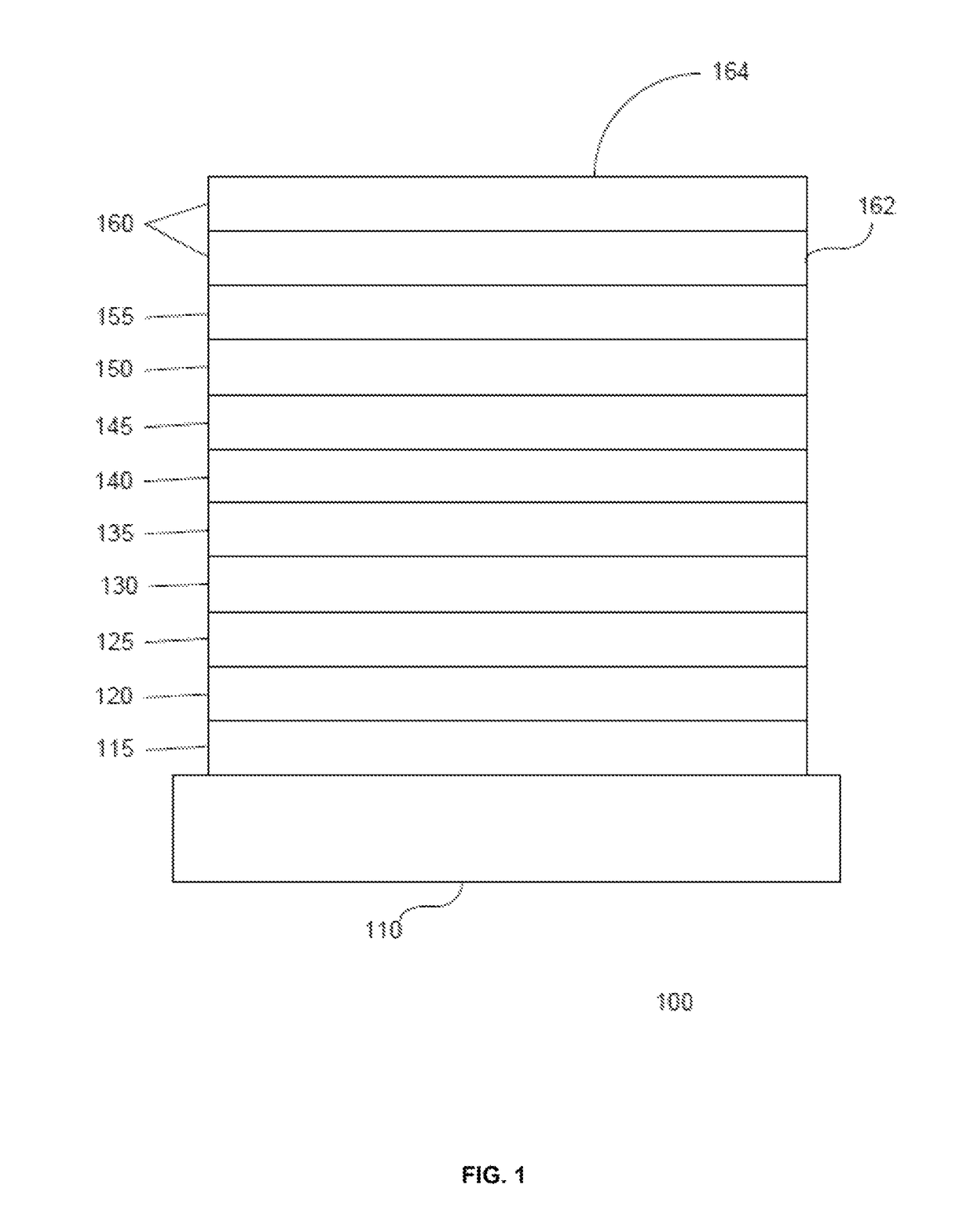

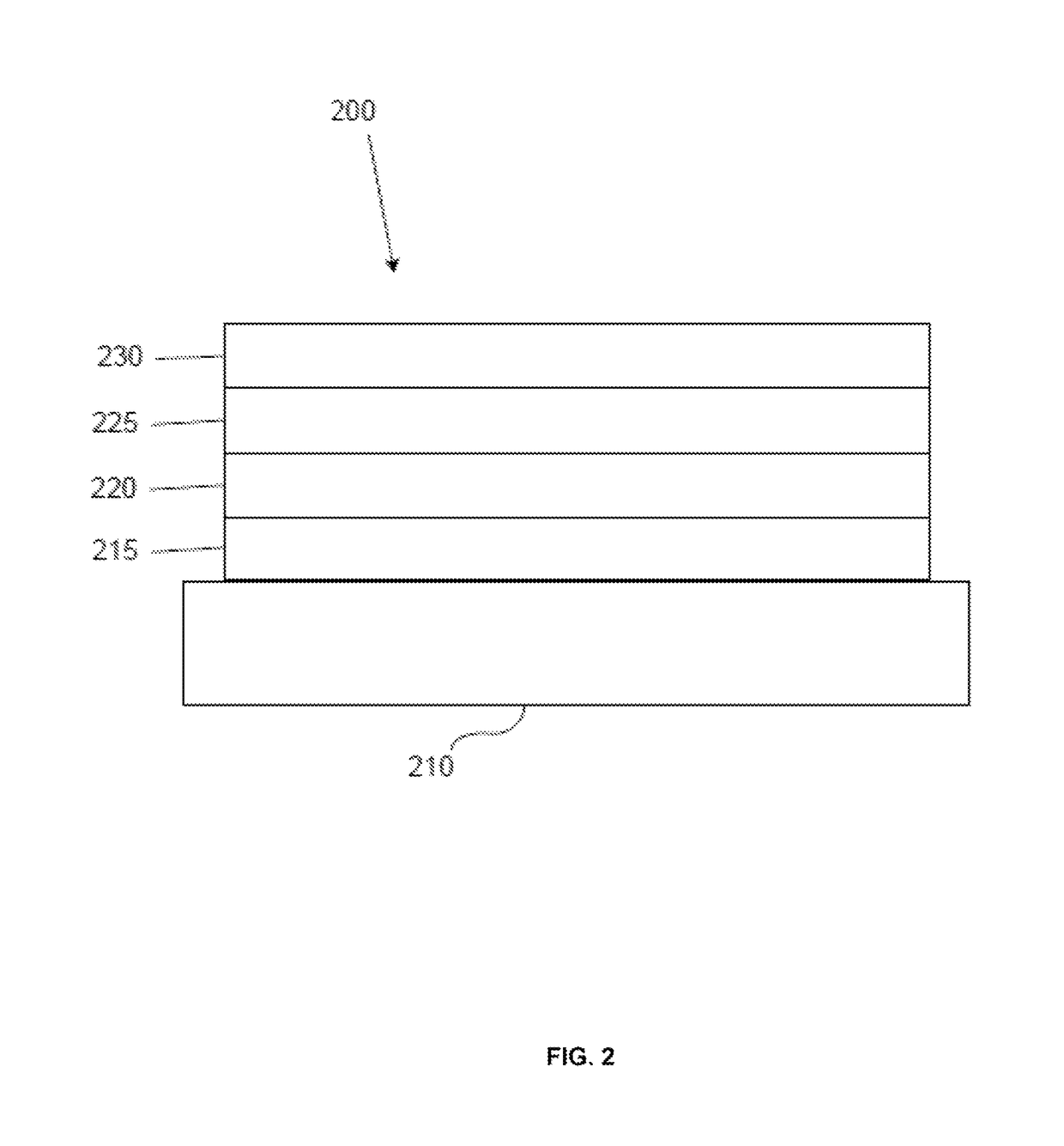

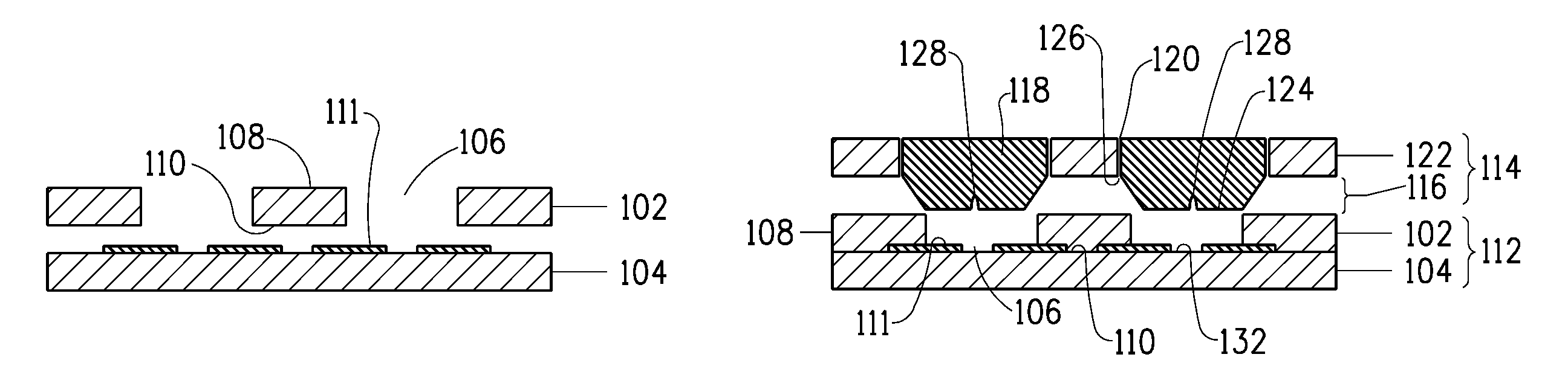

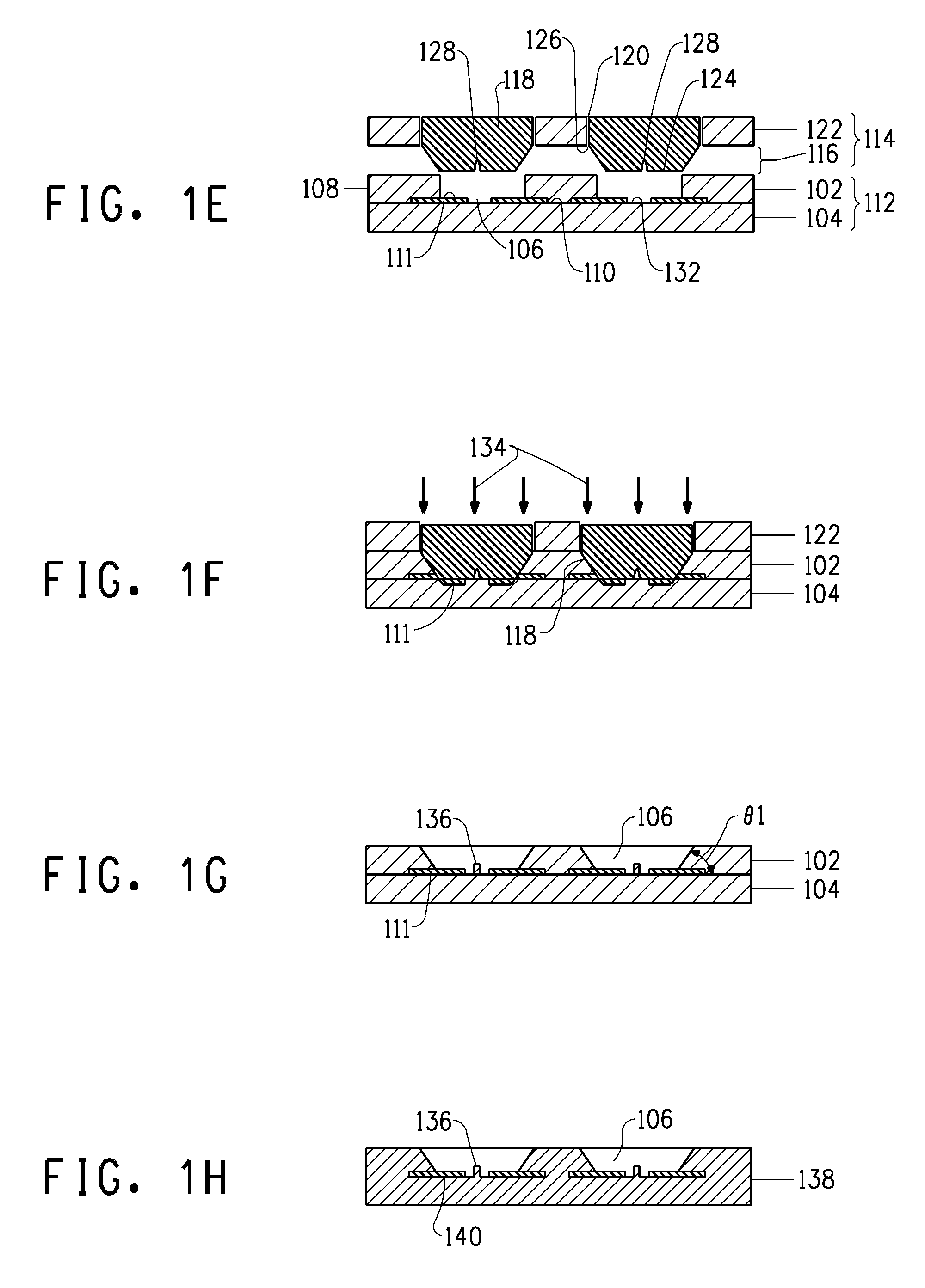

OLED device having enhancement layer(s)

