Combustor for gas turbine engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

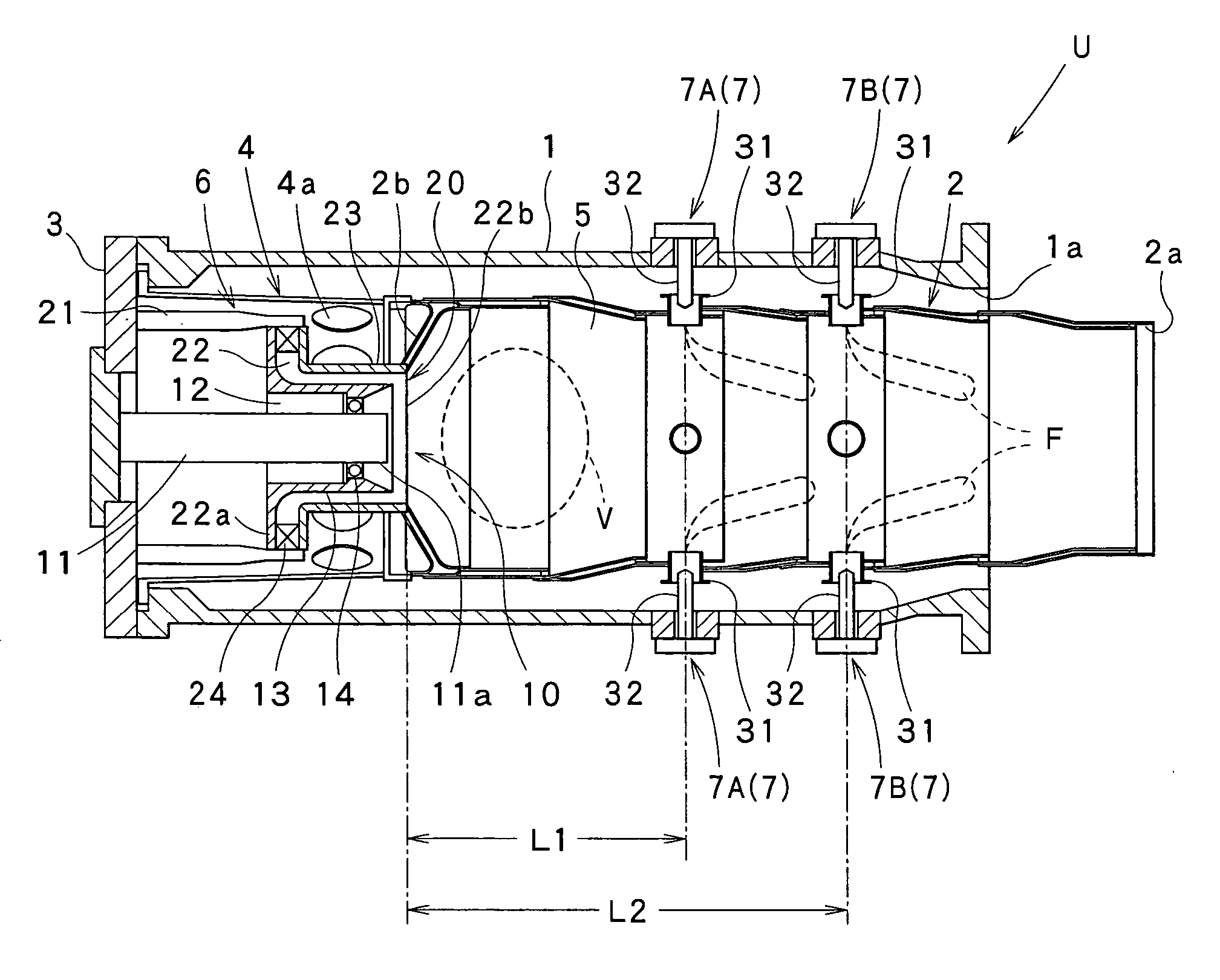

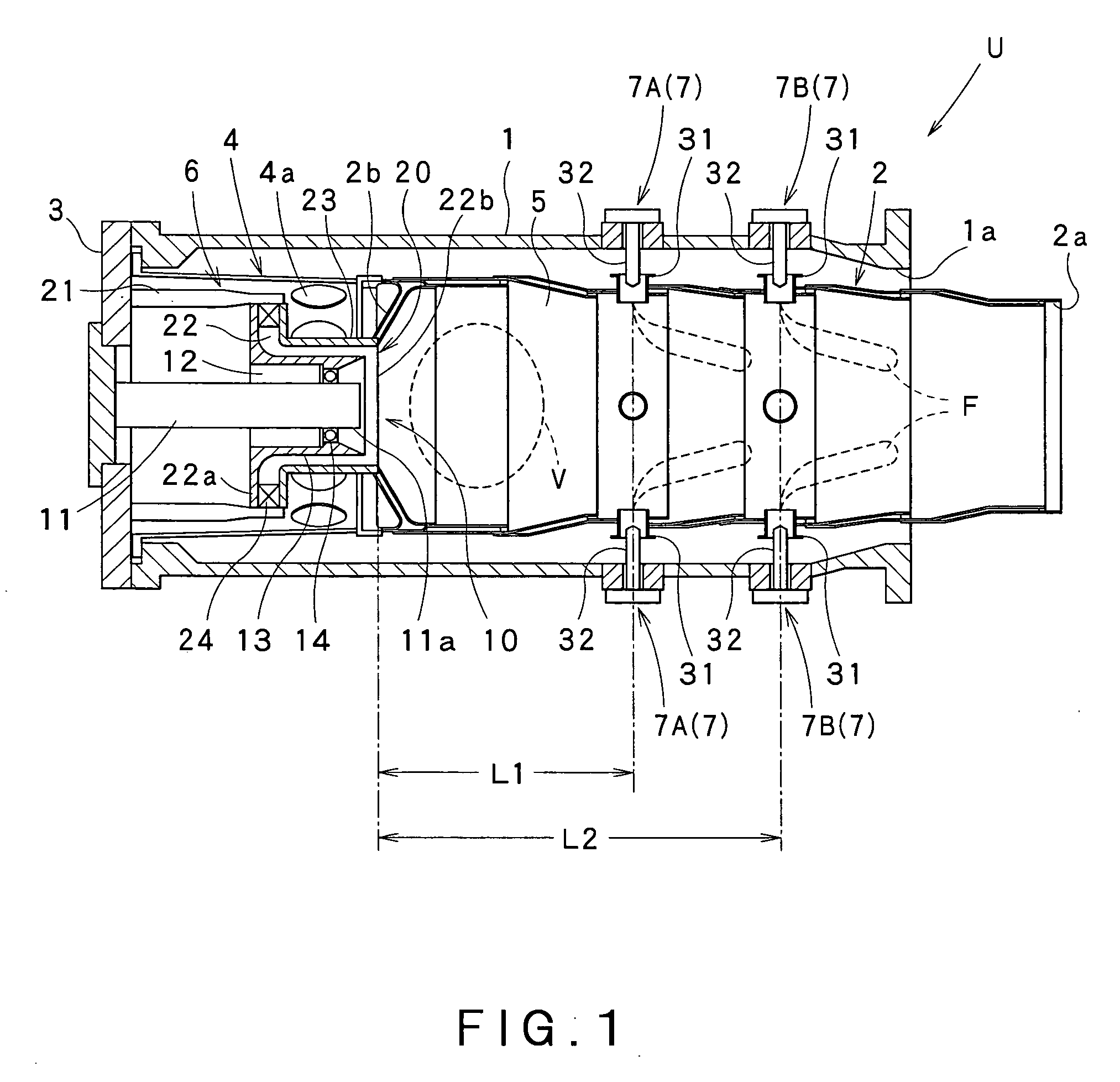

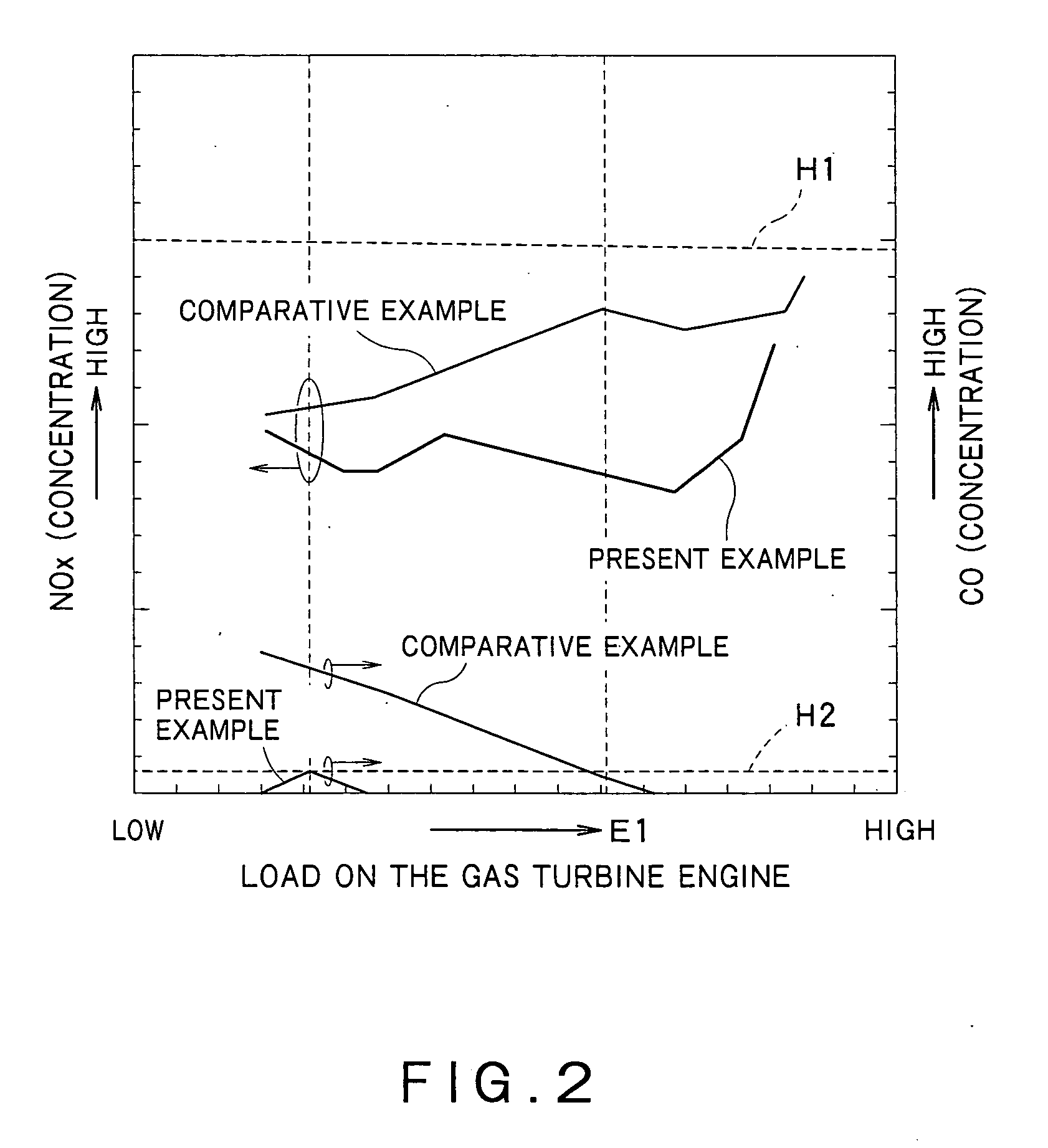

[0020] A combustor in a preferred embodiment according to the present invention will be described by way of example with reference to FIGS. 1 and 2.

[0021] Referring to FIG. 1 showing a combustor U in a preferred embodiment according to the present invention included in a gas turbine engine, the combustor U has a combustor casing including a flow sleeve 1, namely, an outer sleeve, and an inner tube 2, namely, an inner sleeve, extended inside the flow sleeve 1.

[0022] One end of the flow sleeve 1 and one end of the inner tube 2 are closed by an end wall 3. The other end of the flow sleeve 1 is an air inlet 1a and the other end of the inner tube 2 is an exhaust outlet 2a.

[0023] The interior of the inner tube 2 is divided into a liner head 4 on the side of the end wall 3 and a combustion chamber 5 on the side of the exhaust outlet 2a by a partition wall 2b having a shape resembling an annular plate disposed at a predetermined longitudinal position.

[0024] The liner head 4 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com