Pressure blasting laboratory layout design

A layout design, laboratory technology, applied in the direction of measuring devices, industrial buildings, instruments, etc., can solve the problems of main building and personnel injury, insecurity, occupying large indoor space, etc., to improve the economic benefits of enterprises, convenient production and operation, The effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

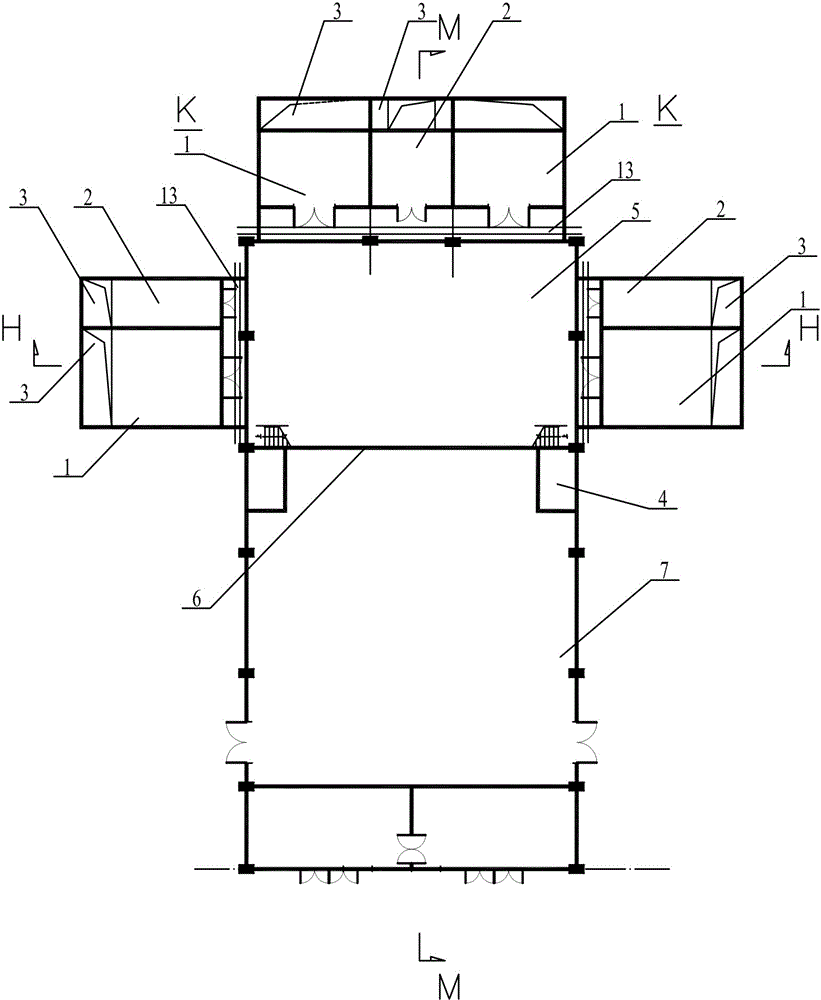

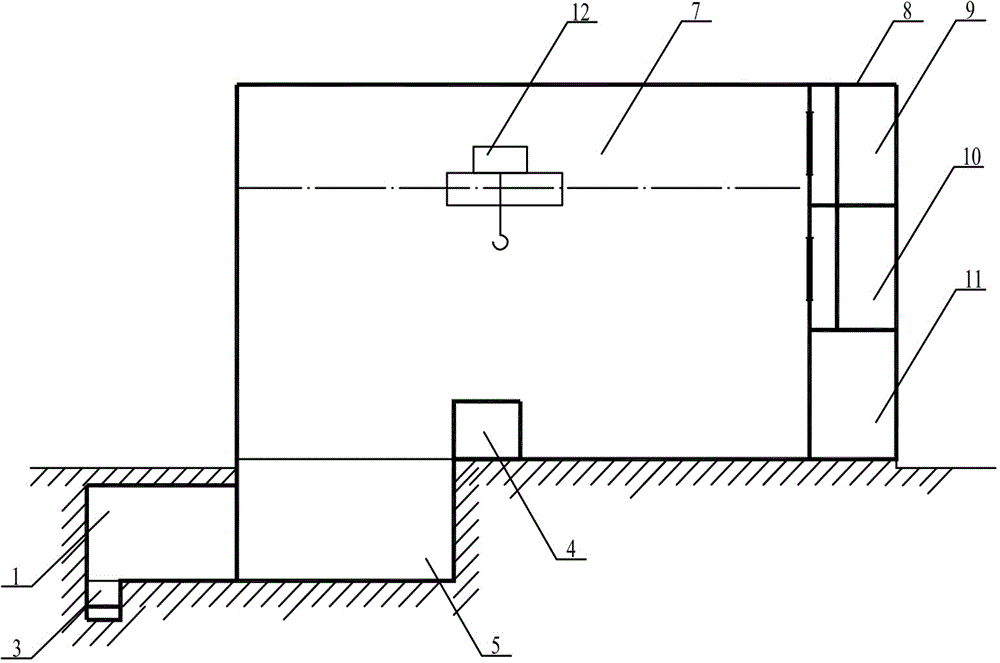

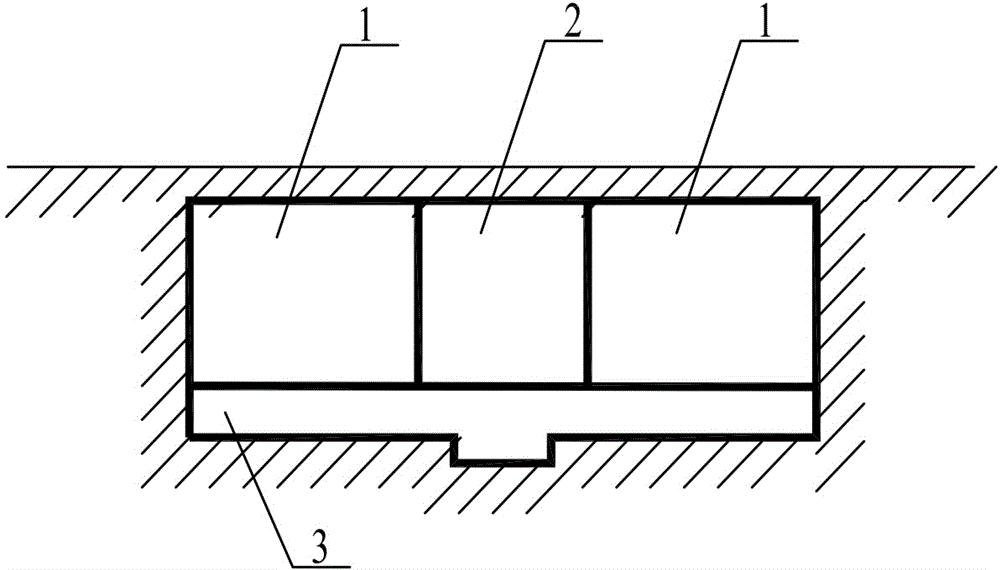

[0018] See attached figure 1 , the present invention includes a preparation area 5 and several hydraulic blasting chambers 1 arranged underground, as well as a control room 4, an object storage area 7 and an office area 8 arranged on the ground, and the hydraulic blasting chamber 1 is provided with an independent or shared pressurized The machine room 2, several hydraulic blasting rooms 1 and the pressurized machine room 2 are respectively set in the shape of "product" outside the preparation area 5 underground of the laboratory; the object storage area 7 is set on the side of the office area 8 on the ground of the laboratory and Facing the preparation area 5; the control room 4 is arranged in the object storage area 7 and faces both sides of the preparation area 5 side; the several hydraulic blasting chambers 1 and the booster room 2 are isolated from the underground structure of the preparation area 5 Seam 13 is disengaged; the hydraulic blasting chamber 1 is formed by pouri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com