Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Increased pozzolanic activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Masonry, mortar, and stucco cement compositions

This invention pertains to a process of making ASTM quality masonry cement, mortar cement, and stucco cement (also called plastic cement) and to the products themselves which are useful in making ASTM quality mortar for masonry construction or ASTM quality stucco for plastering construction. These cements are classified as hydraulic cements and are made using selected pozzolan(s), such as natural pozzolan and fly ashes, Portland Cement, hydrated lime, and an air-entraining agent. Other additives, such as fibers, may be added to further modify its properties. The pozzolans act as functional ingredients in the mix rather than as a filler. As a result, concentrations of greater than 25 wt. % and more pozzolan can be produced.

Owner:OLDCASTLE ARCHITECTURAL

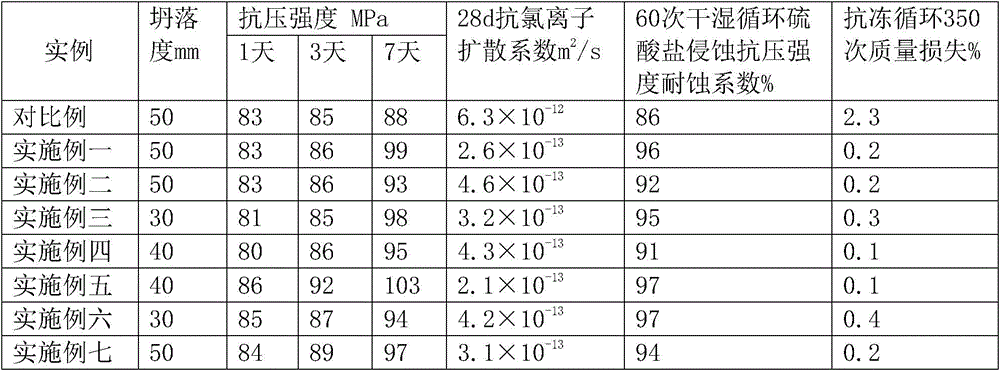

Autoclaving-free prestressed high-strength tube pile concrete and tube pile manufacturing method

The invention relates to autoclaving-free prestressed high-strength tube pile concrete and a tube pile manufacturing method. The concrete is prepared from the following components in parts by mass: 300-420 parts of PI or PII 52.5 cement, 5-80 parts of mineral powder, 5-100 parts of lithium slag powder, 5-40 parts of glass microbead powder, 680-720 parts of sand, 1125-1170 parts of broken stones, 125-135 parts of water, 4-5 parts of a polyocarboxy acid water reducing agent and 2-5 parts of an exciting agent. After stirring and shaping are performed, only constant-pressure steaming is performed for 6-8 hours, the strength requirement of C80 can be met, the energy consumption is reduced, and besides, the lithium slag powder which is industrial waste is utilized for the autoclaving-free concrete tube pile, so that the problem of resource wasting and the problem of environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

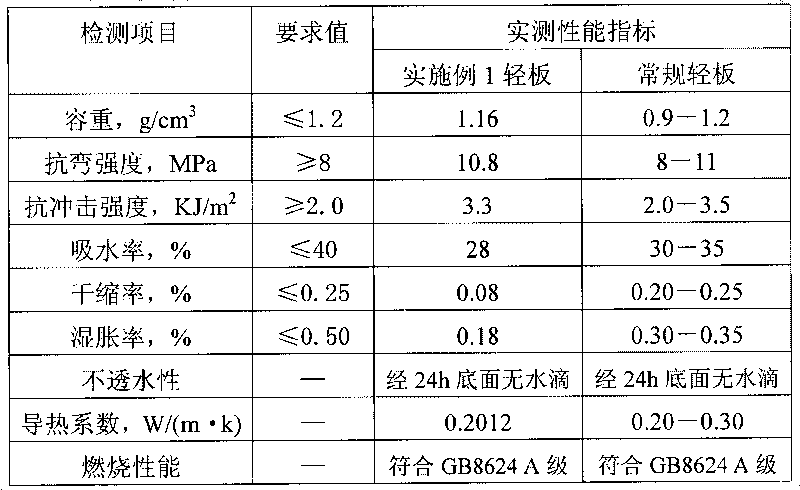

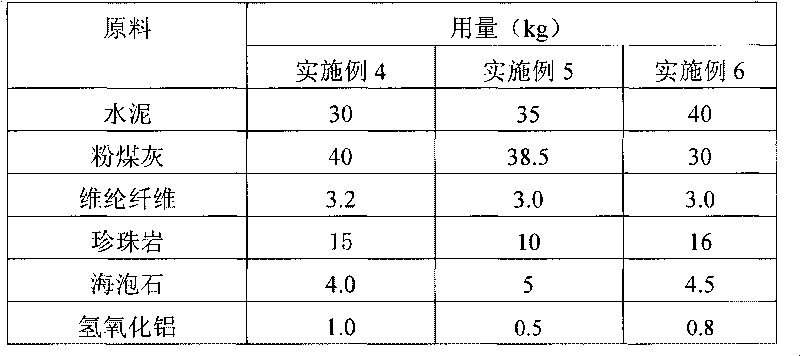

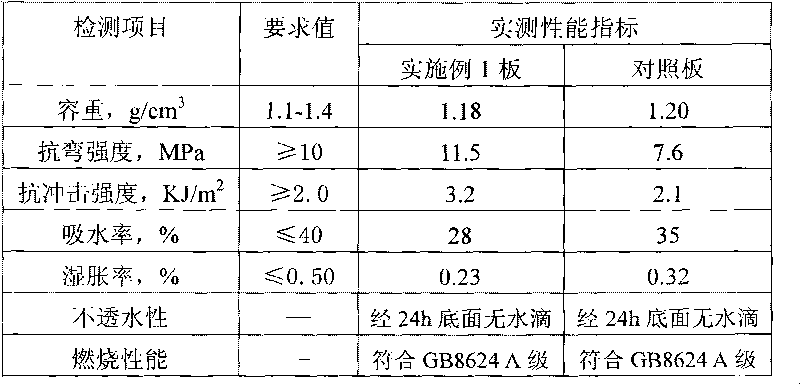

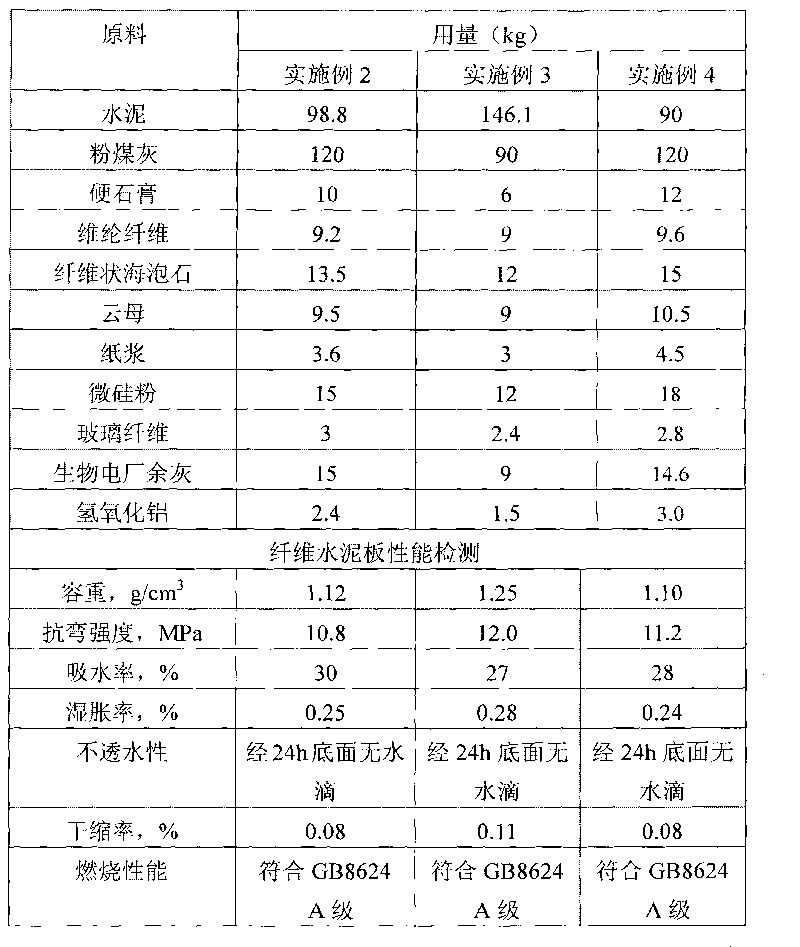

Light decorative plate material with high doping quantity of fly ash

ActiveCN101736852AImprove performanceImprove flexural strengthConstruction materialSolid waste managementPerliteAsbestos

The invention relates to a decorative plate material with high doping quantity of fly ash and a production method thereof, which belong to the field of construction materials. The decorative plate material comprises cement, fly ash, polyvinylformal fibre, perlite, meerschaum, pulp, micro silicon powder, glass fibre and polyacrylamide. A right amount of micro silicon powder is added into a formula, the floating of a light material in the wet process can be reduced, the use quantity of the fly ash in the decorative plate material is also enhanced greatly, and the highest doping quantity can reach 40%. The wet process of the conventional asbestos-free cement flat plate is properly improved, and the maintained decorative plate material has the advantages of economy, applicability, flame retardant, light weight, small contraction, environmental protection, heat insulation, moisture prevention and good durability after being sprayed with paint.

Owner:CHINA BUILDING MATERIALS ACAD

Ultrahigh strength high-performance fiber concrete at C160 strength grade and preparation method thereof

ActiveCN107382205APrevent pulling outImprove energy consumptionSolid waste managementModified carbonCarbon nanotube

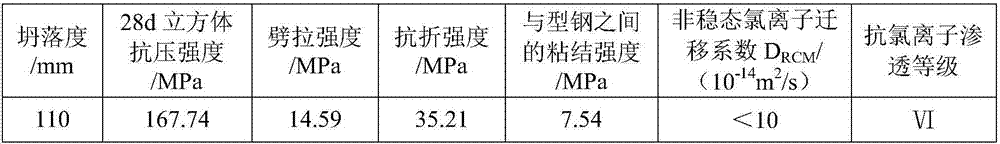

The invention discloses an ultrahigh strength high-performance fiber concrete at C160 strength grade and a preparation method thereof. The concrete comprises the following components in parts by weight: 485 parts of cement, 82 parts of water, 1000 parts of macadam, 750 parts of fine aggregate, 70 parts of coal ash, 73 parts of rice hull ash, 102 parts of silica fume, 14.0 parts of water reducer, 9.5 parts of excitant, 1.6 parts of cellulosic fiber, 40 parts of hydroxy modified carbon nano tube dispersion liquid, 37 parts of graphene oxide dispersion liquid and 2.6 parts of de-foaming agent. The prepared concrete has higher toughness, durability, higher bonding strength with profile steel, compressive strength reaching up to 167.74MPa, breaking strength reaching up to 35.21MPa, splitting strength reaching up to 14.59MPa, bonding strength with profile steel reaching up to 7.54MPa and chloride penetration resistance grade at VI-grade. When the ultrahigh strength high-performance fiber concrete is applied to a profile steel concrete combined structure, the cooperative working property between the profile steel and the concrete is effectively exerted and the defects of poor bonding property of the profile steel and the concrete and incapability of fully utilizing the respective mechanical properties of the profile steel and the concrete can be overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

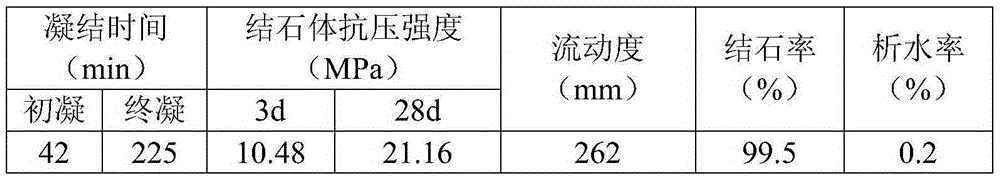

Geopolymer composite grouting material, and preparation method and use method thereof

The invention discloses a geopolymer composite grouting material, and a preparation method and a use method thereof. The preparation method comprises the following steps: uniformly mixing cement clinker, metakaolin, silica fume, blast furnace slag, fly ash, metal mine tailing, quicklime, a water reducer and dispersible latex powder according to a certain ratio, and grinding to prepare fine powder until the sieving residue ratio of a square hole sieve with the fineness of 45[mu]m is not greater than 30%. Solid wastes comprising the blast furnace slag, the fly ash and the metal mine tailings are adopted in the invention, so the cost of the material is reduced, the fluidity of the material is improved, and the compressive strength of the geopolymer composite grouting material is also improved without increasing the cost.

