Metal case and manufacturing method therefor

A technology for metal shells and manufacturing methods, applied in metal shells, metal processing, metal processing equipment, etc., can solve problems such as poor surface wear resistance, easy wear and peeling of paint, and affect product appearance, so as to improve wear resistance and facilitate Operation, beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

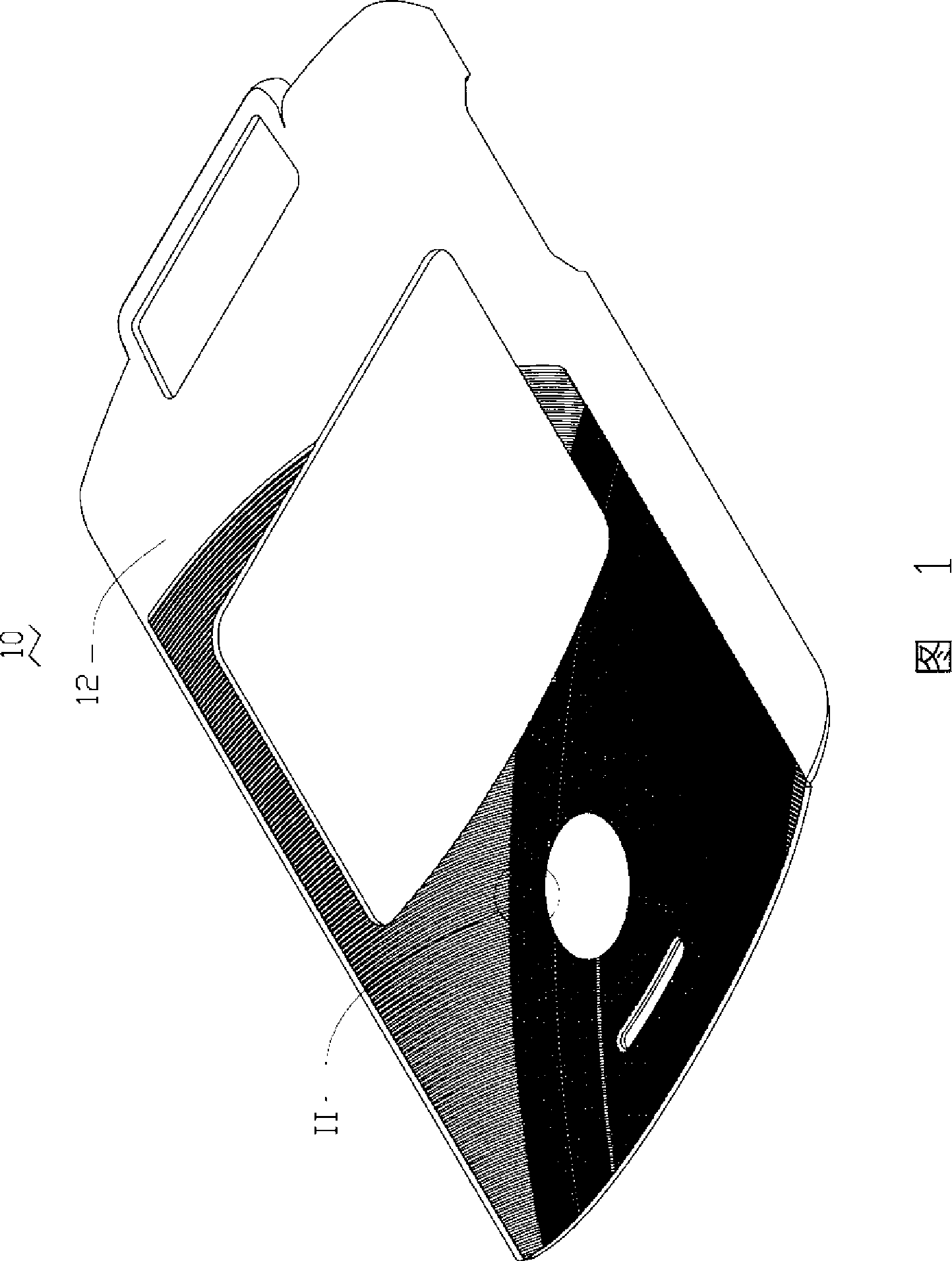

[0019] Please refer to FIG. 1 and FIG. 2 , the metal case 10 of the first preferred embodiment of the present invention can be applied to portable electronic devices, such as mobile phones.

