Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

392results about How to "With UV protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light, thin thermal-wet comfort multifunctional knitted fabric and preparation method thereof

ActiveCN105220336AGood moisture absorption and heating performanceOne-way moisture guide function is goodWeft knittingDyeing processYarnMoisture absorption

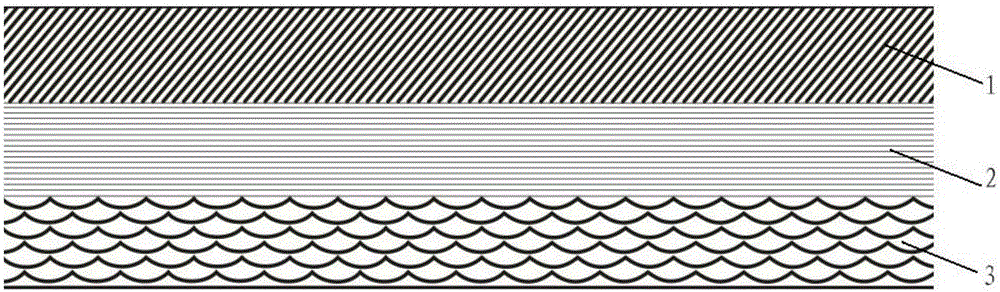

The invention provides light, thin thermal-wet comfort multifunctional knitted fabric and a preparation method thereof. The fabric is formed by weaving first yarn, second yarn, third yarn and fourth yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer. The outer layer is formed by weaving the first yarn. The middle layer is formed by weaving the second yarn and the third yarn. The inner layer is formed by weaving the fourth yarn. The moisture-absorption and heat-generating heating up value of the fabric meets the standard requirements in the textile industry, moisture adsorption performance, quick drying performance, comprehensive sweat-discharge quick drying performance and other indexes meet values required by national standards before and after the fabric is washed, and the heat-preserving rate index meets the values required by the national standards; meanwhile, the fabric has a good moisture retention function, moisture needed by human skin is locked, and human skin aging can be effectively relieved.

Owner:武汉爱帝针纺实业有限公司

Camellia oil wet wipe

InactiveCN106727093AWith sterilizationGood moisturizing effectCosmetic preparationsToilet preparationsChemical industryAdjuvant

The invention relates to the field of daily chemical industry, specifically to camellia oil wet wipe. The camellia oil wet wipe is composed of wet wipe cloth and a wet wipe liquid. The wet wipe liquid is composed of the following substances (by weight): 25-35 parts of camellia oil, 10-15 parts of tricaprylin, 5-10 parts of dodecyl dihydrogen phosphate, 30-40 parts of sorbitol, 10-20 parts of propylene glycol, 5-8 parts of essence of eucalyptus leaves, 5-10 parts of an adjuvant, 15-20 parts of an aloe extracting solution, 5-8 parts of plant essential oil and 25-35 parts of RO pure water. According to the camellia oil wet wipe provided by the invention, camellia oil is added. The camellia oil contains active materials (such as vitamins, tea polyphenol and carotene) which are beneficial to human body, and has advantages of sterilization, UV protection, good moisture retention performance and oxidation resistance. By adding the natural bacteriocidal substances such as essence of eucalyptus leaves and natural plant extracting solutions, the wet wipe has dual effects of sterilization and skin care, is safe and nontoxic, and is environment-friendly and healthy.

Owner:QINGDAO HUANAN SHENGYUAN FRUIT IND CO LTD

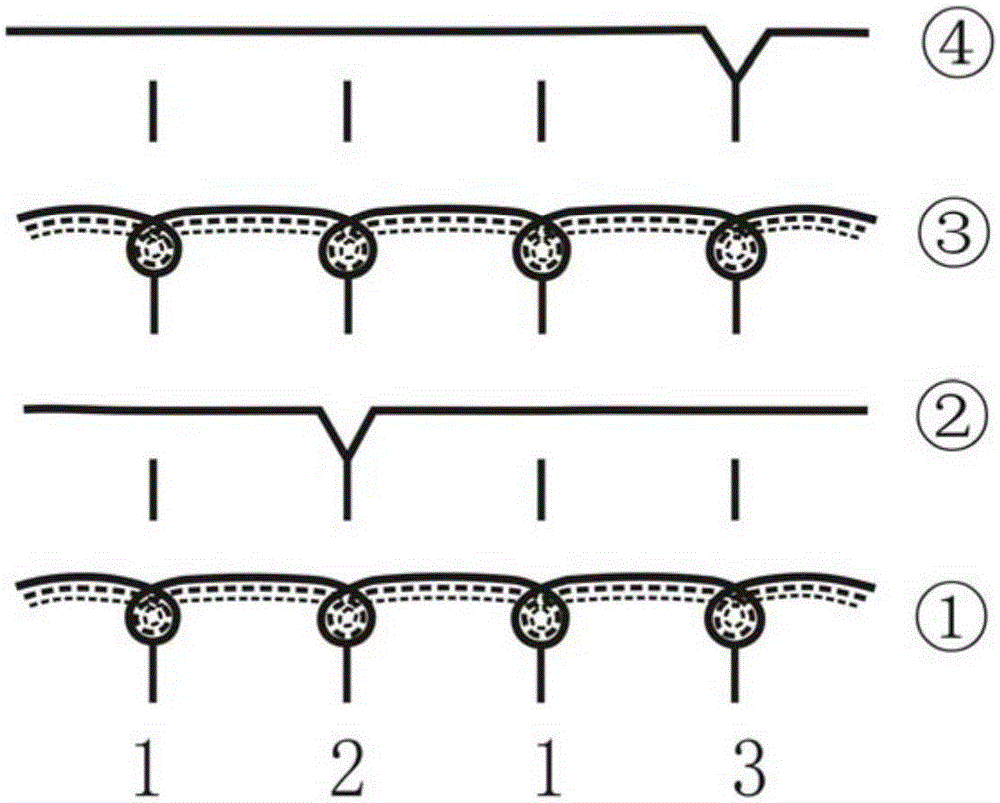

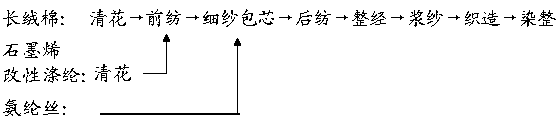

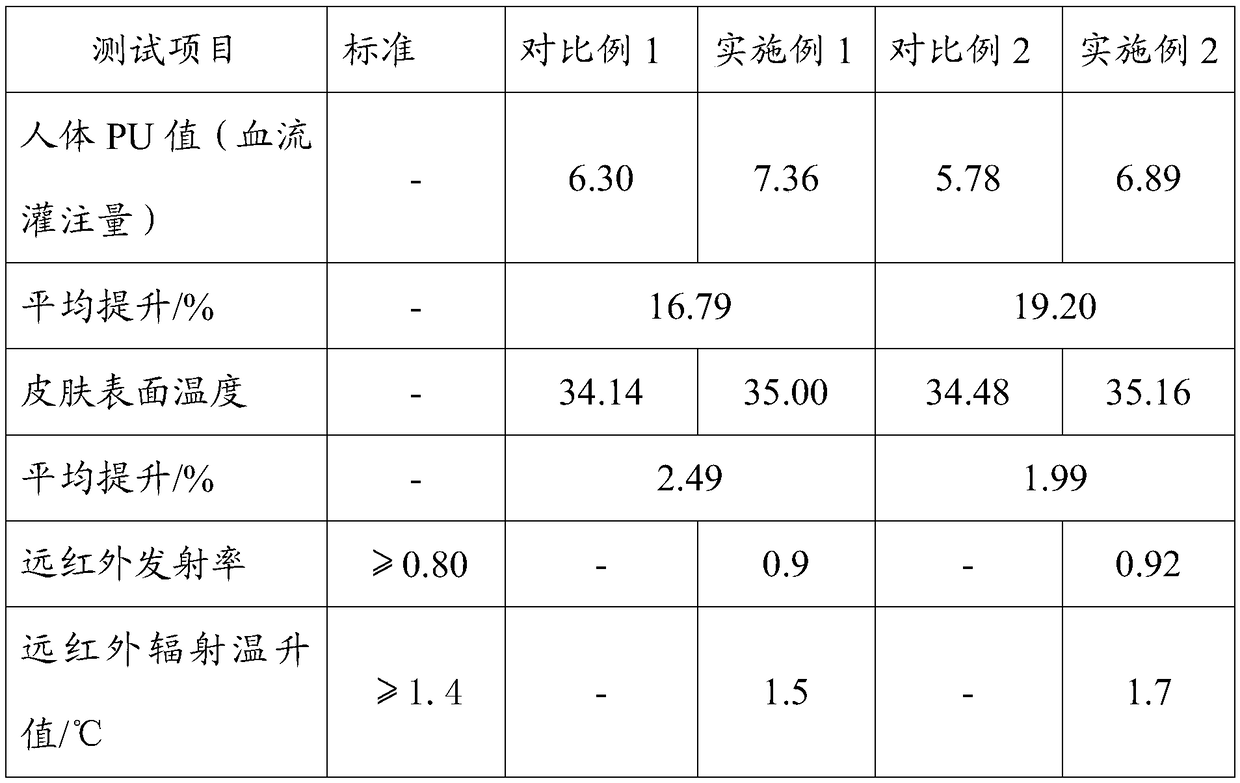

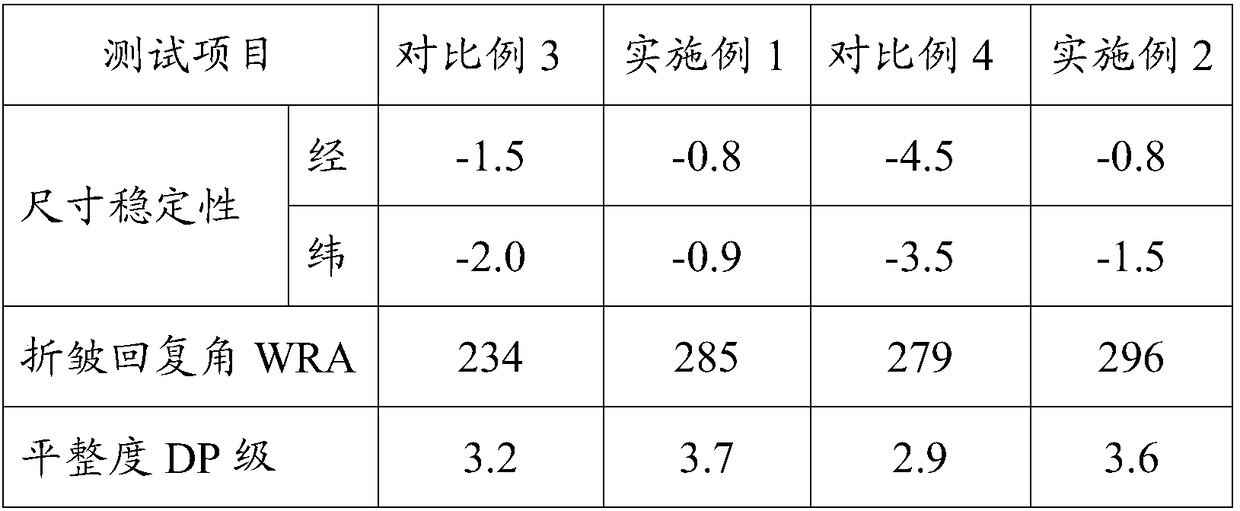

Production method of graphene-modified fiber core-spun elastic yarn and graphene-modified fiber core-spun elastic fabric