ActiveUS9960386B2Easy to operateMaximizing non-radiative transferSolid-state devicesSemiconductor/solid-state device manufacturingExcited stateRadiative transfer

A method for improving the operation of an OLED includes maximizing on-radiative transfer of excited state energy from the OLED's organic emissive material to surface plasmon polaritons in an enhancement layer by providing the enhancement layer no more than a threshold distance away from the organic emissive layer; and emitting light into free space from the enhancement layer by scattering the energy from the surface plasmon polaritons through an outcoupling layer that is provided proximate to the enhancement layer but opposite from the organic emissive layer.

Owner:UNIVERSAL DISPLAY

High-protein-content growth-promoting environment-friendly fish feed and preparation method thereof

InactiveCN105767594APromote growthPromote reproductionClimate change adaptationAnimal feeding stuffSynbioticsPhytase

The invention discloses a high-protein-content growth-promoting environment-friendly fish feed. The high-protein-content growth-promoting environment-friendly fish feed comprises the following raw materials: bean cakes, cotton meal, corns, bran, fish meal, rapeseed cakes, spirulina powder, seaweed powder, wheat middling, polygonatum sibiricum powder, fish oil, calcium lactate, calcium dihydrogen phosphate, lysine, methionine, aspartic acid, glutamic acid, a vitamin mixture, minerals, phytase, synbiotics, a traditional Chinese medicine compound additive and a food attractant. The high-protein-content growth-promoting environment-friendly fish feed is rich in nutrition, and rich in contents of proteins, amino acids, vitamins, probiotics and growth substances; thus, the high-protein-content growth-promoting environment-friendly fish feed is capable of effectively promoting growths and breeding of the fishes, and improves yields and qualities of the fishes.

Owner:LIANYUNGANG HENGTU FARMING DEV CO LTD

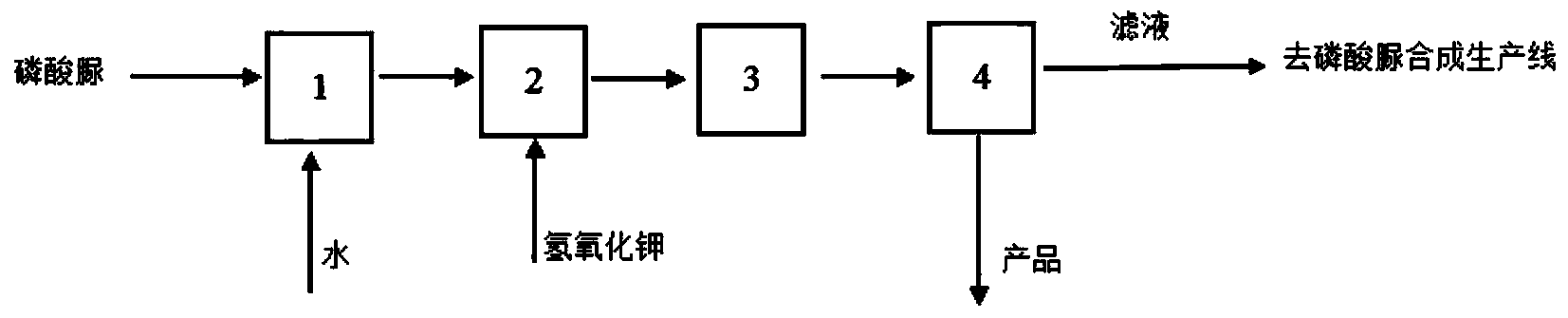

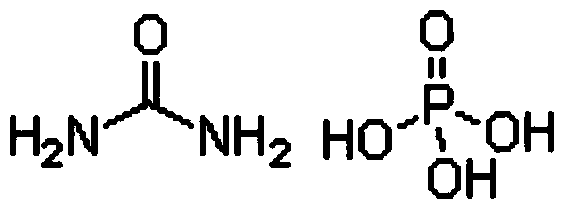

Production method of dipotassium phosphate

InactiveCN104003362ASimplify the production processReduce energy and water consumptionPhosphorus compoundsPotassium hydroxideHeavy metals

The invention relates to the technical field of chemical engineering and particularly relates to a production method of dipotassium phosphate. The method comprises the following step: carrying out a reaction on urea phosphate and potassium hydroxide in a stirring manner for 20 to 70 minutes by controlling a reaction temperature within 50 DEG C to 90 DEG C and controlling a pH (Potential Of Hydrogen) value at a final point of the reaction within 8 to 9.5 so as to prepare the dipotassium phosphate product. The produced dipotassium phosphate product completely conforms to the standard of food-grade dipotassium phosphate by controlling the whole process conditions, i.e., the content of the dipotassium phosphate is between 98.15% and 98.31%, the pH (10g / L of solution) is between 8.9 and 9.2, the content of water insoluble matters is between 0.11% and 0.17%, the content of fluorides is between 8.04mg / kg and 9.13mg / kg, the content of arsenic is between 2.03mg / kg and 2.71mg / kg, the content of heavy metal is between 8.9mg / kg and 9.4mg / kg as well as the loss on drying is between 1.64% and 1.82% according to physical and chemical indexes in a manner of sampling analysis.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

Silica sol and silica-containing epoxy resin composition

ActiveUS20160068664A1Lower emission rateSmall moisture absorption coefficientOther chemical processesSilicon compoundsEpoxySilica particle

The silica sol of the invention contains silica particles having a mean primary particle size of 20 to 100 nm and which has a silica particle size / mean primary particle size ratio, determined through dynamic light scattering, of 3.0 or less, wherein the silica particles are surface-treated with an organic silane compound and have an α-ray emission rate of 0.005 counts / cm2·hr or less and a moisture absorption coefficient, determined after allowing the silica particles to stand for 48 hours at 23° C. and a relative humidity of 50 RH %, of 0.5 mass % or lower.

Owner:NISSAN CHEM IND LTD

Emulsion for fuel oil and its emulsified fuel oil

InactiveCN1328112AReduce concentrationLower emission rateRefining by water treatmentFuel oilEngineering

Am emusifying liquid for fuel oil is prepared from 6 surfactants including rosin solution, alkanolamide, lipoacyl diethanolamine, fatty alcohol polyoxyethylene ether, etc. and water. It can be used along with water to obtain emulsified diesel oil or emulsified heavy oil. Its advantages are high stability of emulsified fuel oil within 3 months, saving oil by 15-25%, no black smoke in tail gas, andreducing smoke by 64%, co by 62%, SO2 by 58% and No by 51%.

Owner:陈平

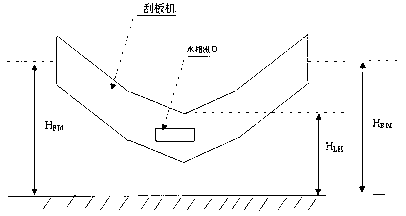

Treatment method of high concentration waste alkali solution

ActiveCN102877351AOvercome the explosionLower emission ratePulp liquors combustionHigh concentrationCyclohexanone

The invention relates to a treatment method of a high concentration waste alkali solution. The method includes: spraying waste alkali into an alkali recovery furnace, using a fuel to support combustion, combusting the waste alkali in the presence of an oxygen-containing gas to generate steam as a by-product, conducting electric precipitation to recover dry alkali ash, and making a molten material formed in combustion flow out of a chute at the furnace bottom. The method is characterized by: using a nozzle to jet one or several bundles of high-speed fluids so as to impact, cool and break the molten material from the chute into granular or powdered coarse alkali; bringing the granular or powdered coarse alkali into a cylindrical pipeline, and making the coarse alkali enter solid-liquid separation equipment selected from a scraper or a screw conveyor under the driving of a water flow, and separating a solid phase so as to obtain moisture-containing coarse alkali; and bringing the water phase separated by the solid-liquid separation equipment into a trough, a water tank or other intermediate containers, and then performing pressurization to circulate the water phase to the cylindrical pipeline and the nozzle. The method provided in the invention has the advantages of being able to completely recover the molten material generated by waste alkali combustion and generating no wastewater, thus being able to be used for cyclohexanone and other chemical industrial production and having good environmental protection significance and economic benefits.

