Wood-concrete-composite systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

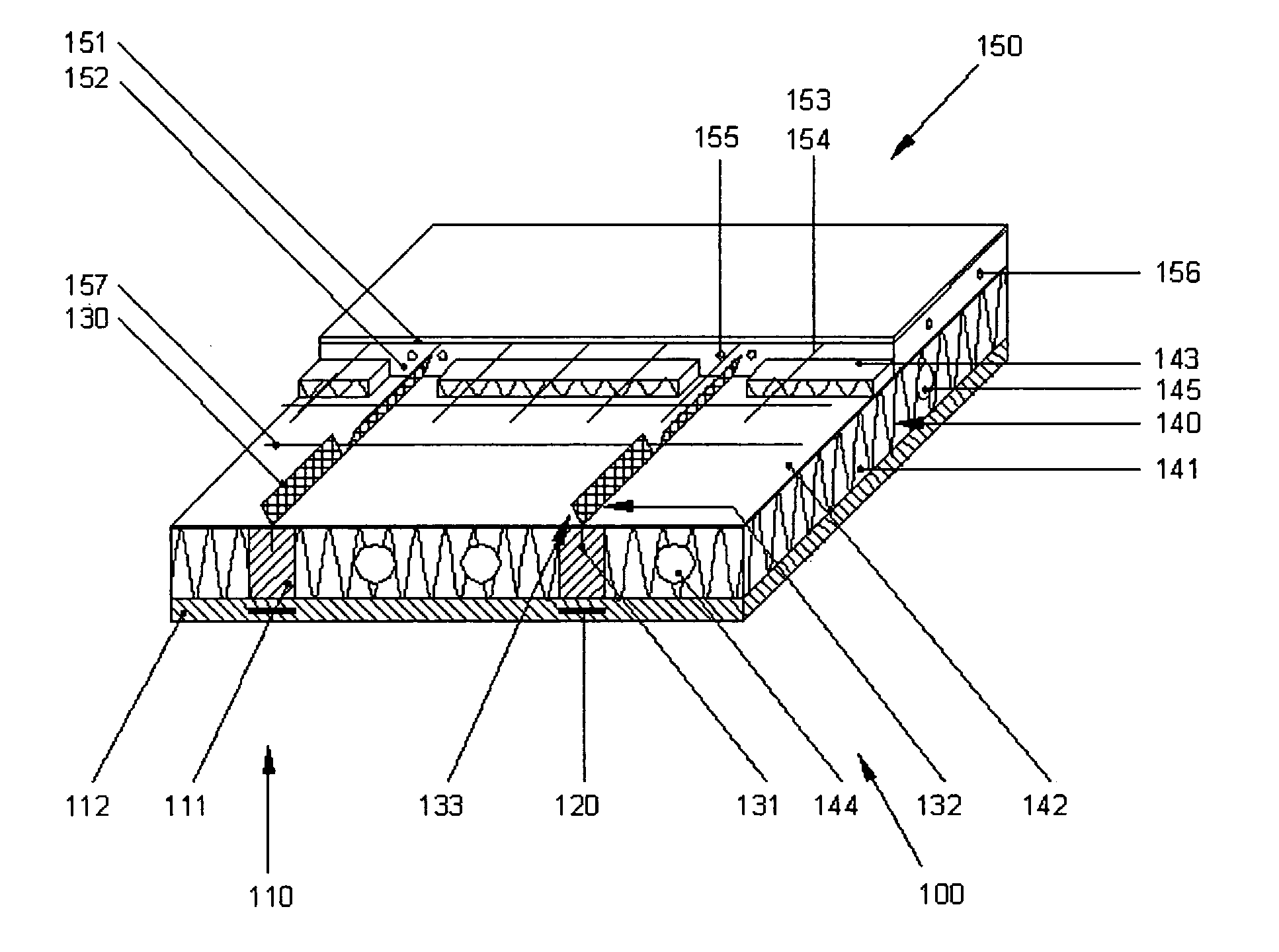

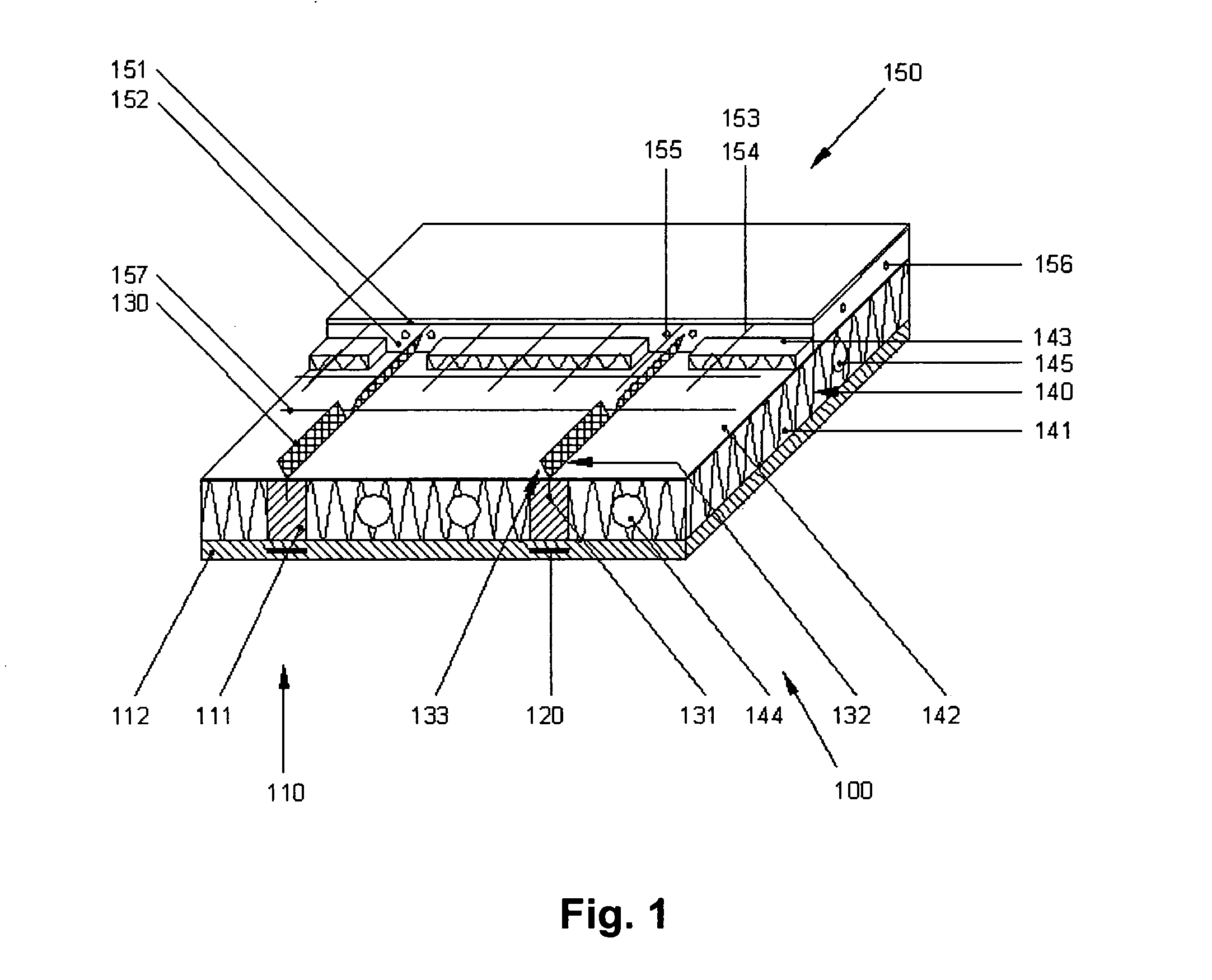

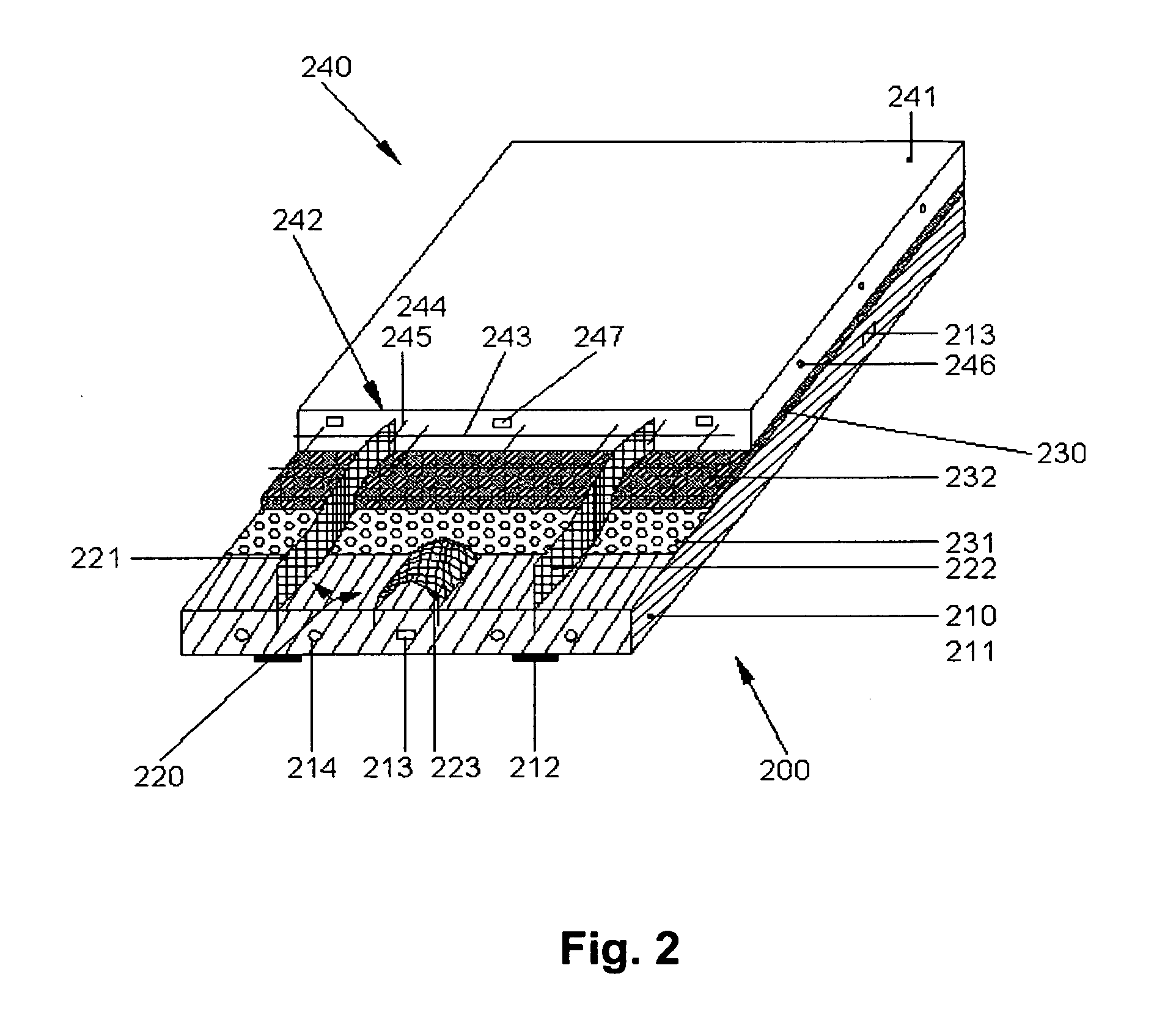

[0017] The wood concrete composite system according to this invention includes wooden construction components, a (at least) on one side bordering concrete construction unit and a (at least) single intermediate layer that creates at least a partial separation and / or uncoupling between the materials wood and concrete. The purpose of the intermediate layers is to (at least) partly separate and / or uncouple the wood and concrete in geometry, mechanics and / or physical (i.e. thermal, sound, vibration) performance. This uncoupling does however not reduce the composite action between wood and concrete substantially, since otherwise an economical solution is not to be obtained.

[0018] The rigid connection between the wood and concrete is achieved by gluing at least one end of the connecting devices into the wooden construction components. The other end reaches trough the intermediate layer and rests rigidly into the concrete section by mechanical friction after the curing of the concrete.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Mechanical properties | aaaaa | aaaaa |

| Thermal properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com