ActiveCN108823718AImproves shrink resistanceImprove wrinkle resistanceWeft knittingWarp knittingPolyesterFiber

The invention discloses a production method of graphene-modified fiber core-spun elastic yarn and graphene-modified fiber core-spun elastic fabric. The graphene-modified fiber core-spun elastic yarn is a core-spun spandex filament obtained by blending graphene-modified polyester fibers and combed cotton. The graphene-modified fiber core-spun elastic fabric comprises a woven elastic fabric body anda knitted elastic fabric body. The fabric has the functions of resisting bacteria, achieving far-infrared heating, promoting micro-circulation, preventing ultraviolet radiation and the like and has good creasing resistance and shape retention performance. The graphene-modified fiber core-spun elastic yarn and the graphene-modified fiber core-spun elastic fabric can be applied to the field of woven garments and knitting sports, and the market of elastic functional products is developed.

Owner:山东宏儒纺织科技有限公司

Light-fast auto membrane

InactiveCN103820044AWith heat insulationWith UV protectionNon-macromolecular adhesive additivesFilm/foil adhesivesZinc compoundsThermal insulation

The invention relates to a light-fast auto membrane. The light-fast auto membrane comprises the following components by mass: 100 parts of PVC, 20-30 parts of an elasticizer DOP, 2.5-3.5 parts of a barium-zinc compound stabilizer, 5-25 parts of a nano filler; 0.5-1.0 part of an anti-UV531, 1.0-2.0 parts of an accelerant ACR, 0.1-1 part of an antioxidant CB, 8-15 parts of rutile-type titanium dioxide and 0.01-0.05 part of a pigment. The light-fast auto membrane has the characteristics of thermal insulation, ultraviolet resistance and high-temperature resistance, and is low in manufacturing cost.

Owner:JIANGSU DAHAI PLASTIC

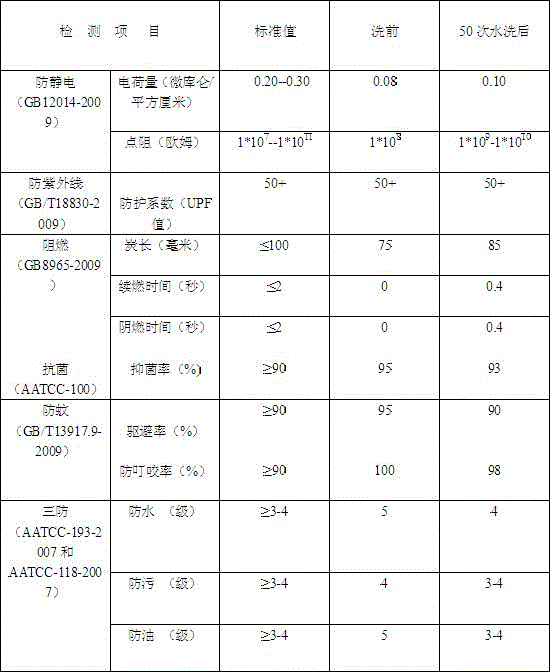

Production method of multi-functional composite fabric

InactiveCN106400259AFlame retardantWith anti-staticWoven fabricsVegetal fibresEngineeringSoil resistance

The invention discloses a production method of multi-functional composite fabric and belongs to the technical field of production methods and technologies of special clothes processed fabric. To solve the technical problem above, the following technical scheme is adopted. Provided is the production method of composite multi-functional fabric. The method comprises the steps of A, spinning and weaving; B, dyeing and conducting ultraviolet-proof arrangement; C; conducting flame-retardant arrangement; D, conducting antibacterial and anti-mosquito treatment; E, conducting three-anti treatment, namely oil-proof, waterproof and soil resistant treatment. The multi-functional composite fabric meanwhile has all the following 8 functions: flame retardancy, destaticization, oilproofness, soil resistance, waterproofness, antibacterial and mosquito repellence. Actual demands are basically met, and a safe and reliable guarantee for users of special environment is provided.

Owner:新乡市新科防护科技有限公司

Composition and method for finishing surface of preservative-treated wood engineering material used outdoors

InactiveCN103013328AResist decayResist mildewAnti-corrosive paintsCoating impregnationLoss rateOrganic film

The invention relates to a composition and method for finishing thwe surface of a preservative-treated wood engineering material used outdoors. The composition comprises an organo-silicon polymer, a holy polymer resin, a titanic oxide, an organic solvent component and a monomer mixture. An organic film is formed on the surface of the preservative wood engineering material through a surface finishing technology so that the surface ornamental feature of the wood engineering material is increased, simultaneously the preservative wood engineering material is endowed with good water-resisting property and weather resistance property, the outdoor use performance of the preservative wood engineering material is increased, the service life of the preservative wood engineering material is effectively prolonged, and the damage to environments is reduced. The preservative wood engineering material obtained by the invention has the advantages that the loss rate of an effective constituent copper is reduced from above 90% to 8%-15%, wherein the loss rate of the copper in an untreated material is above 90%, and after aging tests, the chromaticity indexes delta a*, delta b*, luminosity equation delta L* and chromatism delta E*of the surface of the treated material are obviously less than that of the untreated material, the weight loss rate of the treated material is 5%-8%, and the strength loss of the treated material is 5%-12%.

Owner:TIANJIN UNIV OF SCI & TECH

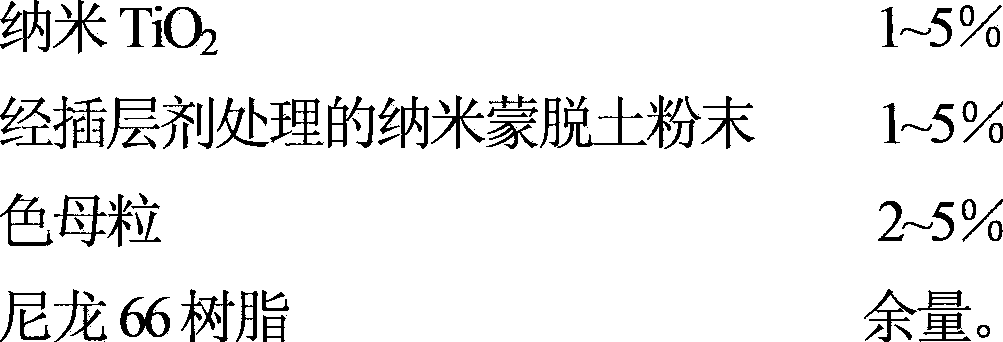

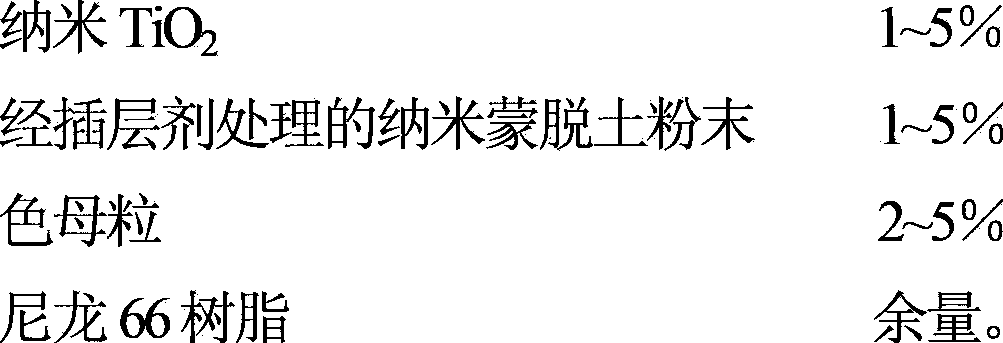

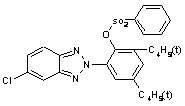

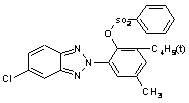

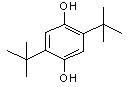

Functional nylon 66 fiber and preparation method thereof

ActiveCN103882548ABroad-spectrum antimicrobial heat resistanceEasy to dyeFilament forming substance formingFilament/thread formingNylon 66Optoelectronics

The invention discloses a functional nylon 66 fiber and a preparation method thereof. The method performs blending granulation of nylon 66 resin slices, nanometer TiO2, and nanometer montmorillonite treated by an intercalator, and then performs melt blending spinning of the obtained master batch, nylon 66 slices, and nylon color master batch, and the functional nylon 66 fiber with multiple functions is produced by combination of specially-shaped spinneret plates with differentiation technology. The functional nylon 66 fiber is colored, has a specially-shaped cross section, has performance of ultraviolet resistance, bacterial resistance, static electricity resistance, flame retardation and infrared ray absorption, and is used for high-grade garment materials, knitted products, room textile, medical textile, and the like.

