Low-cost fine-grain weak-texture magnesium alloy sheet and manufacturing method thereof

The technology of a magnesium alloy plate and its manufacturing method is applied in the field of low-cost magnesium alloy and its manufacture, which can solve problems such as difficulties in the application of rare earth magnesium alloy plates, and achieve the effects of no precious alloy elements, wide application of the process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The chemical composition of the Mg-Ca-Zn-Zr series magnesium alloy sheet is shown in Table 1. The manufacturing method is:

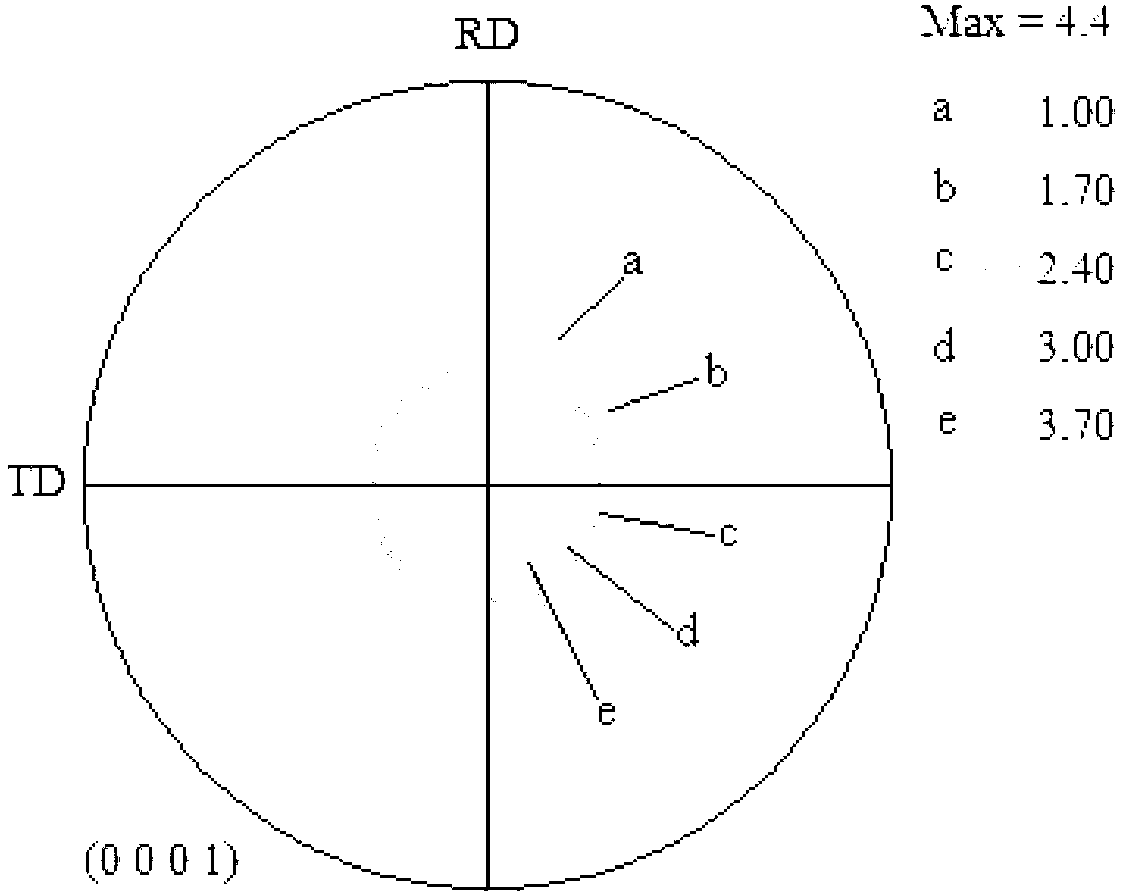

[0055] The magnesium alloy billet (microstructure such as figure 1 shown) is heated to 500° C. for solution treatment, the holding time is 0.5 min / mm, and the Mg-Ca-Zn-Zr series magnesium alloy of this embodiment is obtained after rolling. During hot rolling, the roll surface is preheated to 150°C, the rolling start temperature is 450°C, the final rolling temperature is 350°C, and the single pass reduction rate is 20-30%; during warm rolling, the roll surface is preheated to 150°C , Magnesium alloy plate on-line heat supplement, rolling temperature is 220 ℃, single pass reduction rate is 20-40%; when cold rolling, the cold rolling reduction is 10%, and the final plate thickness is 0.4mm.

