Steam-curing-free durable concrete containing metakaolin and construction method of segments

A technology of metakaolin and concrete, which is applied in the field of metakaolin non-steam curing durable concrete and segment construction, which can solve the disadvantages of concrete strength, durability and cracks in the later stage, the lack of resistance to chloride ion penetration of concrete, and the impact on shield segment structure Safety and other issues, to achieve the effect of saving space and investment, good working performance and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0027] 1) According to the weight ratio of the raw material components, respectively weigh Portland cement, fly ash, metakaolin, natural sand, crushed stone, polycarboxylate water reducer, and mixing water in corresponding parts by weight;

[0028] 2) Under the condition of 15℃~35℃, mix natural sand and crushed stone into component A, mix ordinary portland cement, fly ash and metakaolin into component B, mix polycarboxylate superplasticizer and Tap water is mixed as component C;

[0029] 3) Put component A into the concrete mixer, then add component B into the mixer, turn on the concrete mixer and mix for 10 seconds, then add component C into the mixer, and then mix components A, B and C together for 90 ~150 seconds stop;

[0030] 4) Put the steel cage precisely made according to the design size into the mold, and distribute the concrete prepared in 3) in two layers: lay the first layer first, vibrate the cloth at the same time, and lay the second layer after the vibration is...

Embodiment 4-6

[0051] According to the weight ratio of the raw material components, weigh the corresponding parts by weight of Portland cement, fly ash, metakaolin, natural sand, gravel, polycarboxylate water reducer, mixing water, and carry out The steps in Example 1-3 make metakaolin non-steam curing durable concrete segments. The weight ratio of raw material components is as shown in table 4:

[0052] Each component of table 4 embodiment 4-6 is composed

[0053]

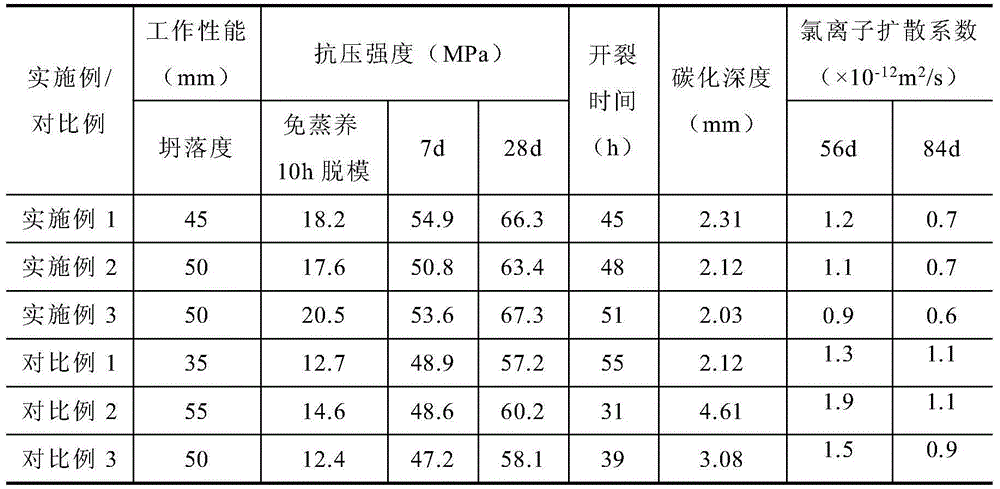

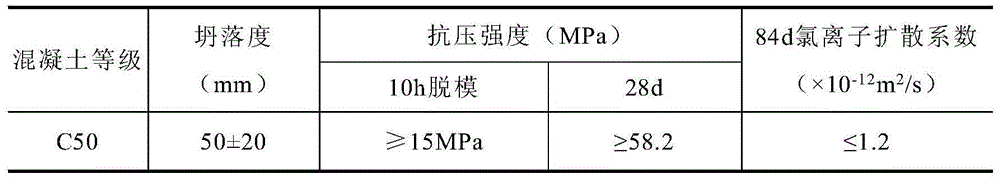

[0054] The main performance parameters of the concrete that each embodiment makes in table 4 are as shown in table 5:

[0055] Table 5 embodiment 4-6 makes concrete performance index

[0056]

[0057] Each raw material parameter is as follows among the embodiment 4-6:

[0058] The Portland cement used is P.O.42.5 Portland cement produced by Ningbo Yuyao Shunjiang Cement Factory, with a specific surface area of 360m 2 / kg, standard consistency water consumption 27.4%, initial setting time 146min, final setting time 20...

Embodiment 7-9

[0066] According to the weight ratio of the raw material components, weigh the corresponding parts by weight of Portland cement, fly ash, metakaolin, natural sand, gravel, polycarboxylate superplasticizer, and mixing water, and carry out the mixing process at 30°C. The steps in Example 1-3 make metakaolin non-steam curing durable concrete segments. The weight ratio of raw material components is as shown in table 6:

[0067] Each component composition of table 6 embodiment 7-9

[0068]

[0069] The main performance parameters of the concrete that each embodiment makes in table 6 are as shown in table 7:

[0070] Table 7 embodiment 7-9 makes concrete performance index

[0071]

[0072] The ordinary Portland cement used in the present embodiment 7-9 is the P.O.42.5 type Portland cement produced by Ningbo Yuyao Shunjiang Cement Factory, and the specific surface area is 360m 2 / kg, standard consistency water consumption 27.4%, initial setting time 146min, final setting tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Clotting time | aaaaa | aaaaa |

| Final setting time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com