Method for preparing conducting film LiFePO4 cladding material containing nitrogen

A conductive carbon film, coating technology, used in chemical instruments and methods, circuits, electrical components, etc., can solve problems such as no precedent, no successful precedent, etc., to control reaction temperature and reaction time, fast reaction temperature and reaction. Good consistency of time and crystal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment one: Paste preparation

[0038] Take 222.9 grams of FePO with a purity of 99.99% 4 4H 2 O with 99.99% pure LiOH H 2 O. The polyacrylonitrile emulsion (40 wt %) was placed in a ball mill tank at 800 rpm for 10 minutes at a mass ratio of 9.31:1:5 to prepare a paste.

Embodiment 2

[0039] Embodiment two: paste dehydration

[0040] Take 222.9 grams of FePO with a purity of 99.99% 4 4H 2 O with 99.99% pure LiOH H 2 O and polyacrylonitrile emulsion (40wt%) were placed in a ball mill tank with a mass ratio of 9.31: 1: 15 and mixed for 20 minutes at a speed of 600 rpm to make a paste, put it into a quartz reactor, and adjust the microwave output power to 1KW , so that the temperature of the reactants was controlled at 150°C. FePO 4 4H 2 O and LiOHH 2 Emulsion polymerization and dehydration of O and polyacrylonitrile to form spherical FePO coated with polyacrylonitrile membrane 4 and LiOH mixture. FePO 4 And the particle size of LiOH is less than 100nm.