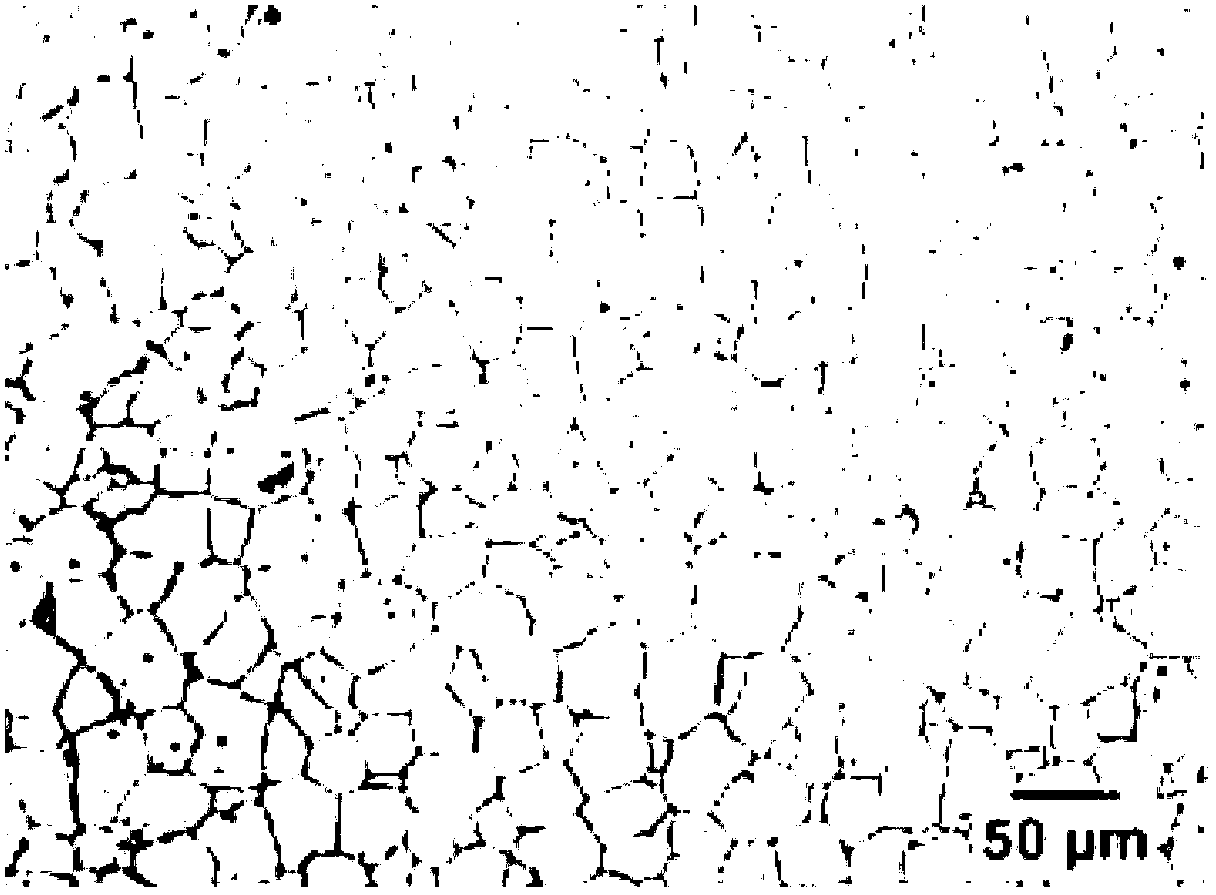

[0056] The magnesium alloy billet microstructure of embodiment 1 is as follows figure 1 As shown, its structure is equiaxed crystal, and the average grain si...