Owner:LIAONING YINZHU CHEMTEX GROUP

Anti-ultraviolet transparent hard coating film for in-mold decoration (IMD)

ActiveCN101955699AGuaranteed normal formationMeet the molding tensile performance requirementsSynthetic resin layered productsCoatingsPolyesterUltraviolet

The invention relates to an anti-ultraviolet transparent hard coating film for in-mold decoration (IMD), which is formed by coating a transparent hard coating on a transparent substrate. The transparent hard coating comprises the following components in part by weight: 20 to 40 parts of polyester acrylate oligomer, 10 to 30 parts of organic-inorganic hybrid oligomer, 0.5 to 5 parts of ultraviolet absorption precursor, 1.0 to 10 parts of hydrogen proton donor, 0.5 to 7 parts of photoinitiator, 0.5 to 7 parts of active amine, 0.05 to 2 parts of leveling agent and 30 to 70 parts of solvent, wherein the thickness of the hard coating is 2 to 6mu m. The anti-ultraviolet transparent hard coating film solves the problems of ageing, yellowing, embrittlement and the like of a product irradiated by ultraviolet rays, solves the problems of oxygen inhibition and hydrogen proton consumption and ensures the formation of an ultraviolet absorbent; and the film meets the requirements of the IMD on forming and stretching by combining raw materials and controlling the thickness of the hard coating, and the stretching and forming height of the film can be 7 to 8mm at most but the film cannot be embrittled.

Owner:CHINA LUCKY FILM CORP

Transparent metal dielectric composite material

InactiveCN1425555ADelay decayImprove transmittanceOther chemical processesLayered productsDielectricMicrowave

The transparent composite metal dielectric material consists of two inducing layers and one functional layer between the two inducing layers and features that each inducing layer consists of two layers of different transparent dielectric film and the two inducing layers may have different optical thickness. The function layer may have doped inducing layer material to form multiple quantum well structure. By means of multiple reflection and quantum well-like resonant effect, the composite material anti-reflects the electromagnetic wave in required wave band while reflecting electromagnetic waves of other wavelengths. The present invention may be used as windoe material or transparent body material a well as in producing metal semiconductor photoelectronic detector and other relevant device.

Owner:张会琴 +1

Preparation method of electromagnetic functional compound fabric

InactiveCN102493176AUniform dispersionWith UV protectionFibre typesDistilled waterPolyethylene glycol

The invention relates to a preparation method of an electromagnetic functional compound fabric. The method comprises the following steps of: (1) dissolving Fe3O4 nano magnetic-particles in distilled water, ultrasonically stirring at high speed, dropwise adding a sodium oleate solution, continuously stirring, then cooling to 30-60 DEG C, and adding polyethylene glycol to form nano magnetofluid; (2) soaking the fabric in an NaOH solution, heating and cleaning, putting the cleaned fabric into a mixed aqueous solution containing aniline and a doping acid, taking the fabric out and airing, soaking the aired fabric into a mixed aqueous solution containing ammonium persulfate and a doping acid, soaking and rolling once, and then placing at 0-10 DEG C; and (3) soaking the fabric obtained in the step (2) into the nano magnetofluid obtained in the step (1), soaking and rolling once, then soaking the rolled fabric into an acetate solution, taking out and airing to obtain the finished product. The preparation method disclosed by the invention is simple and feasible, safe and environment-friendly and has low requirements on equipment performance; and the electromagnetic functional compound fabric prepared by using the preparation method disclosed by the invention has the advantages of good flexibility, favorable electrical conductivity and wide application prospect.

Owner:DONGHUA UNIV

Infrared radiation-isolating film material for building glass

The infrared radiation-isolating film material for building glass consists of base layer and functional layer, the base layer is transparent medium film substrate material for improving the mechanical property of the film and the functional layer has thickness of 3-2000 nm and comprises one or more medium film with at least one layer of metal medium film or dielectric film. In the functional layer or base layer, there is titania, zirconium oxide or other strong ultraviolet absorbing medium to make the film possess some ultraviolet protecting capacity at the same time. The material may be madeto cover partial or whole ultraviolet area by means of regulating the nanoparticles zie. The material has high transparency to visible light, complete infrared radiation isolating function and high ultraviolet-proof function, and may be used to reach the functions of saving energy and protecting health.

Owner:李宏强

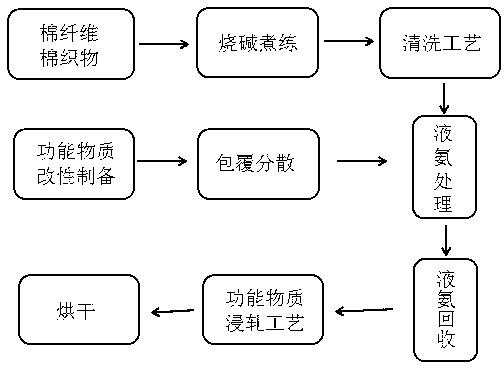

Filled type cotton fiber and preparation method thereof

The invention discloses a preparation method of the filled type cotton fiber. The preparation method of the filled type cotton fiber comprises the following steps: conducting a caustic scouring process on the cotton fiber or cotton fabrics; conducting a cleaning process; conducting modified preparation of functional substances; dispersing the functional substances in liquid ammonia; conducting a liquid ammonia treatment process; recycling the liquid ammonia; and dehydrating and stoving; The caustic scouring process is used for eliminating impurities in a center chamber of the cotton fiber and enabling most of the end ports of the center chamber of the cotton fiber to be opened, the modified preparation of the functional substances refers to put the cotton fiber into the liquid ammonia which is provided with functional particles in a diffusion mode to be treated, and the functional particles are enabled to be permeated into the center chamber and holes of the cotton fiber by means of a permeation function of the center chamber of the cotton fiber and the function which detaches hydrogen bonds of cellulose molecules. The invention further discloses a filled type cotton fiber. The cotton fiber prepared by the method has the advantages of being anti-bacterial, health-care, capable of releasing negative ions, ultraviolet-resistant and the like.

