Method for manufacturing large silicon oxide ceramic sheet

A manufacturing method and technology of silicon oxide, which is applied in the field of ceramic products, can solve the problems of not being able to adapt to market demand, complex control conditions, and small format of finished products, and achieve the effects of low operation and maintenance costs, improved corrosion resistance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

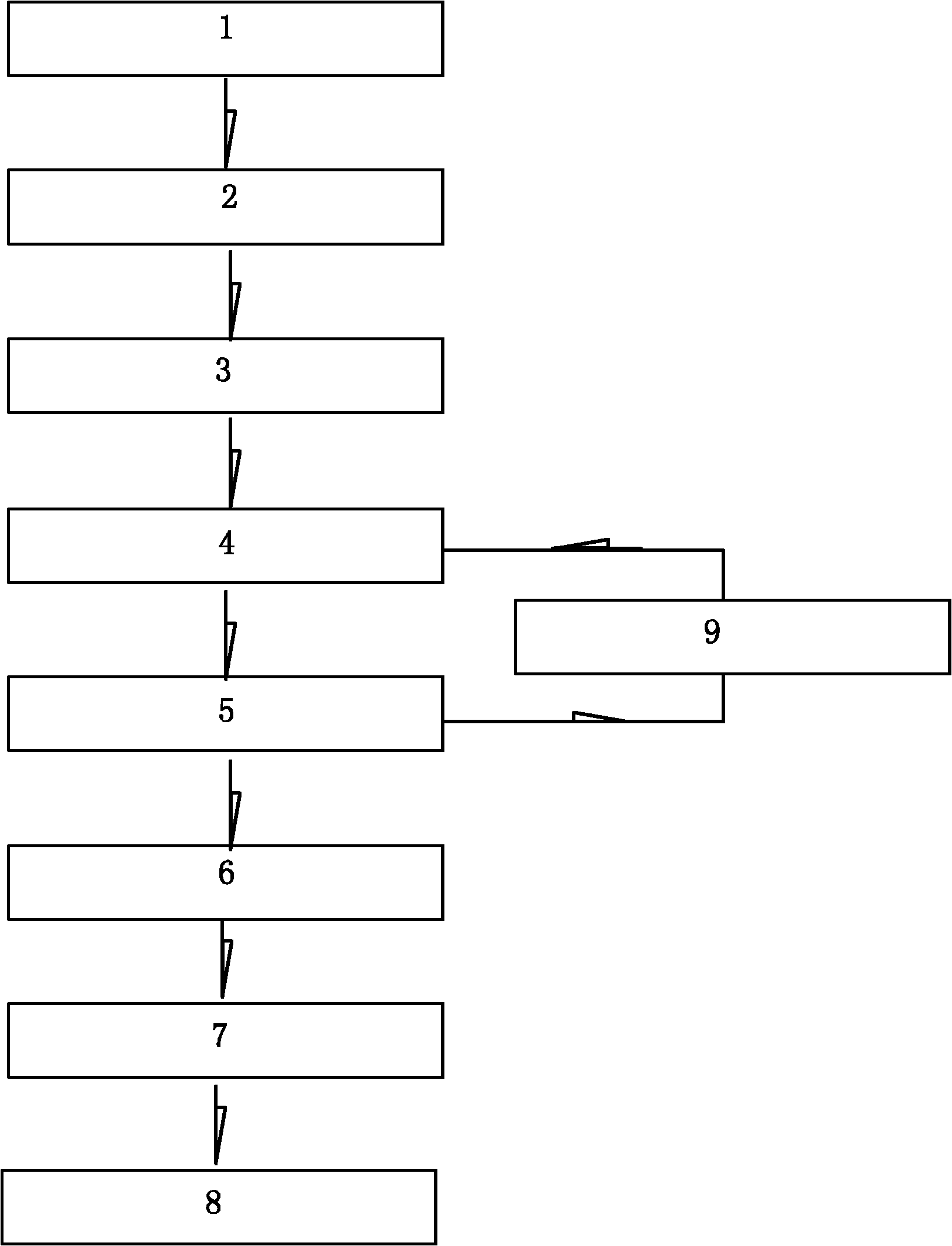

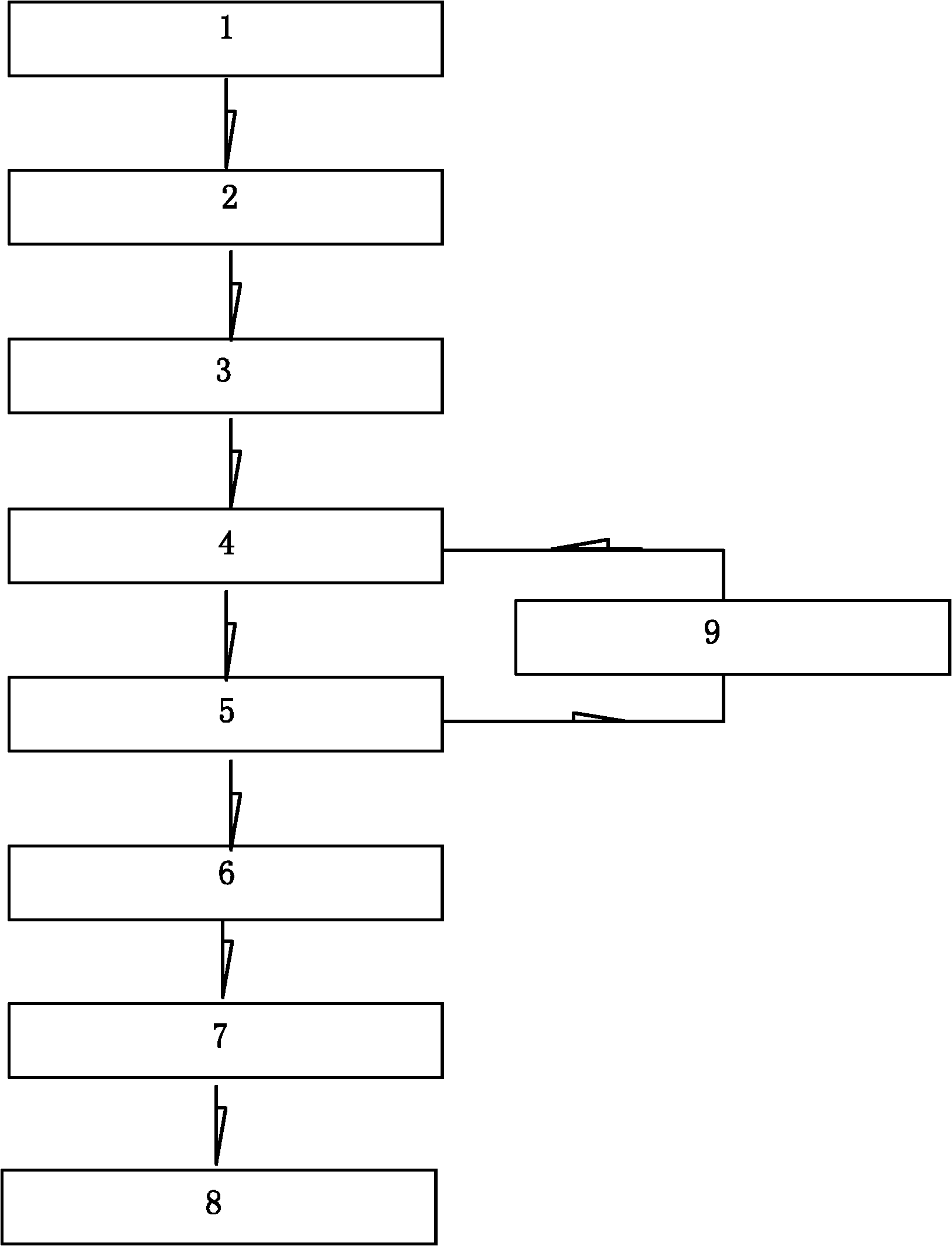

[0040] The method for manufacturing a large silicon oxide ceramic plate of the present application includes four steps of preparing raw material clay particles, preparing a green large silicon oxide ceramic plate, preparing a large silicon oxide ceramic thin plate and preparing a finished product of the large silicon oxide ceramic plate:

[0041] (1) Preparation of raw clay particles

[0042] Raw material weight ratio: (kg)

[0043] 60 parts of acicular wollastonite, 30 parts of clay, 20 parts of mullite, 20 parts of china clay, 20 parts of feldspar, and 30 parts of bentonite; acicular wollastonite accounts for 33.34% of the total weight of the raw materials; the acicular silicon The aspect ratio of limestone is 20:1;

[0044] Grind other raw materials into fine powder with a particle size of 250 mesh, and then mix with acicular wollastonite, add water in an amount of 30% of the weight of the raw materials, and after uniform mixing, after screening and iron removal, it become...

Embodiment 2

[0059] Raw material weight ratio: (kg)

[0060] 30 parts of acicular wollastonite, 25 parts of clay, 15 parts of mullite, 15 parts of china clay, 20 parts of feldspar, and 30 parts of bentonite; acicular wollastonite accounts for 28.57% of the total weight of the raw materials; the acicular silicon The aspect ratio of limestone is 16.5:1;

