Preparation method for fiber composite material reinforcing strip

A technology of fiber composite materials and reinforcement strips, which is applied in the field of preparation of inflatable stretch arm reinforcement strips, can solve the problems of elastic reinforced steel strips being easily magnetized per unit mass, and achieve light weight, high straightness, good elasticity and recovery performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment 1: The preparation method of the fiber composite reinforcement strip in this embodiment is carried out according to the following steps:

[0021] 1. Lay the bottom Vectran fiber cloth: Lay the bottom Vectran fiber cloth on the horizontal work surface to ensure that the fiber cloth has no in-plane prestress;

[0022] 2. Brush glue: along the length direction of the bottom Vectran fiber cloth, evenly brush epoxy resin glue on the surface of the bottom Vectran fiber cloth;

[0023] 3. Spread the carbon fiber cloth in the middle layer: spread the carbon fiber cloth flat, and paste it on the top of the bottom Vectran fiber cloth treated in step 2 to obtain two layers of composite fiber cloth;

[0024] 4. Glue brushing: evenly brush epoxy resin glue on the surface of the carbon fiber cloth obtained in step 3 to obtain two layers of composite fiber cloth;

[0025] 5. Spread the upper layer of Vectran fiber cloth: pave the upper layer of Vectran fiber cloth...

specific Embodiment approach 2

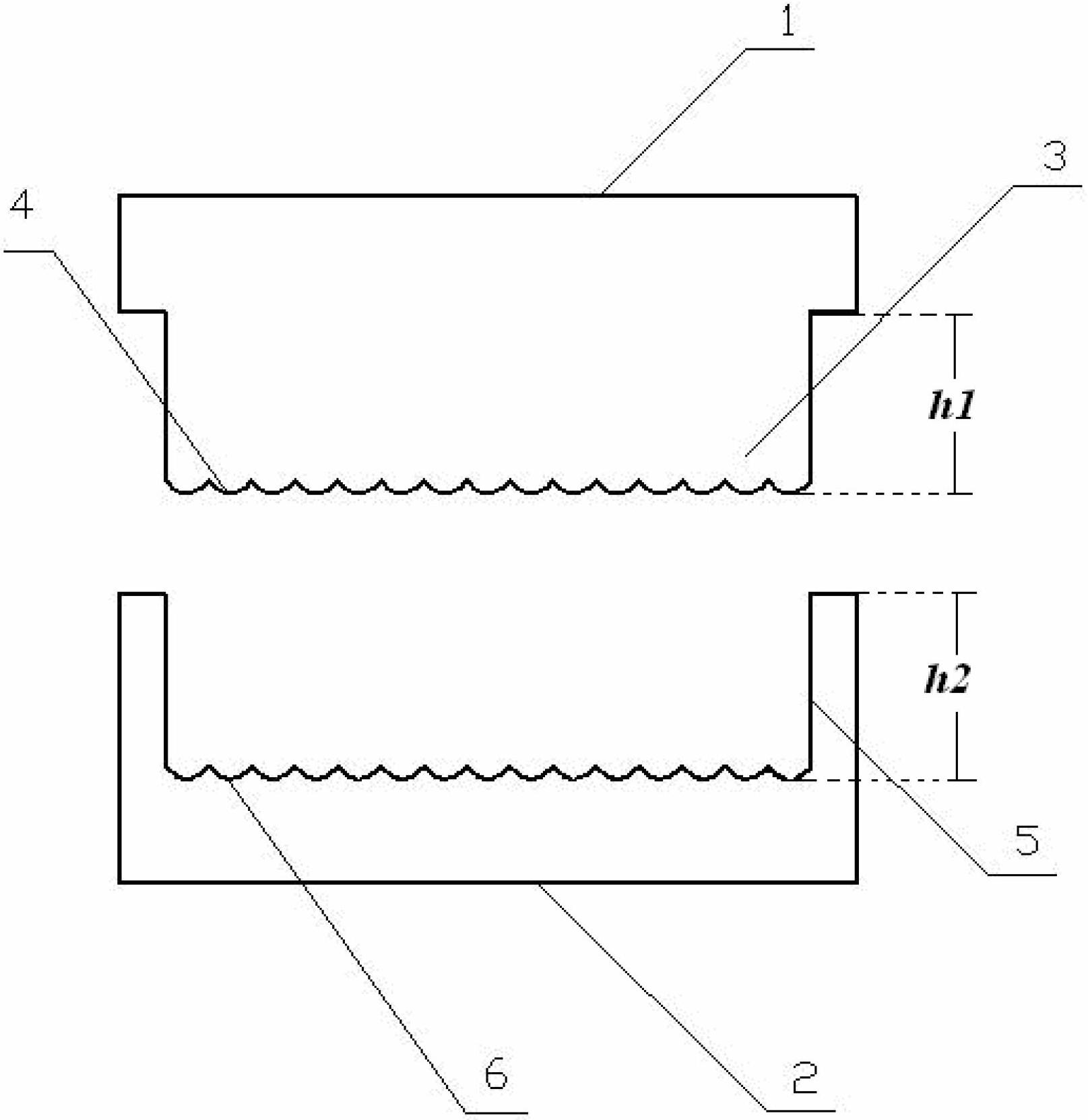

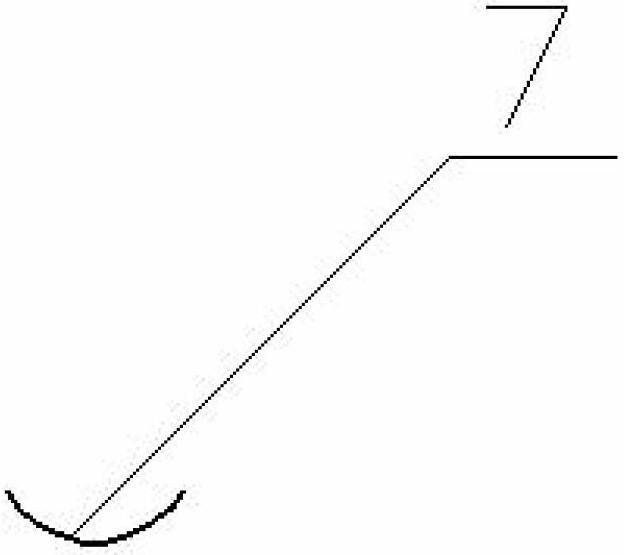

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the special mold described in step six is composed of male mold 1 and female mold 2, male mold 1 is provided with boss 3, and the surface of boss 3 is provided with There are a plurality of protruding marks 4, the female mold 2 is provided with a groove 5, the surface of the groove 5 is provided with a dimple 6 matching the protruding mark 4, and the outer contour line 7 of the cross section of the protruding mark 4 forms a circle arc. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the surface of the boss 3 is provided with 5-50 convex marks 4 . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com