Owner:CHINA PETROCHEMICAL CORP

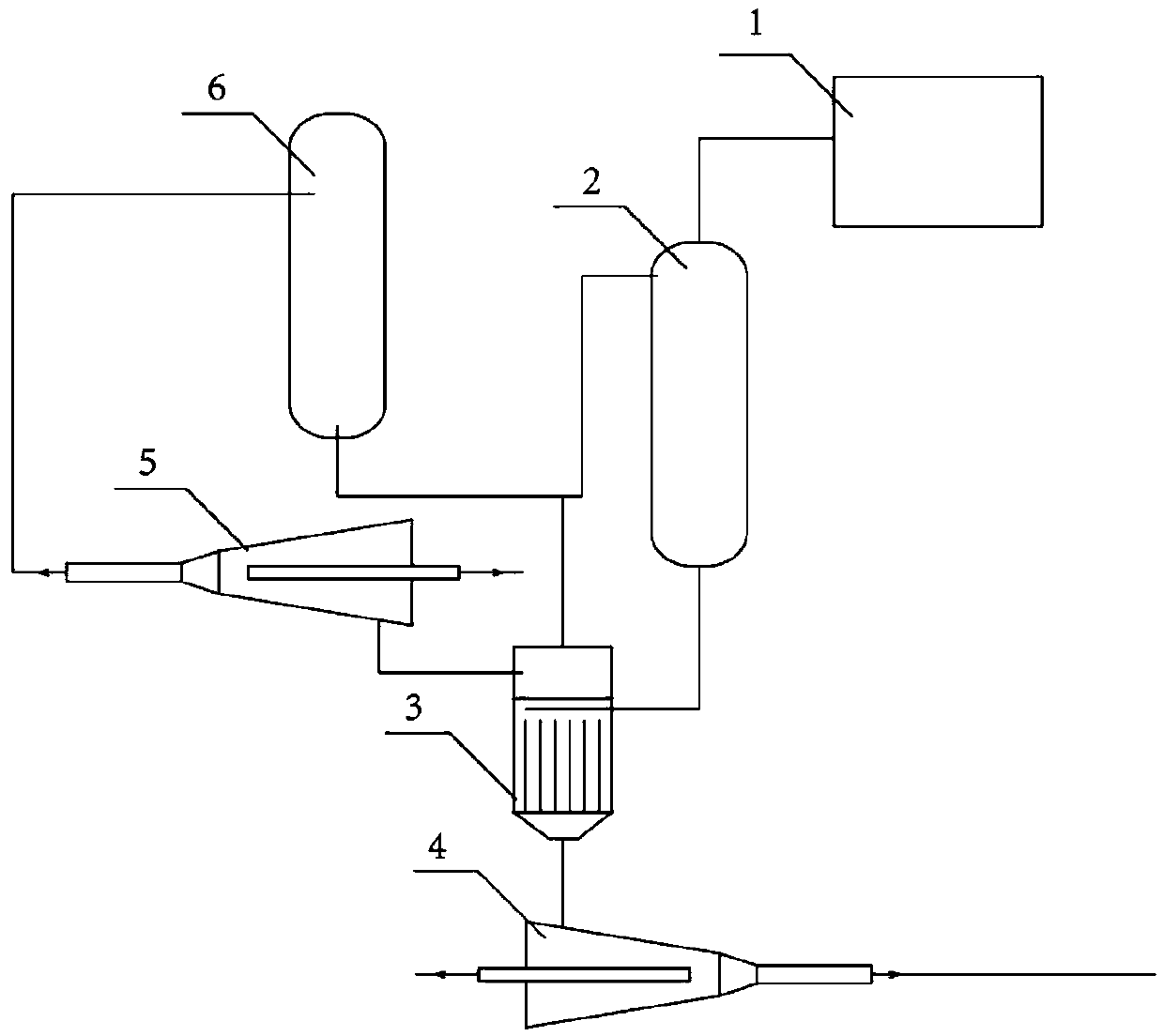

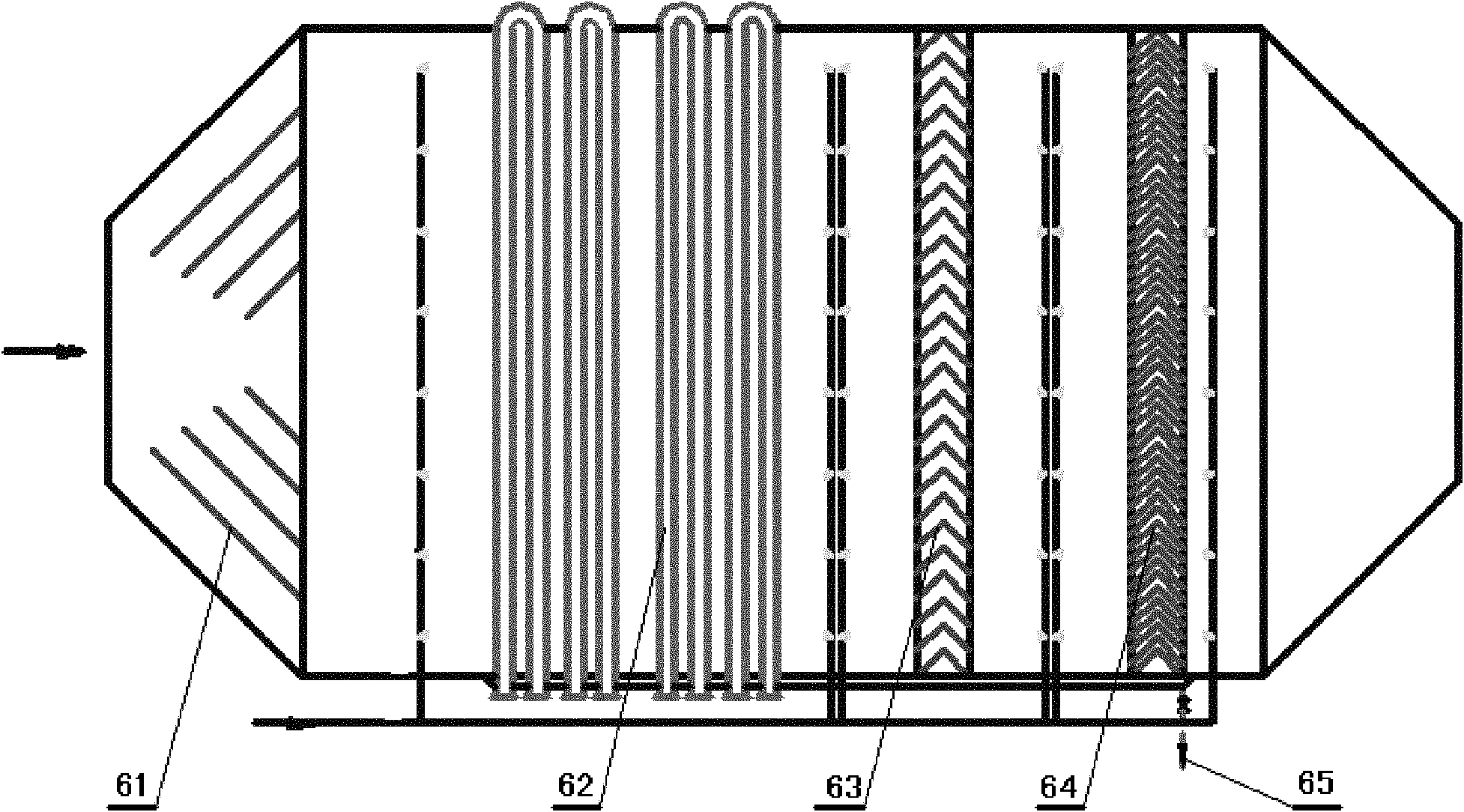

Online low-nitrogen oxygen-rich combined combustion energy-saving system

InactiveCN102721041ASimple structureReasonable designIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionPre treatmentCoal

The invention discloses an online low-nitrogen oxygen-rich combined combustion energy-saving system. The system comprises a pretreatment comprehensive coal hopper which is mounted on a chain-type coal firing boiler, feeds the raw coal in layers and in rows into a chain-type coal firing boiler grate and sorting powdery coal on line; a drying / preheating heat exchanger for drying and delivering the powdery coal which is sorted by the pretreatment comprehensive coal hopper and preheating the air; a coal powder fine-sorting device connected with the drying / preheating heat exchanger and used for finely sorting the powdery coal which is dried by the drying / preheating heat exchanger; and a low-nitrogen oxygen-rich coal powder combustor used for feeding the high-quality coal powder which is finelysorted by the coal powder fine-sorting device into the chain-type coal firing boiler grate. The online low-nitrogen oxygen-rich combined combustion energy-saving system has the advantages of simple structure, reasonable design and good use effect; can treat inferior coal on line to obtain the energy-saving modification technique with the optimum use effect while minimizing the minimum cost, can increase the utilization efficiency of inferior coal, reduce the waste of energy and reduce the use cost.

Owner:SHAANXI PANLONG IND

Method of making concrete

ActiveUS8357240B2Reduce humidityLower emission rateSolid waste managementCeramicwareCompressive strengthPolymer chemistry

A method of preparing a light weight concrete composition using expanded polymer particles that includes a) replacing from about 10 to about 50 volume percent of the coarse aggregate in the concrete composition with prepuff particles; and b) preparing the concrete composition by combining ingredients comprising 3-40 volume percent cement, 1-50 volume percent fine aggregate, 0-40 volume percent coarse aggregate, 10-22 volume percent water, and 5-40 volume percent of prepuff particles. The prepuff particles have an average particle diameter of from 0.2 mm to 5 mm, a bulk density of from 0.02 g / cc to 0.56 g / cc, an aspect ratio of from 1 to 3. The concrete composition has a density of from about 90 to about 135 lb. / ft3 and after it is set for 28 days, has a compressive strength of at least 1800 psi as tested according to ASTM C39.

