Magnesium alloy plate working method and special apparatus

A sheet material processing method, magnesium alloy sheet technology, applied in applications, household appliances, other household appliances, etc., can solve the problems of low density, unfavorable electronic shielding effect, low strength and rigidity, etc., and achieve good plasticity, strength and rigidity performance Excellent, good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

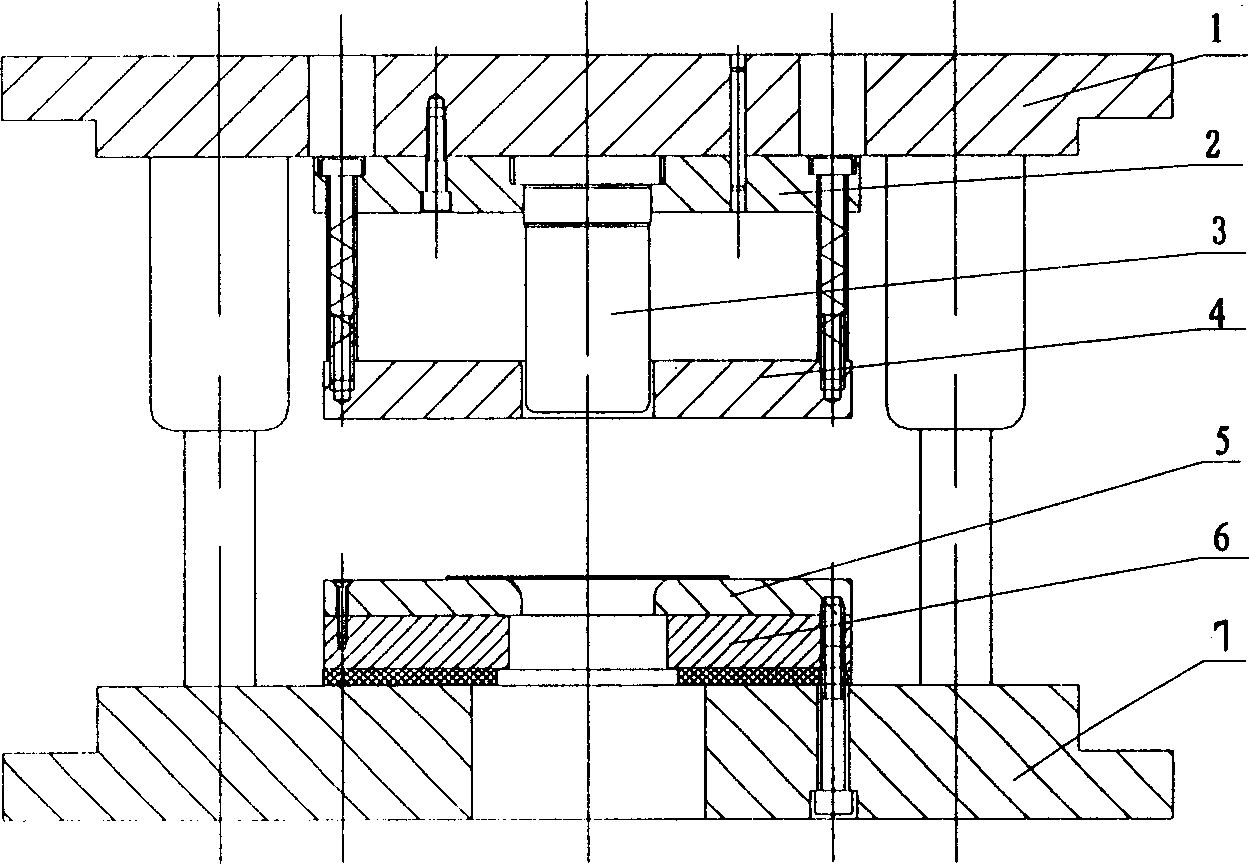

[0023] Using plate stamping technology to form magnesium alloy shell-shaped parts on magnesium alloy (MB2) plates, the specific operations are as follows:

[0024] 1) Install the mold and perform alignment adjustment;

[0025] 2) Check the heating system, preheat the mold to 200-260°C, and the holding time is 1 minute, 1.5 minutes, and 1 minute for each millimeter thickness blank;

[0026] 3) The magnesium alloy sheet is heated to 200-350°C, and the holding time is 1.5 minutes, 1.5 minutes, and 1 minute for each millimeter thickness of the blank;

[0027] 4) Put the magnesium alloy sheet into the mold after using the lubricant; apply the lubricant on the mold and the magnesium alloy sample respectively, the lubricant can be animal oil such as lard, or MnS 2 ;

[0028] 5) Start the stamping and stamping device, the punch starts to move down, and the stamping and forming start. The drawing ratio is controlled within the range of 1.5-3, and the drawing speed is 50-80mm / min; unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com