Owner:SHANDONG UNIV OF SCI & TECH

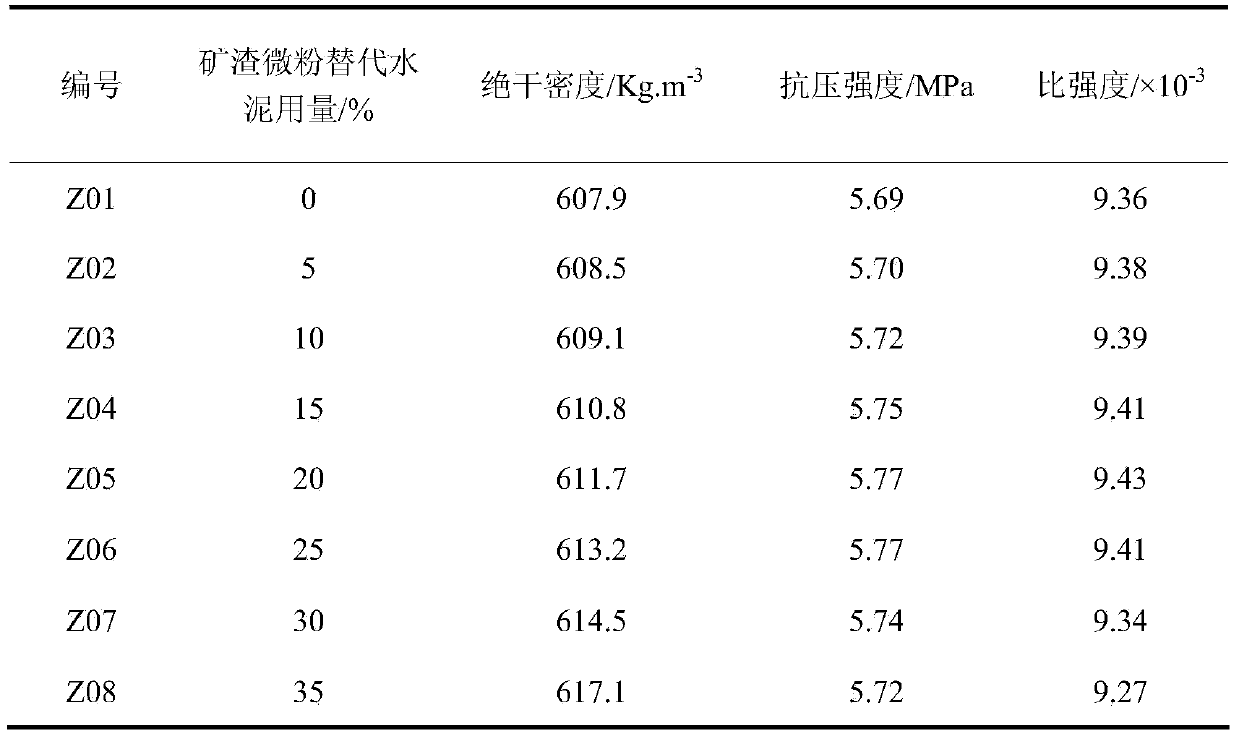

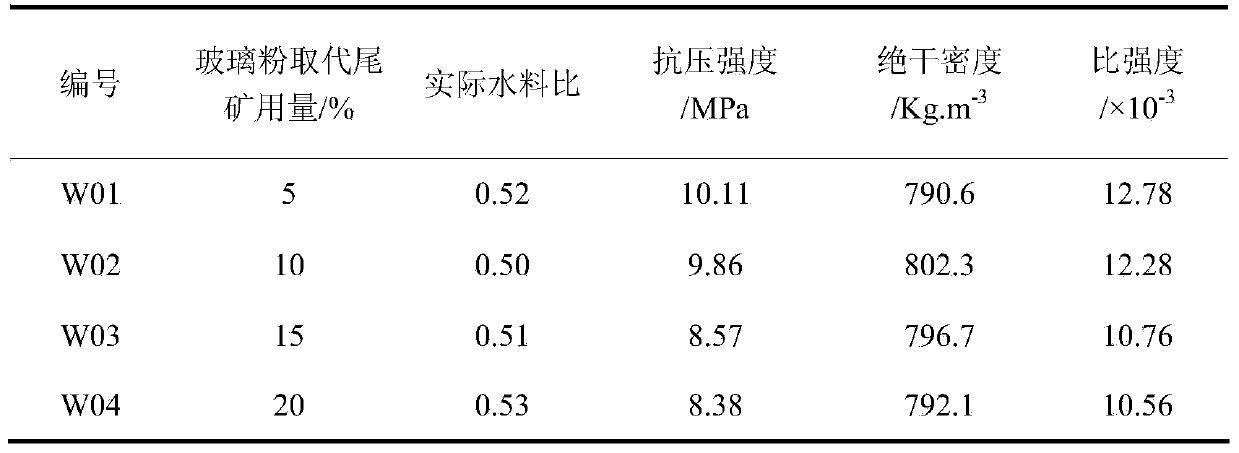

Light and high strength aerated concrete prepared with glass powder and preparation method thereof

ActiveCN103723988AFor high load-bearing requirementsThe high demands on load-bearing capacity meet theCement productionCeramicwareEconomic benefitsUltimate tensile strength

The invention discloses a light and high strength aerated concrete prepared with glass powder and a preparation method thereof. The inventor further improves kaolin tailings aerated concrete, and uses the glass powder to substitute partial tailings so as to remarkably enhance product strength. In addition, regulation of the use amount of aluminum powder and external addition of an early-strength agent CaCl2 effectively improve product density without losing overmuch strength; the bodying and gas forming expansion are coordinated by regulating time for agitation, and finally, the light and high strength aerated concrete with good heat-insulated performance, proper weight and higher strength is prepared. The light and high strength aerated concrete and the preparation method thereof fully utilize resources, lower production cost, have good economic benefits, improve the strength and keep lower intensity on the basis of ensuring the heat-insulated performance of the aerated concrete building blocks, can meet the high requirement of the present buildings on the bearing performance of the aerated concrete, and meanwhile satisfy the demand of environmental-friendly buildings.

Owner:GUANGXI UNIV

Coarse-aggregate-containing C240-strength-grade ultrahigh-performance fiber concrete and preparation method

ActiveCN107285708AImprove toughnessImprove deformation abilitySolid waste managementModified carbonCellulose fiber

The invention discloses coarse-aggregate-containing C240-strength-grade ultrahigh-performance fiber concrete and a preparation method. The concrete is composed of, by mass, 578 parts of cement, 62 parts of water, 880 parts of rubble, 800 parts of fine aggregate, 70 parts of coal ash, 60 parts of rice husk ash, 154 parts of silicon ash, 16.5 parts of water reducer, 11.5 parts of excitant, 1.7 parts of cellulosic fiber, 90 parts of steel fiber, 51 parts of hydroxyl modified carbon nanotube dispersion, 54 parts of oxidized graphene dispersion and 2.9 parts of defoamer. The concrete prepared by the method has high toughness and durability and has high binding strength with section steel, compressive strength reaches 249.65MPa, bending strength reaches 50.88MPa, splitting tensile strength reaches 24.78MPa, the binding strength with the section steel reaches 10.54MPa, and chlorion anti-permeation grade reaches VI grade. When the concrete is used in a section steel and concrete combined structure, cooperative working performance between the section steel and the concrete can be brought into play effectively, and the defects that the section steel and the concrete are poor in binding performance and respective mechanical performance of the section steel and the concrete cannot be brought into full play are made up.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

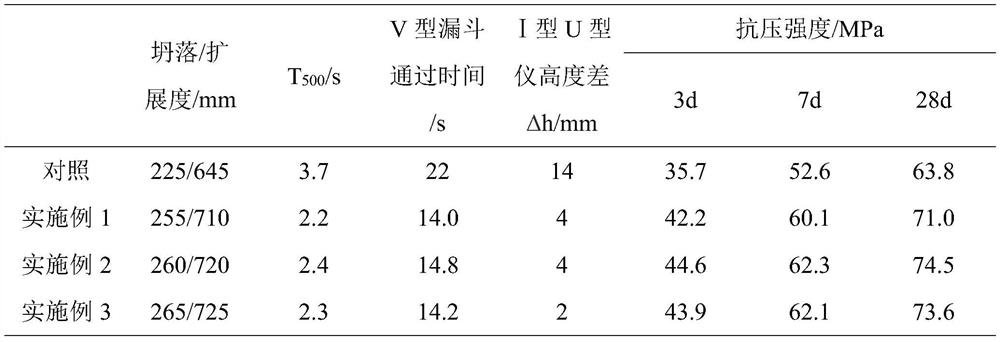

Slope self-compacting concrete and pouring construction method thereof

InactiveCN111777385AIncreased pozzolanic activityImprove early strengthRoof covering using sealantsCoastlines protectionSlagSilicon dioxide

The invention provides a slope self-compacting concrete. The slope self-compacting concrete is prepared from the following components in parts by weight: 60 to 70 parts of Portland cement, 60 to 100 parts of coarse aggregate, 48 to 78 parts of fine aggregate, 15 to 30 parts of mineral admixture and 0.6 to 2.1 parts of an additive, wherein the water-binder ratio is 0.26 to 0.35; the coarse aggregate is granite stone; the fine aggregate is river sand; the mineral admixture is a mixture of steel slag, fly ash and silicon powder according to a mass ratio of 1: 1: 0.5; the additive is a water reducing agent; and the steel slag is steel slag micro-powder subjected to surface modification by nano silicon dioxide. The steel slag micro-powder is subjected to surface silicon dioxide modification, the volcanic ash activity of the steel slag micro-powder is improved, the steel slag micro-powder can replace a part of a conventional admixture, meanwhile, the early strength of the doped concrete is improved, the application range of the steel slag concrete is expanded, and the production cost is also reduced.

Owner:SHANDONG WATER CONSERVANCY CONSTR ENG CO LTD

Preparation technology of nanometer SiO2 composite cement

The invention belongs to the field of building industry, in particular to a preparation technology of nanometer SiO2 composite cement, which mainly provides the technology for preparing nanometer SiO2 from agricultural waste rice hulls at low price and preparing ultrahigh-intensity and ultrahigh-durability nanometer SiO2 composite cement through mixing the nanometer SiO2 into the cement materials. The preparation technology is characterized in that the problems of high cost and difficult nanometer material dispersion of the nanometer SiO2 preparation in the prior art can be solved, and the prepared SiO2 composite cement has incomparable excellent performance compared with other cement materials.

Owner:安徽海螺材料科技股份有限公司

Preparation method of rubber-powder-doped modified slag micro-powder concrete

InactiveCN108002728APromote generationImprove surface roughnessSolid waste managementSlagWaste rubber

The invention discloses a preparation method of rubber-powder-doped modified slag micro-powder concrete. In the preparation method, slag and coal gangue are subjected to dual excitation of heat and chemistry, formation of a gelling substance is promoted, so that the material has higher tephra activity; waste rubber powder is subjected to surface etching and modification treatment, so that the surface roughness of rubber particles is improved, and the binding capacity of the rubber powder and a cement matrix is effectively improved; and in addition, the slag material is subjected to grinding and activation, so that the powder is more fine and can be packed into the gap between the rubber powder and cement mortar, also the compatibility between the slag and the rubber powder and between theslag and the cement mortar is also improved, the three components are connected more tightly, and thus the slag powder plays a role of a lubricant among the cement particles, thereby increasing the fluidity of the mortar, and when the material bears external loads, the waste rubber powder and the cement matrix give play to synergic effect and shear the stress, and the elasticity and toughness of the material are enhanced.

