Method for adding particles in composite material and particle adding device

A composite material and mixing device technology, applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve the problems of sucking particles, clogging, etc., to avoid particle clogging, solve the effect of oxidation slag inclusion, strong shearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The embodiment of the present invention provides a method for adding particles in the process of mixing and preparing composite materials, including:

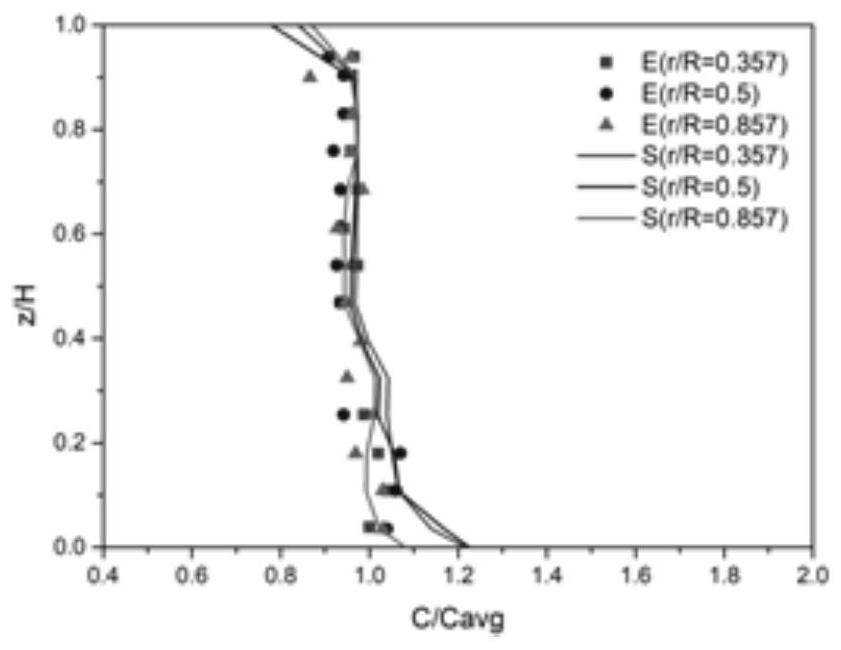

[0049] Verification: The experiment in which the turbine paddle is stirred in a stirring tank with a baffle (see the journal paper "Experimental investigation and CFD simulation of liquid–solid–solid dispersion in a stirred reactor") was selected as the comparative verification object, which is a typical For the liquid-solid-solid mixing problem, see the results figure 1 ,Right now figure 1 is the axial concentration distribution diagram of sand in the glycerin-sand-red mud liquid-solid-solid system, where, figure 1 Among them, S represents the numerical simulation, and E represents the experimental results.

[0050] according to figure 1 It can be seen that the simulation results are in good agreement with the experimental results. The accuracy of the current numerical model in simulating the liquid-solid-solid mixi...

Embodiment 2

[0053] The embodiment of the present invention provides a method for adding particles in the process of stirring and preparing composite materials, wherein the matrix material is AZ91D magnesium alloy, and its chemical composition (wt.%) is shown in the following table:

[0054] Al Zn mn Si Cu Ni Fe be Mg 9.3 0.7 0.23 0.02 0.001 0.001 0.002 0.0015 balance

[0055] The particles are Ti particles, and the experimental parameters are: the stirring speed is 400rpm, the stirring temperature is 580°C, this temperature is the semi-solid stirring temperature, the magnesium alloy melt is the continuous phase, and the primary crystal grains and Ti particles are the dispersed phase, as follows:

[0056]

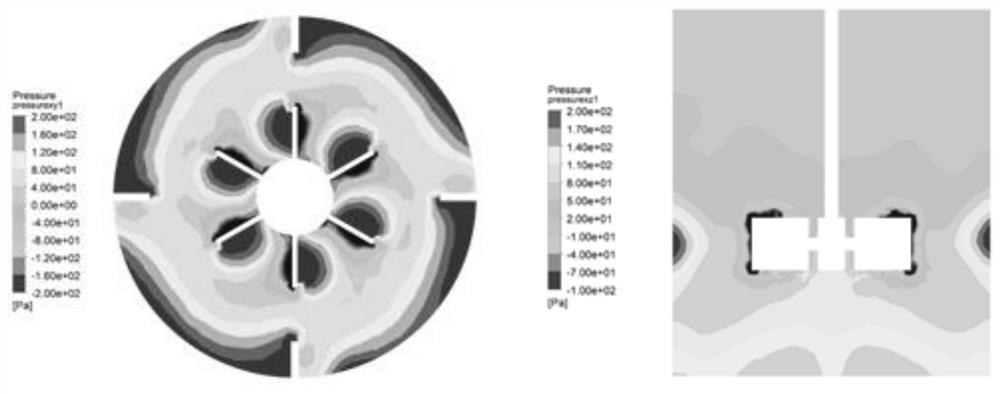

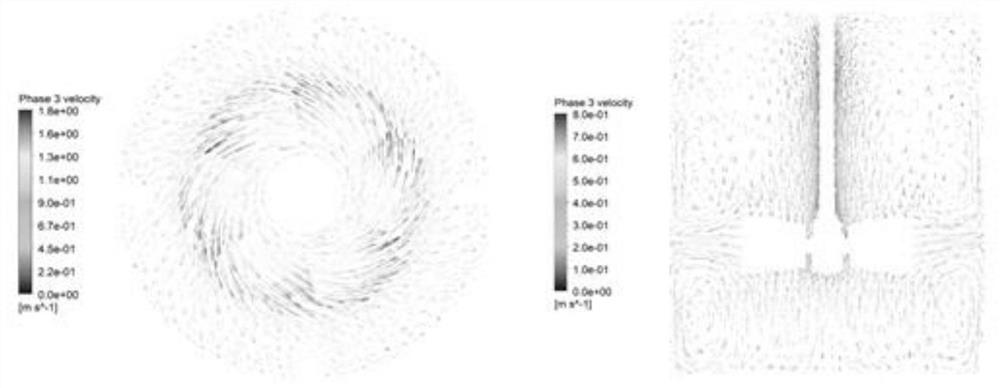

[0057] The mixing device includes: a crucible, the structure of which is as Figure 4 As shown, its geometric dimensions are as follows: the opening diameter of the top of the crucible is 260mm, the diameter of the bottom is 240mm, the height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com