Integrated universal distiller

A technology of distillation apparatus and distillation bottle, which is applied to chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve problems such as uneven heating, influence of experimental results, distillation failure, etc., to shorten the warm-up time, Good condensation effect, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

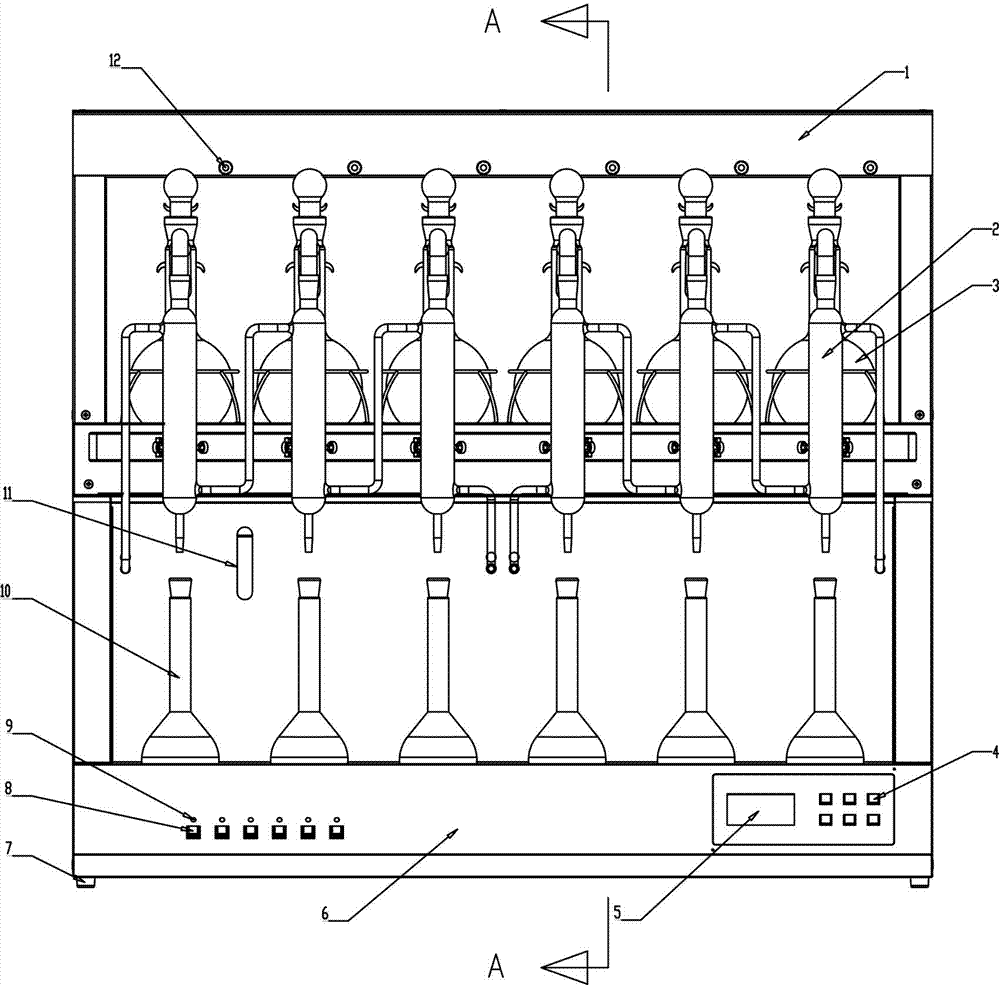

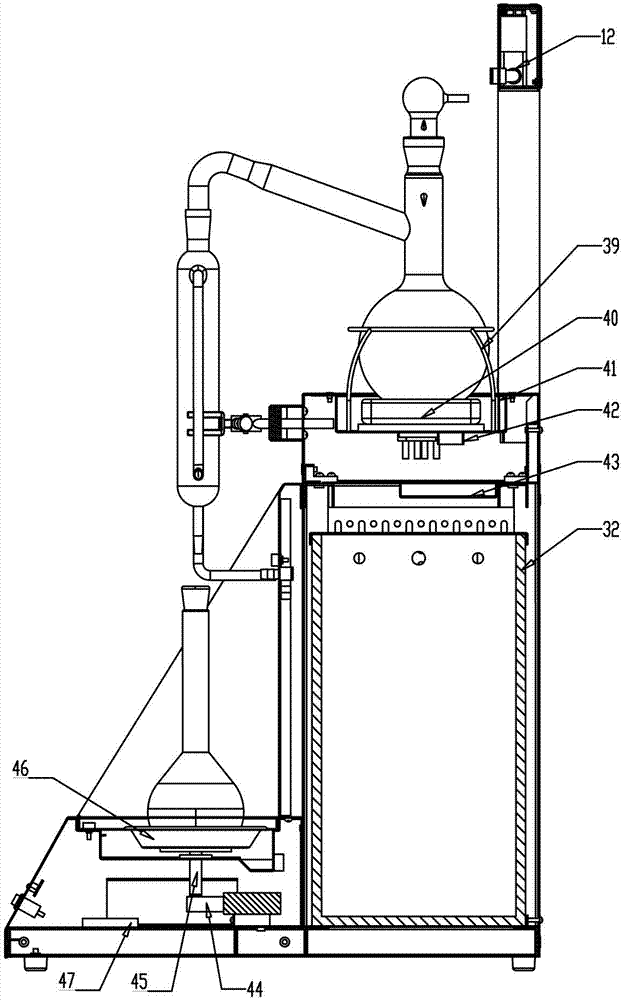

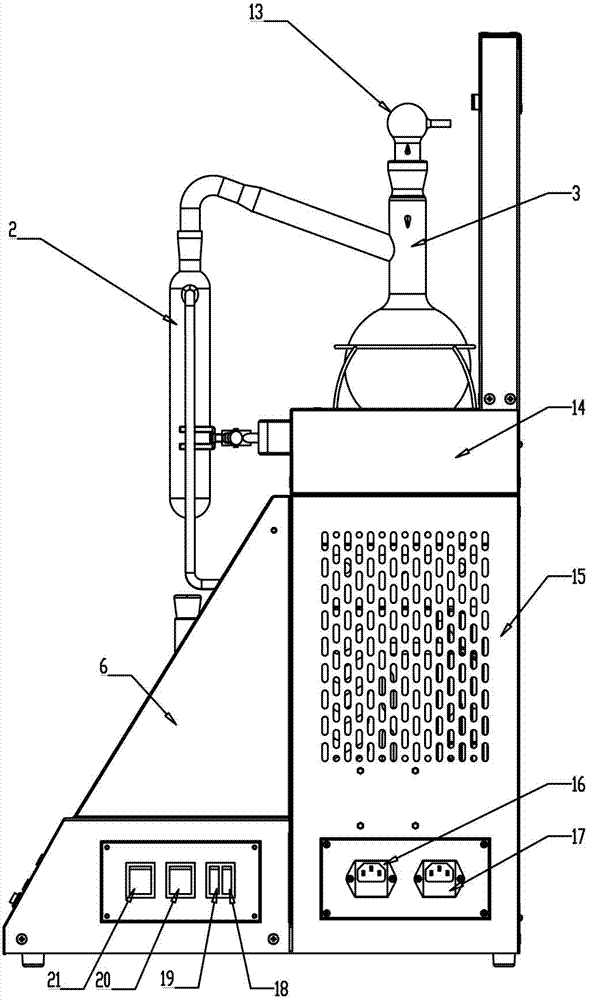

[0029] The present invention as Figure 1-6As shown, the integrated universal distillation apparatus includes a heating device, a cooling device, a volume control device, an anti-suckback device, a shell and a support, and is characterized in that: the heating device adopts six independent heating units, each heating The unit includes a ceramic electric heater 40, a stove frame 41, a stove cover 39, a distillation bottle 3, a heating control button 8, a heating status indicator light 9, and a control circuit 33; the ceramic electric heater 40 is fixed on the stove frame 41 corresponding to the heating box 14 Above, the furnace cover 39 is located above the ceramic electric heater 40, and the distilling bottle 3 is placed in the furnace cover 39; the housing 6 is provided with six heating control buttons 8, a heating status indicator light 9, a functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com