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

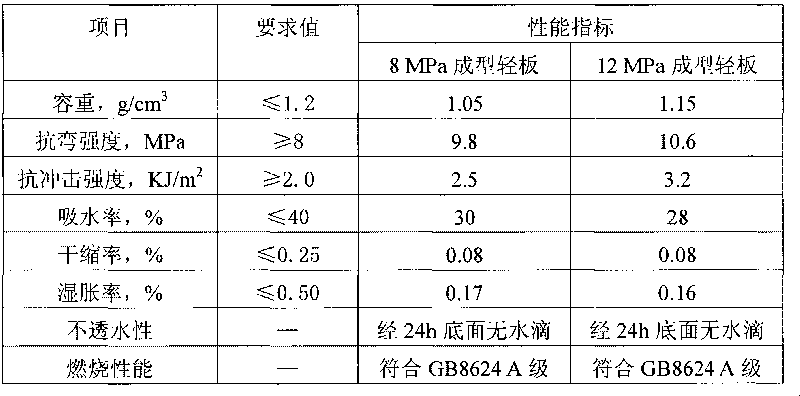

Fibre cement plate with high doping quantity of fly ash

InactiveCN101736853AReduce dosageIncrease dosageConstruction materialSolid waste managementEmberAluminium hydroxide

The invention discloses an economic type fibre cement plate with high doping quantity of fly ash and a preparation method thereof. The light fibre cement plate comprises cement, fly ash, anhydrite, polyvinylformal fibre, fibrous meerschaum, mica, pulp, micro silicon powder, glass fibre, biological power plant ember and aluminium hydroxide. A right amount of micro silicon powder and a right amount of anhydrite are added, the bending strength of a plate material can be greatly enhanced, the industrial wastes of the fly ash, the biological power plant ember and the like are doped, and the material cost can be lowered. The wet process of an asbestos-free cement flat plate is adopted, a wetted plate blank does not need to be pressurized, and the fibre cement plate has the advantages of economy, applicability, flame retardant, light weight, small contraction, environmental protection, moisture prevention and good durability after being cured by steam.

Owner:CHINA BUILDING MATERIALS ACAD

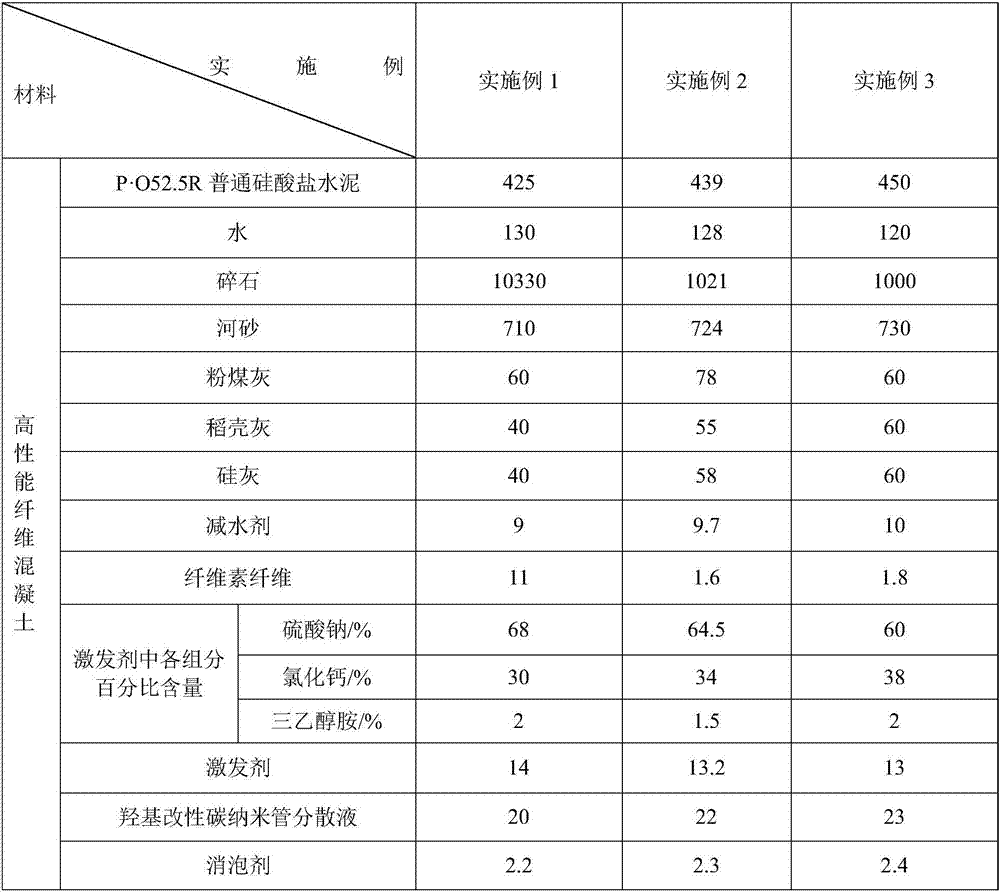

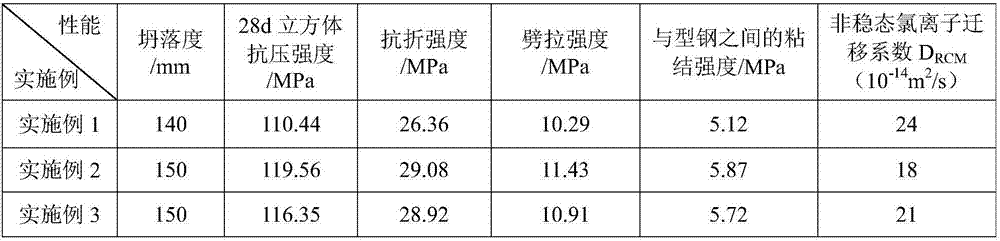

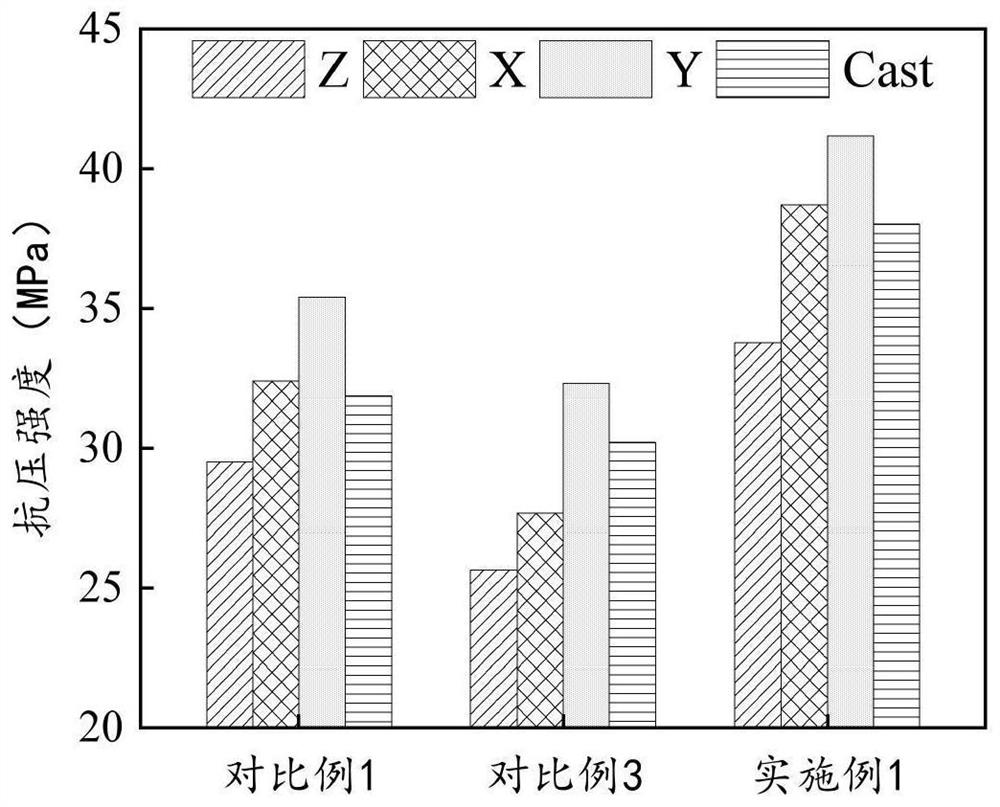

High-performance fiber concrete with C110 strength grade and preparation method thereof

The invention discloses high-performance fiber concrete with a C110 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 425 to 450 parts of cement, 120 to 130 parts of water, 710 to 730 parts of river sand, 1000 to 1030 parts of crushed stones, 60 to 90 parts of fly ash, 40 to 60 parts of rich husk ash, 40 to 60 parts of silicon ash, 9 to 10 parts of a water reducing agent, 13 to 14 parts of an exciting agent, 1.1 to 1.8 parts of cellulose fibers, 20 to 23 parts of a hydroxyl-modified carbon nanotube dispersion solution and 2.2 to 2.4 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel. The high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

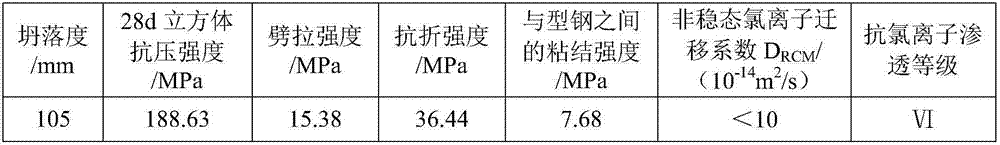

Ultrahigh-strength and high-performance fiber concrete with C180 strength grade and preparation method thereof

ActiveCN107352913AImprove volume stabilityInhibit plastic shrinkageSolid waste managementIonFlexural strength

The invention discloses ultrahigh-strength and high-performance fiber concrete with a C180 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 505 parts of cement, 70 parts of water, 1000 parts of crushed stones, 770 parts of fine aggregate, 70 parts of fly ash, 78 parts of rich husk ash, 118 parts of silicon ash, 15 parts of a water reducing agent, 10 parts of an exciting agent, 1.7 parts of cellulose fibers, 43 parts of a hydroxyl-modified carbon nanotube dispersion solution, 45 parts of a graphene oxide dispersion solution and 2.7 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel; the compression strength reaches 188.63MPa, the flexural strength reaches 36.44MPa, the splitting tensile strength reaches 15.38MPa, the bonding strength with the section steel reaches 7.68MPa and a chloride ion anti-leakage grade reaches a grade VI. The ultrahigh-strength and high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

