Slope self-compacting concrete and pouring construction method thereof

A technology of self-compacting concrete and inclined planes, applied in the field of concrete, can solve the problems of limited application, low performance of admixtures, and low activity of admixtures, and achieve the effects of reducing production costs, expanding application range, and improving pozzolan activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Further preferably, the preparation method of the steel slag micro-powder modified on the surface of nano silicon dioxide also includes the steps:

[0051] The fine powder washed with dilute alkaline solution is then washed with 0.6-1% silane coupling agent solution, and then heat-treated after natural air drying;

[0052] The surface of the silica sol modified steel slag powder has abundant hydroxyl groups, and the leaching with a low concentration of silane coupling agent solution can introduce silicon oxygen groups on the surface of the modified steel slag powder to improve the surface lubricity of the steel slag powder. After blending into concrete, it is beneficial to improve the fluidity of concrete;

[0053] Preferably, the admixture also includes one or more of anti-cracking agent, water retention agent, defoamer, retarder;

[0054] In order to further improve the working performance of the concrete, various admixtures can be added to adapt to different applicati...

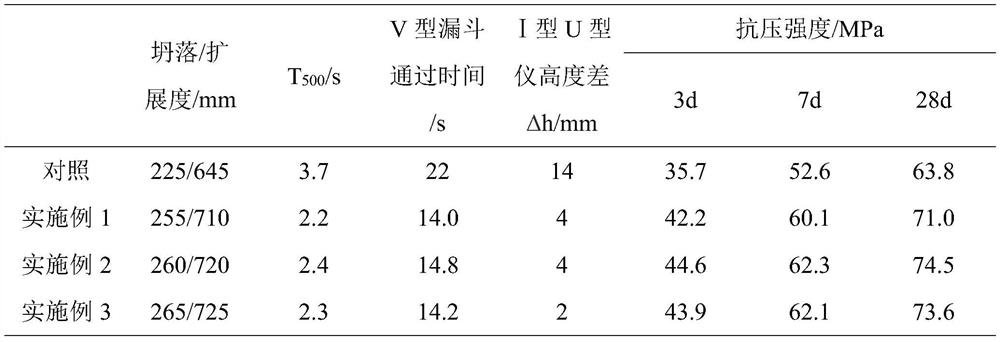

Embodiment 1

[0059] A slope self-compacting concrete, which has the following components by weight: 64 parts of 42.5 Portland cement, 70 parts of coarse aggregate, 56 parts of fine aggregate, 18 parts of mineral admixture, 0.8 part of water reducer; water-binder ratio 0.31;

[0060] The coarse aggregate is granite stone with a particle size of 5-16mm and continuous gradation;

[0061] The fine aggregate is river sand, the fineness modulus is 2.9, and the sand in Zone II;

[0062] The mineral admixture is a mixture of steel slag, fly ash and silicon powder, and its mass ratio is 1:1:0.5;

[0063] The water reducer is a composite water reducer formed by compounding sulfamate-comb polycarboxylic acid in a mass ratio of 1:1.8;

[0064] The steel slag is steel slag micropowder modified by nano silicon dioxide surface;

[0065] The preparation method of the steel slag micropowder modified on the surface of the nano silicon dioxide is:

[0066] S1. Steel slag crushing and grinding, mixed with...

Embodiment 2

[0069] A slope self-compacting concrete, which has the following components by weight: 64 parts of 42.5 Portland cement, 70 parts of coarse aggregate, 56 parts of fine aggregate, 18 parts of mineral admixture, 0.8 part of water reducer; water-binder ratio 0.31;

[0070] The coarse aggregate is granite stone with a particle size of 5-16mm and continuous gradation;

[0071] The fine aggregate is river sand, the fineness modulus is 2.9, and the sand in Zone II;

[0072] The mineral admixture is a mixture of steel slag, fly ash and silicon powder, and its mass ratio is 1:1:0.5;

[0073] The water reducer is a composite water reducer formed by compounding sulfamate-comb polycarboxylic acid in a mass ratio of 1:1.8;

[0074] The steel slag is steel slag micropowder modified by nano silicon dioxide surface;

[0075] The preparation method of the steel slag micropowder modified on the surface of the nano silicon dioxide is:

[0076] S1. Steel slag crushing and grinding, mixed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com