Device capable of conducting dust removal and arsenic recovery on non-ferrous smelting smoke at same time

A smelting flue gas and non-ferrous technology, applied in the field of environmental protection and metallurgy, can solve the problems of unfavorable arsenic purity and failure to deal with it, and achieve the effects of improving purity, reducing the impact of impurities, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

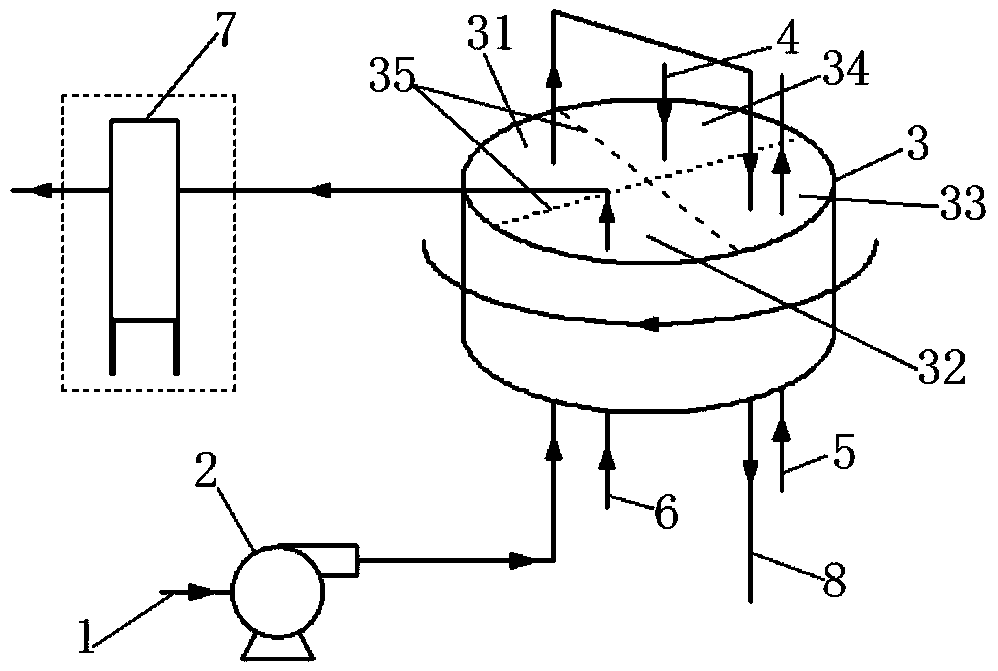

[0020] Such as figure 1 , figure 2 As shown, the present invention is a device capable of simultaneously removing dust and collecting arsenic from non-ferrous smelting flue gas, including a fan (2), an integrated device for dust removal and analysis (3) and a rapid cooling and arsenic collecting device (7), which are connected in sequence. : The dust removal and arsenic integrated device (3) includes a turntable (38), an outer casing (30) and a turntable driving device; the turntable (38) is installed in the outer casing (30), and the turntable (38) and the outer casing (30 ) is provided with a sealing layer (39); there are several installation holes evenly distributed in the four partitions on the turntable (38), each installation hole is equipped with an interception pipe (36), and the interception pipe is used for dust interception and the precipitation of arsenic; the inner side of the turntable (38) is also provided with a partition (35), which divides the turntable (38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com