Method for widening steel-concrete combination

A technology of concrete and raw concrete, which is applied in bridge reinforcement, bridge parts, erection/assembly of bridges, etc. It can solve problems such as unsatisfactory requirements, achieve fast construction, reduce bridge deck cracking, and have good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

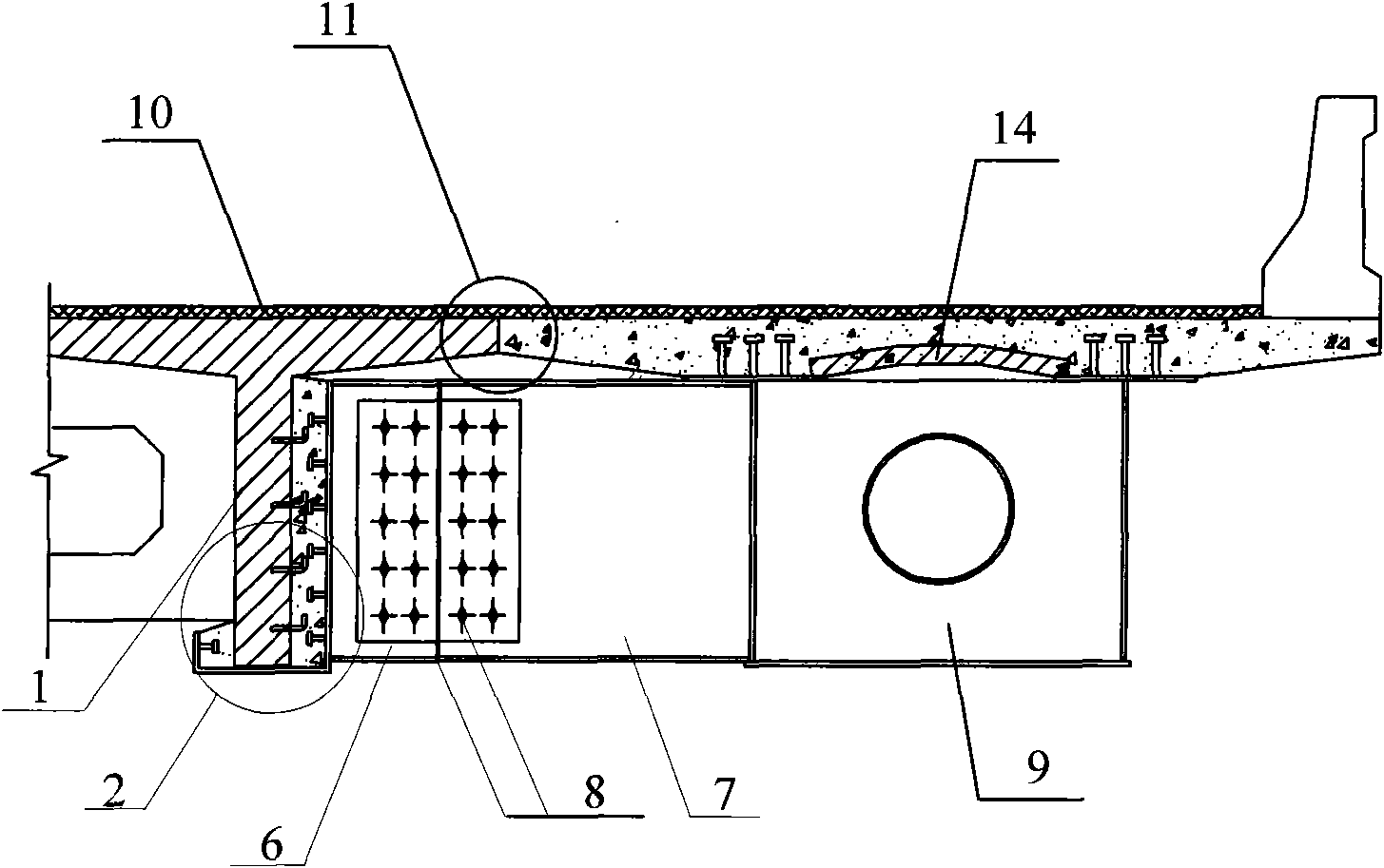

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] Construction procedure of the present invention is:

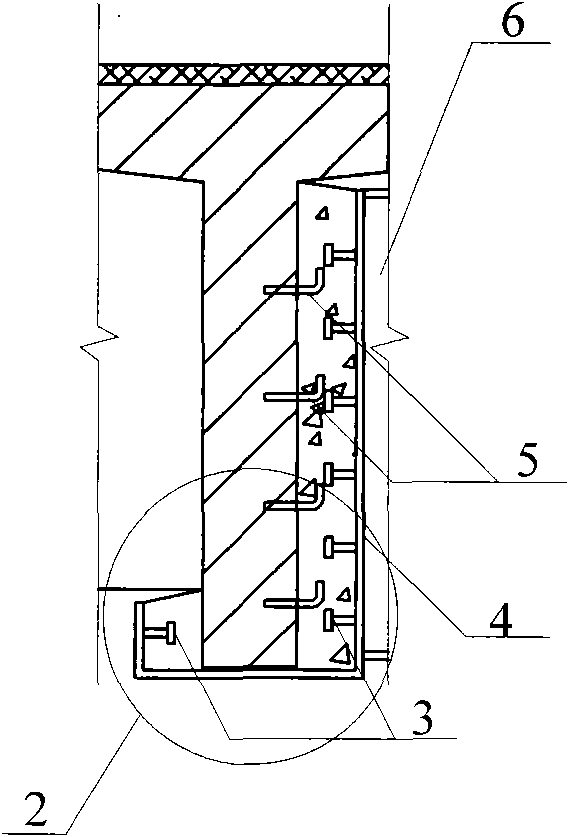

[0023] 1) Gouging the outer side of the web of the original concrete beam 1, and planting L-shaped short steel bars 5, adopting the steel plate connector 4 with studs 3 on the inner side, wrapping it on the outer side of the original concrete beam 1, and reserving pouring holes; pouring reinforcement area Concrete forms the steel plate-concrete composite anchorage connector 2, and reserves the composite anchorage zone's extended corbel 6 for subsequent connection;

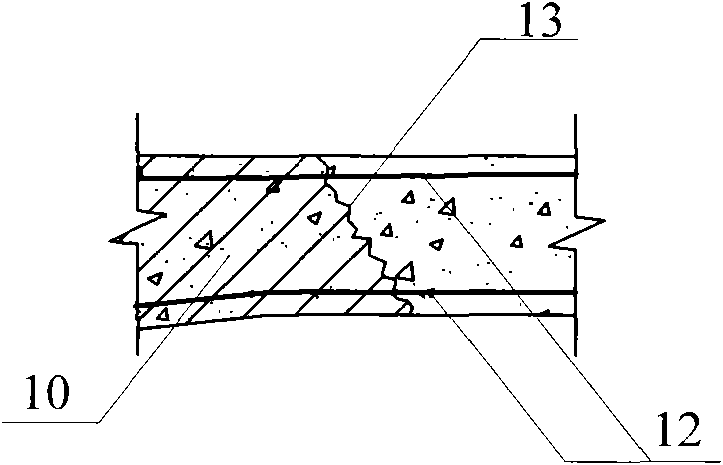

[0024] 2) Connect the widened steel beam 9 and the cross-connected steel beam 7 together on site (it can also be completed in the steel structure processing plant), and hoist and position them to the designated position. The widened steel girder 9 can adopt box-shaped or I-shaped cross-sections, and the use of box-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com