Non-disassembly automobile three-way catalyst cleaning agent

A three-way catalytic converter and cleaning agent technology, which is applied in the direction of detergent composition, detergent compounding agent, detergent composition solvent, etc., can solve the problems of long working hours, difficult operation, unsuitable for car owners, etc., and achieve extended use Long life, reduce operation steps, improve the effect of poor exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Raw material of cleaning agent for three-way catalytic converter without disassembly:

[0046] Surfactant 20%

[0047] Polymer amine dispersant 15%

[0048] Fuel Friction Modifier 10%

[0049] Rust inhibitor 10%

[0050] Solvent 35%

[0051] Gasoline Additive 10%

[0052] Among them, the surfactant is a silicone component, and its structural formula is B(A)mB: wherein, m is 2; A is a diallyl polymer polyether, and its structural formula is: -CH 2 -CH(CH 3 ) 2 -O-[CH 2 -CH 2 O]x-[CH 2 -CHR-O-]y-CH(CH 3 ) 2 -CH 2 -, wherein x=y=200; R is H; B is hydrophobic silicone, and its structural formula is: -Si(CH 3 )-[O-Si(CH 3 ) 3 ] 2 .

[0053] The polymer polar amine dispersant is BASF Kerocom PIBA 03.

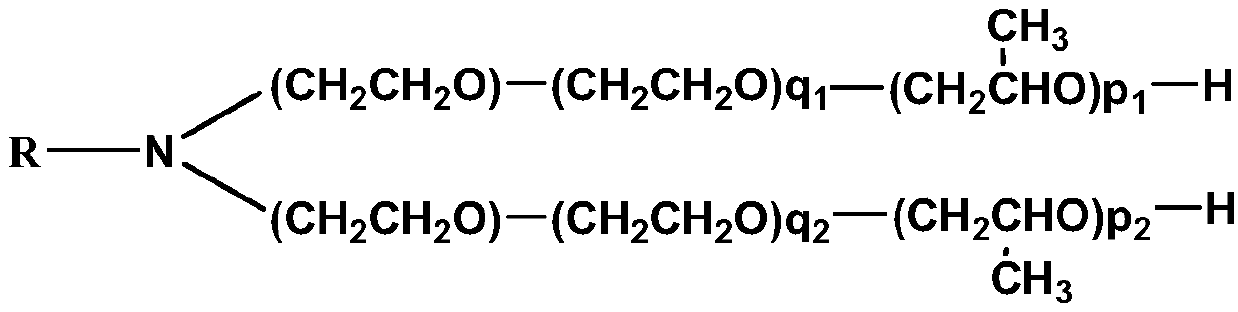

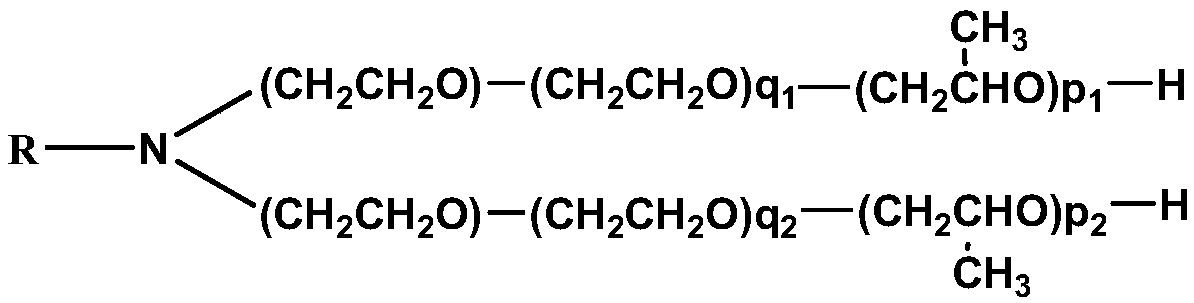

[0054] The fuel friction modifier adopts polyether modified animal and vegetable amines, and its structural formula is:

[0055]

[0056]Wherein, R is sunflower oil; q1+q2=30, p1+p2=60, q1=q2=15, p1=p2=30,.

[0057] The antirust agent is coconut acid diet...

Embodiment 2

[0060] Raw material of cleaning agent for three-way catalytic converter without disassembly:

[0061] Surfactant 15%

[0062] Polymer amine dispersant 25%

[0063] Fuel Friction Modifier 6%

[0064] Rust inhibitor 5%

[0065] Solvent 34%

[0066] Gasoline Additive 15%

[0067] Among them, the surfactant is a silicone component, and its structural formula is B(A)mB: wherein, m is 2; A is a diallyl polymer polyether, and its structural formula is: -CH 2 -CH(CH 3 ) 2 -O-[CH 2 -CH 2 O]x-[CH 2 -CHR-O-]y-CH(CH 3 ) 2 -CH 2 -, where x is 80, y is 200; R is H; B is hydrophobic silicone, and its structural formula is: -Si(CH 3 )-[O-Si(CH 3 ) 3 ] 2 .

[0068] The polymer polar amine dispersant is Huntsman Surfonamine B-100.

[0069] The fuel friction modifier adopts polyether modified animal and vegetable amines, and its structural formula is:

[0070]

[0071] Wherein, R is linseed oil; q1+q2=0, p1+p2=0, q1=q2=p1=p2=0.

[0072] The antirust agent is coconut oil mo...

Embodiment 3

[0075] Raw material of cleaning agent for three-way catalytic converter without disassembly:

[0076] Surfactant 1%

[0077] Polymer amine dispersant 20%

[0078] Fuel Friction Modifier 10%

[0079] Rust inhibitor 5%

[0080] Solvent 54%

[0081] Gasoline Additive 10%

[0082] Among them, the surfactant is a silicone component, and its structural formula is B(A)mB: wherein, m is 200; A is a diallyl polymer polyether, and its structural formula is: -CH 2 -CH(CH 3 ) 2 -O-[CH 2 -CH 2 O]x-[CH 2 -CHR-O-]y-CH(CH 3 ) 2 -CH 2 -, where x=y=145; R is H; B is hydrophobic silicone, and its structural formula is: -Si(CH 3 )-[O-Si(CH 3 ) 3 ] 2 .

[0083] The polymer polar amine dispersant is Surfonamine L-100.

[0084] The fuel friction modifier adopts polyether modified animal and vegetable amines, and its structural formula is:

[0085]

[0086] Wherein, R is cotton seed oil; q1+q2=20, p1+p2=30, q1=5, q2=15, p1=10, p2=20.

[0087] The antirust agent is oleic acid mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com