Finely ground high-titanium slag and fly ash composite high-performance concrete

A high-performance concrete, high-titanium slag technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc. Protect the environment, good quality, reduce the effect of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

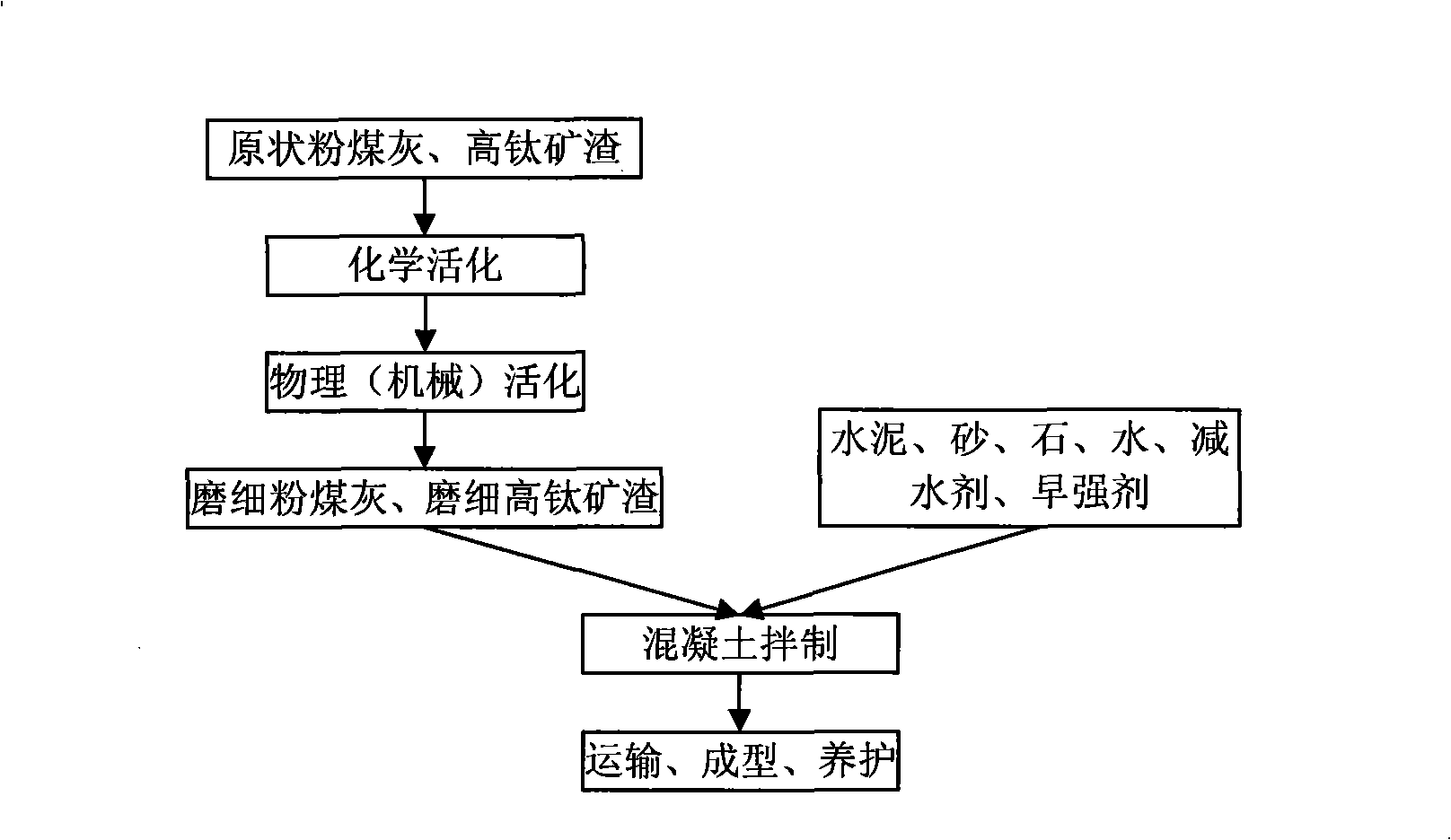

Method used

Image

Examples

Embodiment Construction

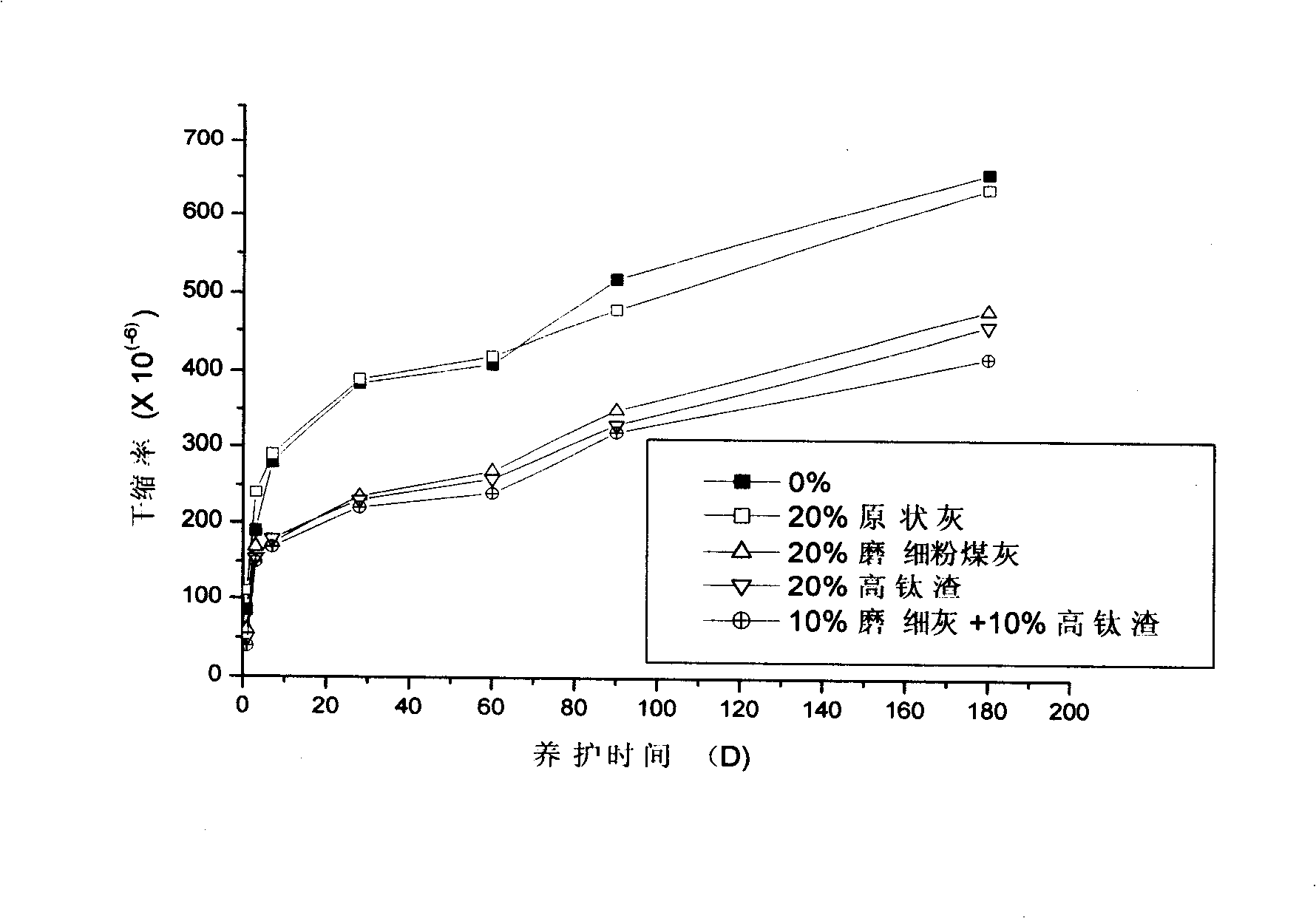

[0019] The laboratory prepared C60 concrete for testing, the results are shown in Table 2 and figure 2 . Tests have shown that the volume stability of high-performance concrete compounded with ground high-titanium slag and fly ash is better than that of high-performance concrete prepared with single-mix grinding of fine fly ash or finely ground high-titanium slag (that is, ground high-titanium slag and pulverized coal). The dry shrinkage value of high performance concrete prepared with ash compound is small, see figure 2 ); compressive strength, axial compressive strength, and static elastic modulus in physical and mechanical properties, and the former are better than the latter, while the flexural strength and splitting tensile strength are basically the same, see Table 2 for details.

[0020] Table 2 Mechanical properties of C60 high performance concrete 28d

[0021] edit

No

Admixture dosage

(MPa)

Flex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com