A kind of beneficiation method for recovering polymetallic from gold-bearing gravity separation tailings

A technology for gravity separation of tailings and beneficiation methods, applied in solid separation and other directions, can solve the problems of low comprehensive recovery rate and comprehensive utilization rate of metals, and achieve the effects of low environmental pollution, low emission rate and huge economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

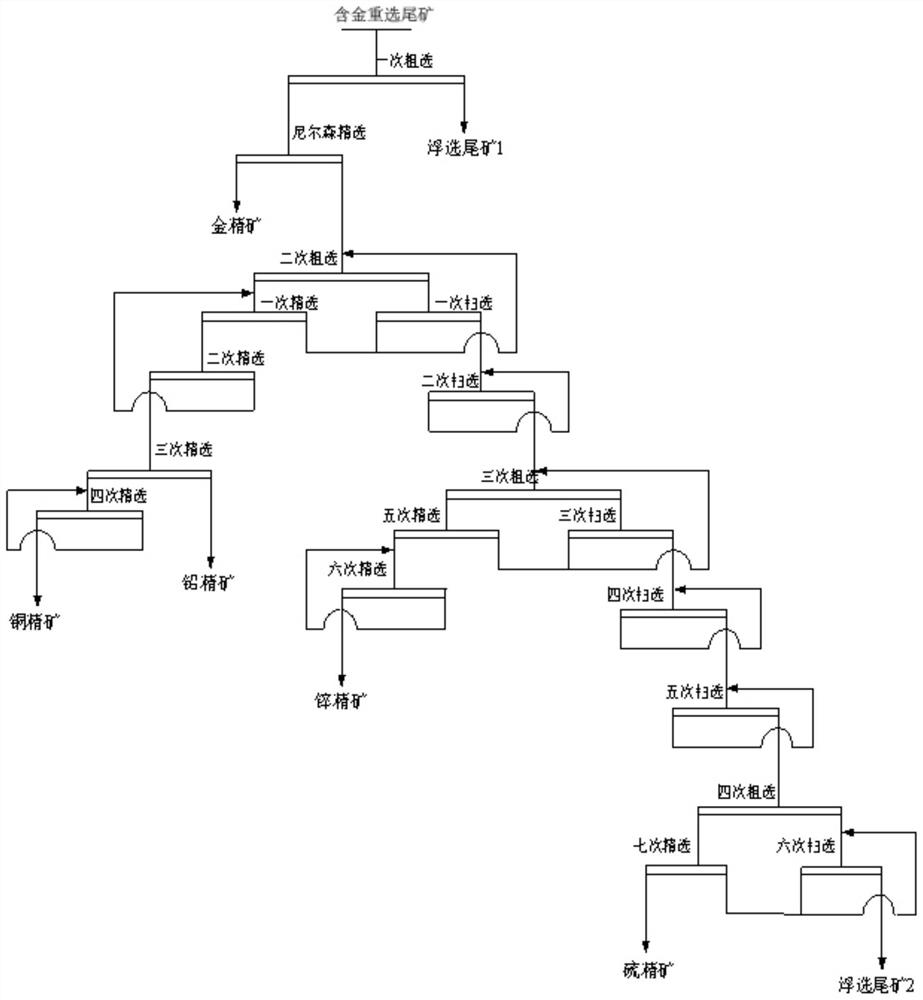

[0029] Process such as figure 1 shown;

[0030] Add water to the gold-bearing gravity separation tailings and stir to make a slurry with a mass concentration of 35%; the gold-containing gravity separation tailings are gravity separation tailings obtained from gold-bearing lead-zinc ores after jigging gravity separation, and their solid components contain 1.5g of Au / t, containing Pb18%, Cu 2.0%, Zn 2.7% by mass percentage, and the part with a particle size of ≤0.074 mm accounts for 85% of the total mass;

[0031] Add activator water glass to the pulp, and then stir evenly to make activated pulp; the amount of water glass added is based on the solid content of 300g / t pulp;

[0032] Put the activated pulp in the flotation machine, add collectors and foaming agents in sequence, and then perform a roughing to obtain a roughing concentrate and a roughing tailings; the collector is butyl xanthate , the addition amount is according to the solid component in 200g / t ore slurry; The d...

Embodiment 2

[0045] Method is with embodiment 1, and difference is:

[0046] (1) The mass concentration of ore pulp is 40%; the solid component of gold-bearing gravity separation tailings contains Au 1.3g / t, and contains Pb15%, Cu 1.8%, Zn 2.5% by mass percentage, and the part with a particle size of ≤0.074 mm accounts for the total mass 90%;

[0047] (2) The amount of water glass added is based on the solid content of 350g / t pulp;

[0048] (3) The amount of butyl xanthate added is based on the solid content of 150g / t pulp; 11 # The amount of oil added is based on the solid content of 40g / t pulp;

[0049] (4) The mass concentration of the secondary pulp is 40%, and the gravity value selected by Nielsen is 60G;

[0050] (5) The mass concentration of the tertiary pulp is 33%; the tertiary pulp is added with lime to adjust the pH value to 11; the amount of zinc sulfate added is 350g / t according to the solid content of the tertiary pulp; , the addition of pine oil is 55g / t three times the ...

Embodiment 3

[0060] Method is with embodiment 1, and difference is:

[0061] (1) The mass concentration of ore pulp is 45%; the solid component of gold-bearing gravity separation tailings contains Au 1.2g / t, and contains Pb12%, Cu 1.6%, Zn 2.3% by mass percentage, and the part with a particle size of ≤0.074 mm accounts for the total mass 95%;

[0062] (2) The amount of water glass added is based on the solid content of 300g / t pulp;

[0063] (3) The amount of butyl xanthate added is based on the solid content of 100g / t pulp; 11 # The amount of oil added is based on the solid content of 30g / t pulp;

[0064] (4) The mass concentration of the secondary pulp is 50%, and the gravity value selected by Nielsen is 40G;

[0065] (5) The mass concentration of the tertiary pulp is 35%; the tertiary pulp is added with lime to adjust the pH value to 10; the amount of zinc sulfate added is 300g / t the solid component of the tertiary pulp; the addition of ethylsulfide nitrogen is 400g / t the solid compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com