Radiation shield concrete and preparation method thereof

A concrete and radiation protection technology, applied in the field of building materials, can solve the problems such as barite and lead powder cannot be widely used, the chemical composition of steel slag is inconsistent, and the ability to protect against neutron rays is poor. The effect of reducing the water-cement ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

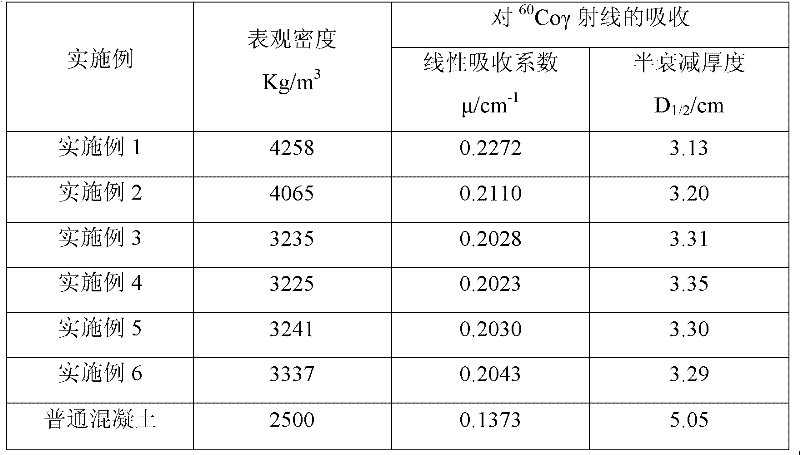

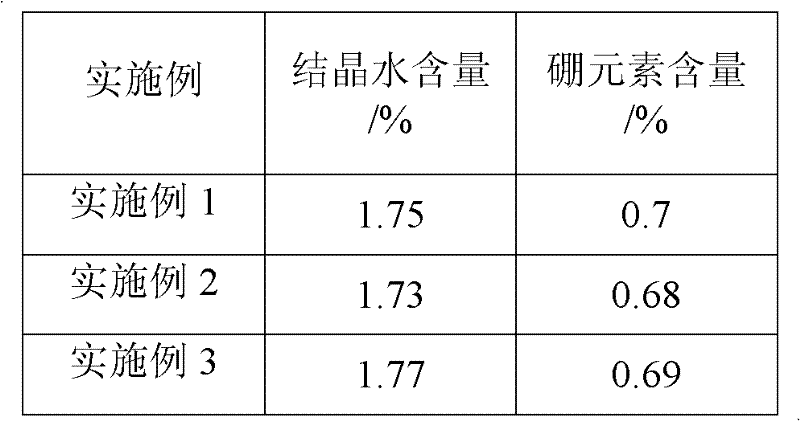

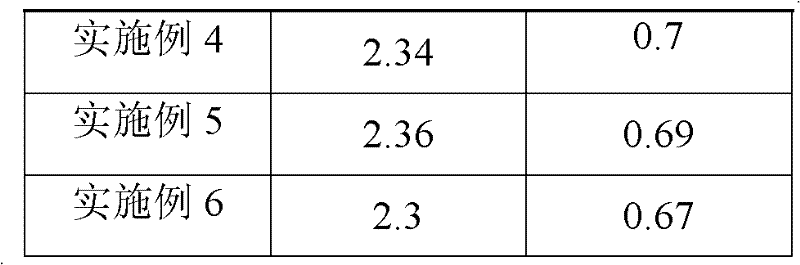

Examples

Embodiment 1~6

[0027] Embodiment 1~6 a kind of preparation method of radiation-proof concrete

[0028] 1) to prepare 1m 3 Take radiation-proof concrete as an example, select raw materials according to the ratio in Table 1, and the details of each raw material are as follows:

[0029] Cement: Choose 42.5 grade ordinary Portland cement.

[0030] Inorganic mineral admixture: fly ash is ordinary secondary ash; silicon powder is ordinary silicon powder, with a specific surface area of 150,000-250,000m 2 / kg;

[0031] Coarse aggregate: steel segment, cylindrical shape, particle size 5-18mm, diameter 3-8mm, maximum length no more than 15-20mm, apparent density 7500kg / m 3 ;Steel slag: Egang steel slag with stable quality (mass loss ≤ 5%) after being stored for one year and tested for stability by steaming (refer to the national standard "Steel slag powder used in cement and concrete (GB / T 20491-2006)") , gradation 5-20mm, apparent density 2912kg / m3, bulk density 1743kg / m3 3 , the water absorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com