Isotropic graphite product and preparation method thereof

A graphite product and isotropic technology, applied in the field of isotropic graphite products and its preparation, can solve the problems of high cost, limited molding method, and scarce resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

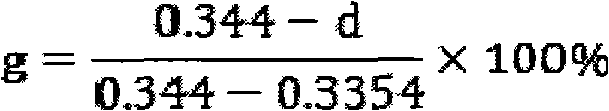

Examples

Embodiment 1

[0025] A kind of isotropic graphite product, its raw material comprises binder and aggregate, the mass ratio of binder and aggregate is 0.45: 1, and the composition of described aggregate is: natural microcrystalline graphite accounts for aggregate mass The microcrystalline graphite is purified natural microcrystalline graphite with a fixed carbon content of 99.9% and a particle size of ≤40 μm; the binder is coal tar pitch.

[0026] A kind of preparation method of isotropic graphite product, comprises the following steps:

[0027] In the first step, the binder and the aggregate with a mass ratio of 0.45:1 are uniformly kneaded in a kneader at a temperature of 150 ° C. The components of the aggregate are: natural microcrystalline graphite accounts for 1% of the mass of the aggregate 100%; the microcrystalline graphite is purified natural microcrystalline graphite, with a fixed carbon content of 99.9%, and a particle size≤40 μm; the binder is coal tar pitch,

[0028] In the sec...

Embodiment 2

[0034] A kind of isotropic graphite product, its raw material comprises binder and aggregate, the mass ratio of binder and aggregate is 0.45: 1, and the composition of described aggregate is: natural microcrystalline graphite accounts for aggregate mass 90%, pitch coke accounts for 10%; the microcrystalline graphite is purified natural microcrystalline graphite, the fixed carbon content is 99.9%, and the particle size is ≤40 μm; the binder is coal tar pitch.

[0035]A kind of preparation method of isotropic graphite product, comprises the following steps:

[0036] In the first step, the binder and the aggregate with a mass ratio of 0.45:1 are uniformly kneaded in a kneader at a temperature of 150 ° C. The components of the aggregate are: natural microcrystalline graphite accounts for 1% of the mass of the aggregate 90%, pitch coke accounts for 10%; the microcrystalline graphite is purified natural microcrystalline graphite, the fixed carbon content is 99.9%, and the particle s...

Embodiment 3

[0042] A kind of isotropic graphite product, its raw material comprises binder and aggregate, the mass ratio of binder and aggregate is 0.45: 1, and the composition of described aggregate is: natural microcrystalline graphite accounts for aggregate mass 90% of the aggregate, the rest is pitch coke, accounting for 10% of the aggregate mass; the microcrystalline graphite is purified natural microcrystalline graphite, that is, the natural ore with a fixed carbon content of 95% after the ore is purified by chemical or physical methods. Microcrystalline graphite, the particle size of which is less than or equal to 40 μm; the binder is pitch.

[0043] A kind of preparation method of isotropic graphite product, comprises the following steps:

[0044] In the first step, the binder and the aggregate with a mass ratio of 0.45:1 are kneaded uniformly in a kneader at a temperature of 140 ° C. The microcrystalline graphite is purified natural microcrystalline graphite, that is, the raw ore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com