Embodiment 3

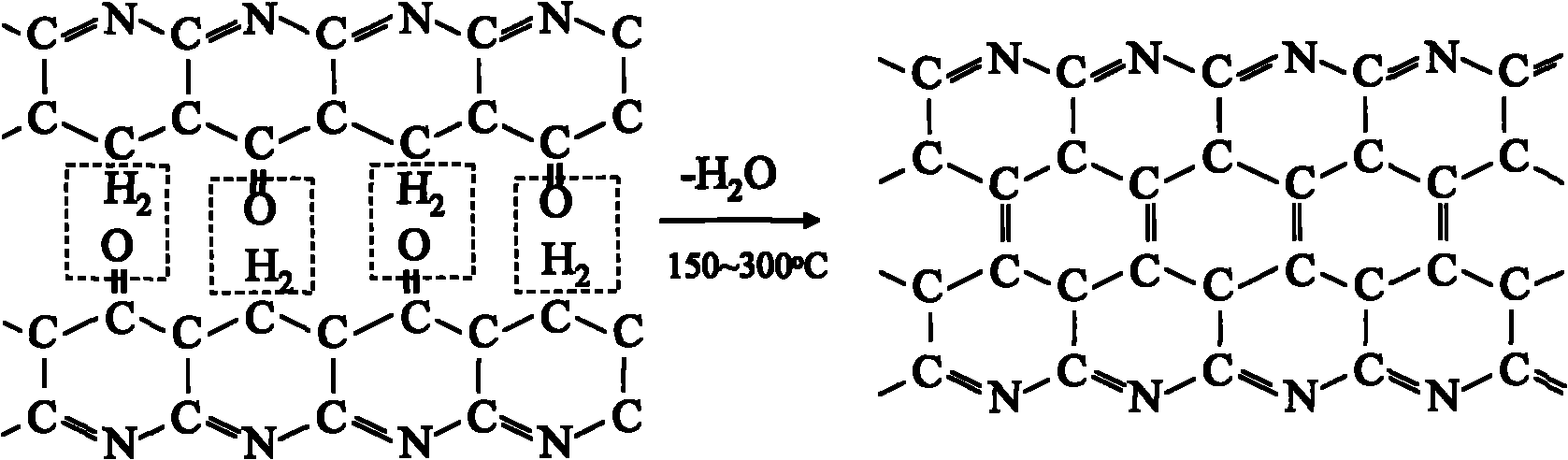

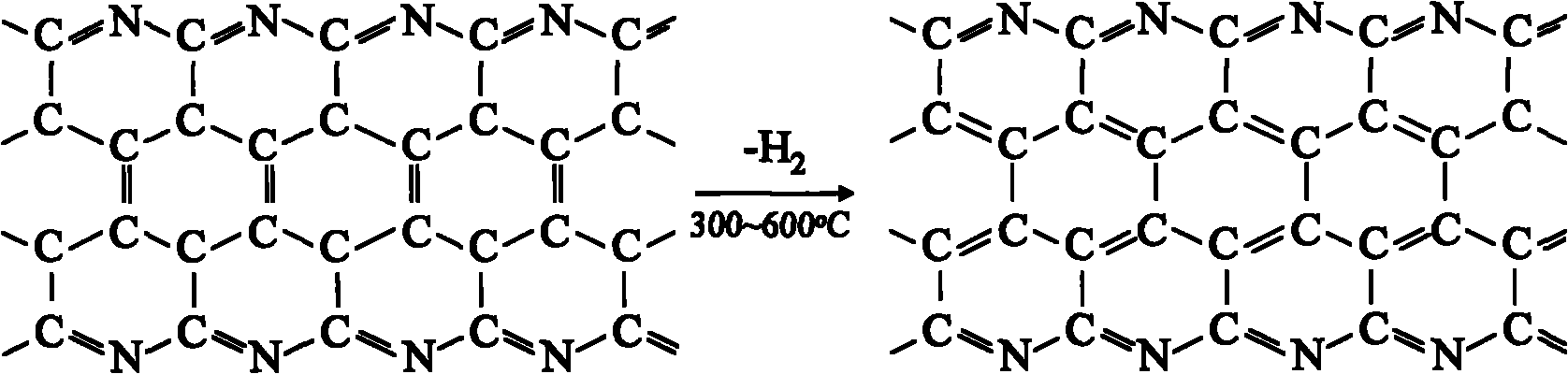

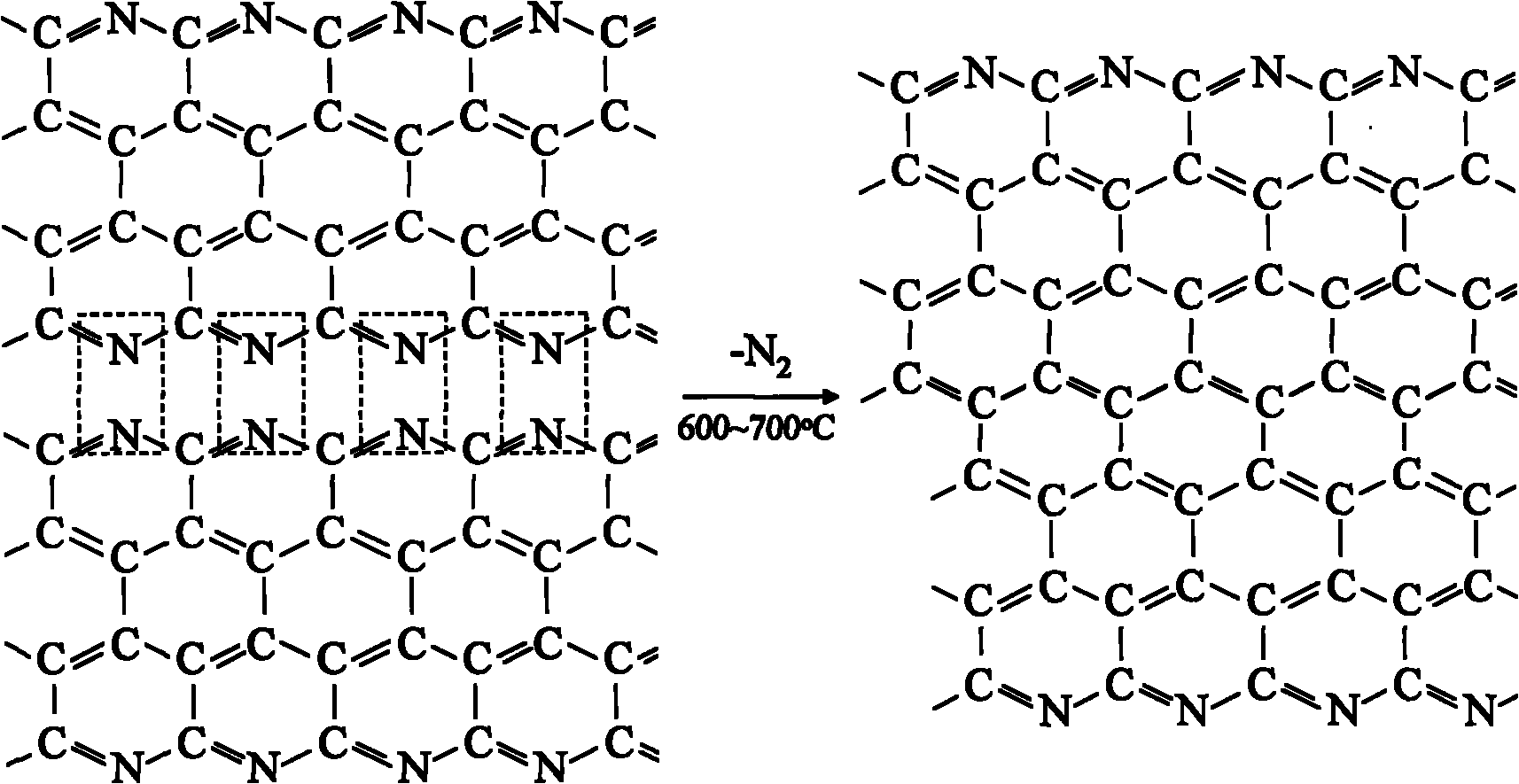

[0041] Example 3: Formation prototype of carbonized film

[0042] Take 222.9 grams of FePO with a purity of 99.99% 4 4H 2 O with 99.99% pure LiOH H 2 O and polyacrylonitrile emulsion (40wt%) were placed in a ball mill tank with a mass ratio of 9.31: 1: 20 and mixed for 30 minutes at a speed of 200 rpm to make a paste and put it into a quartz reactor. Adjust the microwave output power to 1KW , so that the temperature of the reactants was controlled at 150°C. FePO 4 4H 2 O and LiOHH 2 Emulsion polymerization and dehydration of O and polyacrylonitrile to form FePO coated with polyacrylonitrile membrane 4 and LiOH mixture. Oxygen was introduced into the reactor at a rate of 10mL / min, and the microwave output power was increased to control the temperature rise of the reactant at 1°C / min from 150°C to 300°C. 4 The cyclization reaction and stabilization process of the polyacrylonitrile film occur on the LiOH mixture particles, forming an incomplete carbonized film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com