Owner:SYNTHEON HLDG SPA

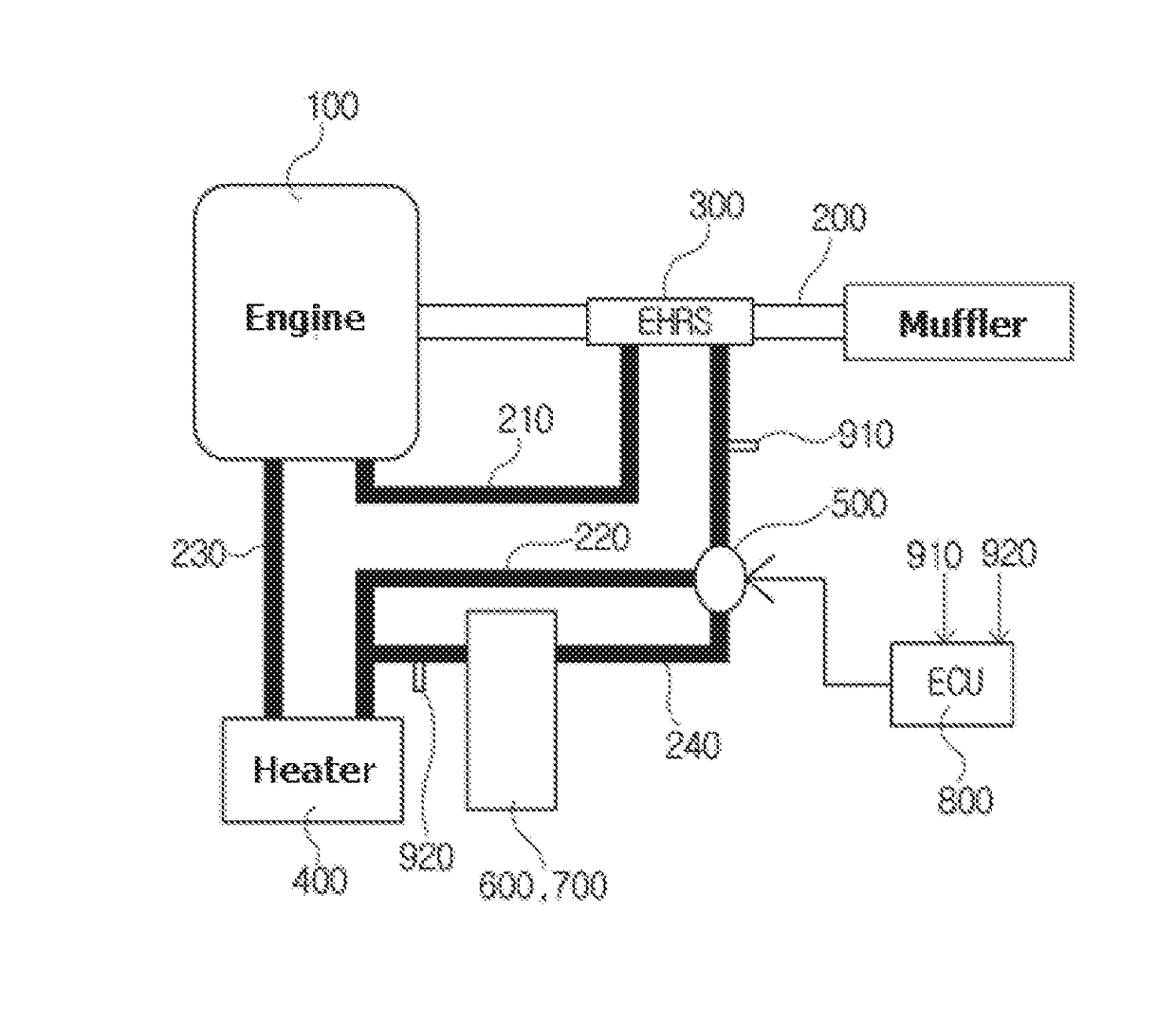

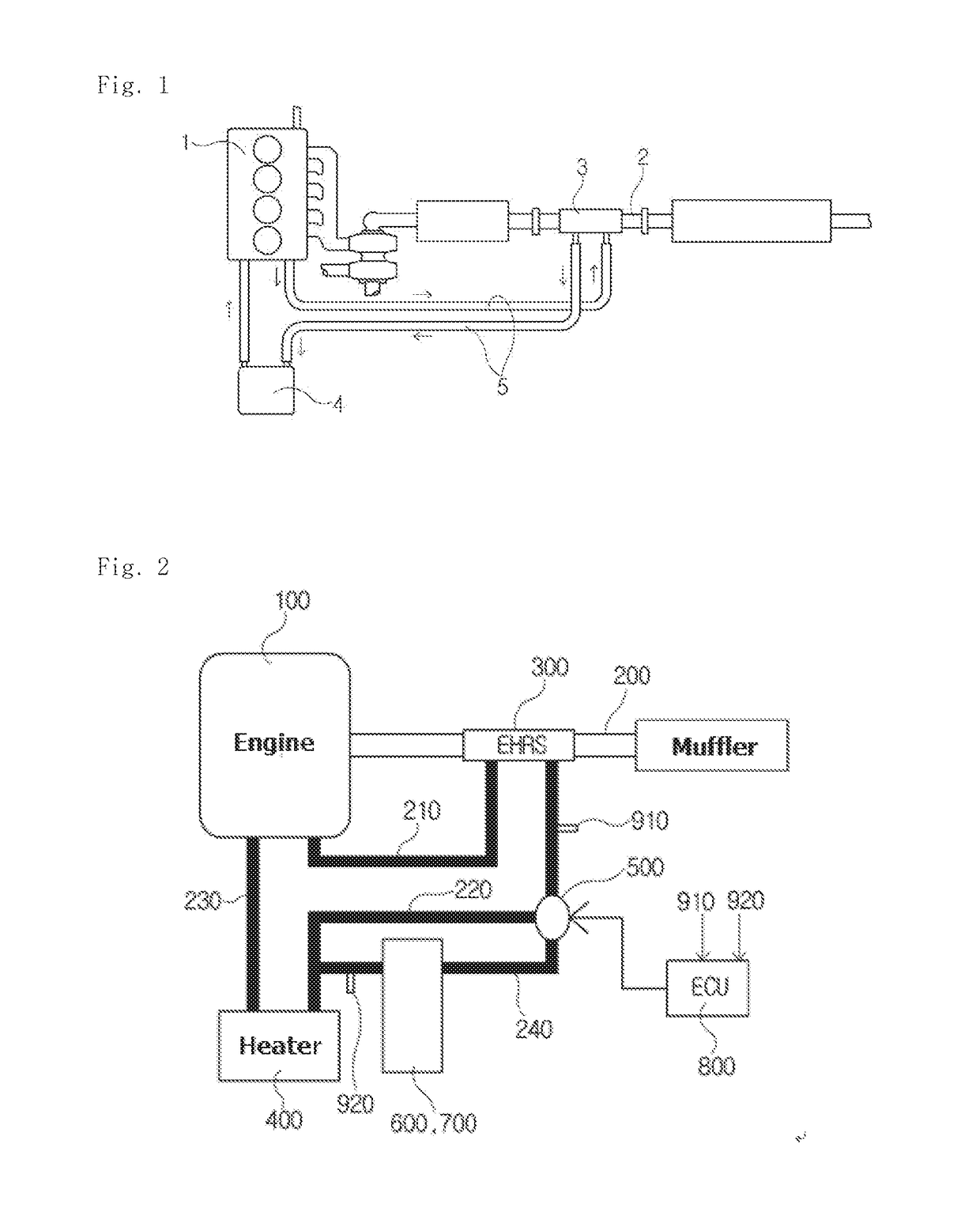

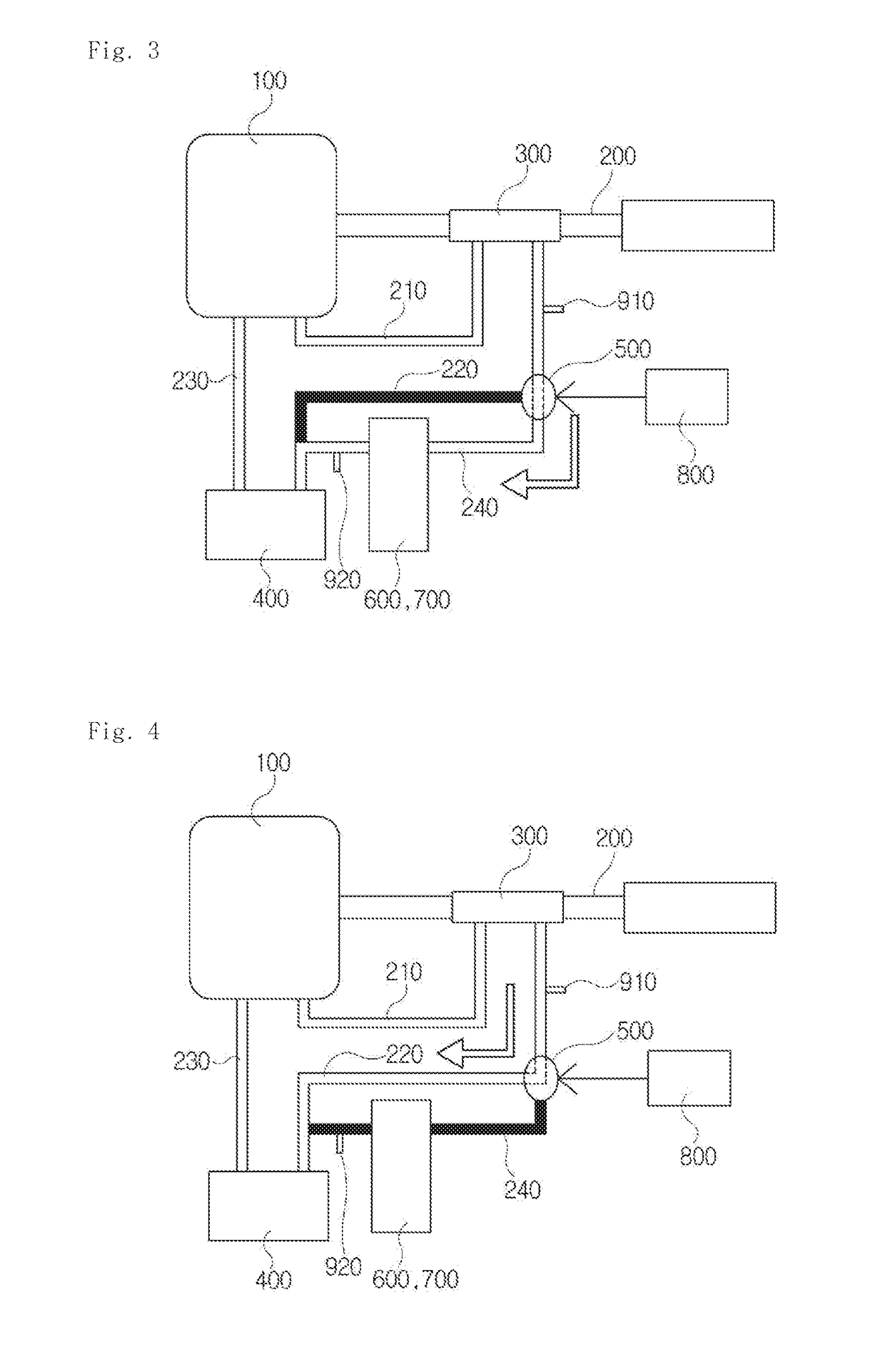

Exhaust heat regenerator for vehicle

ActiveUS20170145980A1Fast warm-upReduce fuel consumptionLiquid coolingCoolant flow controlFuel efficiencyPollutant emissions

Disclosed herein is an exhaust heat recovery apparatus for a vehicle, in which a heat accumulator has improved heat accumulation performance and heat exchange performance, whereby an engine can be rapidly warmed up in a cold start so that fuel efficiency can be enhanced, a pollutant emission rate can be reduced, and it is possible to heat a passenger compartment immediately after the engine starts.

Owner:HANON SYST

Manufacturing method of biomass environment-protective lubricant oil

The invention relates to a production method of biomass environment protective lubricating oil. The lubricating oil is produced by the following steps of taking renewable castor oil as a main raw material and rapeseed oil as an auxiliary material, and then adding a small amount of chemical auxiliary. After trial application, the biomass environment protective lubricating oil produced by the method of the invention completely has the basic functions of mineral lubricating oil, has high viscosity index and strong abrasion resistance, can be widely used for internal combustion engines of automobiles, ships and agricultural machinery, etc., and can also be used for metal working, especially metal plate cold-rolling. Above 90 percent of the raw materials of the biomass environment protective lubricating oil are renewable vegetable oil with wide source and low cost, no exhaust gas is discharged when in production, and compared with the mineral lubricating oil, the emission rate of noxious gases is reduced by more than 80 percent when in use. The production and use of the biomass environment protective lubricating oil need the massive planting of the castor and the rape, which plays an important role in improving rural economy, increasing the income of farmers, and accelerating the development of agriculture industrialization.

Owner:颜克绳

Electronic device and method of manufacturing the same

InactiveUS20110180938A1Lower emission rateFilm/foil adhesivesSemiconductor/solid-state device detailsPolymer scienceHydrogen atom

In an electronic device, a silicone adhesive bonding first and second members is made from a composition comprising: (A) 100 parts by mass of an organopolysiloxane containing in one molecule at least two alkenyl groups and being free of silicon-bonded hydroxyl and alkoxy groups wherein the content of cyclic siloxanes having 4 to 20 siloxane units is at most 0.1 mass %; (B) an organopolysiloxane containing in one molecule at least two silicon-bonded hydrogen atoms and being free of an alkenyl group, and silicon-bonded hydroxyl and alkoxy groups; (C) at least 0.05 parts by mass of an adhesion promoter; (D) 100 to 2000 parts by mass of a thermally conductive filler; and (E) a hydrosilylation-reaction catalyst. (B) is contained such that the silicon-bonded hydrogen atoms is in the range of 0.5 to 10 mol per 1 mol of the alkenyl groups of (A), and the sum of (B) and (C) is 0.5 to 10 mass % of the sum of (A), (B) and (C).

Owner:DENSO CORP +1

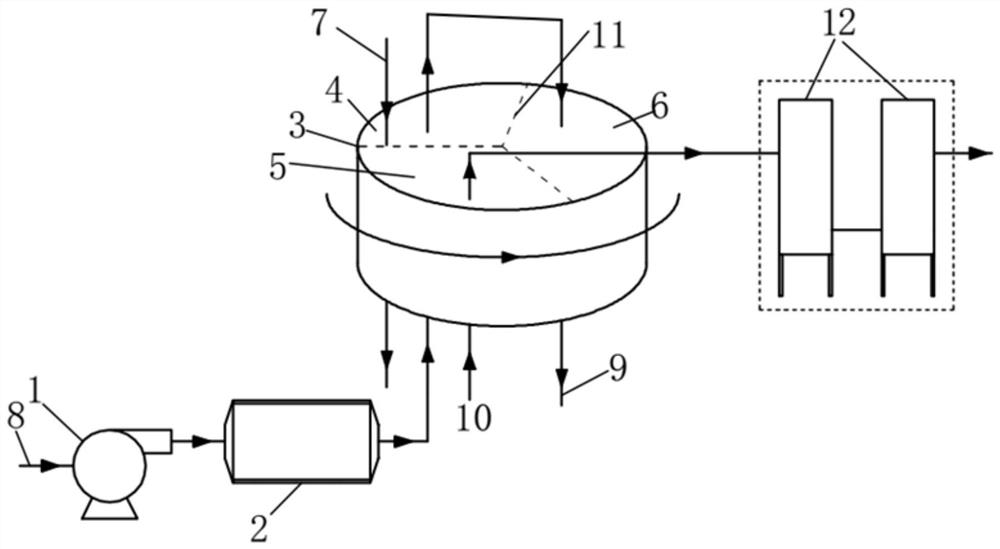

Method and Apparatus for Controlling Gas Turbine Combustor

InactiveUS20120055161A1Reduce nitrogen oxide emissionsLower emission rateFuel supply regulationContinuous combustion chamberCombustion chamberCombustor

An apparatus for controlling a gas turbine combustor having a diffusion combustion burner and a premix combustion burner comprising: a rotating speed detector for detecting a rotating speed of gas turbine, a recorder for recording the detected value of the rotating speed of gas turbine detected by the rotating speed detector, an arithmetic unit for calculating a change with time of the rotating speed of gas turbine in accordance with details of the detected value of the rotating speed of gas turbine recorded in the recorder, and a fuel control unit for judging a starting situation of reduction in the rotating speed of gas turbine on the basis of the change with time of the rotating speed of gas turbine calculated by the arithmetic unit and controlling respectively a fuel flow rate for the diffusion combustion burner to be fed to the diffusion combustion burner installed in the gas turbine combustor and a fuel flow rate for the premix combustion to be fed to the premix combustion burner.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Lead zinc ore beneficiation wastewater treatment method and treatment device for lead zinc ore beneficiation wastewater

InactiveCN106186428ALow costLower emission rateWaste water treatment from quariesTreatment involving filtrationBeneficiationTreatment unit

The invention relates to the technical field of wastewater treatment, in particular to a lead zinc ore beneficiation wastewater treatment method and a treatment device for the lead zinc ore beneficiation wastewater. By means of setting the structure of the device, the device can realize accurate coupling of chemical precipitation and membrane treatment methods, so that lead zinc ore beneficiation wastewater can be treated by coupling of chemical precipitation and membrane treatment; meanwhile, the shortcoming that a membrane treatment unit is damaged due to improper acidity in a chemical precipitation process is overcome, and the cost of lead zinc ore beneficiation wastewater treatment is reduced.