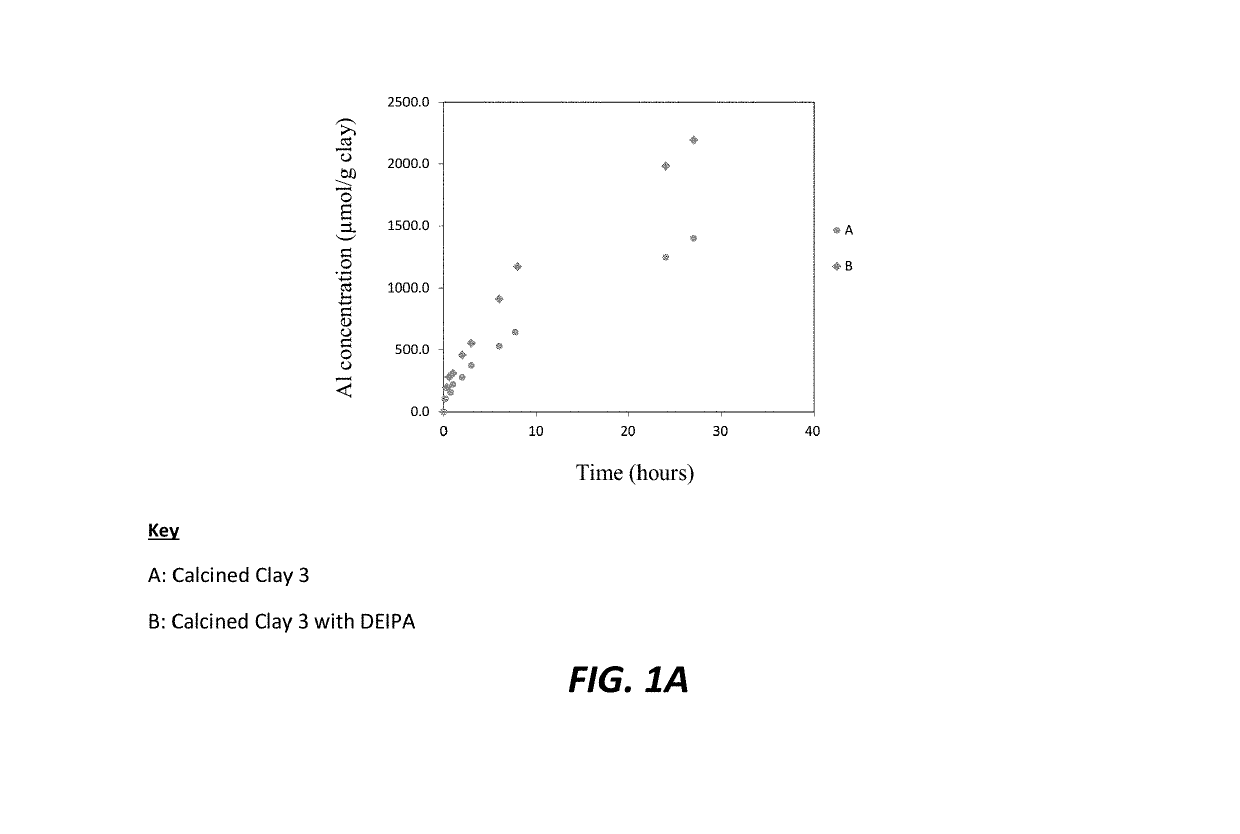

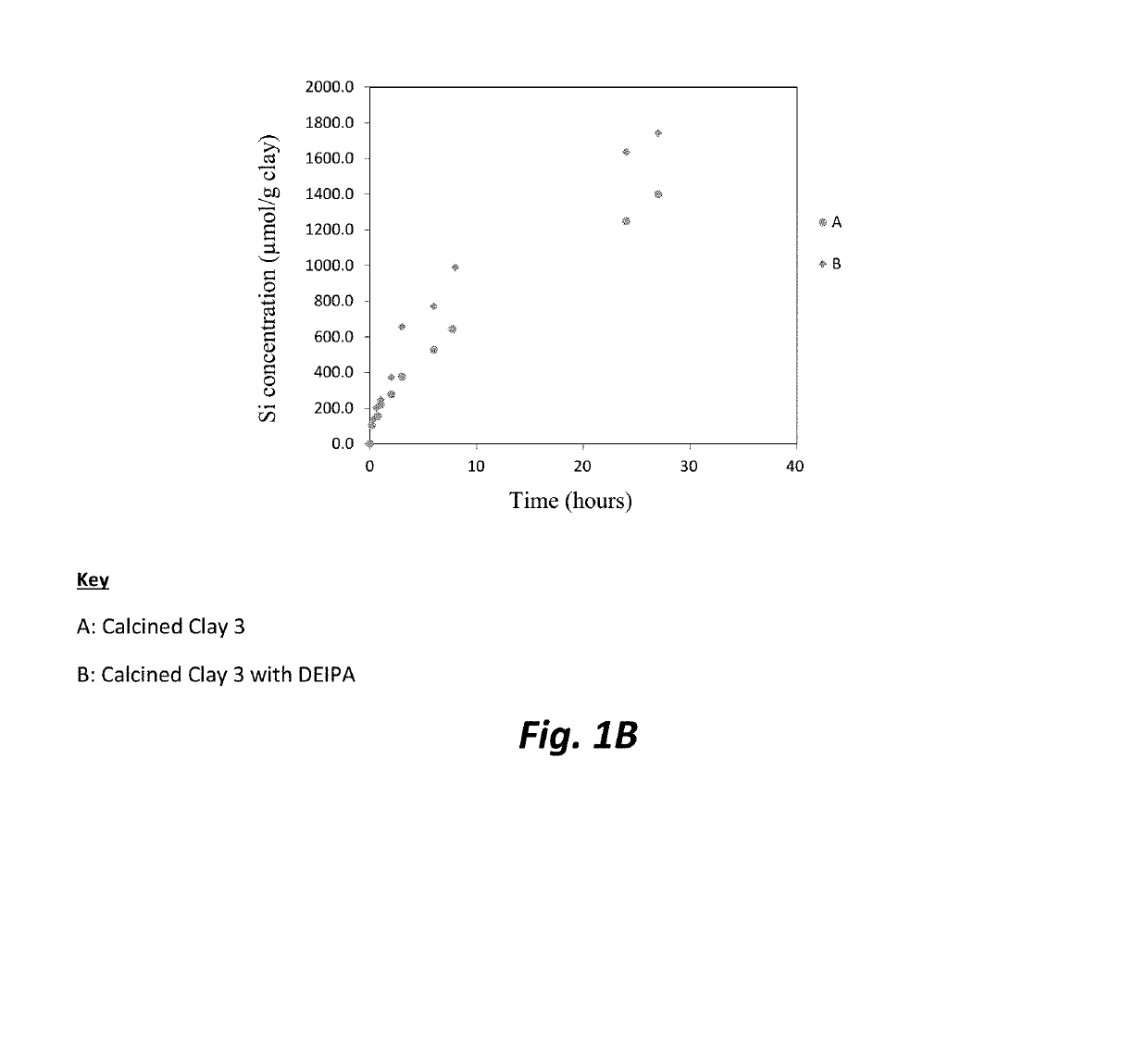

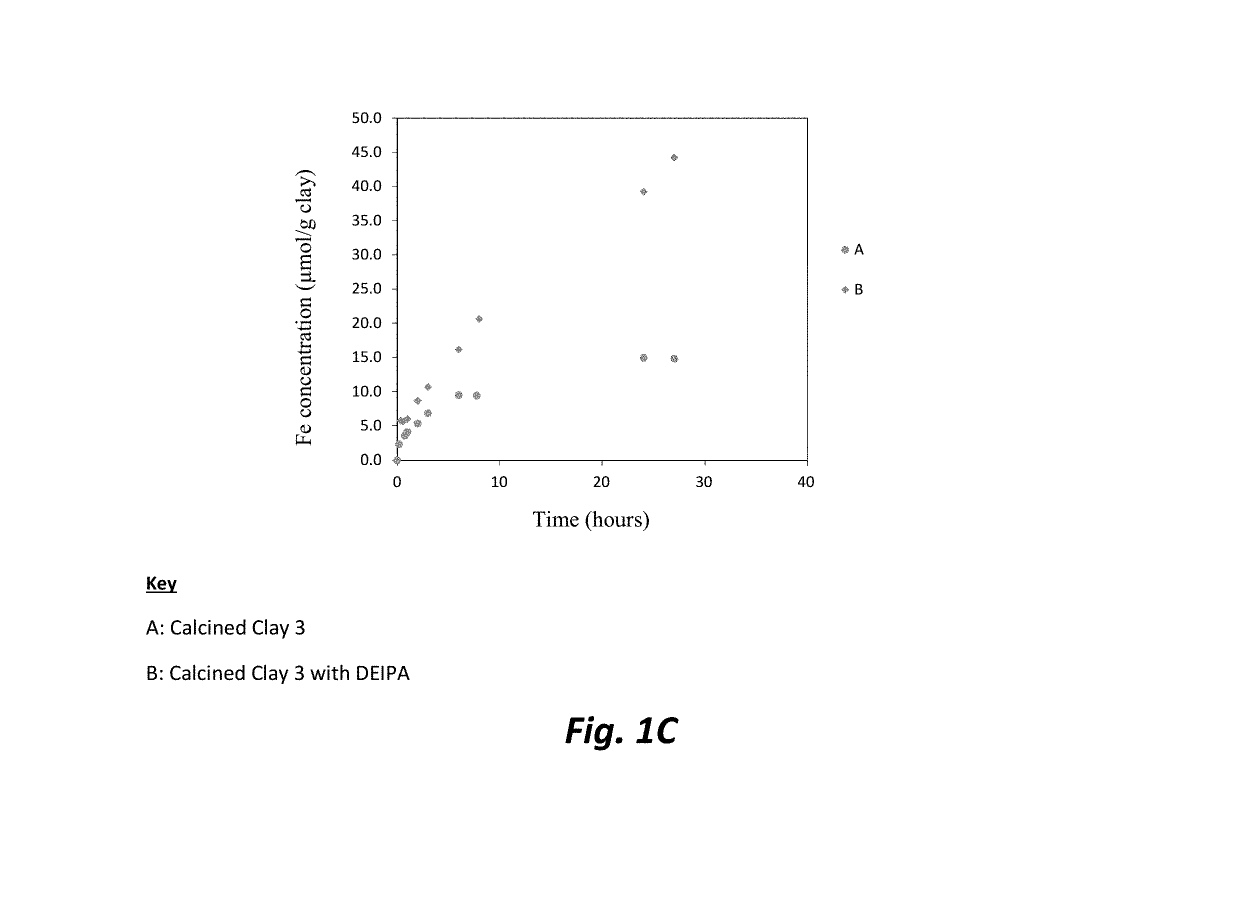

Enhancing calcined clay use with inorganic binders

ActiveUS20190144334A1Increasing pozzolanic reactivityImprove strength propertiesSolid waste managementCement productionUltimate tensile strengthMaterials science

The present invention discloses cementitious compositions which contain hydratable cement, limestone, or mixture thereof, having improved strength properties due to the presence of calcined clay and certain higher alkanolamines, wherein the calcined clay has an Fe203 content of greater than one percent (1%). Also disclosed are exemplary additives and methods for enhancing strength of cement and / or limestone compositions.

Owner:GCP APPL TECH INC

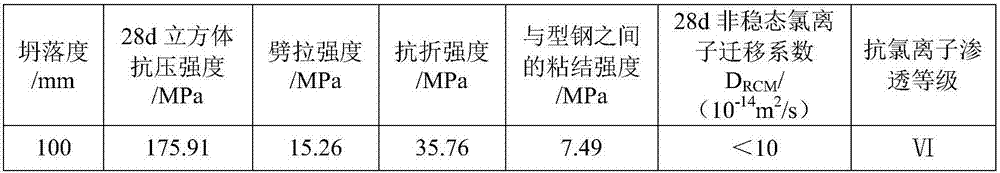

Ultrahigh-strength and high-performance fiber concrete with C170 strength grade and preparation method thereof

ActiveCN107352912AOvercoming brittlenessOvercome crackingSolid waste managementModified carbonFlexural strength

The invention discloses ultrahigh-strength and high-performance fiber concrete with a C170 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 497 parts of cement, 74 parts of water, 1000 parts of crushed stones, 760 parts of fine aggregate, 80 parts of fly ash, 75 parts of rich husk ash, 111 parts of silicon ash, 14.4 parts of a water reducing agent, 10 parts of an exciting agent, 1.6 parts of cellulose fibers, 41 parts of a hydroxyl-modified carbon nanotube dispersion solution, 42 parts of a graphene oxide dispersion solution and 2.6 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel; the compression strength reaches 175.91MPa, the flexural strength reaches 35.76MPa, the splitting tensile strength reaches 15.26MPa, the bonding strength with the section steel reaches 7.49MPa and a chloride ion anti-leakage grade reaches a grade VI. The ultrahigh-strength and high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and preparation method thereof

ActiveCN113024189AHigh tensile strengthHigh elastic modulusSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and a preparation method thereof. The ultrahigh-strength hybrid fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers, a carboxyl modified polyvinyl alcohol polymer and nano titanium / graphene oxide dispersion liquid according to the mixing ratio of (550-560): (760-770): (830-840): (65-70): (103- 108): (125-135): (5.4-5.6): (70-75): (20-21): (16-17): (3-3.3): (14.5-15): (7.5-8): (13.3-13.6): (21-21.5): (22-23.5): (42-46). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanical property and durability of the concrete and the bonding property between the concrete and the profile steel are obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

