Intelligent FRP (Fiber Reinforce Plastic)-concrete composite structure and manufacturing method thereof

A composite structure and concrete technology, applied to truss structures, joists, girders, etc., can solve the problems of prestress bond loss, prestress loss monitoring difficulties, etc., achieve small prestress loss, reduce construction costs, equipment and Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

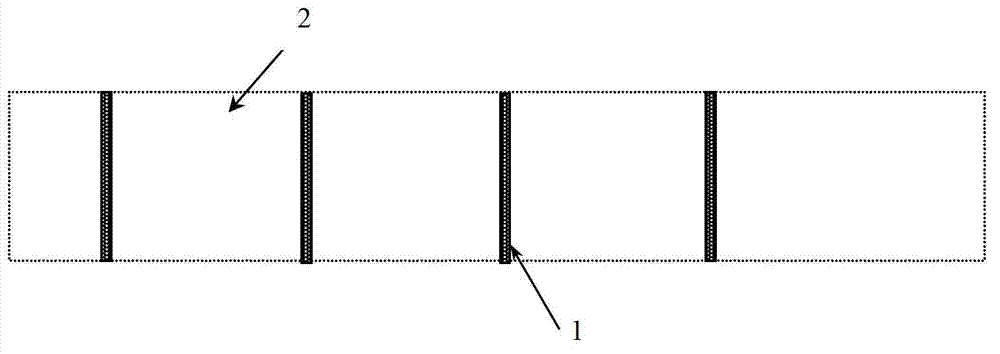

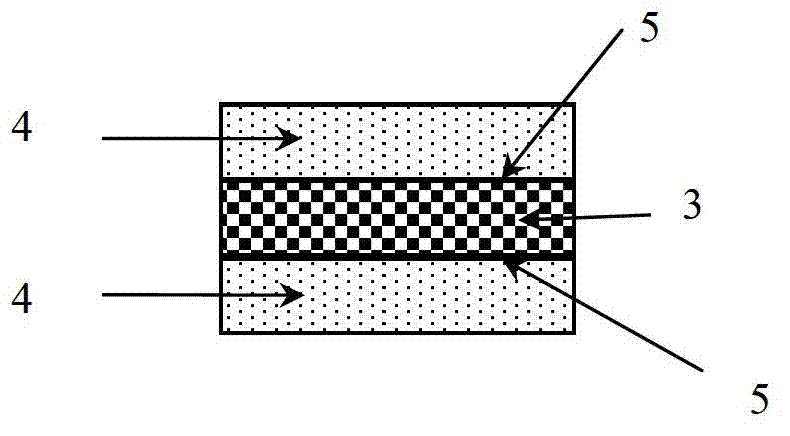

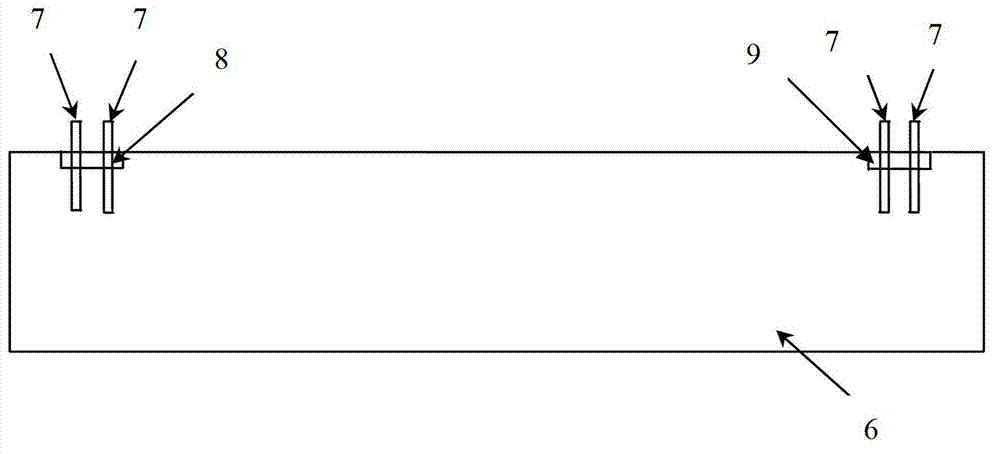

[0094] For the cross-sectional dimensions and reinforcement of the reinforced concrete core used in this test, see Figure 12 , 13 , the section size is width×height=150×300mm; the length is 3100mm, and the calculated span is 2700; the concrete is C30 grade, and the bottom of the test beam is a row of tensile steel bars The top erecting steel bar is The stirrup adopts Ф8 dense area interval of 90mm, non-encrypted area interval of 180mm, and the thickness of the concrete protective layer is 25mm. The intelligent FRP layer bonding, measuring electrode installation and four-point bending test of the intelligent FRP-concrete composite structure are as follows: Figure 14 and 15 As shown, a total of 4 measuring and measuring electrodes are installed, which can monitor the intelligent FRP-concrete composite structure in different regions and perform damage location.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com