Owner:VONTRON MEMBRANE TECH CO LTD

Exhaust heat regenerator for vehicle

ActiveUS10309364B2Improved heat accumulation performance and heat exchange performanceImprove fuel efficiencyLiquid coolingAir-treating devicesFuel efficiencyPollutant emissions

Disclosed herein is an exhaust heat recovery apparatus for a vehicle, in which a heat accumulator has improved heat accumulation performance and heat exchange performance, whereby an engine can be rapidly warmed up in a cold start so that fuel efficiency can be enhanced, a pollutant emission rate can be reduced, and it is possible to heat a passenger compartment immediately after the engine starts.

Owner:HANON SYST

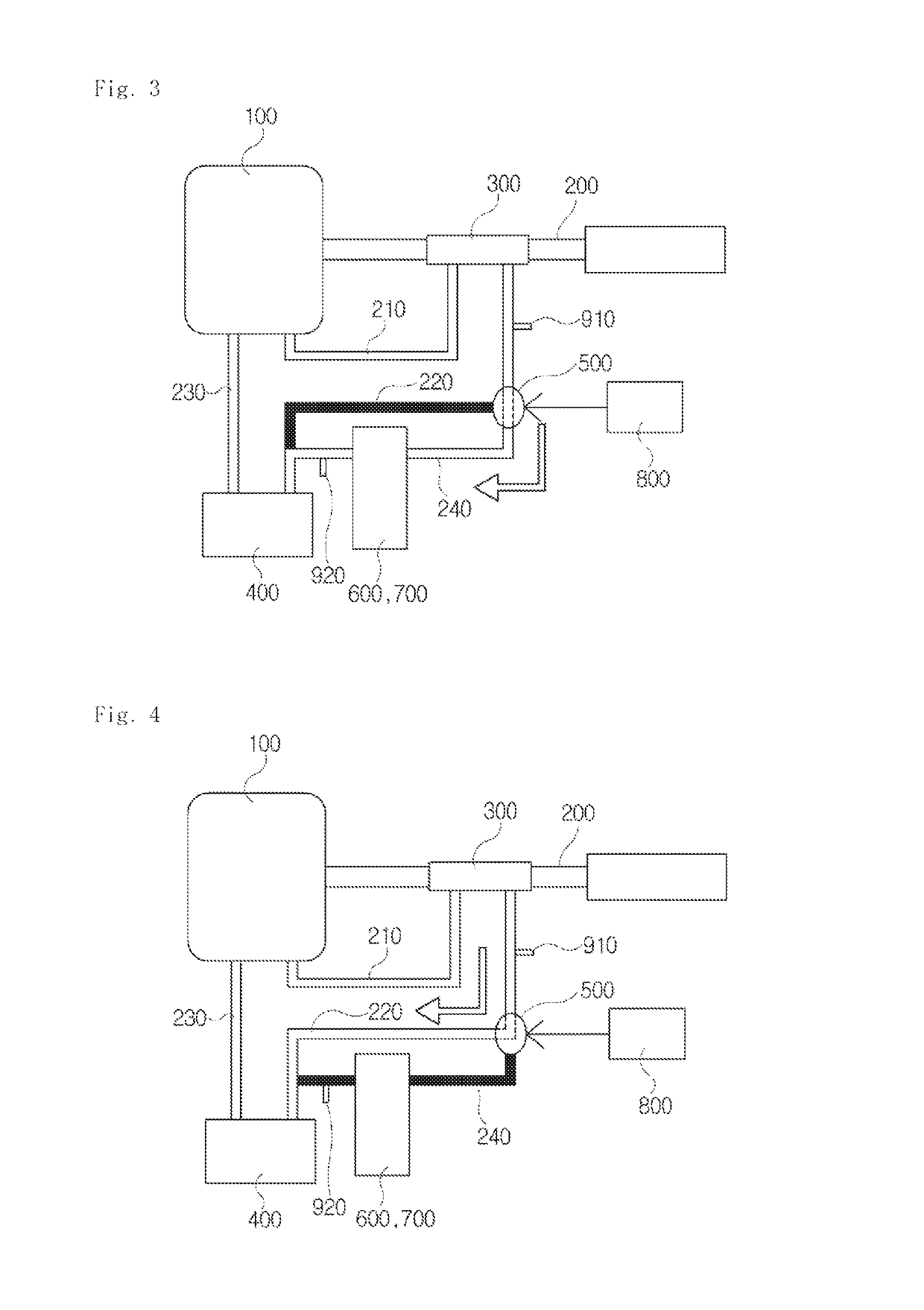

Device capable of conducting dust removal and arsenic recovery on non-ferrous smelting smoke at same time

InactiveCN110433607AWill not touch each otherLower emission rateGas treatmentDispersed particle separationEngineeringQuenching

The invention provides a device capable of conducting dust removal and arsenic recovery on non-ferrous smelting smoke at the same time. The device comprises a fan, a dust removal and arsenic precipitation integrated device and a quenching arsenic recovery device which communicate with one another in sequence, wherein a turntable which is connected with a driving device through a transmission shaftis arranged in the dust removal and arsenic precipitation integrated device, through holes through which the smoke runs are formed in the turntable, intercepting pipes used for adsorbing smoke dust and partition boards used for dividing an arsenic precipitation and removal device into a dust removal region, an arsenic precipitation region, an arsenic removal region and an injection region are arranged on the turntable, the through holes are formed in the upper ends and the lower ends of the dust removal region, the arsenic precipitation region, the arsenic removal region and the injection region respectively, the through hole in the lower end of the dust removal region is connected with the fan, the through hole in the upper end of the dust removal region is connected with the through hole in the upper end of the arsenic precipitation region, the through hole in the lower end of the arsenic precipitation region is connected with a smoke outlet, the arsenic precipitation region is connected with a cooling device, the arsenic removal region is connected with a heating device, and the through hole in the upper end of the arsenic removal region is connected with the quenching arsenicrecovery device. By means of the device capable of conducting dust removal and arsenic recovery on the non-ferrous smelting smoke at the same time, operation of dust removal and arsenic precipitationcan be conducted by one device, and not only is a smoke treatment technology simplified, but also the purity of recovered finished product arsenic can be improved.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

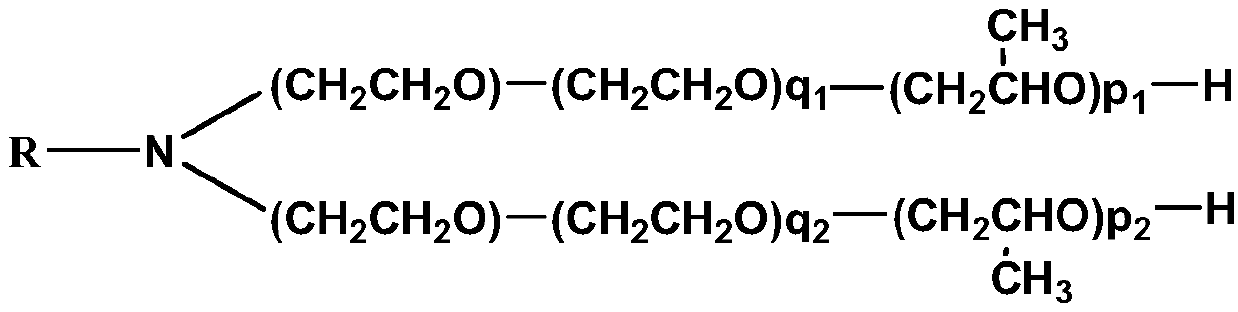

Non-disassembly automobile three-way catalyst cleaning agent

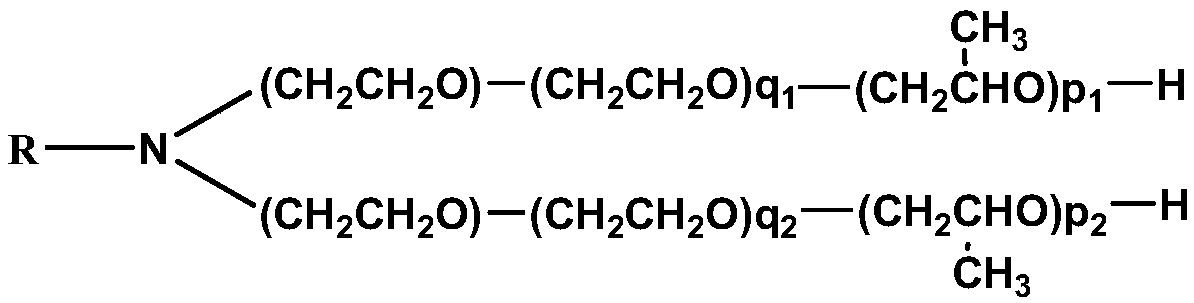

InactiveCN109609293AImprove surface activityReduce surface tensionNon-ionic surface-active compoundsOrganic detergent compounding agentsFuel tankGasoline

The invention discloses a non-disassembly automobile three-way catalyst cleaning agent. The cleaning agent is prepared from a surface active agent, a macromolecular amine dispersing agent, a fuel oilfriction improver, an anti-rust agent, a solvent and a gasoline additive. Some functional poly-molecular compounds are combined with a cleaning agent and auxiliaries, by directly adding the raw materials into an oil tank, the whole oil way is cleaned, stubborn carbon deposition and oil sludge on gas inlet system prats are effectively dissolved, and the problems of air vent clog, power decrease, oil consumption increase and the like are solved; the tail gas exhaust rate is lowered, a three-way catalyst is protected, and the service life is prolonged; operation steps are reduced, and the matteris settled at one go.

Owner:ZHONGSHAN FEITE YONGWANG AUTOMOTIVE PROD CO LTD

Oil and water separation and purification system for automobile coating wastewater

ActiveCN109678290AImprove separation efficiencyExtended temperature rangeFatty/oily/floating substances removal devicesTreatment involving filtrationBoiling pointEvaporation

The invention relates to an oil and water separation and purification system for automobile coating wastewater. The oil and water separation and purification system for the automobile coating wastewater comprises a wastewater collecting system, a crude separation system, a water separation type whirlcone, an oil separation type whirlcone as well as pipelines for connection, and is characterized inthat the crude separation system comprises a multi-stage filtering tower and a low-boiling-point evaporation device; coating wastewater is collected and differentiated by the wastewater collecting system, enters the multi-stage filtering tower to be filtered and enters the low-boiling-point evaporation device; high-boiling-point wastewater which flows out of the low-boiling-point evaporation device enters the water separation type whirlcone; low-boiling-point wastewater enters the oil separation type whirlcone; the multi-stage filtering tower and the low-boiling-point evaporation device communicate with a tail gas purification device; and spraying water of the tail gas purification device is connected with a water phase outlet of the oil separation type whirlcone. The wastewater is divided into two ways to be treated separately and the treatment quantity is large, so that the wastewater treatment efficiency is improved and the oil and water separation effect is improved; furthermore,waste water in the wastewater treatment process is purified, so that unpleasant odor or toxic and pungent odor generated in the wastewater treatment process is treated.