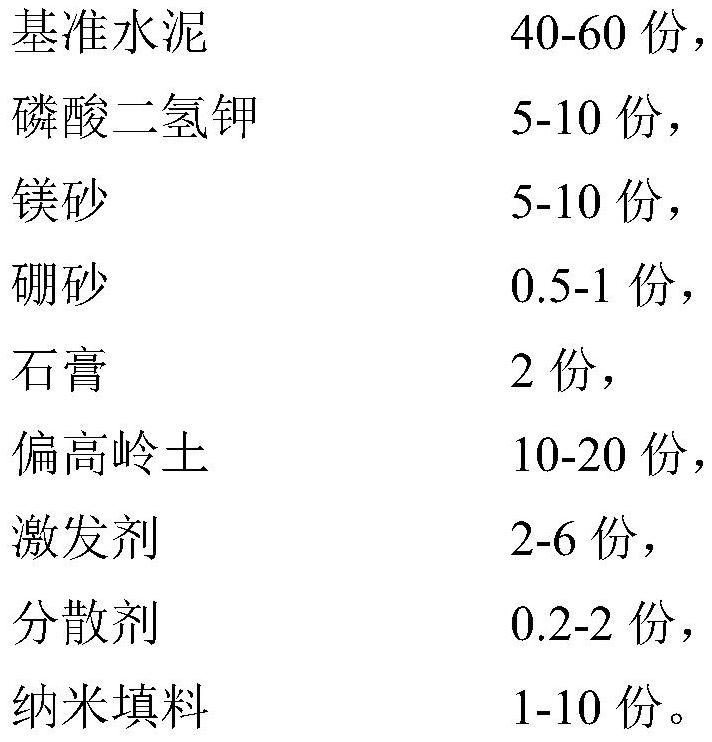

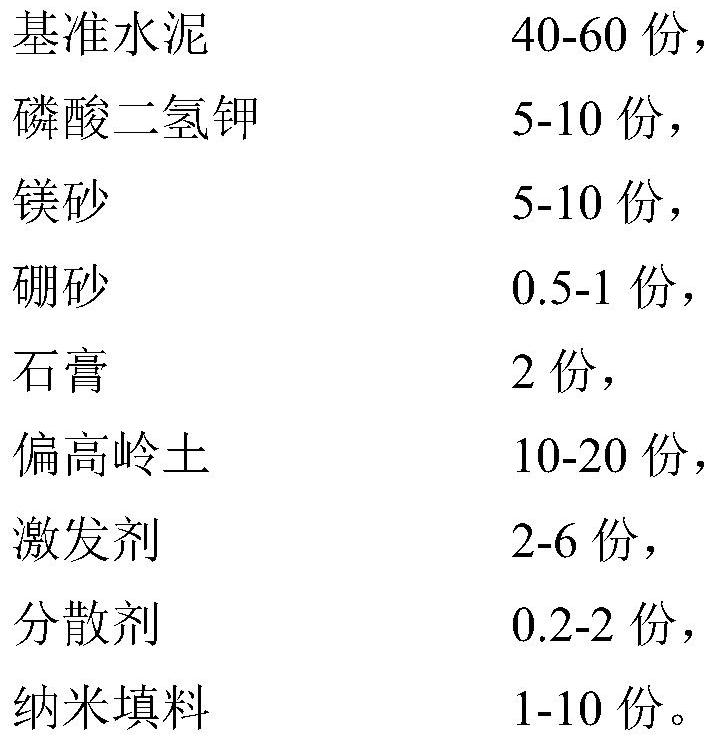

Auxiliary cementing material with high chloride ion corrosion resistance and preparation method thereof

ActiveCN112624720AAvoid corrosionImprove the curing rate of chloride ionCement productionRebar corrosionKaolin clay

The invention provides an auxiliary cementing material with high chloride ion corrosion resistance, and relates to the technical field of building materials. The chloride ion erosion resistant auxiliary cementing material is prepared from the following raw materials in parts by weight: 40-60 parts of reference cement, 5-10 parts of monopotassium phosphate, 5-10 parts of magnesia, 0.5-1 part of borax, 2 parts of gypsum, 10-20 parts of metakaolin, 2-6 parts of excitant, 0.2-2 part of dispersing agent and 1-10 parts of nano filler. The auxiliary cementing material disclosed by the invention not only can reduce the content of free chloride ions in concrete, but also can enhance the chloride ion migration resistance and reduce the corrosion damage of reinforcing steel bars.

Owner:GUANGZHOU TESTING CENTRE OF CONSTRUCTION QUALITY AND SAFETY CO LTD

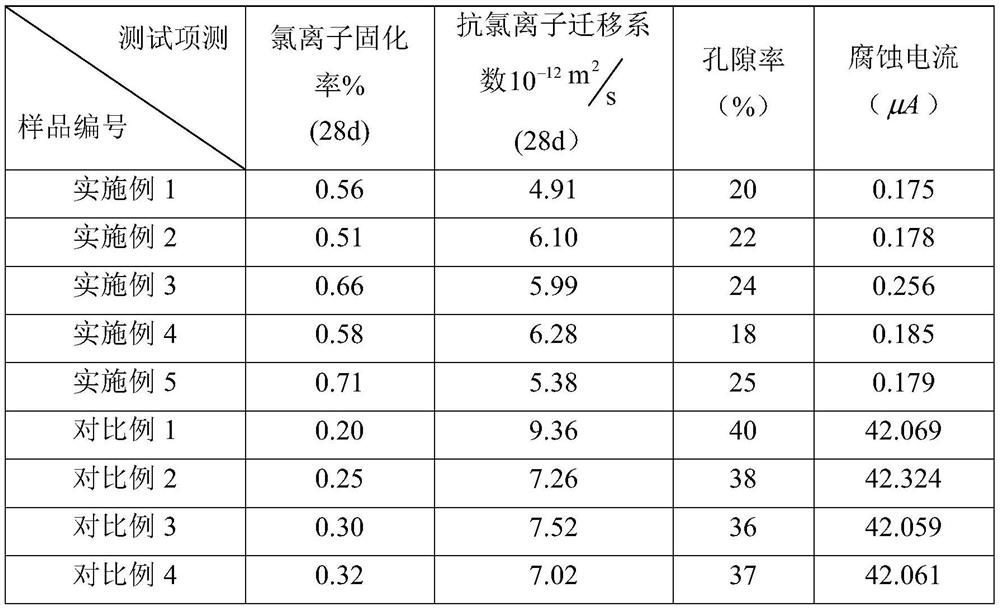

3D-printable aeolian sand anti-freezing concrete as well as preparation method and use method thereof

ActiveCN114292073AImprove mechanical propertiesIncreased durabilityAdditive manufacturing apparatusSolid waste managementCelluloseWater reducer

The invention provides 3D-printable aeolian sand anti-freezing concrete as well as a preparation method and a use method thereof, and belongs to the technical field of concrete. The aeolian sand anti-freezing concrete capable of 3D printing provided by the invention is prepared from the following preparation raw materials in parts by weight: 166-186 parts of Portland cement not lower than 42.5 grade; 3 to 13 parts of silica fume; 6 to 16 parts of fly ash; 330 to 350 parts of aeolian sand; 1-5 parts of a water reducing agent; 0.1 to 1.5 parts of cellulose ether; 0.05 to 0.5 part of starch ether; 0.1 to 1.5 parts of a defoaming agent; 0.2 to 4 parts of polypropylene fiber; 60 to 75 parts of water; the aeolian sand is aeolian sand subjected to alkali treatment. The aeolian sand anti-freezing concrete provided by the invention not only can realize 3D printing, but also is excellent in mechanical property and durability, and the conditions of shortage of natural sand and abundant aeolian sand resources in desert areas are adjusted according to local conditions, and local materials are used.

Owner:HEBEI UNIV OF TECH +1

High-performance fiber concrete at C60 strength grade and preparation method thereof

ActiveCN107445548APrevent pulling outImprove energy consumptionSolid waste managementFiberUltimate tensile strength

The invention discloses high-performance fiber concrete at a C60 strength grade and a preparation method thereof. The concrete comprises the following components in parts by mass: 360-380 parts of cement, 145-160 parts of water, 700-720 parts of river sand, 1020-1040 parts of gravel, 80-125 parts of fly ash, 40-60 parts of rice hull ash, 6-7.5 parts of a water reducing agent, 9-10 parts of a shrinkage reducing agent, 12.5-14 parts of an excitant, 1.1-1.8 parts of cellulosic fibers, 16-20 parts of a carboxyl butadiene styrene polymer an 1.7-1.8 parts of an antifoaming agent. The prepared concrete has high toughness and excellent durability, has high bonding strength with section steel, can effectively achieve the cooperative working performance between the section steel and the concrete when applied to a section steel and concrete combined structure, and overcomes the defects that the adhesive property between the section steel and the concrete is poor and respective mechanical properties of the two cannot be fully achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Decoration type ultra-high-performance concrete material and preparation method thereof

The invention discloses a decoration type ultra-high-performance concrete material and a preparation method thereof, wherein the decoration type ultra-high-performance concrete material comprises, byweight, 90-110 parts of white cement, 22-32 parts of white silica fume, 24-32 parts of quartz powder, 18-26 parts of heavy calcium powder, 190-220 parts of white quartz sand, 2-4 parts of a preservative, 2.5-4 parts of organic fiber, 2.7-4.5 parts of a polycarboxylic acid efficient water reducing agent, 0.006-0.01 part of a defoamer, and 20-27 parts of water. The invention further discloses a preparation method of the decoration type ultra-high-performance concrete material. According to the present invention, the decoration type ultra-high-performance concrete material can be used for preparing various special-shaped structures, has excellent decorative performance, can achieve excellent decoration effect, and further has characteristics of excellent mechanical property, excellent durability and broad application prospects; and the preparation method has characteristics of simpleness, convenience, easy performing, low cost and effectively reduced construction cost.

Owner:HUAXIN CEMENT +1

High-performance fiber concrete with a C50 strength grade and preparation method of high-performance fiber concrete

ActiveCN107434384APrevent pulling outImprove energy consumptionSolid waste managementCellulose fiberMechanical property

The invention discloses high-performance fiber concrete with a C50 strength grade and a preparation method of the high-performance fiber concrete. The concrete comprises the following components in parts by mass: 330-350 parts of cement, 160-175 parts of water, 710-730 parts of river sand, 1010-1030 parts of gravels, 90-130 parts of coal ash, 20-50 parts of rice hull ash, 5-7 parts of water reducing agent, 8-9 parts of shrinkage reducing agent, 12-14 parts of exciting agent, 1.1-1.7 parts of cellulose fiber, 12-15 parts of carboxyl styrene butadiene polymers and 1.7-1.8 parts of defoaming agent. The prepared concrete has relatively high toughness and excellent durability and has relatively high bonding strength with profile steel; and when the high-performance fiber concrete is used in a profile steel and concrete combined structure, the coordinated working performance between the profile steel and the concrete can be effectively exerted, and the defects that the bonding performance of the profile steel and the concrete is poor and the mechanical properties of the profile steel and the concrete cannot be sufficiently exerted are made up.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