Owner:JIANGSU YDTEX GRP LTD

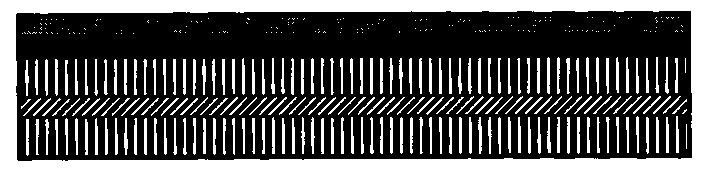

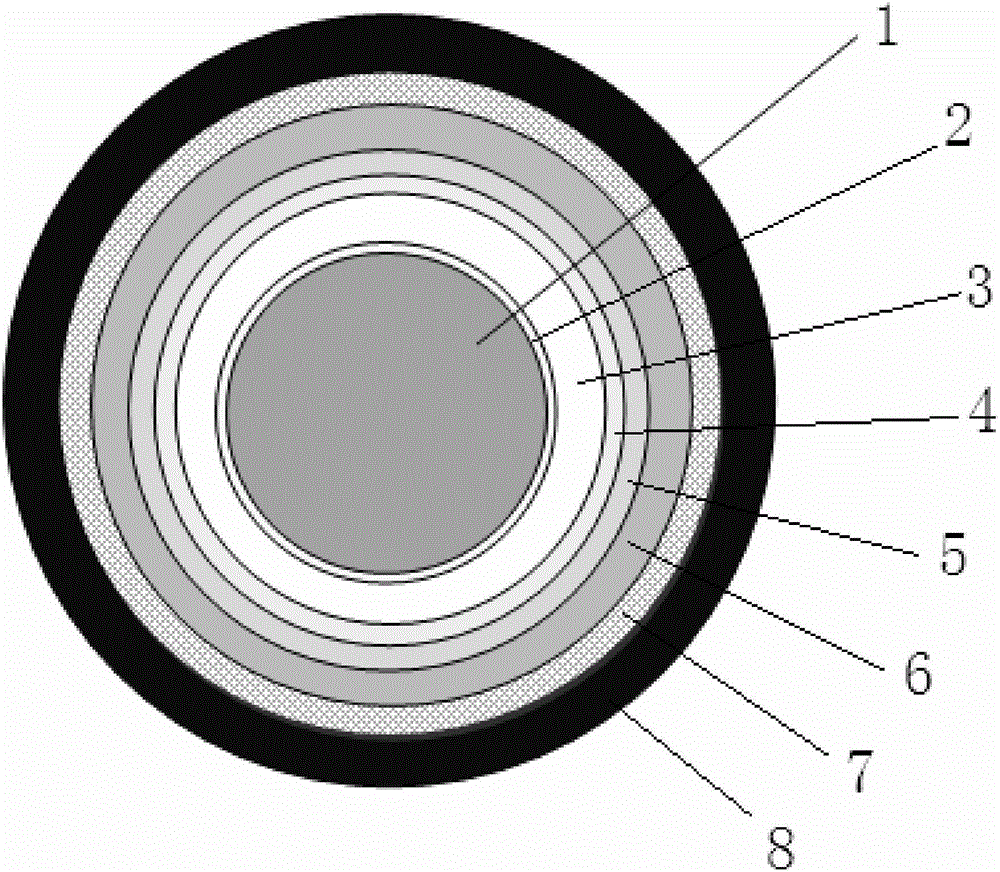

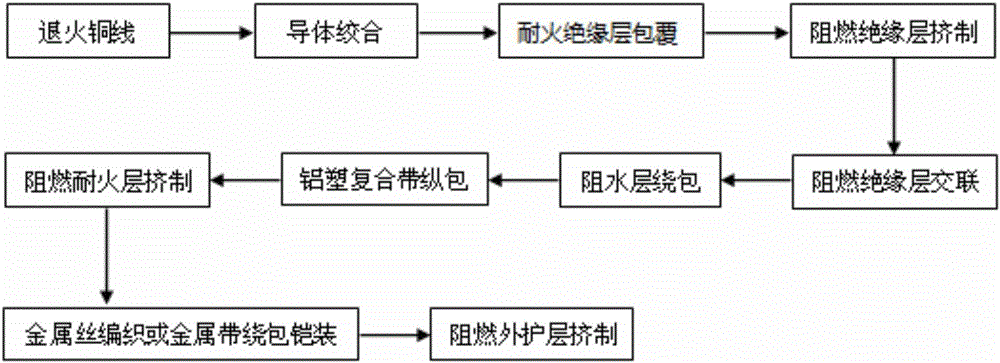

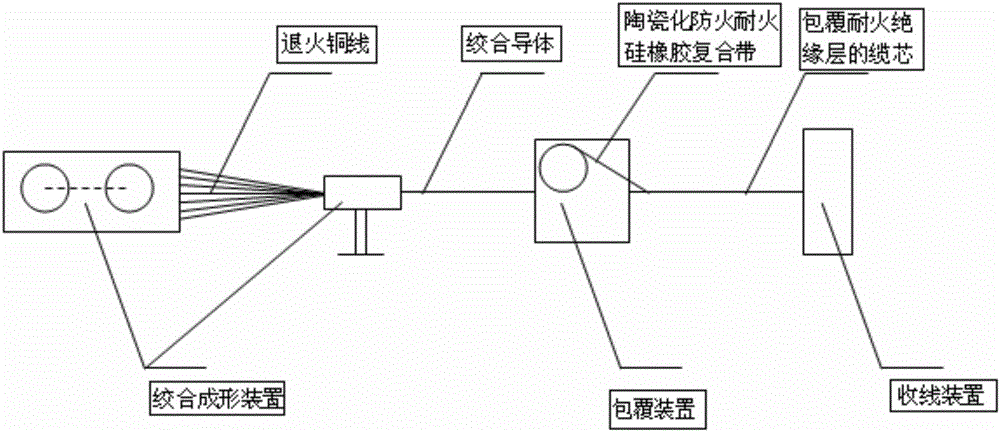

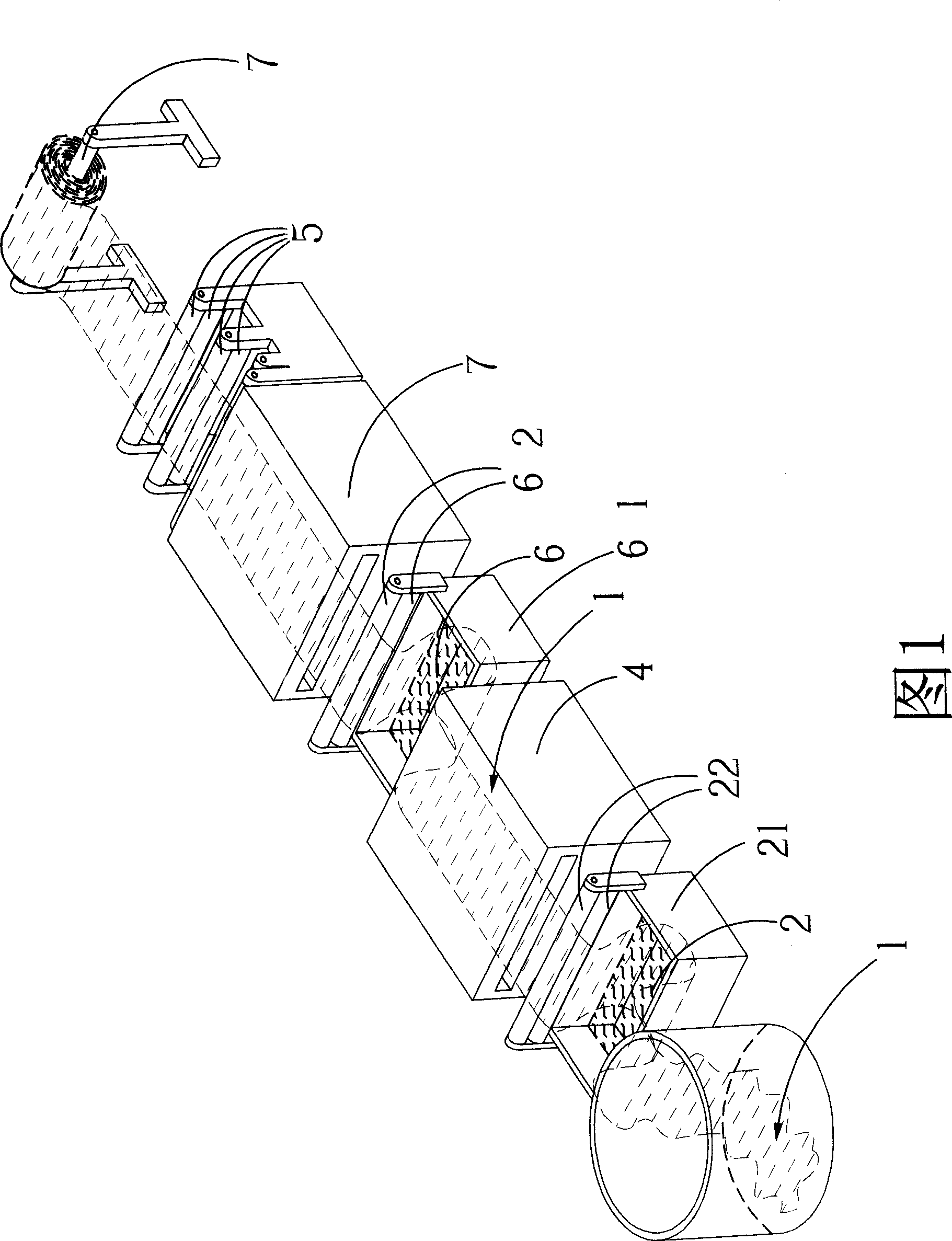

Flame-retardant and fire-resistant direct current power cable applied to rail transit and production system and method

ActiveCN106448796ASimple processingIncrease productivityNon-insulated conductorsClimate change adaptationBlocking layerSmoke

The invention discloses a flame-retardant and fire-resistant direct current power cable applied to rail transit and a production system and method. The cable comprises a stranded conductor, a fire-resistant insulation layer, a flame-retardant insulation layer, a water-blocking layer, a flame-retardant and fire-resistant waterproof isolation layer, an armor layer and a flame-retardant outer protective layer. The flame-retardant and fire-resistant waterproof isolation layer comprises an inner longitudinal package aluminum-plastic composite belt, and an outer flame-retardant and fire-resistant polyolefin cover. The longitudinal package aluminum-plastic composite belt and the flame-retardant and fire-resistant polyolefin cover are spliced and combined into a composite integral structure. The stranded conductor is formed by stranding annealed copper wires into a regular stranded conductor or soft conductor of 50mm<2> to 400mm<2>. The fire-resistant insulation layer is formed by wrapping double-layer ceramic fireproof and fire-resistant silicone rubber composite tapes on a wrapping device in an overlapped manner. An ultraviolet light irradiation crosslinking halogen-free low smoke flame-retardant polyolefin insulation material is extruded on an insulation extrusion crosslinking production device to form a coating structure. The cable provided by the invention has the advantages of high flame-retardant and fire-resistant ability, good insulation performance, great fire resistance and high cable production efficiency.

Owner:JINAN RUITONG RAILWAY ELECTRIC SERVICE

Non-corrosiveness automobile cleaning and polishing wax

The invention discloses non-corrosiveness automobile cleaning and polishing wax. The non-corrosiveness automobile cleaning and polishing wax is prepared from the following raw materials in parts by weight: 4 to 8 parts of kieselguhr, 7 to 13 parts of epoxy resin, 4 to 6 parts of an ultraviolet absorbent, 1 to 4 parts of a surfactant, 5 to 7 parts of light calcium carbonate, 1.5 to 2.5 parts of dimethylbenzene, 8 to 12 parts of polyvinyl alcohol, 7 to 16 parts of hydrofluoric acid, 2 to 4 parts of sodium benzoate, 5 to 7 parts of acetone, 2 to 5 parts of paraffin, 7 to 11 parts of AEO-9, 5 to 8 parts of beeswax, 4 to 7 parts of amino silicon oil and 3 to 5 parts of bentonite. The non-corrosiveness automobile cleaning and polishing wax has the beneficial effects that the non-corrosiveness automobile cleaning and polishing wax has ultraviolet-proof effect and non-corrosiveness effect, is excellent in cleaning effect, is waterproof, stain-proof, green and environmentally-friendly, and has an excellent protection effect on automobiles.