Owner:中汽(天津)系统工程有限公司

Treatment method of cyclohexanone saponification alkali waste

The invention relates to a treatment method of cyclohexanone saponification alkali waste. The method includes: injecting alkali waste into an alkali recovery furnace, using a fuel to help combustion, combusting the alkali waste in the presence of an oxygen-containing gas, subjecting the tail gas generated by combustion to electric dedusting to recover dry alkali ash, and leaving the melt generated from combustion to flow out from a furnace bottom chute. The method is characterized by: crushing the melt coming from the chute by a fluid into particles or powder, which then enter a water solution, then getting the particles or powder out of the water solution by a solid-liquid separation device, thus obtaining moisture-containing coarse alkali; using a feeding device to deliver the moisture-containing coarse alkali into a one-stage or multi-stage series dryer, which is provided with a scale plate conveyor line, a heat supply air hood, a stirrer and a dehumidifying air hood inside; introducing a high temperature gas into the dryer to serve as a drying heat source, and discharging the water vapor generated by water evaporation of the moisture-containing coarse alkali and the tail gas from thermal conversion out of the system by the dehumidifying air hood disposed in the dryer through a dehumidifying air course system; and after drying the moisture-containing coarse alkali by the dryer, discharging it from a last-stage dryer outlet. The method provided in the invention has the advantages that: complete recovery of melt generated by alkali waste combustion by means of drying the coarse alkali can achieve a good drying effect, the recovered material has a low water content, and no wastewater is generated. Thus, the method can be used for chemical industrial production of cyclohexanone and the like, and has good environmental protection significance and economic benefits.

Owner:CHINA PETROCHEMICAL CORP

Production process for surface-mounting ceramic LED package, surface-mounting ceramic LED package produced by said production process, and mold for producing said package

InactiveUS7871842B2Lower emission rateHigh yieldTailstocks/centresConfectionerySurface mountingMetallurgy

The present invention is related to a surface-mounting ceramic LED package and a method for its production comprising: layering a ceramic green sheet which has a hole and a second ceramic green sheet, inserting a mold with a groove to form a partition in the bottom of the ceramic green sheet substrate, and firing the ceramic green sheet substrate.

Owner:EI DU PONT DE NEMOURS & CO

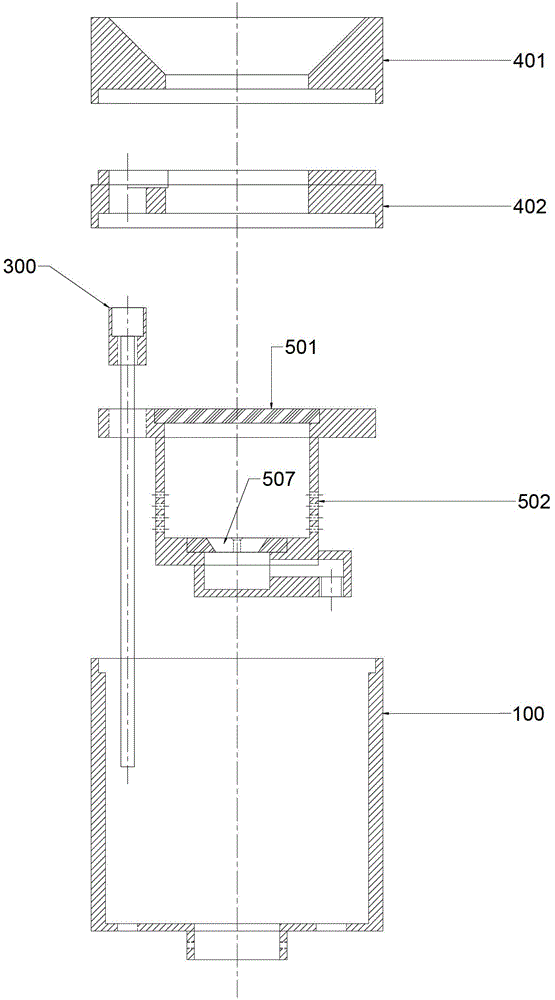

Primary dedusting system for rotating furnace

InactiveCN102586539ALow Dust Emission RateSimple structureManufacturing convertersIncreasing energy efficiencyCooling towerEvaporation

The invention relates to a primary dedusting system for a rotating furnace. The dedusting system comprises the rotating furnace, a spray cooling tower, a ring seam scrubbing tower, a dehydrator and a fan, wherein the coal gas in the rotating furnace is filled into the spray cooling tower through an evaporation flue, and is then sequentially filled into the ring seam scrubbing tower, the dehydrator and the fan through coal gas pipelines; the dedusting system also comprises a dehumidifier which is connected between the dehydrator and the fan in series; and one end of the dehydrator is connected with an outlet of the dehydrator, and the other end of the dehydrator is connected with an inlet of the fan. The primary dedusting system for the rotating furnace not only has lower dust emission rate, but also is simple in structure and lower in cost.

Owner:BAOSHAN IRON & STEEL CO LTD

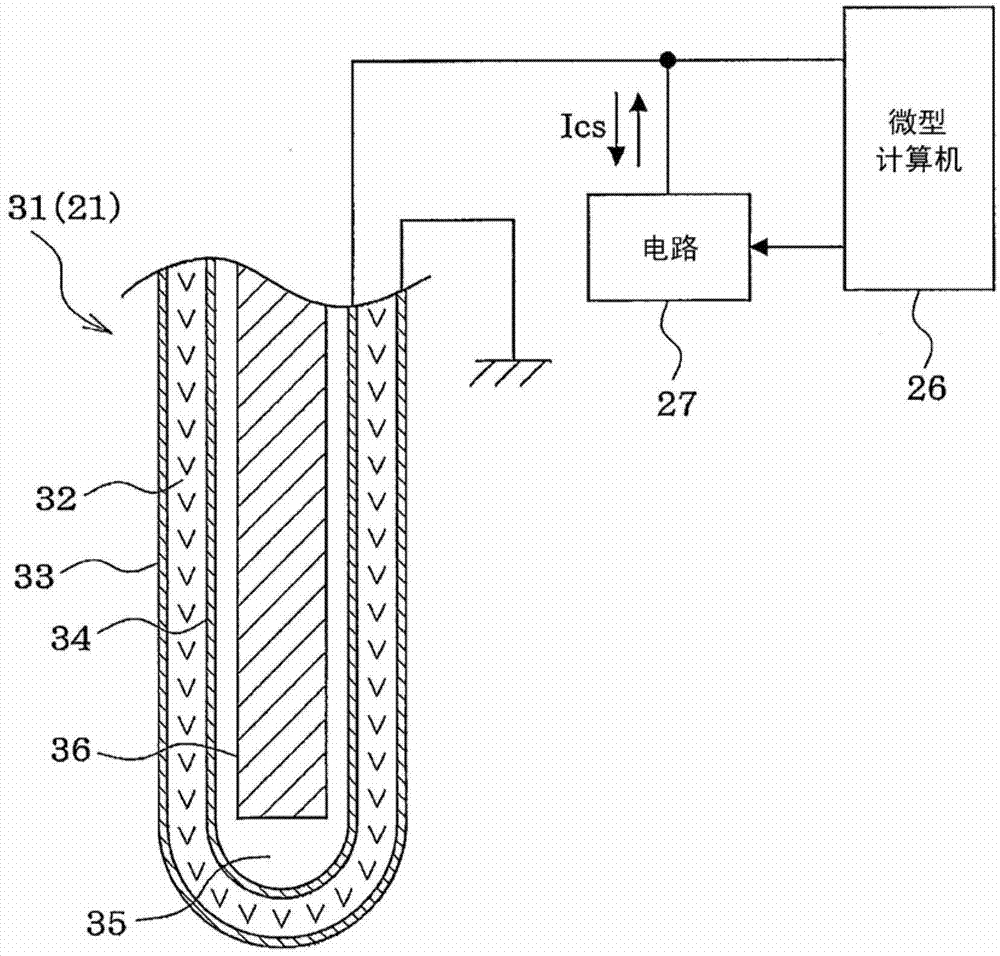

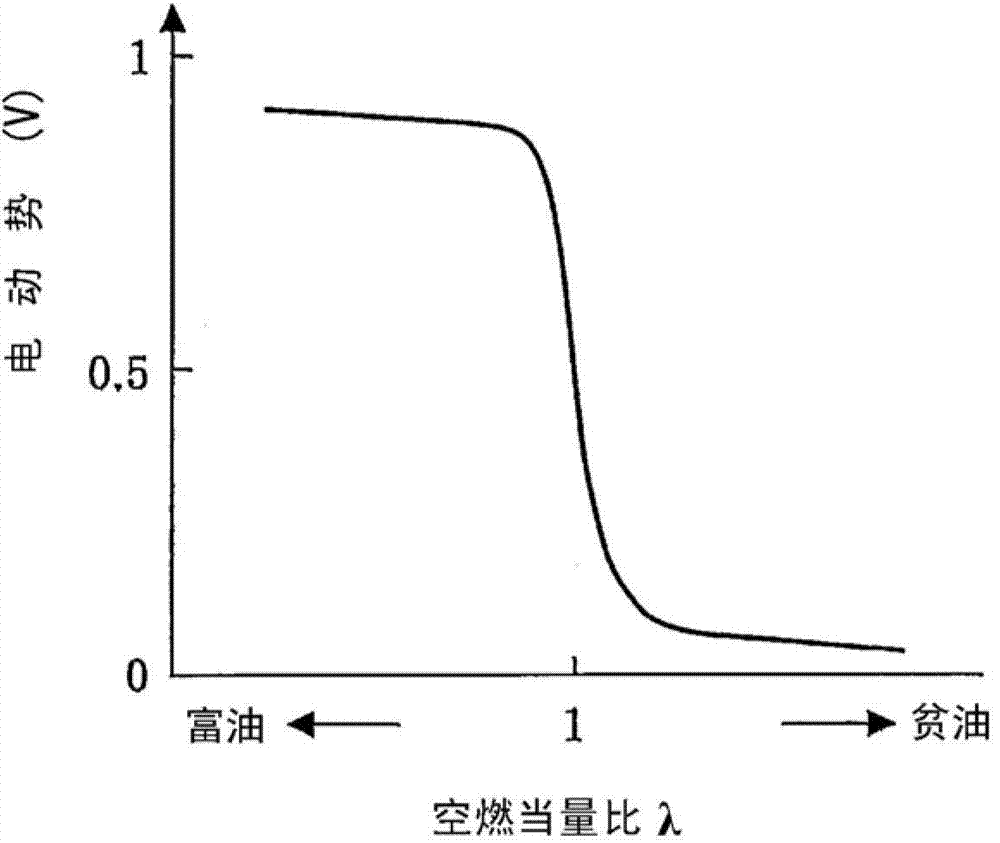

Emission control system for internal combustion engine

InactiveCN103244294AChange the output characteristicsLower emission rateElectrical controlExhaust apparatusPower flowExternal combustion engine

An emission control system for an engine includes a catalyst and an exhaust-gas sensor provided downstream of the catalyst in a flow direction of exhaust gas. The exhaust-gas sensor includes a sensor element that includes a pair of electrodes and a solid electrolyte body located between the electrodes. The emission control system further includes a constant current supply portion that changes an output characteristic of the exhaust-gas sensor by applying a constant current between the electrodes, a rich direction control portion that performs a rich direction control after a fuelling-stop control, and a characteristic control portion that performs a rich responsiveness control during the rich direction control. In the rich direction control, an air-fuel ratio of the exhaust gas is made to be richer. In the rich responsiveness control, the constant current supply portion increases a detection responsiveness of the exhaust-gas sensor with respect to rich gas.