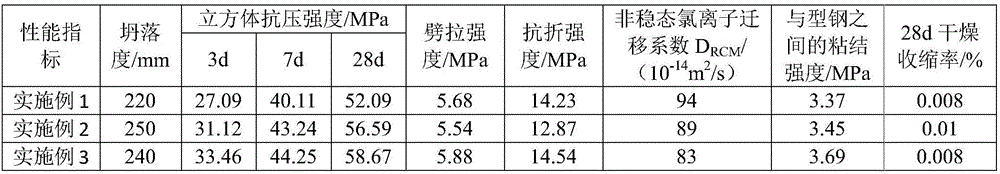

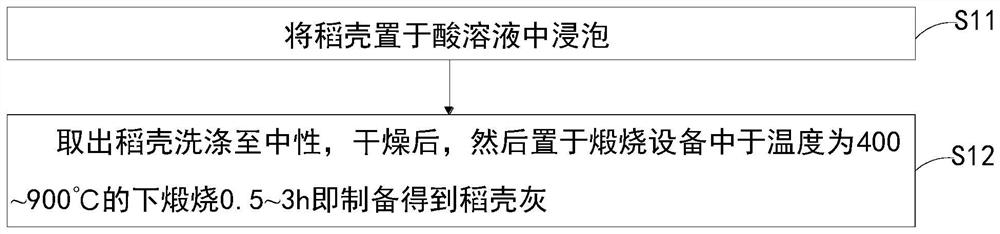

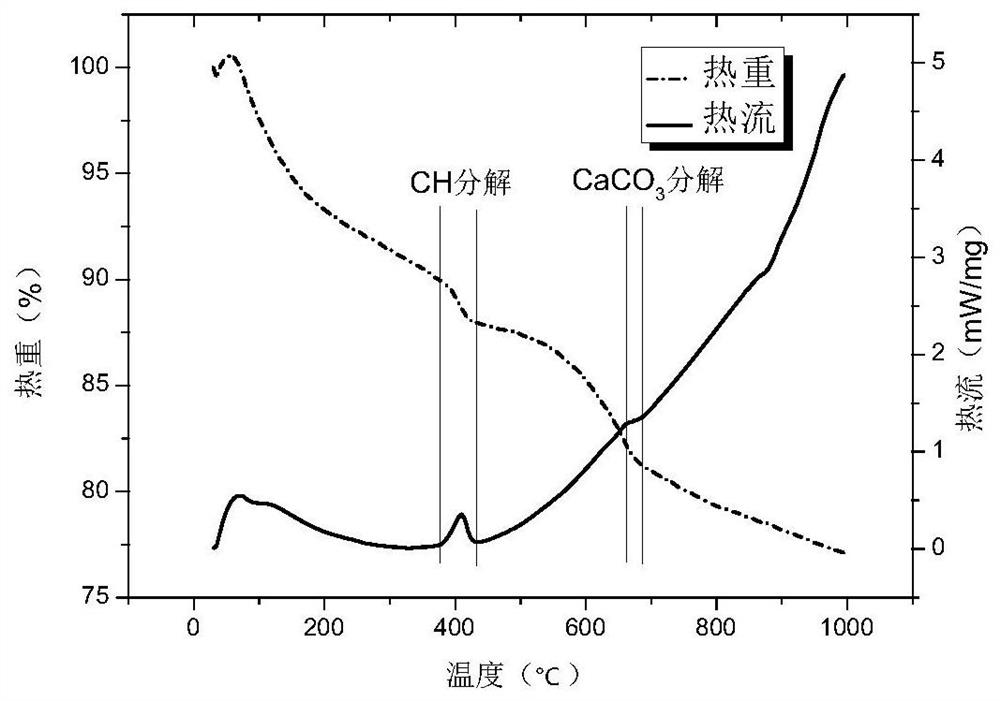

Rice hull ash and preparation method thereof, rice hull ash geopolymer and preparation method thereof

InactiveCN111995272AReduce crystallization susceptibilityLarge specific surface areaCement productionGeopolymerResidual carbon

The invention provides rice hull ash, a preparation method of the rice hull ash, a rice hull ash geopolymer and a preparation method of the rice hull ash geopolymer. The preparation method of the ricehull ash comprises the following steps: soaking rice hulls in an acid solution; taking out the rice husks, washing the rice husks to be neutral, drying the rice husks, and calcining the rice husks incalcining equipment at the temperature of 400-900 DEG C for 0.5-3 hours to obtain the rice husk ash. The invention discloses the preparation method of rice hull ash, K and other impurities hinderingrice hull combustion are removed through soaking treatment in an acid solution, the specific surface area of the rice hull ash is increased, the specific surface area is larger, the surface energy islarger, more active SiO2 is exposed, the volcanic ash activity of the rice hull ash is remarkably improved, and the content of silicon dioxide in the rice hull is remarkably increased and can reach 99.5% or above to the maximum. The rice husks are subjected to high-temperature calcination treatment, so that the content of crystalline silicon dioxide can be obviously reduced, the generation of amorphous silicon dioxide is promoted, the chemical activity is improved, and meanwhile, residual carbon is reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

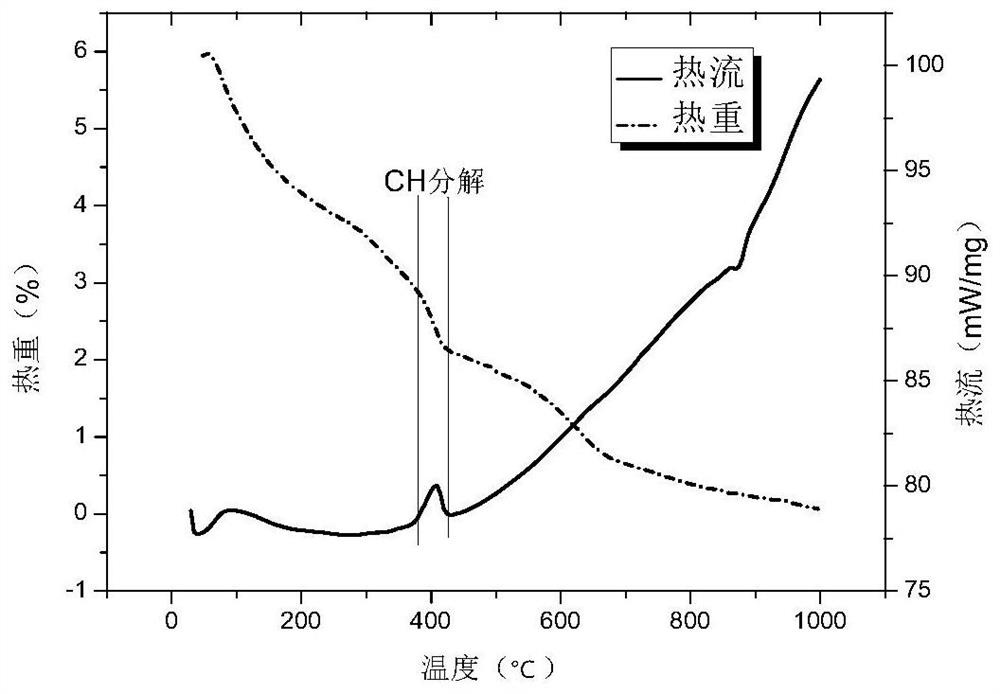

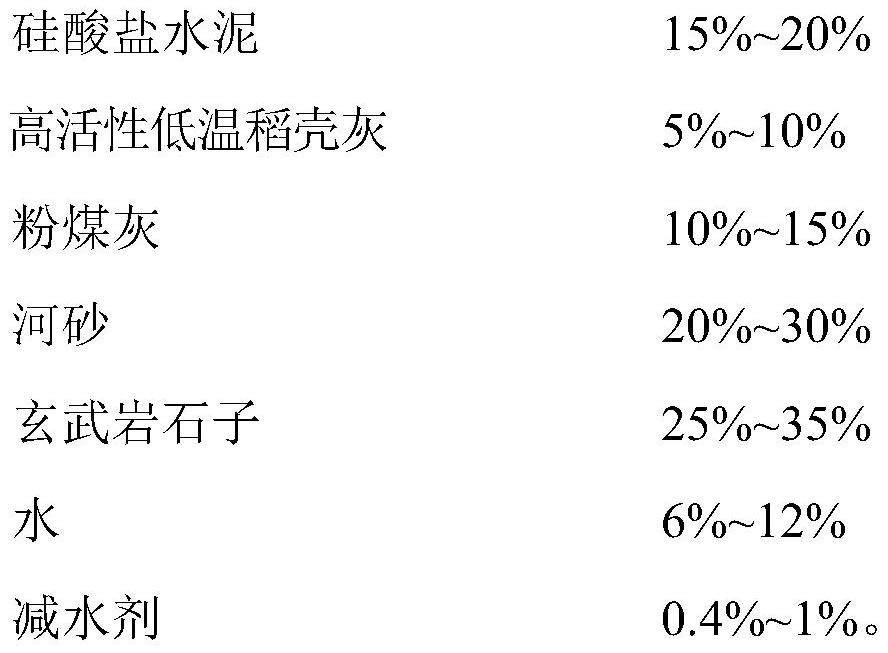

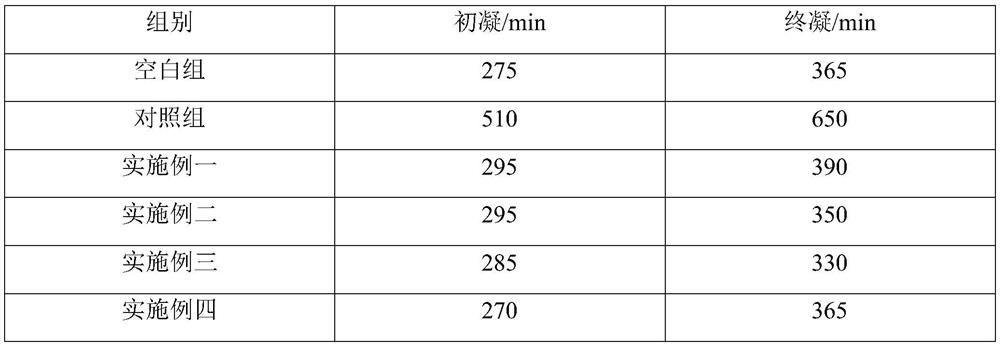

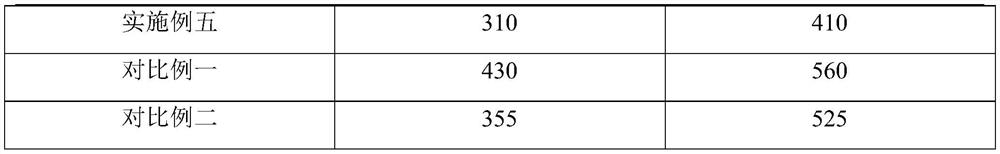

High-activity low-temperature rice hull ash and high-performance concrete doped with rice hull ash

The invention discloses high-activity low-temperature rice hull ash and high-performance concrete doped with the rice hull ash. The active low-temperature rice hull ash is prepared by the following method: subjecting rice hulls to boiling water bath in 1% hydrochloric acid for 1 h, washing the rice hulls with water, then drying the rice hulls in the sun, and removing impurities in the rice hulls;firing the pretreated rice hulls in a furnace at 600-700 DEG C for 30-60 minutes, and then performing cooling; and carrying out ball milling on the fired rice hull ash in a ball mill of 500-800r / min for 10-30min to obtain the high-activity low-temperature rice hull ash of which the SiO2 content exceeds 90wt%. The high-performance concrete doped with the high-activity low-temperature rice hull ashis prepared from the following raw materials in percentage by weight: 15%-20% of Portland cement, 5%-10% of the high-activity low-temperature rice hull ash, 10%-15% of coal ash, 20%-30% of river sand,25%-35% of basalt stone, 6%-12% of water and 0.4%-1% of a water reducing agent. The rice hull ash has high purity and high activity and can effectively replace silica fume to serve as a mineral admixture, the prepared high-performance concrete is excellent in mechanical property, the cement consumption is greatly reduced while the rice hull utilization rate is increased, and the concrete cost isreduced.

Owner:SOUTHEAST UNIV

Method for preparing inorganic fibers by compounding of slag and coal gangue

InactiveCN107973531AHigh early chemical activityImprove early chemical activityGlass making apparatusFiberSlag

The invention discloses a method for preparing inorganic fibers by compounding of slag and coal gangue. According to the method provided by the invention, firstly, desulfurization gypsum and CaO are used as activators, the coal gangue and fly ash are subjected to chemical / thermal composite excitation treatment, the coal gangue and the fly ash are excited by heat, so that the structure of glass networks of the coal gangue and the fly ash is destroyed, active SiO2 and Al2O3 are dissolved out, the dissolved-out active SiO2 and Al2O3 and CaO are subjected to a solid phase reaction, a new substancewith hydraulic activity is generated, and the activity of a pozzolanic reaction of the material is improved; and then the active material and blast furnace slag are mixed and ground, melt centrifugation drawing is performed, so that the inorganic fibers are prepared, the slag and other raw materials are introduced in the manner of fibers, the fibers can be uniformly distributed into a hardened slurry, and a grid structure can be formed, so that the problem of bleeding of concrete is improved, the compactness of the hardened slurry is improved, and the compressive strength and durability of the concrete are improved.