Owner:QINGDAO XIANGJIA INTPROP SERVICE CO LTD

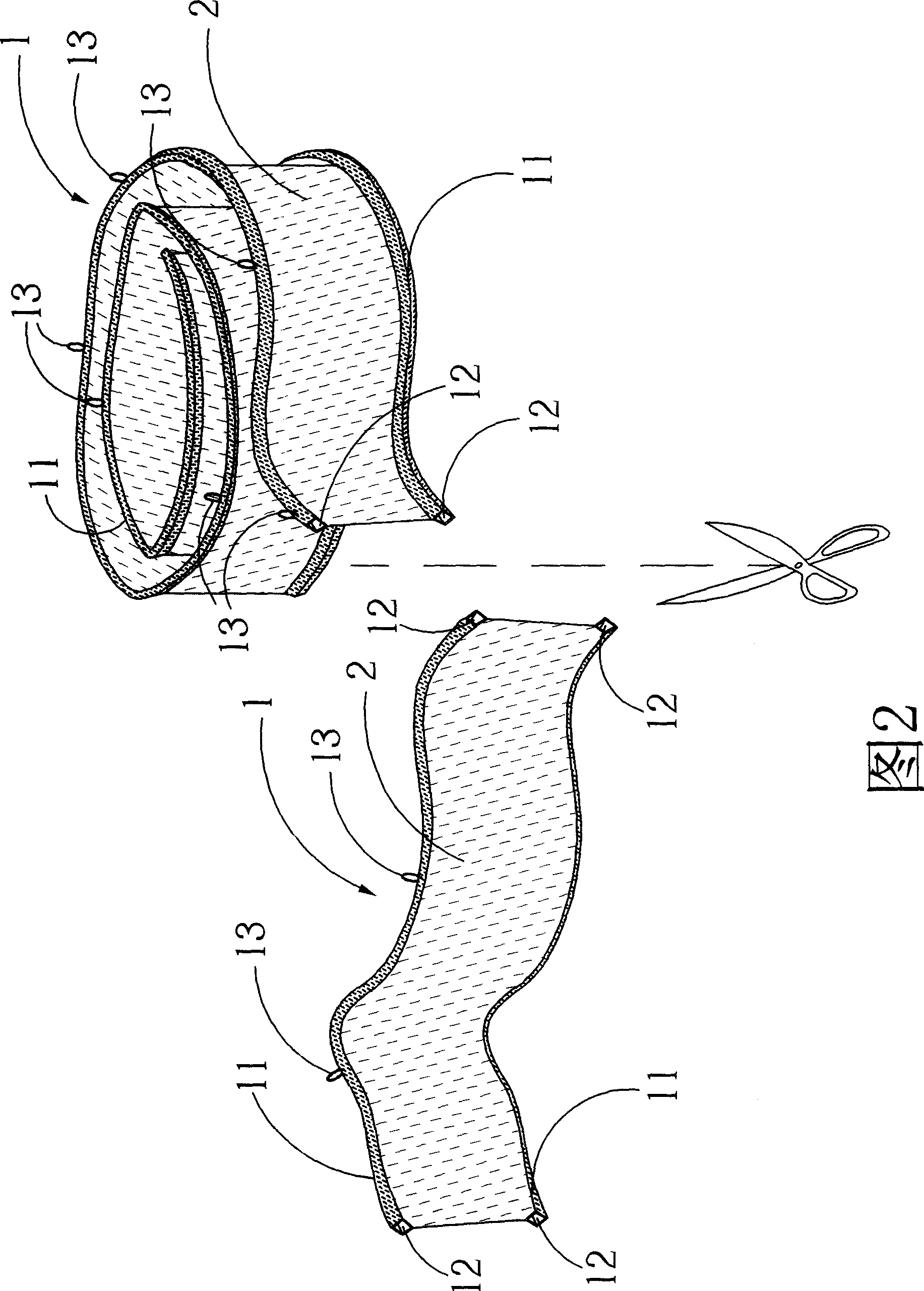

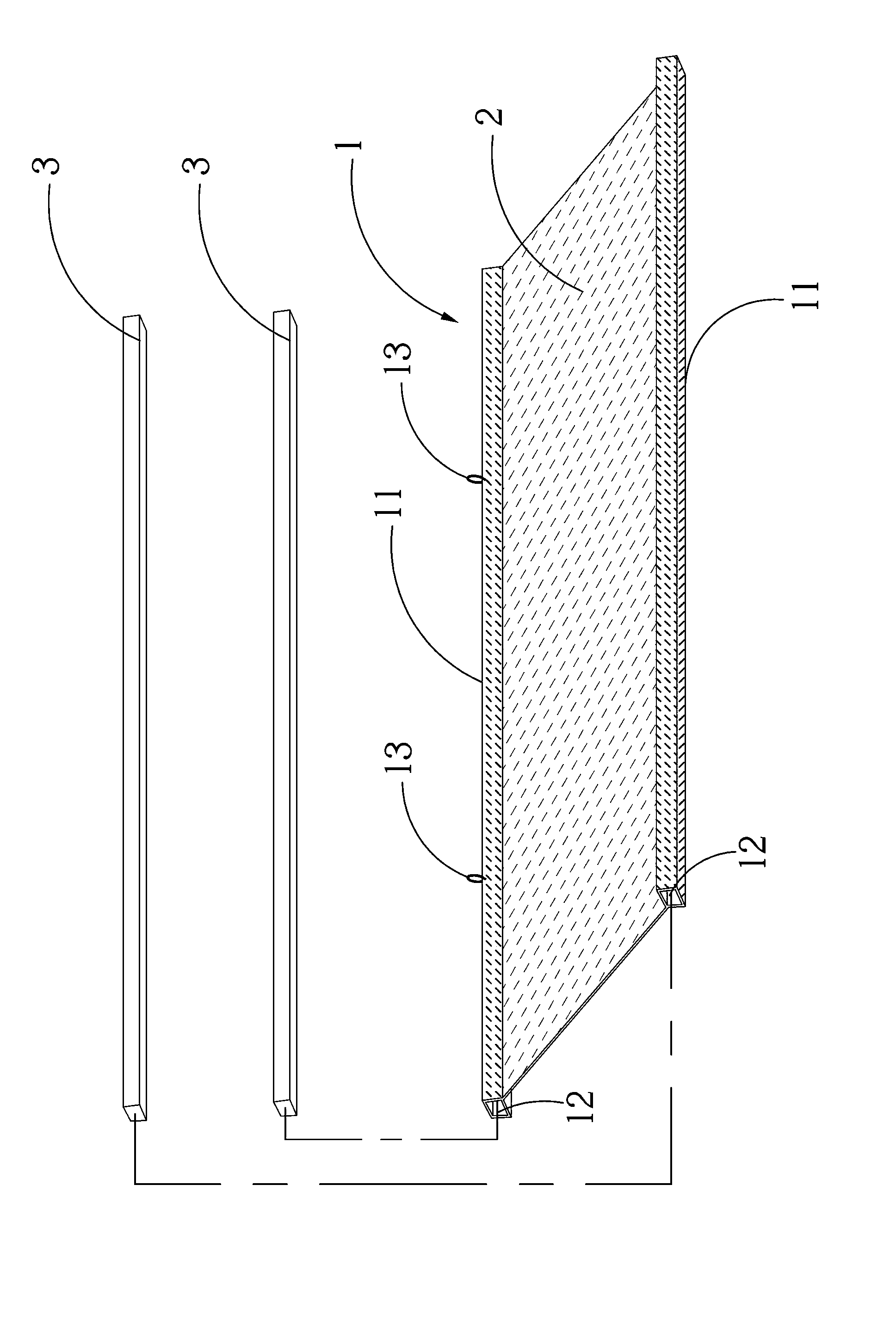

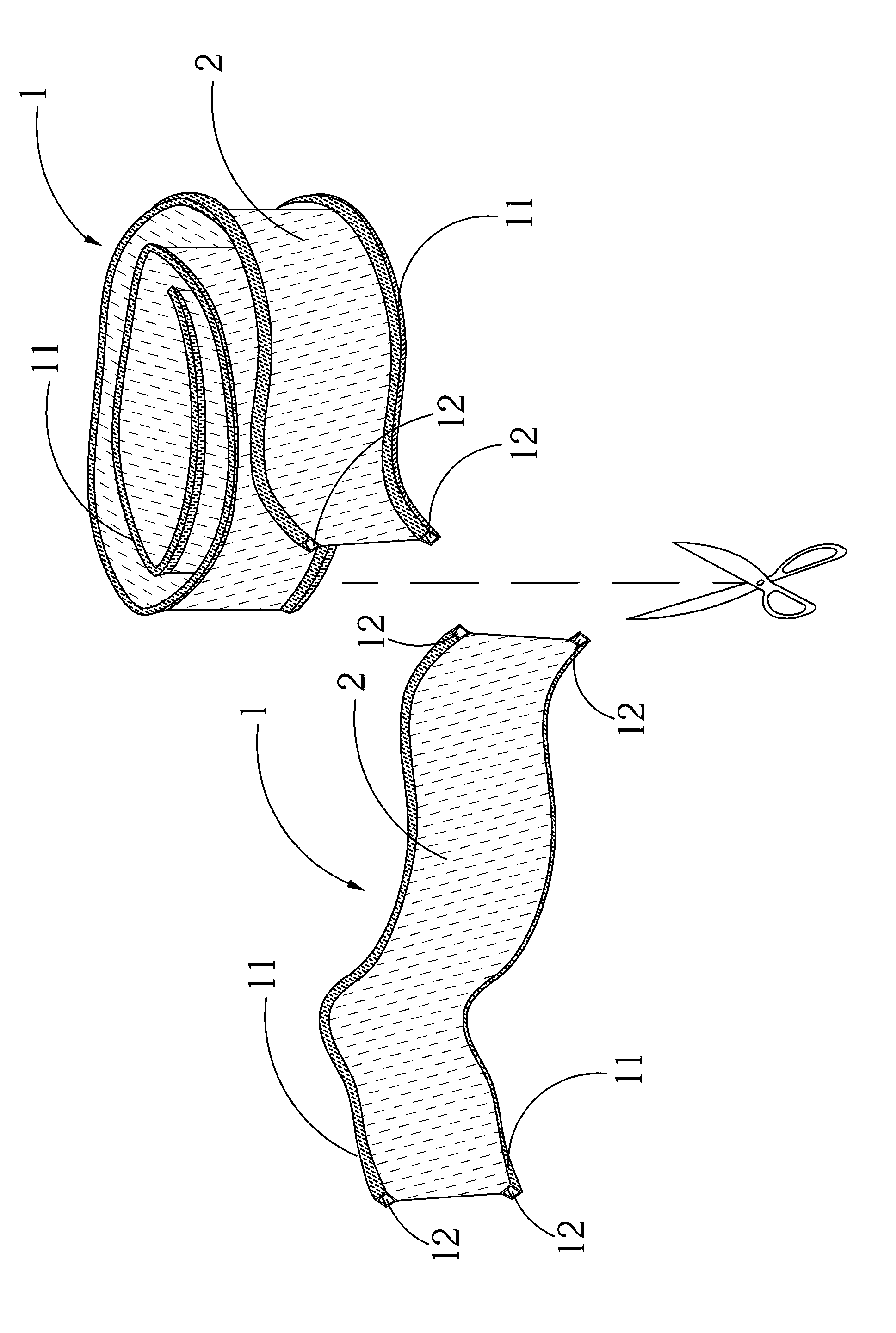

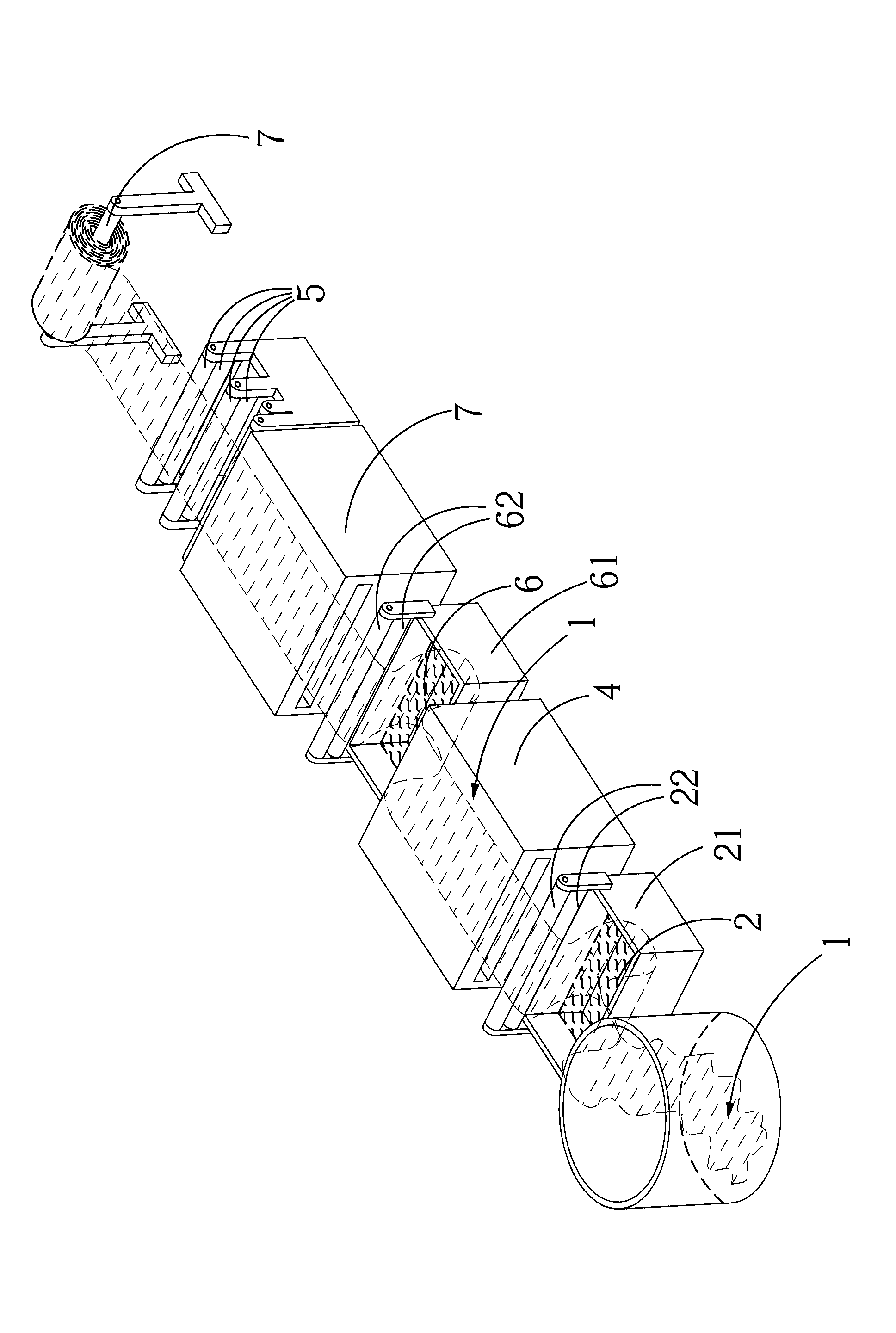

Method for making shutter blade

ActiveCN101377115AEasy to store and transportEasy to processLight protection screensMulti-ply fabricsInterior spaceEngineering

The present invention provides a method for fabricating a louver of a shutter. The method includes the following steps: (a) a strip-shaped textile is woven, and wherein, both long edges of the textile are double-layered in order to form a strip-shaped interior space; (b) the strip-shaped textile is immersed into hardener, that is, the strip-shaped textile passes through the hardener at a predetermined speed; (c) the soaked textile is squeezed, so that the hardener can be uniformly distributed in the textile; (d) the textile soaked with the hardener is baked under a high temperature; and (e) the baked textile is shaped under a high temperature until being flattened, and then can be used as a horizontal or vertical louver.

Owner:LANTEX WINDOW FASHIONS CO LTD

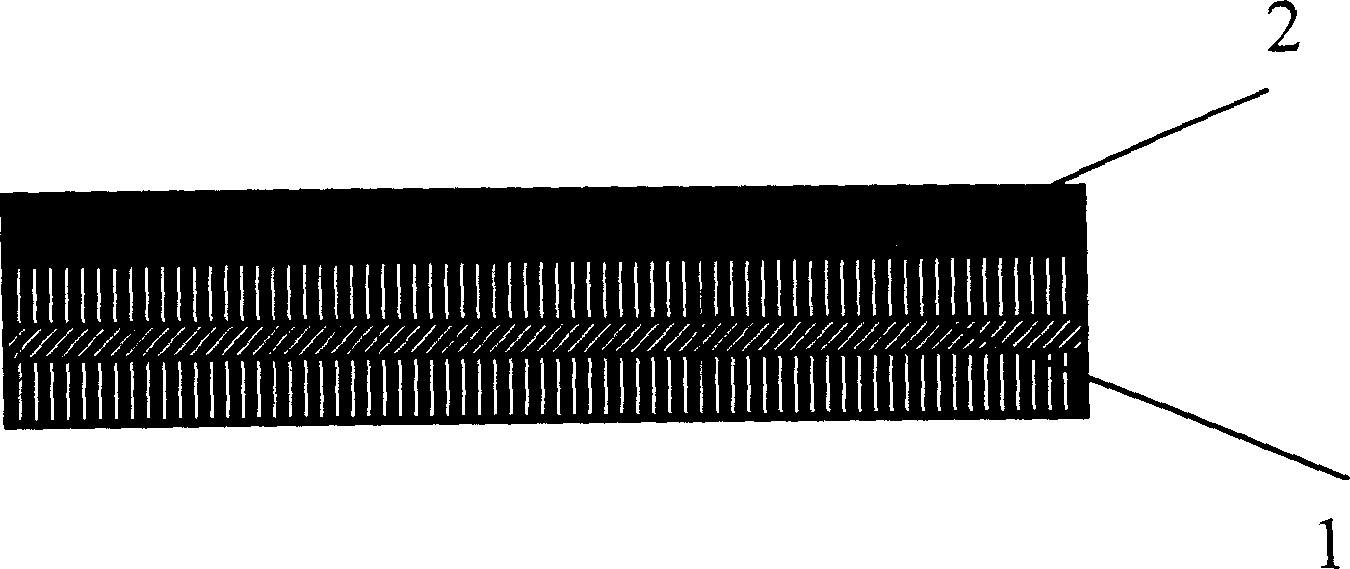

Ultrathin leisure fabric with windproof and breathable functions and manufacturing method thereof

InactiveCN103932436AReduce weightWith windshieldSynthetic resin layered productsLaminationMicrometerCorrosion

The invention relates to an ultrathin leisure fabric with windproof and breathable functions and a manufacturing method of the ultrathin leisure fabric with the windproof and breathable functions. The method includes the steps that material is mixed; a blank is manufactured; pushing and pressing are performed; calendaring is performed; ungreasing treatment is performed; longitudinal stretching is performed; bi-directional stretching is performed in an arc shape; after transverse stretching, agglomeration and solidification are performed; films are attached through a release paper transferring method; the ultrathin leisure fabric is formed through glue compositing on textile fabric. The ultrathin leisure fabric manufactured through the steps is used for the fields of down garments, leisure sportswear, shoemaking and others, the thickness of the teflon microporous film is 2 micrometers-5 micrometers, the pore diameter is 0.5 micrometer-2 micrometers, and the porosity is over 80%. The ultrathin leisure fabric has the multiple functions of being light in weight, windproof, waterproof, breathable and resistant to ultraviolet and corrosion, discharging sweat and keeping warm and is suitable for various products, which are made of functional materials, for kinds of sports, leisure and women and children.

