Polyurethane-based self-healing material and preparation method thereof

A composite material and polyurethane technology, applied in the field of polyurethane-based self-healing materials and their preparation, can solve the problems of difficult expansion of material application, difficulty of self-healing materials with mechanical properties and self-healing effects, etc., to increase mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

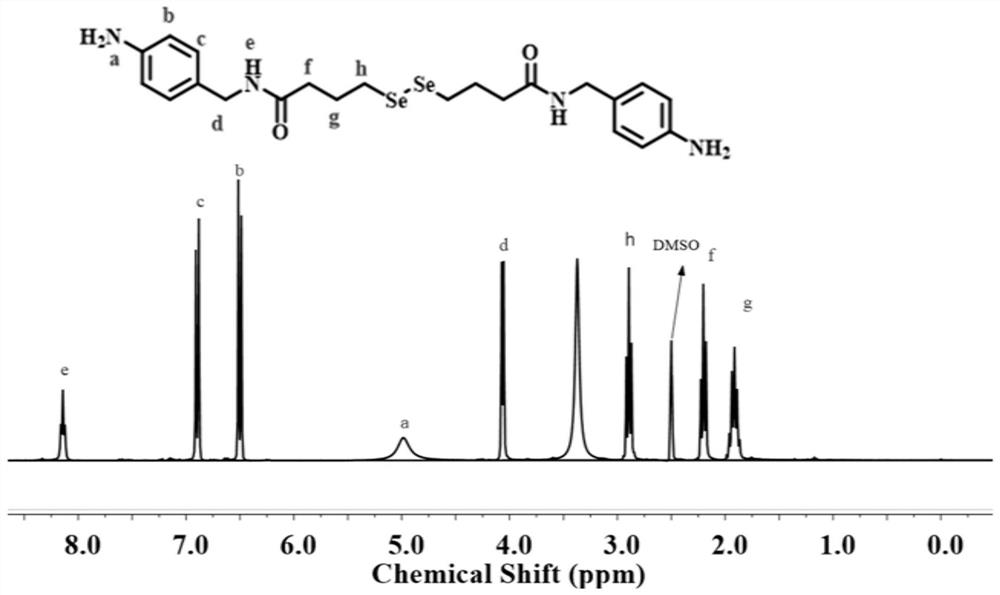

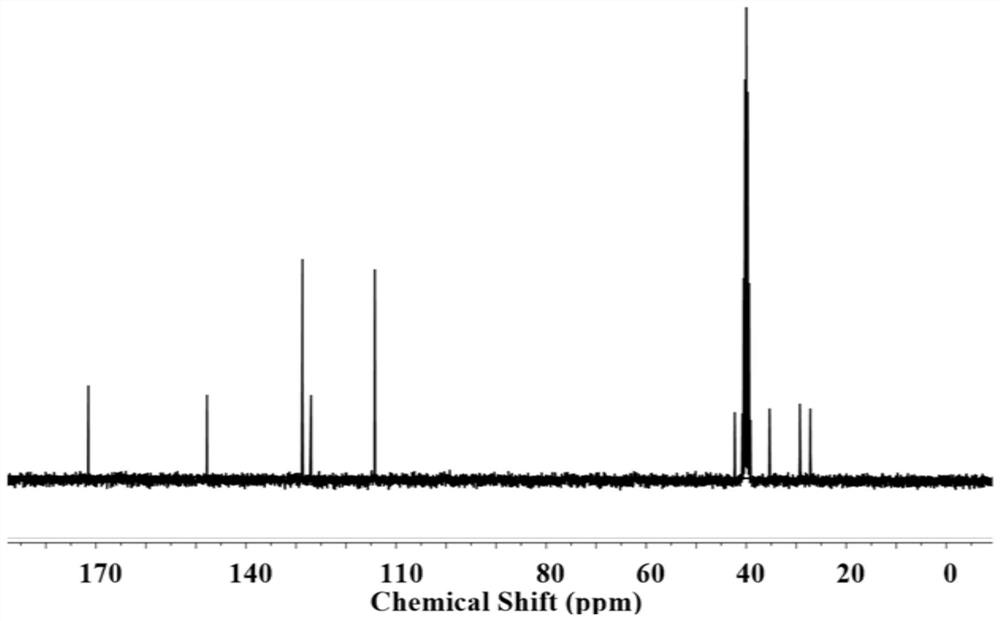

[0060] The synthesis of embodiment 1 diaminodiphenylalkyl diselenide

[0061] Take 1.23g of selenone, 1.00g of 4-aminobenzylamine and 40ml of tetrahydrofuran in a 100ml round bottom flask, stir well, and react at 40°C for 2 hours to obtain diaminodiphenylalkyl diselenide.

[0062] The reaction scheme is as follows:

[0063]

[0064] figure 1 , figure 2 The result of NMR characterization of the synthesized diaminodiphenylalkyl diselenide shows that diaminodiphenylalkyl diselenide was successfully obtained in this example.

Embodiment 2

[0065] The end group modification reaction of embodiment 2 polypropylene glycol

[0066] 1) End group modification of dihydroxypolypropylene glycol (Mn=2000g / mol)

[0067] Get 30g of dihydroxypolypropylene glycol (Shanghai McLean Biochemical Technology Co., Ltd., PPG-2000, number 2, Mn=2000g / mol) and place in a 500ml reaction bottle equipped with a mechanical stirrer, heat at 80°C for 4 hours and pump gas, dehumidify the reaction system. When the humidity of the system is less than 20%, lower the temperature to 70°C, add 6.66g of isophorone diisocyanate (No. 1) and 50mmp of catalyst dibutyltin dilaurate (DBTDL) into the reaction flask, and react in tetrahydrofuran for 60 minutes , to obtain a diisocyanate-terminated prepolymer (No. 4), and carry out infrared tracking on the whole reaction process.

[0068] The reaction scheme is as follows:

[0069]

[0070] 2) Trihydroxypolypropylene glycol (Mn=3000g / mol) end group modification

[0071] Get 30g trihydroxypolypropylene ...

Embodiment 3

[0075] The film-forming synthesis of embodiment 3 self-healing materials

[0076] Taking the molar ratio of diisocyanate-terminated prepolymer and triisocyanate-terminated prepolymer as 1:1 as an example, the preparation method of the polyurethane-based self-healing material of the present invention is as follows:

[0077] In a polytetrafluoroethylene mold, add 4 g of diisocyanate-terminated prepolymer (2 mmol, code 4), 6 g of triisocyanate-terminated prepolymer (2 mmol, code 5) and diaminodiphenylalkyl diselenide in sequence A tetrahydrofuran (20-40mL) solution of ether (2.23g, No. 9) was stirred rapidly, dried in vacuum, solvent removed, and reacted at 60°C for 24h to obtain a polyurethane-based self-healing material (No. 10 / 11). Infrared tracking of the entire reaction process.

[0078] The reaction scheme is as follows Figure 5 As shown, among the substances numbered 10 and 11 in the figure, only the specific structural formula of a part of the repeating unit is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com