Owner:DENSO CORP

Treatment method of cyclohexanone saponification alkali waste

The invention relates to a treatment method of cyclohexanone saponification alkali waste. The method includes: injecting alkali waste into an alkali recovery furnace, using a fuel to help combustion, combusting the alkali waste in the presence of an oxygen-containing gas, subjecting the tail gas generated by combustion to electric dedusting to recover dry alkali ash, and leaving the melt generated from combustion to flow out from a furnace bottom chute. The method is characterized by: crushing the melt coming from the chute by a fluid into particles or powder, which then enter a water solution, then getting the particles or powder out of the water solution by a solid-liquid separation device, thus obtaining moisture-containing coarse alkali; using a feeding device to deliver the moisture-containing coarse alkali into a one-stage or multi-stage series dryer, which is provided with a scale plate conveyor line, a heat supply air hood, a stirrer and a dehumidifying air hood inside; introducing a high temperature gas into the dryer to serve as a drying heat source, and discharging the water vapor generated by water evaporation of the moisture-containing coarse alkali and the tail gas from thermal conversion out of the system by the dehumidifying air hood disposed in the dryer through a dehumidifying air course system; and after drying the moisture-containing coarse alkali by the dryer, discharging it from a last-stage dryer outlet. The method provided in the invention has the advantages that: complete recovery of melt generated by alkali waste combustion by means of drying the coarse alkali can achieve a good drying effect, the recovered material has a low water content, and no wastewater is generated. Thus, the method can be used for chemical industrial production of cyclohexanone and the like, and has good environmental protection significance and economic benefits.

Owner:CHINA PETROCHEMICAL CORP

An integrated device and extraction method for arsenic recovery from non-ferrous smelting flue gas

ActiveCN109092007BTake advantage ofConvenient cycle workCombination devicesGas treatmentFlue gasEnvironmental engineering

The invention provides an integrated device for recovering arsenic from non-ferrous smelting flue gas and an extraction method. The device includes a fan connected in sequence, a high-efficiency dust collector, an arsenic analysis and arsenic removal device, and a rapid cooling arsenic collection device. The arsenic analysis and arsenic removal device is equipped with The turntable is connected with the driving device through the transmission shaft. The turntable is provided with a through hole for passing the flue gas. The turntable is equipped with an interception pipe for absorbing flue gas dust and is used to divide the arsenic analysis and arsenic removal device into an arsenic analysis area and an arsenic removal area. The upper and lower ends of the arsenic analysis area, the arsenic removal area and the injection area are respectively provided with an upper connection port and a lower connection port, and the lower connection port of the arsenic analysis area is connected with a high-efficiency dust collector, and the arsenic analysis area The upper connection port of the arsenic removal area is connected with the upper connection port of the blowing area, the arsenic analysis area is also connected with a cooling device, the arsenic removal area is connected with a heating device, and the upper connection port of the arsenic removal area is connected with a quenching arsenic collection device. The invention can continuously recover the arsenic and improve the purity of the recovered finished arsenic.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

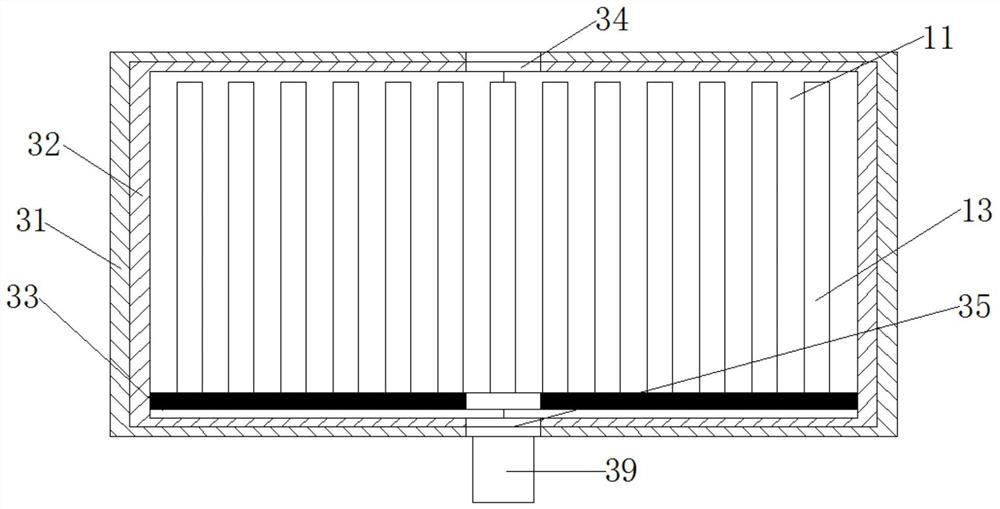

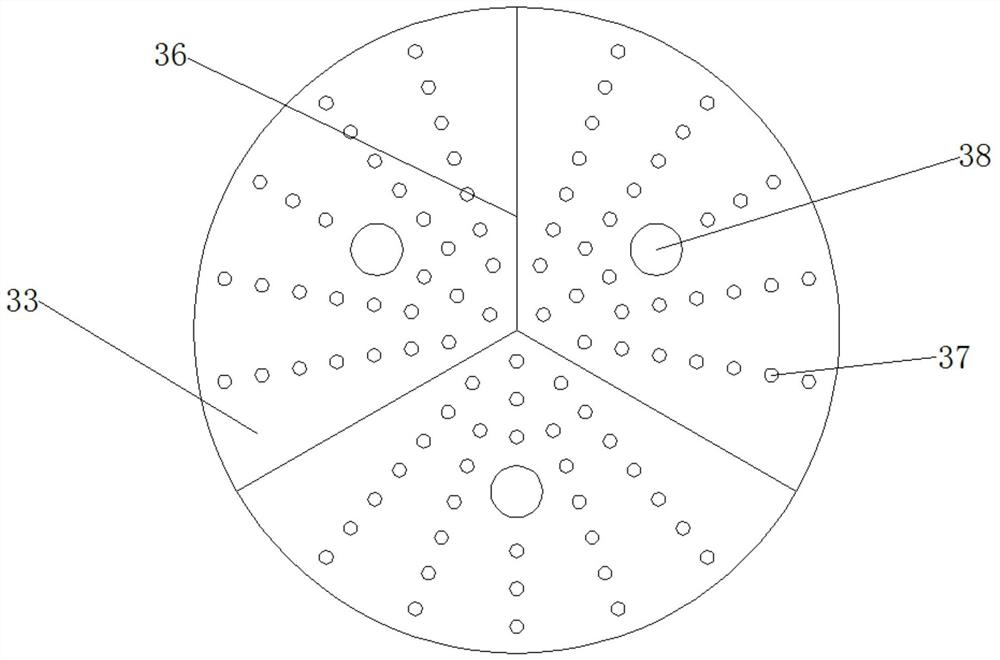

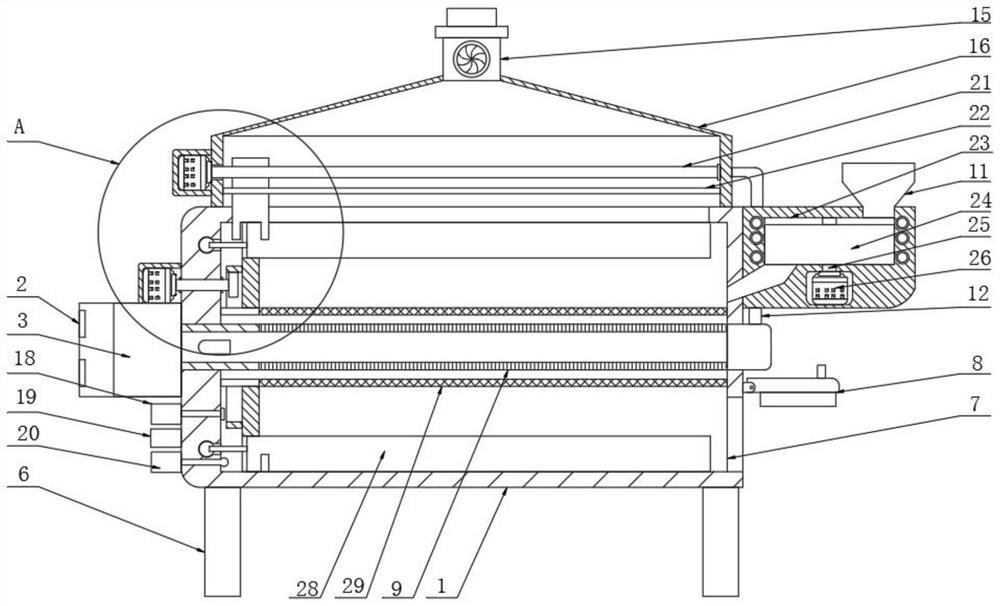

Grain drying and dehumidifying heat pump unit and grain drying circulation heat pump system

PendingCN113670037AIncrease profitImprove drying efficiencyHeat pumpsFood processingThermodynamicsEngineering

The invention discloses a grain drying and dehumidifying heat pump unit and a grain drying circulation heat pump system. According to the technical scheme, the grain drying and dehumidifying heat pump unit and the grain drying circulation heat pump system comprise a drying chamber, a drying cavity is formed in the interior of the drying chamber, a drying and dehumidifying mechanism is arranged in the interior of the drying cavity, a circulation preheating mechanism is arranged on one side of the drying chamber, the drying and dehumidifying mechanism comprises an exhaust pipe, the exhaust pipe is arranged in the interior of the drying cavity, the two ends of the exhaust pipe both penetrate through the drying chamber, the exterior of the exhaust pipe is provided with a material blocking cover plate in a sleeved mode, the two ends of the material blocking cover plate are fixedly connected with the side wall of the drying cavity, the exterior of the material blocking cover plate is provided with a disc in a sleeved mode, and one side of the disc is fixedly connected with an annular inner gear. The grain drying and dehumidifying heat pump unit and the grain drying circulation heat pump system have the beneficial effects that the influence and pollution to the environment during grain drying are reduced, the labor intensity during grain drying is reduced, the automation degree of the drying process is improved, meanwhile, the hot air pushing efficiency is high, the drying efficiency is high, hot air circulation conveying is achieved, the hot air utilization rate is improved, and energy conservation and environment protection are achieved.