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

Non-delayed coagulation phosphorus slag powder for cement-based material and preparation method thereof

PendingCN114057420ALarge specific surface areaAchieve removalSolid waste managementSlagEconomic benefits

The invention discloses retarding-free phosphorus slag powder for a cement-based material and a preparation method thereof and belongs to the technical field of building materials. The method comprises the following steps: carrying out wet grinding on the water-quenched phosphorus slag, mixing and stirring the water-quenched phosphorus slag, an anion capturing agent, water and an alkaline regulator, removing foam during stirring, and filtering and drying the mixture to obtain the water-quenched phosphorus slag. Through treatment and preparation of the phosphorus slag powder, the problem of delayed coagulation of the phosphorus slag powder on a cement-based material can be effectively solved, and the current situation that the phosphorus slag powder is poor in early strength is improved. The preparation method is simple in process, the use amount of various auxiliaries is extremely low, and the influence on the production cost of the phosphorus slag powder is extremely small; therefore, the method has wide applicability and excellent economic benefits in production practice.

Owner:SINOHYDRO BUREAU 7 CO LTD

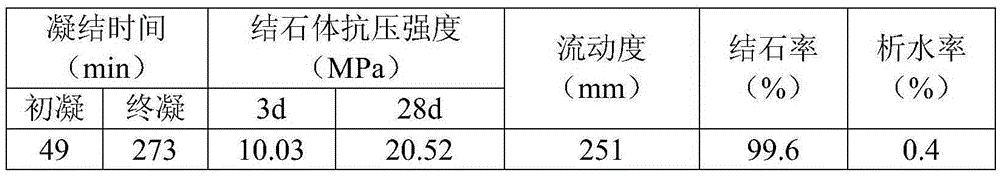

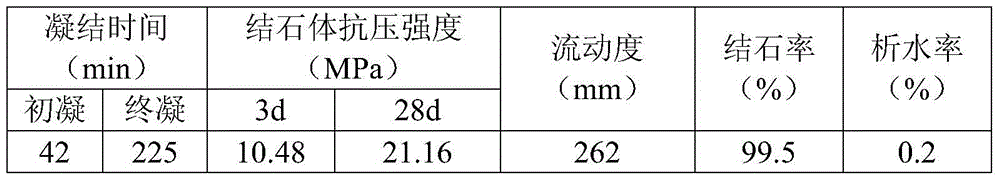

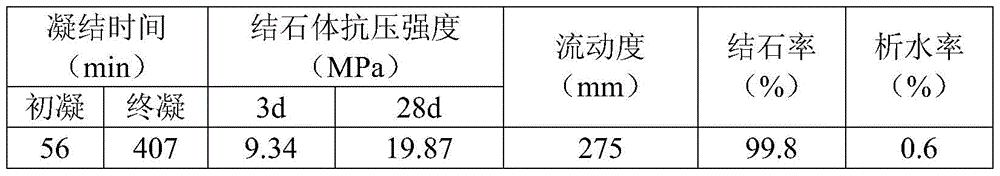

Prestressed pipeline grouting material and preparation method thereof

The invention provides a prestressed pipeline grouting material. The material comprises the following components in percentage by mass: 50-77% of cement, 10-20% of steel slag micro-powder, 5-10% of zeolite powder, 5-15% of grinded rice hull ash, 2-9% of expander, 0.3-1.5% of powdery high-performance water reducer, 0.02-0.04% of defoamer and 0.02-0.06% of retarder. The invention further provides a preparation method of the material simultaneously. The scheme provided by the invention is used for solving the defects in the prior art; steel slag micro-powder, zeolite powder and grinded rice hull ash are used in the material as admixtures; the problems of shrinkage and bleeding are solved by comprehensively utilizing the advantages of the various admixtures, and the durability of the grouting material is improved; meanwhile, the steel slag, zeolite and rice hull ash resources are greatly utilized.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

Low-shrinkage-percentage resin mineral composite cement-based material and preparation method thereof

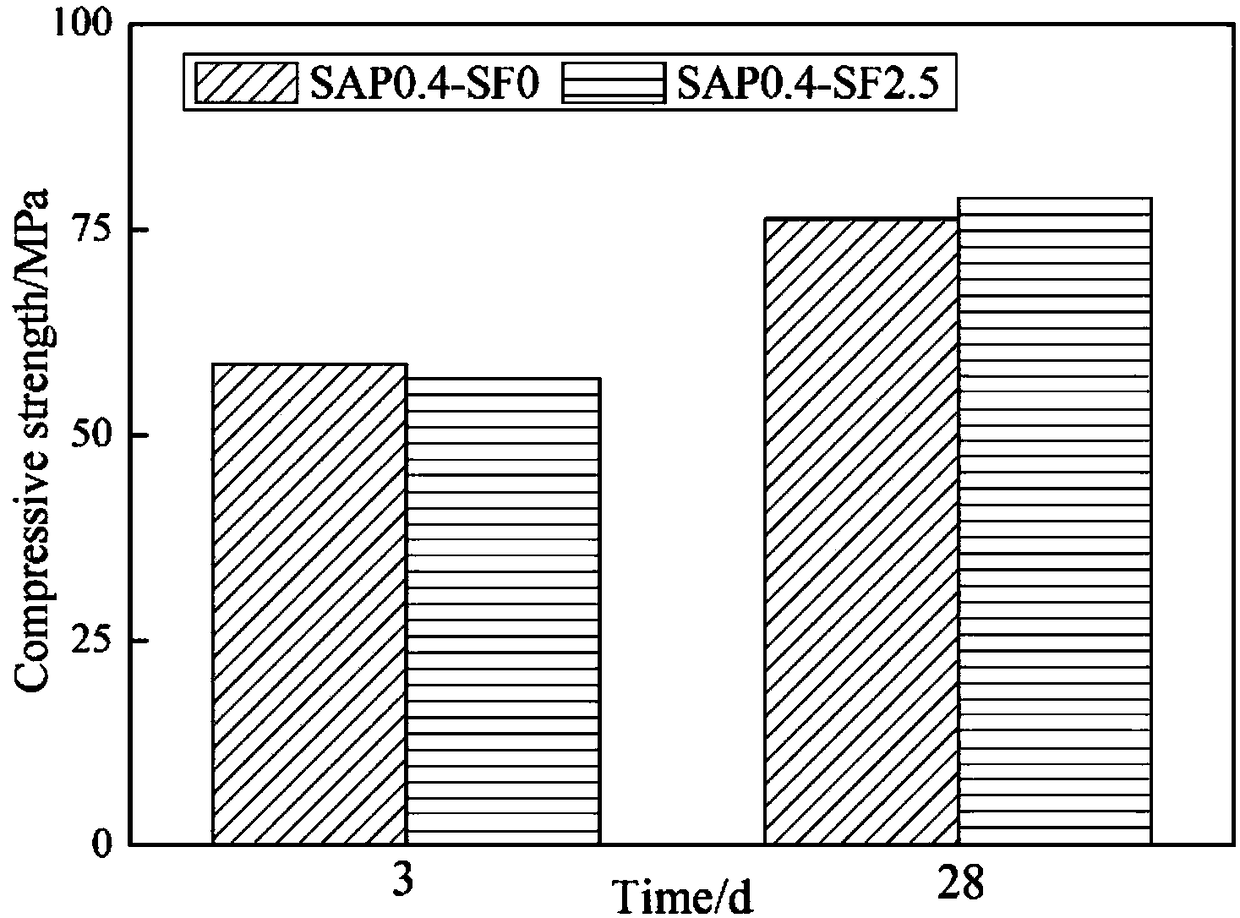

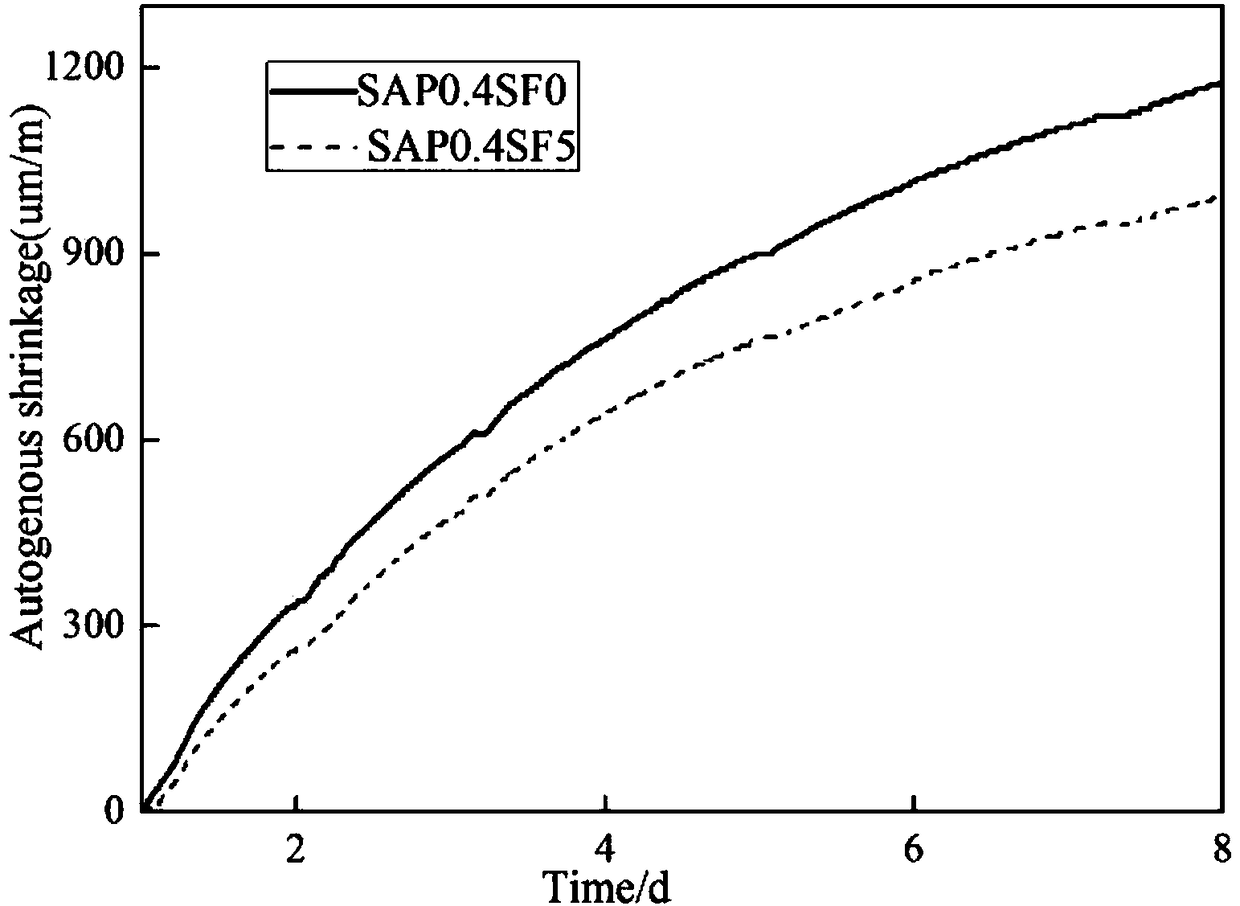

The invention provides a low-shrinkage-percentage resin mineral composite cement-based material and a preparation method thereof. Self-shrinkage of concrete can be reduced easily, conveniently and rapidly, and the early cracking risk can be decreased effectively. The cement-based material is characterized by comprising cement, silica fume, super absorbent resin and water reducers. The cement and the silica fume are blended internally as cementing materials. The super absorbent resin and the water reducers are blended externally. In the cementing materials, the cement accounts for 97.5-95wt% while the silica fume accounts for 2.5-5wt%. The blending amount of the super absorbent resin is 0.2-0.4wt% of the cementing materials. The preparation method is characterized by including the steps offirstly adding water into a stirring device, blending the water reducers with the water, and evenly stirring the mixture; blending the silica fume and the cement with the mixture sequentially to obtain mixed sizing; evenly stirring the super absorbent resin and additional water, and blending the super absorbent resin and the additional water with the mixed sizing.