[0061] The finished product of the silicon oxide ceramic large sheet has the following specifications: length: width: thickness=2000mm:1000mm:3mm;

[0062] Product inspection results: non-combustible; water absorption rate 2.12%; breaking strength, 895N / cm 2 ,, modulus of rupture: 48Mpa, bending degree 34mm; pollution resistance grade 5, chemical corrosion resistance grade GA, radiation: internal irradiation: 0.73, external irradiation: 0.91; freeze-thaw test +20 ~ -35 ℃ intact; Resist 140 ℃ thermal shock, intact.

[0063] The rest are the same as in Example 1.

Embodiment 3

[0065] Raw material weight ratio: (kg)

[0066] 60 parts of acicular wollastonite, 25 parts of clay, 20 parts of mullite, 20 parts of china clay, 20 parts of feldspar, and 30 parts of bentonite; acicular wollastonite accounts for 34.28% of the total weight of the raw materials; the acicular silicon The aspect ratio of limestone is 17.5:1;

[0067] The finished product of the silicon oxide ceramic large sheet has the following specifications: length: width: thickness = 2200mm: 1500mm: 3-4mm;

[0068] Product inspection results: non-combustible; water absorption rate 2.54%; breaking strength, 906N / cm 2 ,, modulus of rupture 50.5Mpa; bending degree 26mm; freeze-thaw test +20 ~ -35 ℃ intact; 140 ℃ thermal shock resistance, intact, pollution resistance grade 5, chemical corrosion resistance grade GA, radiation: internal Irradiation: 0.68, external irradiation: 0.88.

[0069] The rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Destruction strength | aaaaa | aaaaa |

| Modulus of rupture | aaaaa | aaaaa |

| Destruction strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com