Embodiment 2

[0058] Embodiment 2: (comparative example 1)

Embodiment 3

[0063] The chemical composition of the Mg-Ca-Zn-Zr series magnesium alloy sheet is shown in Table 1. The manufacturing method is:

[0064] Heat the magnesium alloy cast slab that meets the composition ratio shown in Table 1 to a temperature of 500°C for solution treatment, and the holding time is 0.5min / mm; during hot rolling, the surface of the roll is preheated to 150°C, and the rolling start temperature is 450°C , the final rolling temperature is 350°C, and the single-pass reduction rate is 20-30%; during warm rolling, the roll surface is preheated to 150°C, and the magnesium alloy plate is reheated online, and the rolling temperature is 220°C, and the single-pass reduction The rate is 20-40%; during cold rolling, the cold rolling reduction is 10%, and the final plate thickness is 0.4mm; annealing at 375°C for 17 minutes is enough.

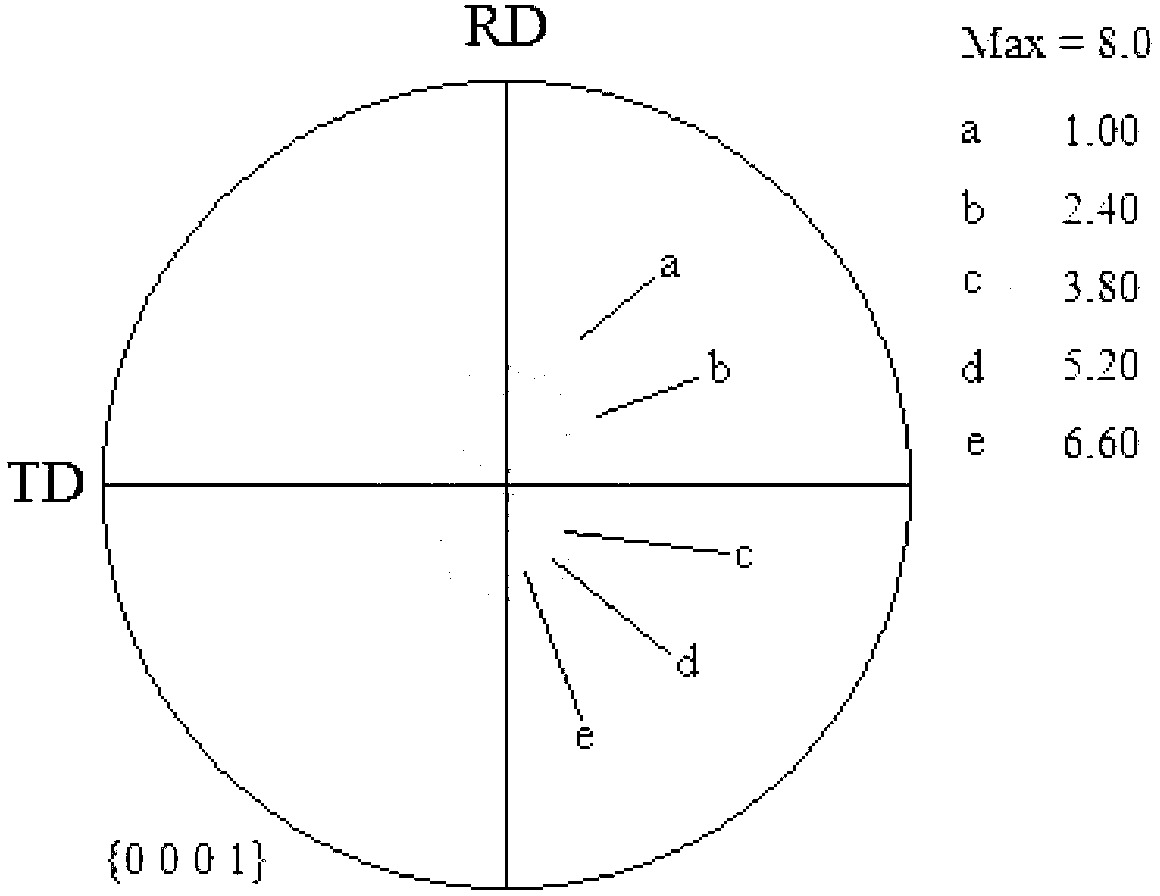

[0065] The microstructure of the Mg-Ca-Zn-Zr series magnesium alloy plate of embodiment 3 is as follows Figure 4 As shown, the grain size d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com