High-activity low-temperature rice hull ash and high-performance concrete doped with rice hull ash

A high-performance concrete and rice husk ash technology, applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of low purity and activity of rice husk ash, unable to effectively enhance the performance of cement-based materials, etc. Achieve the effect of saving cement consumption, easy industrial production and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of high activity low temperature rice husk ash:

[0024] (1) Pretreatment: put the rice husk in a boiling water bath for 60 minutes in 1% hydrochloric acid, wash with water and then dry to remove impurities therein;

[0025] (2) Firing: firing the pretreated rice husks in a furnace at 650°C for 60 minutes, then cooling;

[0026] (3) Grinding: mill the burned rice husk ash for 30 minutes in a ball mill at 700 rpm to obtain high-activity low-temperature rice husk ash.

[0027] The chemical composition of the highly active low-temperature rice husk ash prepared by X-ray fluorescence spectroscopy (XRF) analysis, as shown in Table 1 below, can be seen that the prepared high-activity low-temperature rice husk ash contains more than 95wt% SiO 2 .

[0028] The chemical composition of the highly active low-temperature rice husk ash prepared by Table 1 Example 1

[0029]

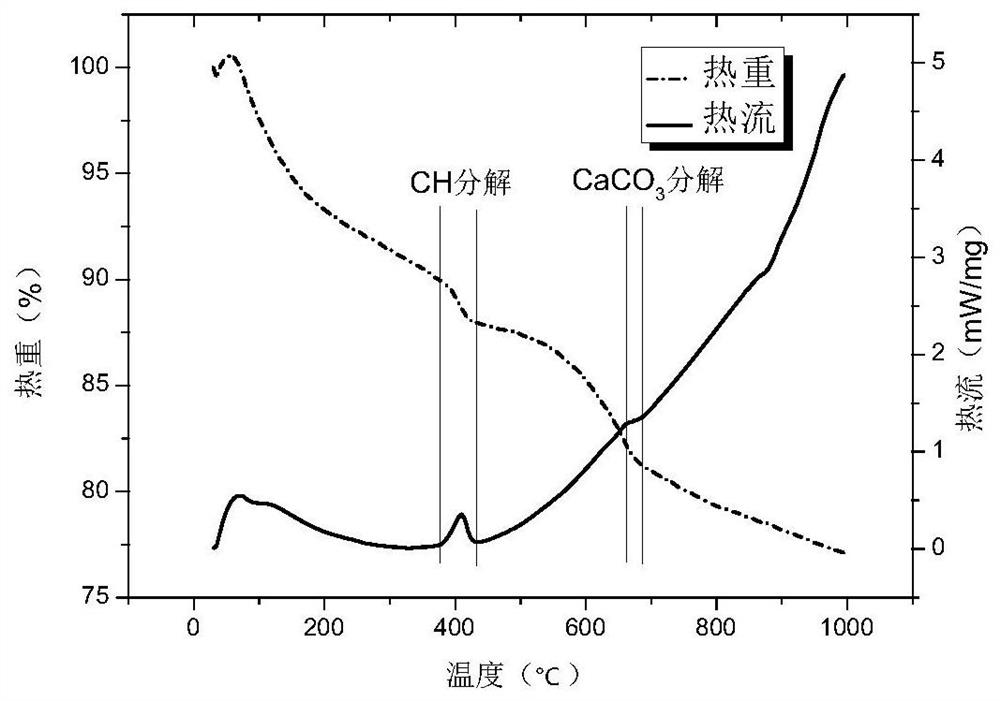

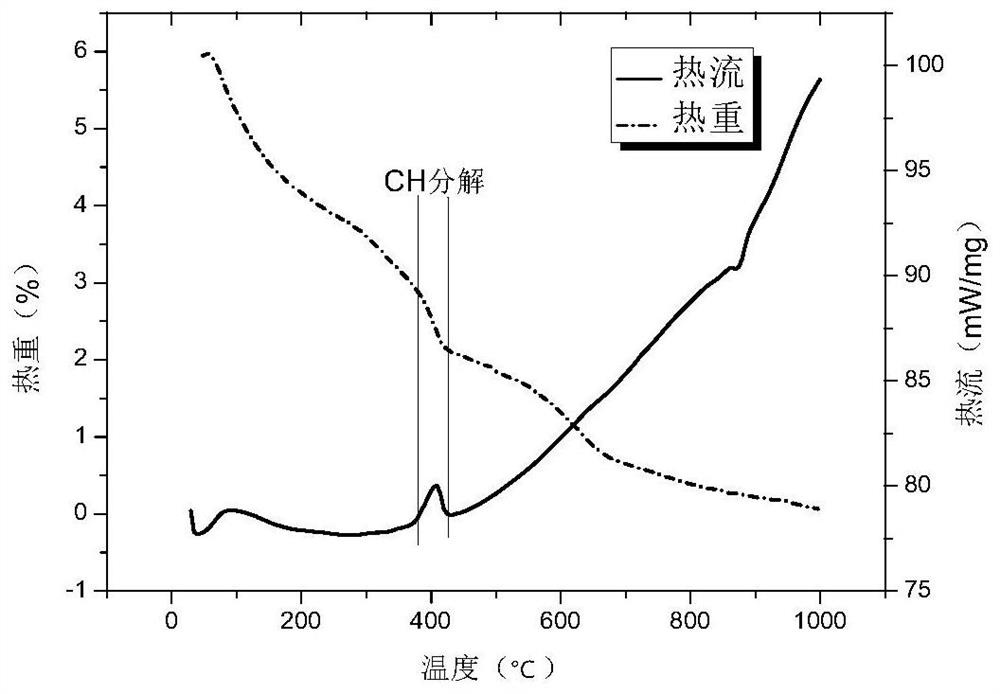

[0030] The high-activity low-temperature rice husk ash prepared was analyzed by DSC / TG the...

Embodiment 2

[0038] Preparation of high activity low temperature rice husk ash:

[0039] (1) Pretreatment: put rice husks in 0.5% hydrochloric acid in a boiling water bath for 45 minutes, wash with water and then dry to remove impurities therein;