Owner:安徽齐品农业发展有限公司

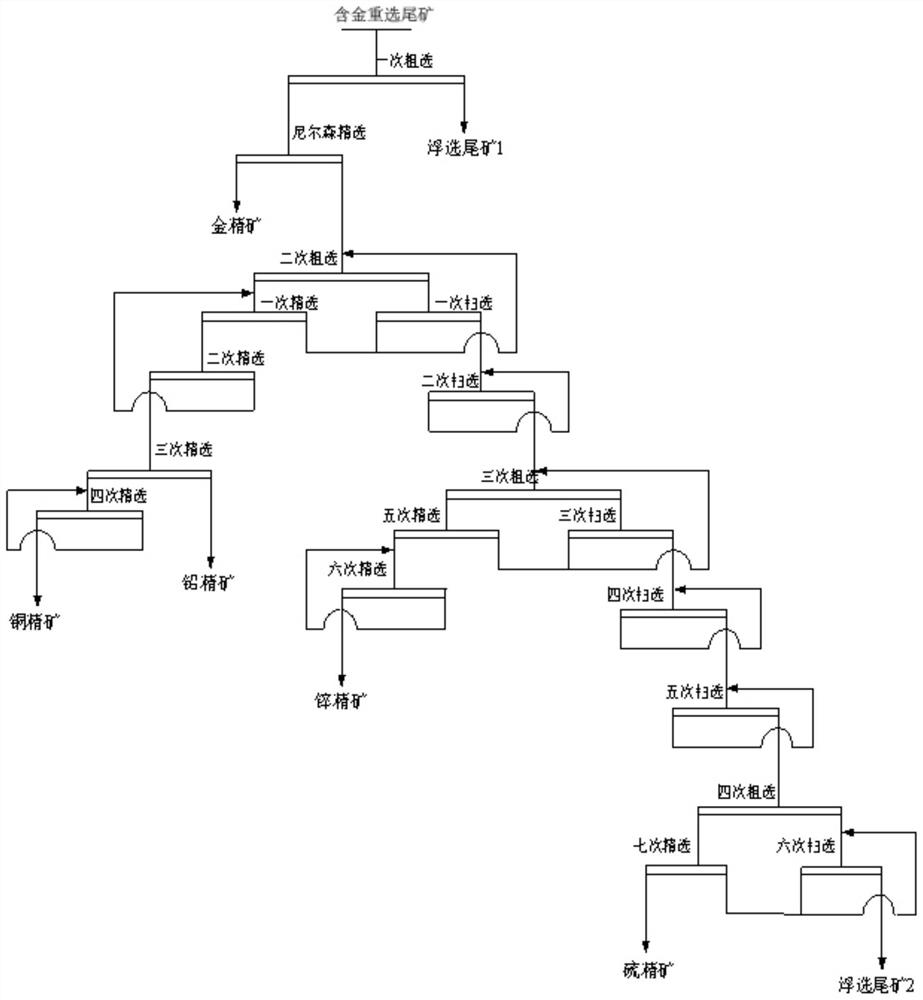

A kind of beneficiation method for recovering polymetallic from gold-bearing gravity separation tailings

Owner:NORTHEASTERN UNIV LIAONING

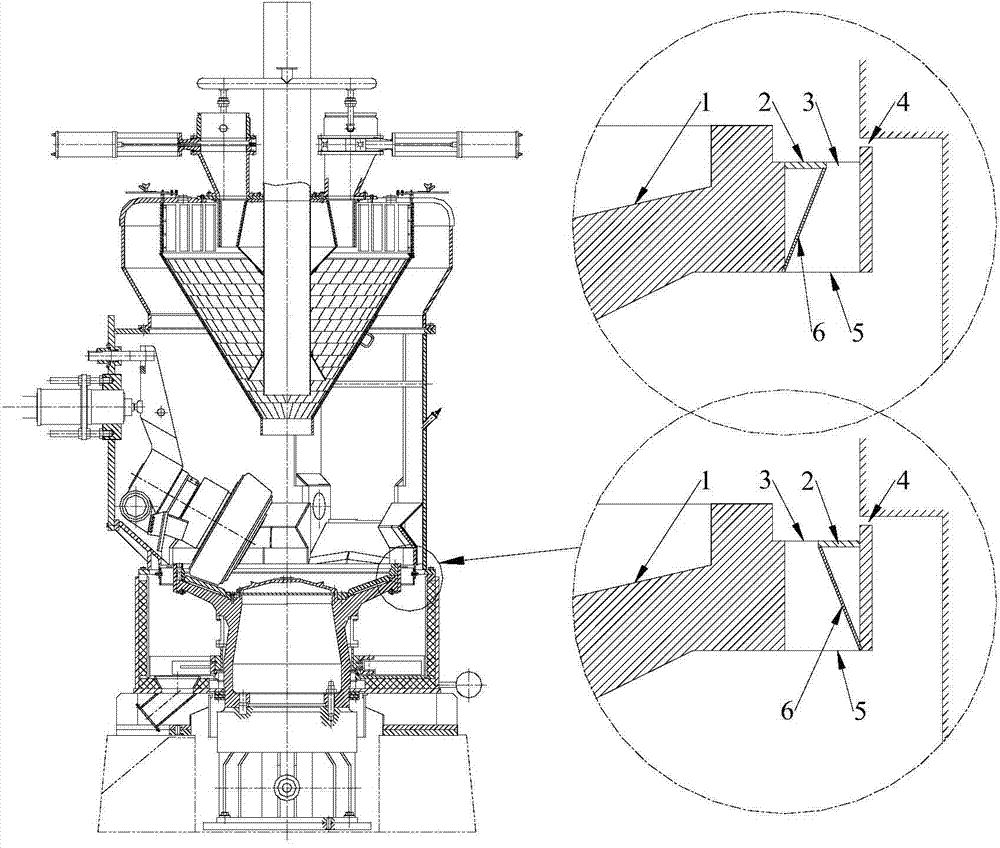

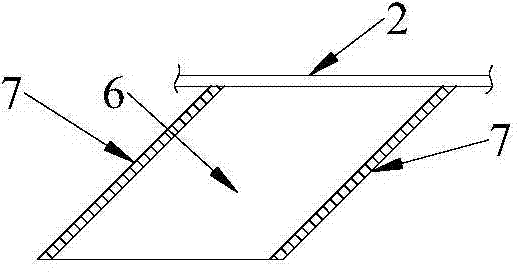

a burner

ActiveCN103062769BImprove combustion efficiencyLower emission rateBurner safety arrangementsGaseous fuel burnerCombustorExhaust fumes

The invention relates to a combustor. The combustor comprises a shell and a furnace body arranged in the shell, the furnace body comprises an igniter, a combustion device and an air and gas mixing device, a flame stabilizing pad used for controlling air and gas mixed gas is further arranged between the combustion device and the air and gas mixing device and is provided with a plurality of groups of air and gas passages arranged surrounding the center of the flame stabilizing pad, each group of air and gas passages comprises a plurality of holes with the axes inclining towards a certain direction, and the holes of the air and gas passages are the same in inclining direction. The flame stabilizing pad can enable the air and gas mixed gas to form spiral gas flow, so that air and gas are mixed more sufficiently, combustion efficiency of the mixed gas is improved, and emission ratio of waste gases such as carbon monoxide is further decreased.

Owner:MEGA ENERGY SCI TECH

Cooling Tower Saturated Water Vapor Recovery Device and Water Saving System Using It

ActiveCN106197061BLower emission rateReduce cost inputSpecific water treatment objectivesTreatment involving filtrationWater savingCooling tower

The invention discloses a cooling tower saturated steam recovery device and a water saving system applying the same. The recovery device comprises a cooling tower body; a conical cap-shaped steam recovery device fully covers the top of the cooling tower body; the steam recovery device includes multiple refrigerant water pipes communicated in multiple directions, and multiple steam recovery units transversely arranged between the refrigerant water pipes closely; the refrigerant water pipes and the steam recovery units are communicated with each other; a refrigerant medium is filled in a cavity; a workshop heat exchange system of the water saving system is connected with the recovery device; a recovery pool is arranged below the recovery device, and is connected with the workshop heat exchange system; a water quality purifier is arranged between the recovery pool and the workshop heat exchange system; and the recovery pool is connected with a water quality stabilizer feeding device. The cooling tower steam recycling rate is higher than 85%, and all steam can be nearly recovered, so tat the emission rate is largely reduced, the water resource utilization rate is increased, and the cost investment is reduced.

Owner:SHIJIAZHUANG LVJIE ENERGY SAVING TECH CO LTD

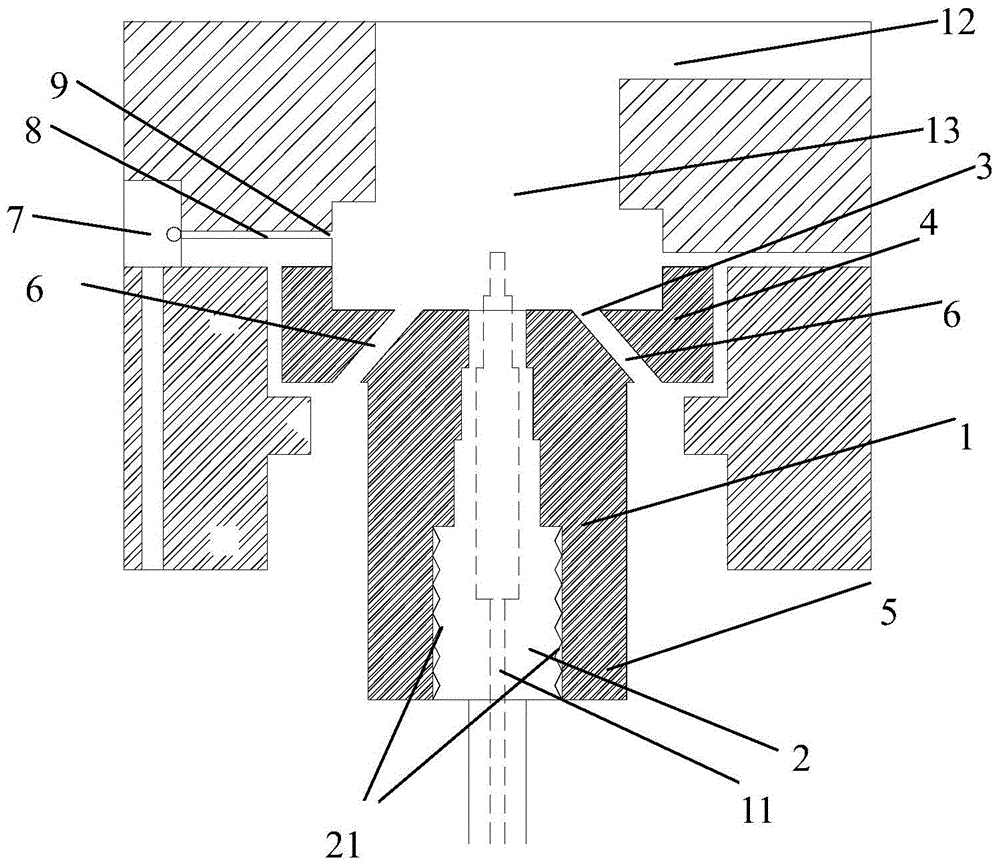

Burner and igniter thereof

ActiveCN104696959BWell mixedImprove combustion efficiencyCombustion ignitionGaseous fuel burnerCombustorCombustion chamber

A burner and an igniter thereof. The burner comprises a combustion gas apparatus, a pressurized air chamber, an igniter, and a combustion area. The combustion gas apparatus comprises a combustion gas chamber (7), a combustion gas channel (8), and a combustion gas outlet (9). The igniter comprises a pressurized air introduction apparatus (1) and an ignition channel (2) that penetrates the pressurized air introduction apparatus (1). The top of the pressurized air introduction apparatus (1) is provided with a recess area (3), and the bottom is provided with multiple air channels (6) that circle the center of the pressurized air introduction apparatus (1). The axes of the multiple air channels (6) are inclined in a same direction such that compressed air is guided to the bottom of the recess area (3) so as to form a rotating air flow that move upwards. The inclining direction of the axes of the multiple air channels (6) is the same as the direction of the combustion gas that enters into the recess area (3) from the combustion gas channel (8), such that the combustion gas is guided into a low pressure area of the rotating air flow that moves upwards, thereby fully mixing the gas and air.

Owner:MEGA ENERGY SCI TECH

Guide apparatus of medium speed coal mill vane throat ring

InactiveCN104772207AReduce local resistanceIncrease wind speedGrain treatmentsDifferential pressureDischarge rate

The invention discloses a guide apparatus of a medium speed coal mill vane throat ring. The guide apparatus comprises a guide plate, the guide plate is arranged at the lower portion of the medium speed coal mill vane throat ring, the upper end of the guide plate is fixed to the edge of the throat ring close to a vane outlet area, and the lower end of the guide plate is fixed to the edge of a vane inlet close to a primary air chamber. The upper end of the guide plate has a same arc degree with the flow position wall surface of the throat ring, the lower end of the guide plate has a same arc degree with the inlet wall surface of the vane, two sides of the guide plate are inclined planes, an inclined angle between each of the inclined planes and a horizontal plane is same to the inclined angles of eddy flow blades, and the thickness of the guide plate is not lower than 5mm. The quantity of the guide plate is same to the quantity of the eddy flow blades in the vane. The guide apparatus can reduce local resistance of the throat ring, reduces the mill bowl differential pressure by about 500Pa, and also reduces the air leakage rate of the dynamic and static clearance of the vane in order to increase the air speed of the outlet of the vane, reduce the pebble coal discharge rate and improve the milling output of the coal mill.

Owner:ZHEJIANG UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com