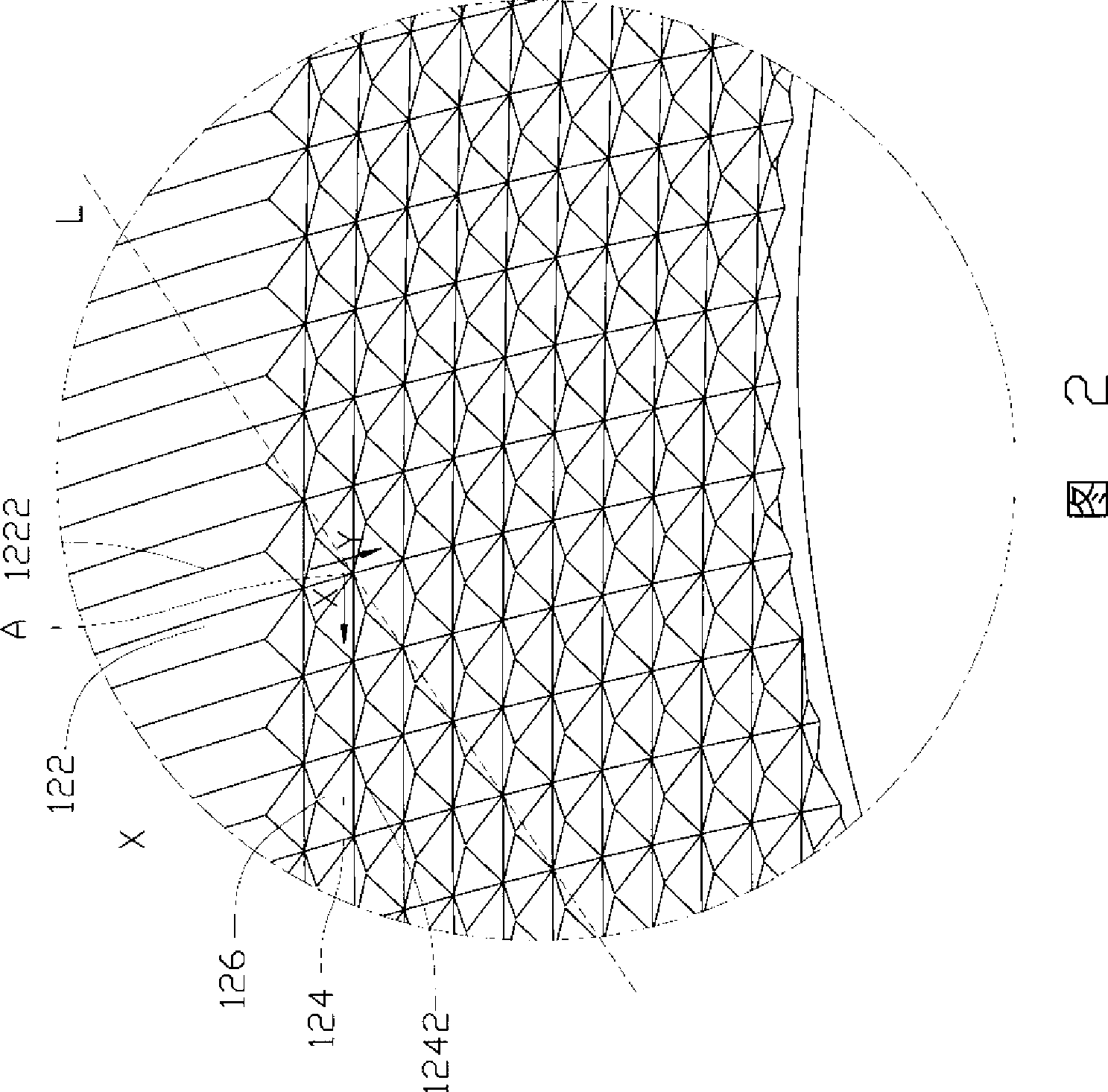

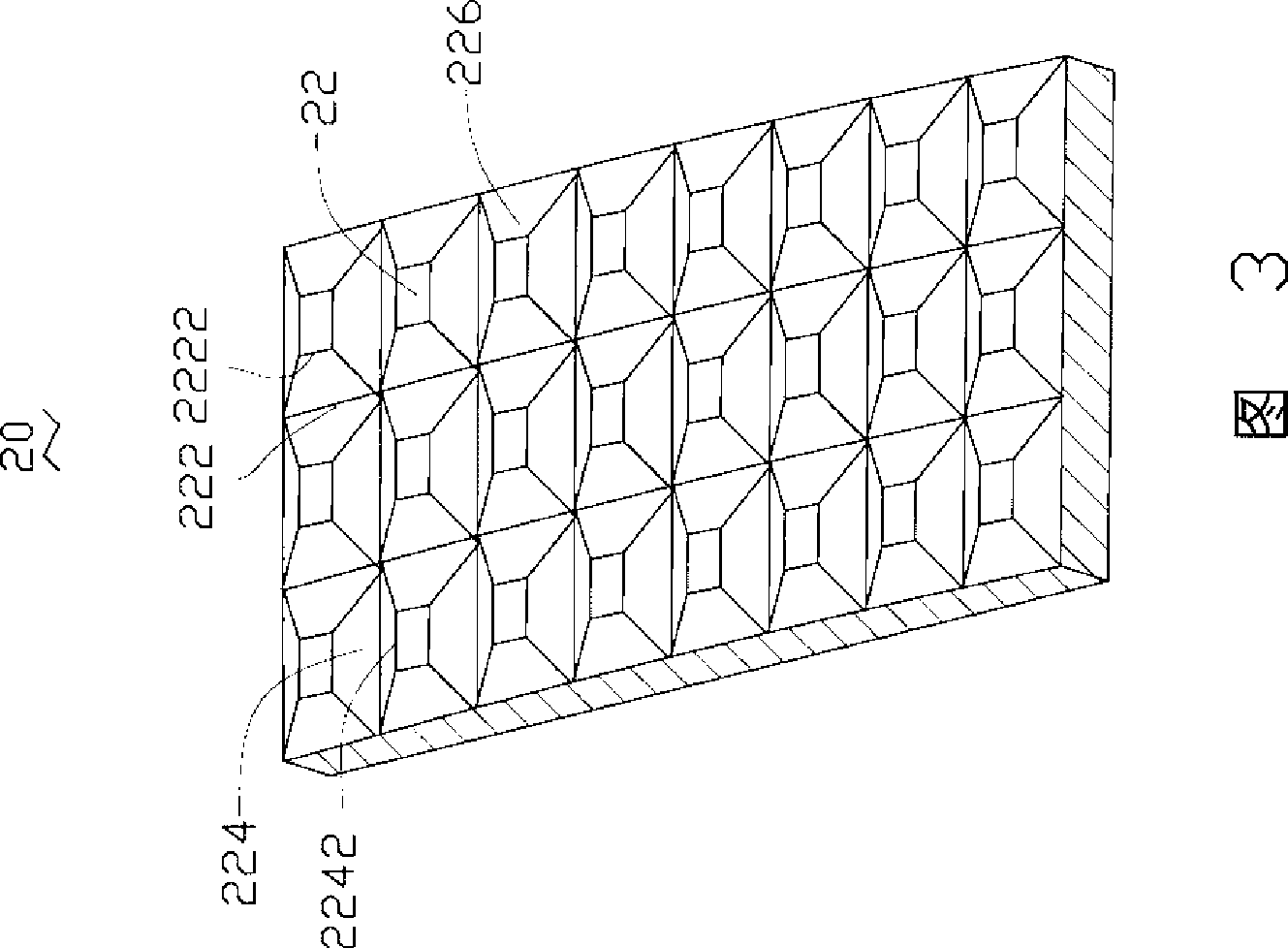

[0020] The metal shell 10 includes a surface 12 on which a plurality of first textures 122 arranged at intervals and a plurality of second textures 124 arranged at intervals are formed. The plurality of first textures 122 have the same curvature, and the second textures 124 have the same curvature. The first textures 122 and the second textures 124 are anti-staggered. The so-called reverse interlacing means that there is an intersection between the first lines 122 and the second lines 124, and the extension direction of the first lines 122 and the extension direction of the second lines 124 are symmetrical with respect to a straight line passing through the intersection. , and the straight line is located on the plane formed by the extending directions of the first texture 122 and the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com