[0040] (2) Firing: firing the pretreated rice husks in a furnace at 600°C for 30 minutes, then cooling;

[0041] (3) Grinding: mill the burned rice husk ash in a ball mill at 500 rpm for 10 minutes to obtain high-activity low-temperature rice husk ash.

[0042] Through X-ray fluorescence spectrum (XRF) analysis, the highly active low-temperature rice husk ash prepared in this embodiment contains more than 90wt% SiO 2 . After DSC / TG thermal analysis method analysis and calculation of its activity index, the activity of the rice husk ash is higher than that of silica fume.

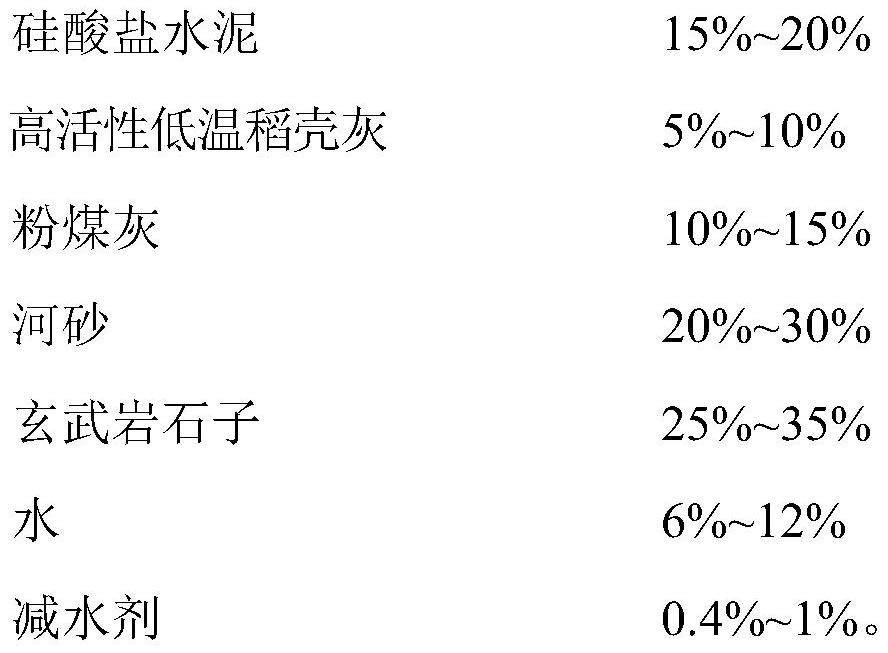

[0043] Using the prepared high-activity low-temperature rice husk ash as raw material, prepare high-performance concrete with the following components:

[0044]

[0045...

Embodiment 3

[0048] Preparation of high activity low temperature rice husk ash:

[0049] (1) Pretreatment: put the rice husk in a boiling water bath for 90 minutes in 1% hydrochloric acid, wash with water and then dry to remove impurities therein;

[0050] (2) Firing: firing the pretreated rice husks in a furnace at 700°C for 60 minutes, then cooling;

[0051] (3) Grinding: mill the burned rice husk ash in a ball mill at 600 rpm for 20 minutes to obtain high-activity low-temperature rice husk ash.

[0052]Through X-ray fluorescence spectrum (XRF) analysis, the highly active low-temperature rice husk ash prepared in this embodiment contains more than 90wt% SiO 2 . After DSC / TG thermal analysis method analysis and calculation of its activity index, the activity of the rice husk ash is higher than that of silica fume.

[0053] Using the prepared high-activity low-temperature rice husk ash as raw material, prepare high-performance concrete with the following components:

[0054]

[0055...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com