Owner:HUZHOU SENNUO FLUORINE MATERIAL TECH

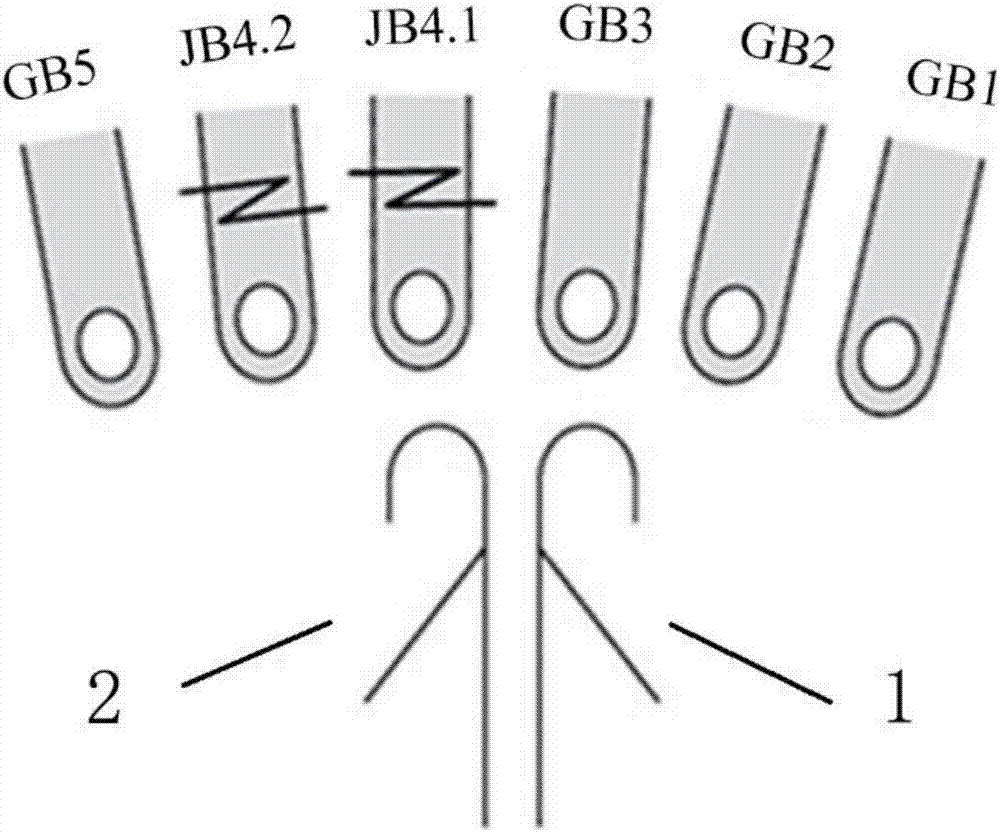

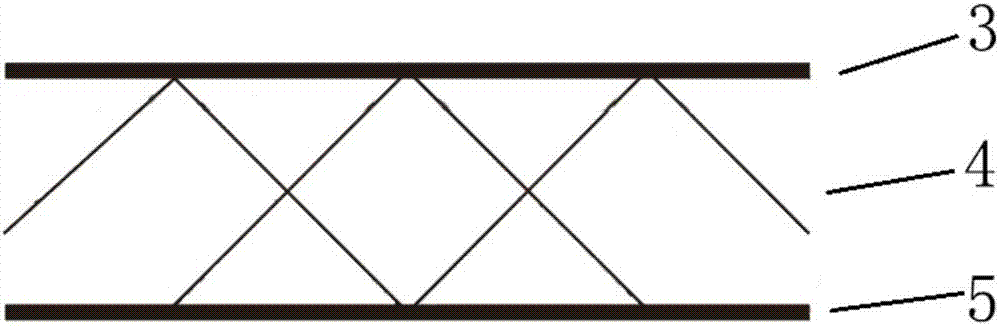

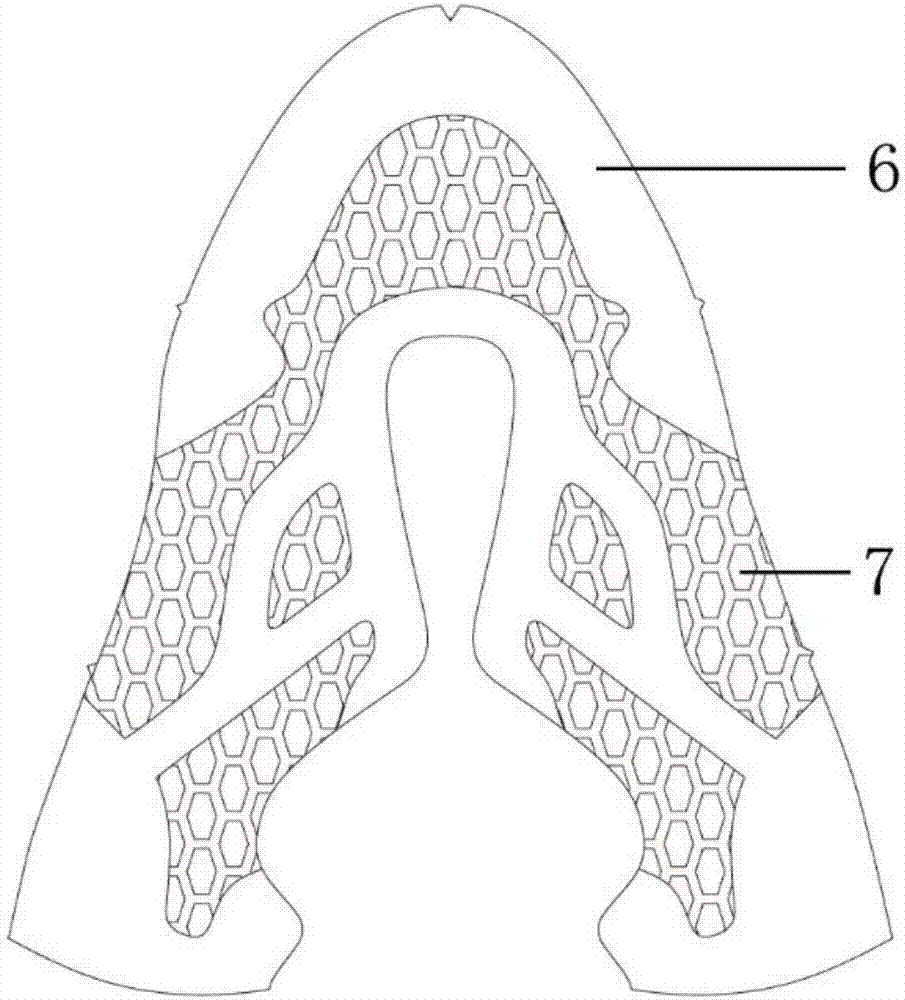

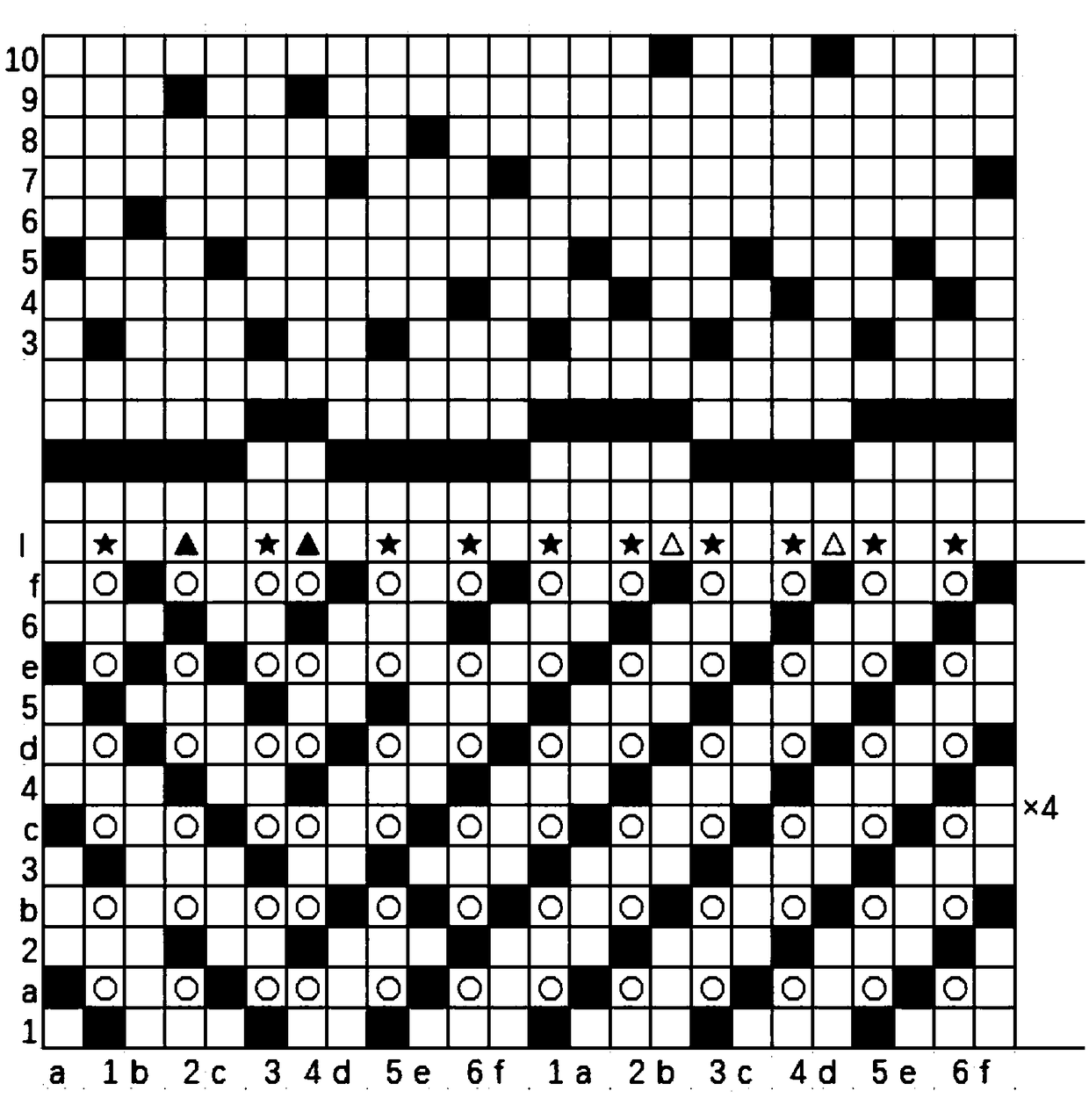

Multifunctional warp-knitted jacquard interval shoe upper fabric of graphene modified polyester fibers and production method thereof

InactiveCN106988001AAntibacterialMoisture wickingOrnamental textile articlesWarp knittingPolyesterFiber

The invention discloses a multifunctional warp-knitted jacquard interval shoe upper fabric of graphene modified polyester fibers and a production method thereof. The warp-knitted jacquard shoe upper fabric is woven by a double needle-bar jacquard machine, the lower surface layer of the fabric is woven with graphene modified polyester fibers, the middle layer of the fabric is woven with monofilaments of polyester or chinlon, and the upper surface layer of the fabric is woven with filaments of polyester or chinlon. The lower surface layer of the fabric is in direct contact with feet, and breathable mesh texture or plain compact texture is adopted. V-type or IXI-type texture of good stability is adopted in the middle layer of the fabric. The upper surface layer of the fabric is a wearing surface, and a shoe upper surface layer which is flexible in structure and abundant in meshes is formed through a jacquard comb. By means of the properties such as anti-bacteria, bacteriostat, moisture absorption and permeability of graphene modified polyester fibers, combined with the characteristics such as good pressure resistance and cushioning performance, permeability and lightness of interval shoe upper fabric and the features of abundant jacquard types, stylish appearance and the like of jacquard fabric, multiple functions are integrated in the warp-knitted jacquard interval shoe upper fabric of graphene modified polyester fibers.

Owner:JIANGNAN UNIV

Integrated nano inorganic wall light heat insulation facing section bar and preparation thereof

InactiveCN101348355AWith thermal insulationEnvironmentally friendlyCovering/liningsSolid waste managementFiberSilicon oxide

The invention relates to an integrated type nano inorganic wall light weight heat preservation veneer and a method for preparing the same. The veneer consists of a heat preservation substrate which is formed by the one-piece pressure moulding of a plurality of inorganic mineral materials and a veneering layer, wherein the heat preservation substrate is prepared by husk type expanded perlite light-weight aggregate, cement, silicon oxide micropowder, wood fiber micropowder, organosilicon emulsion and cement reinforcing agent according to the blending ratio; the veneering layer is prepared by quartz sand, calcium carbonate, cement, silicon oxide micropowder and wood fiber micropowder according to the blending ratio and is in one-piece pressure moulding. Compaed with prior art, the veneer has the advantages of light weight, high strength, good heat insulation and heat preservation effects, tight bonding, energy conservation and environmental protection, resource conservation, easy construction, short construction period, low cost and long service life, etc.