Owner:WUHAN UNIV OF SCI & TECH

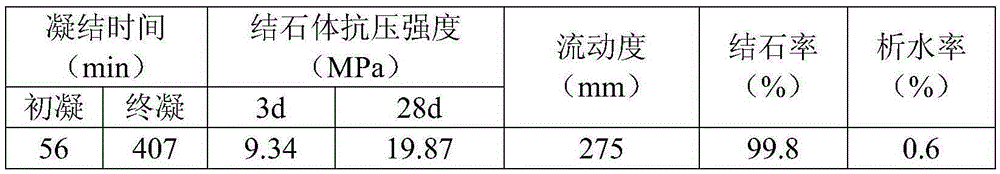

Geopolymer composite grouting material and its preparation and use method

The invention discloses a geopolymer composite grouting material and its preparation and application method. The fine powder prepared by uniformly mixing with dispersible latex powder according to a certain proportion and grinding requires that the sieve with a fineness of 45 μm is not more than 30%. The invention adopts solid waste blast furnace slag, fly ash and metal mine tailings, which reduces the cost of materials, improves the fluidity of materials, and can increase the compressive strength of geopolymer composites without increasing the cost. Grouting material.

Owner:SHANDONG UNIV OF SCI & TECH

Mineral admixture for concrete and preparation method thereof

The invention discloses a mineral admixture for concrete and a preparation method thereof. The mineral admixture comprises the following components in parts by weight: 50-220 parts of mixing plant waste slurry water, 20-100 parts of mixing plant solid waste, 20-150 parts of industrial solid waste, 0.3-1.5 parts of a grinding aid and 0.3-1.5 parts of a dispersing agent. The mineral admixture prepared by the preparation method disclosed by the invention can replace part of cementing materials used in a concrete preparation process while realizing reutilization of various solid waste resources, so that the cost of concrete raw materials is reduced, and the durability of concrete is improved.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

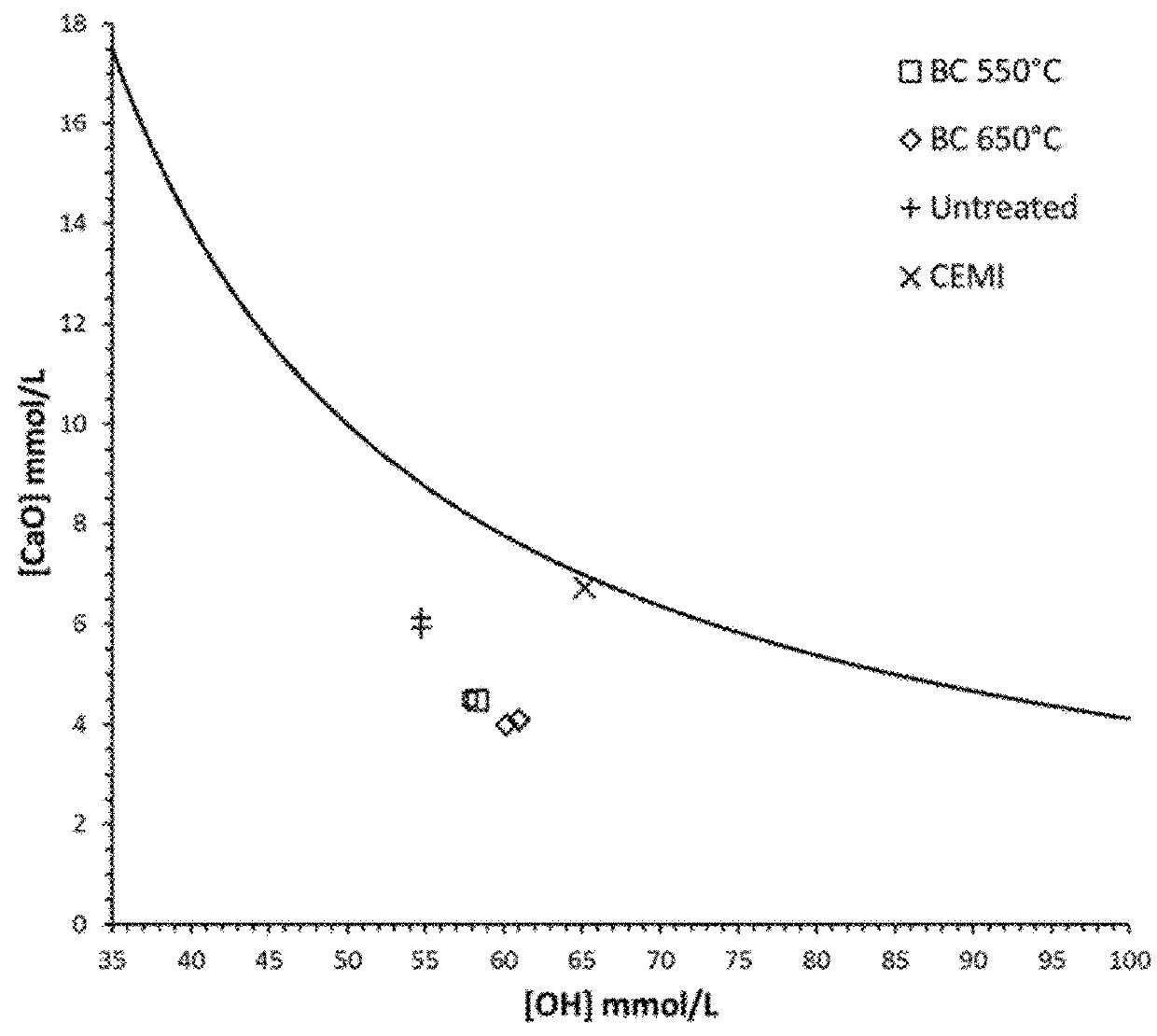

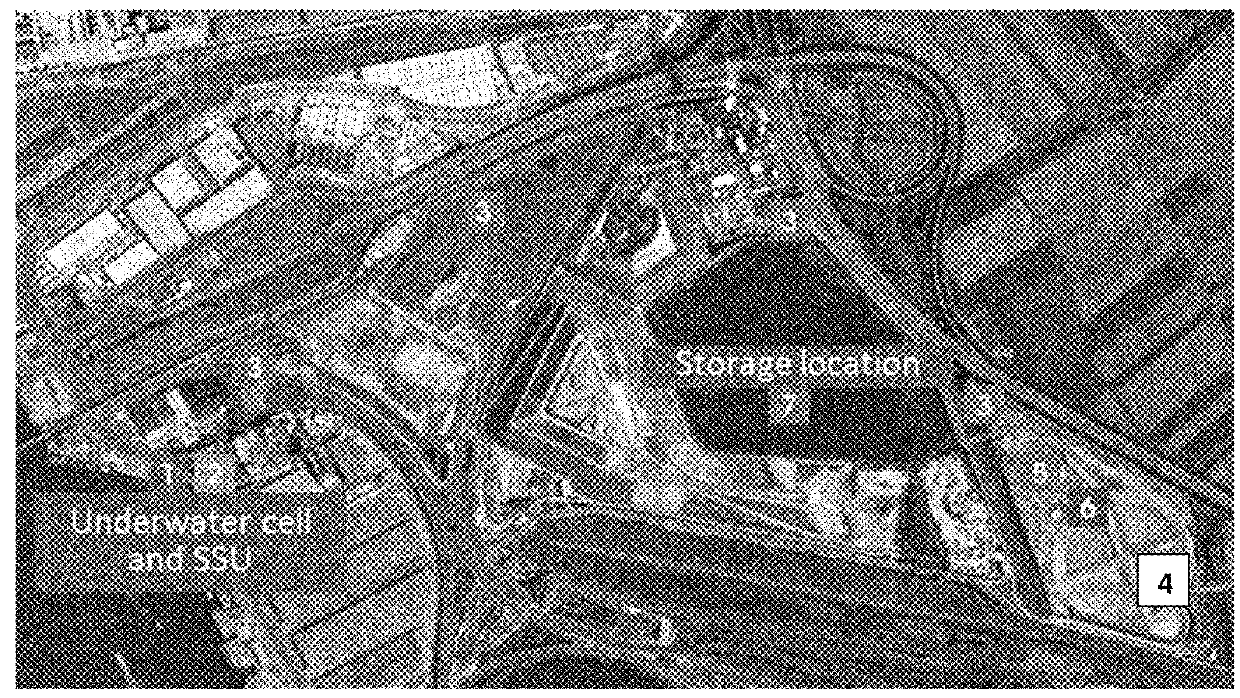

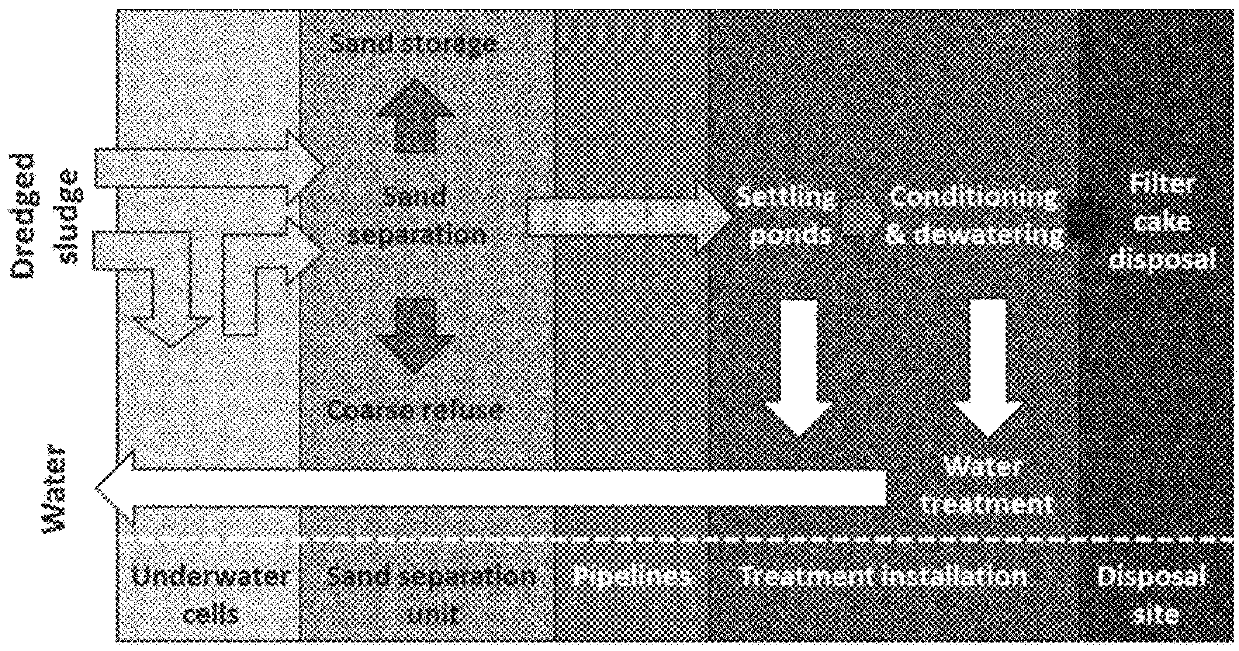

Supplementary cementitious materials comprising dredged sediments

ActiveUS20180162773A1Increased pozzolanic activityEfficient recyclingSolid waste managementCement productionPortland cementSediment

A supplementary cementitious material used in combination with an activator such as Portland cement to produce a hydraulic binder. The supplementary cementitious material is based on physico-chemically treated filter cake product extracted from dredged sediments and can partially replace Portland cement clinker in conventional concrete applications with positive effects on sustainability (reduction of CO2 emissions, upcycling of residues).

Owner:FLEMISH GOVERNMENT DEPT OF PUBLIC WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com