Owner:信阳天意节能技术股份有限公司

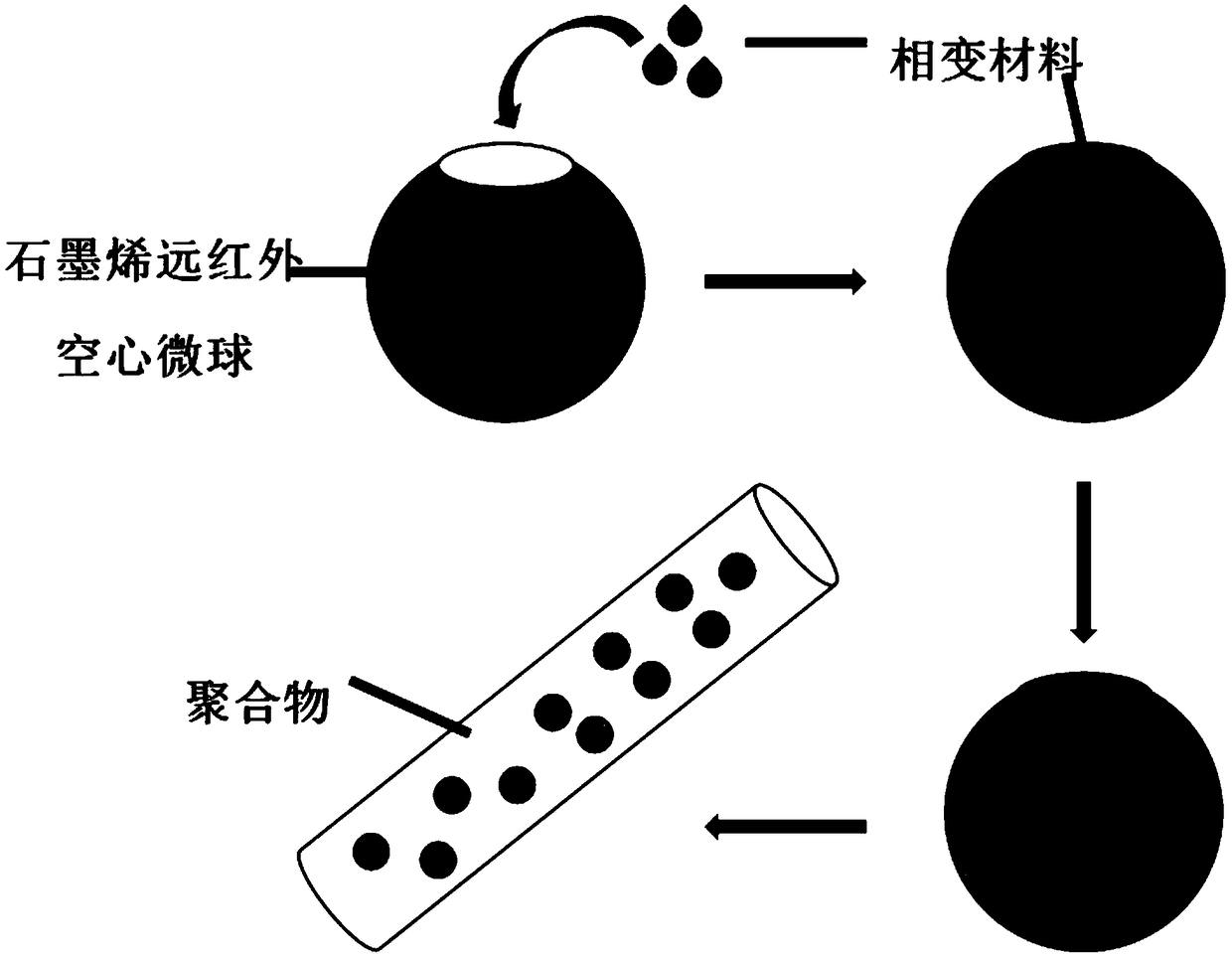

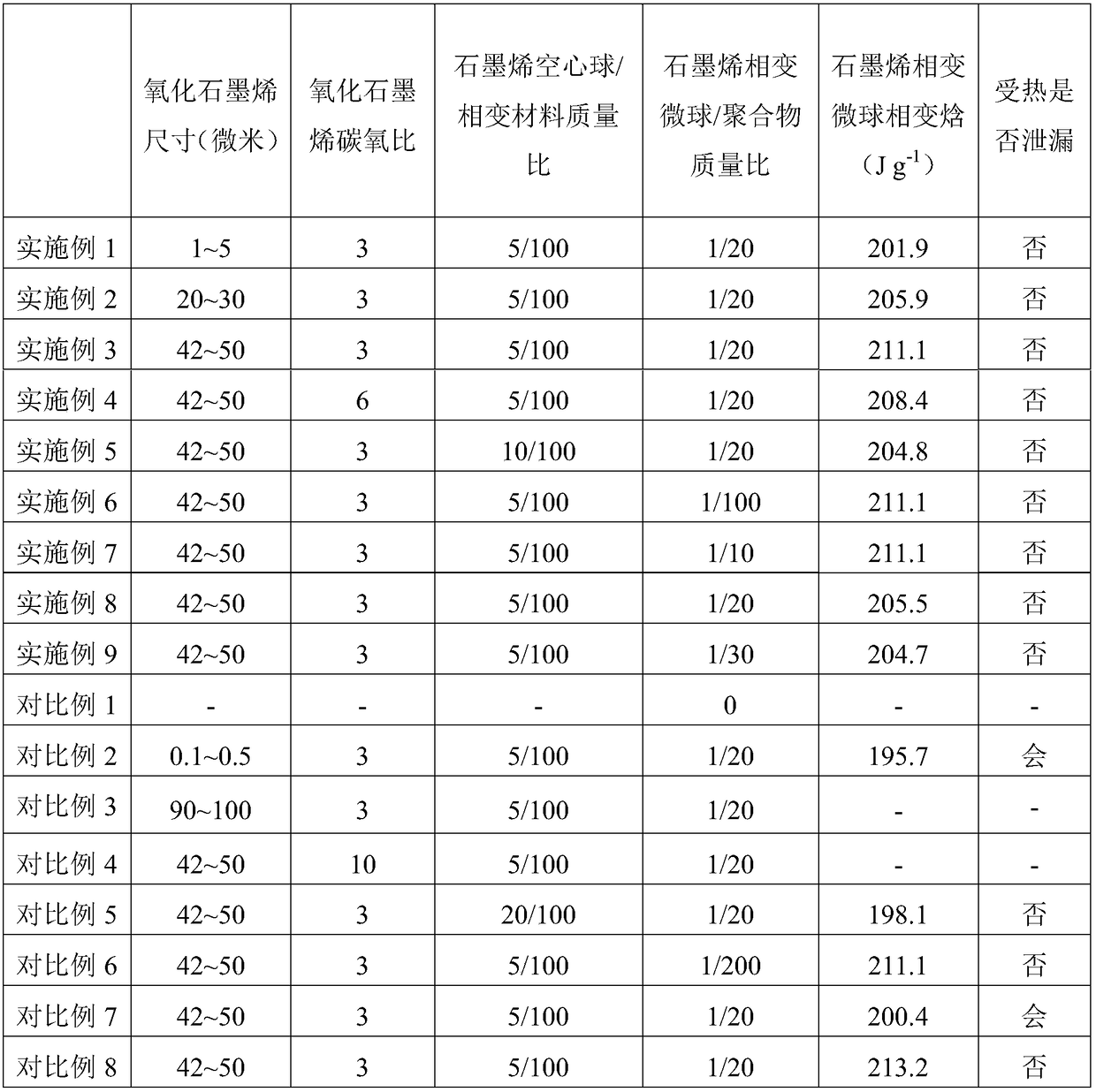

Phase change microspheres, intelligent temperature-adapting fiber and preparation methods thereof

InactiveCN109234825AEnsure coverageImprove mechanical propertiesArtifical filament manufactureMonocomponent polyamides artificial filamentFiberMicrosphere

The invention discloses phase change microspheres, intelligent temperature-adapting fiber and preparation methods thereof. Firstly, graphene far-infrared microspheres adopting mesoporous structures are prepared, then a phase change material is melted and fully the phase change material is infiltrated into cavities of the graphene microspheres to obtain the phase change microspheres adopting core-shell structures. The excess phase change material on the surfaces of the phase change microspheres is removed through pressure filtration, and after cooling, melt blending and spinning are performed on the phase change microspheres and spun-grade polymer chips to obtain composite fiber with an intelligent temperature-adjusting function. Through use of the graphene hollow spheres for wrapping the phase change material, leakage of the phase change material during using is greatly reduced, so that the service life can be significantly prolonged; high heat conductivity of graphene can effectivelypromote heat exchange between the environment and fabric and between the fabric and the surface of a human body, so that the heat response speed of heat storage fabric can be increased; the graphene and nanometer far-infrared powder have a high-efficiency far-infrared radiation function, so that the temperature of the body surface can be increased, and blood circulation is promoted.

Owner:HANGZHOU GAOXI TECH CO LTD

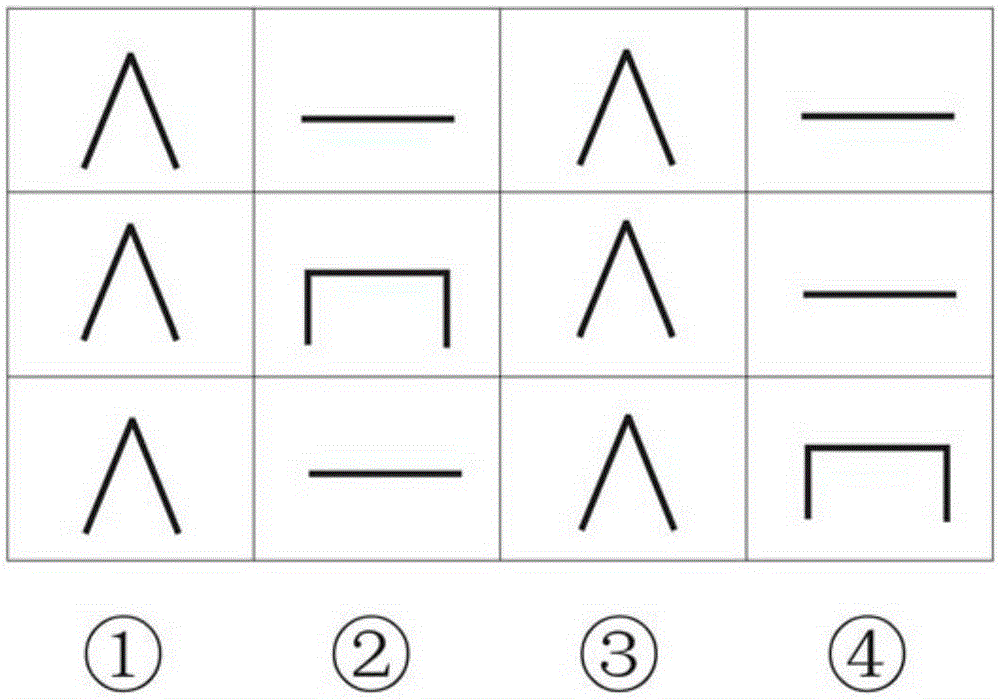

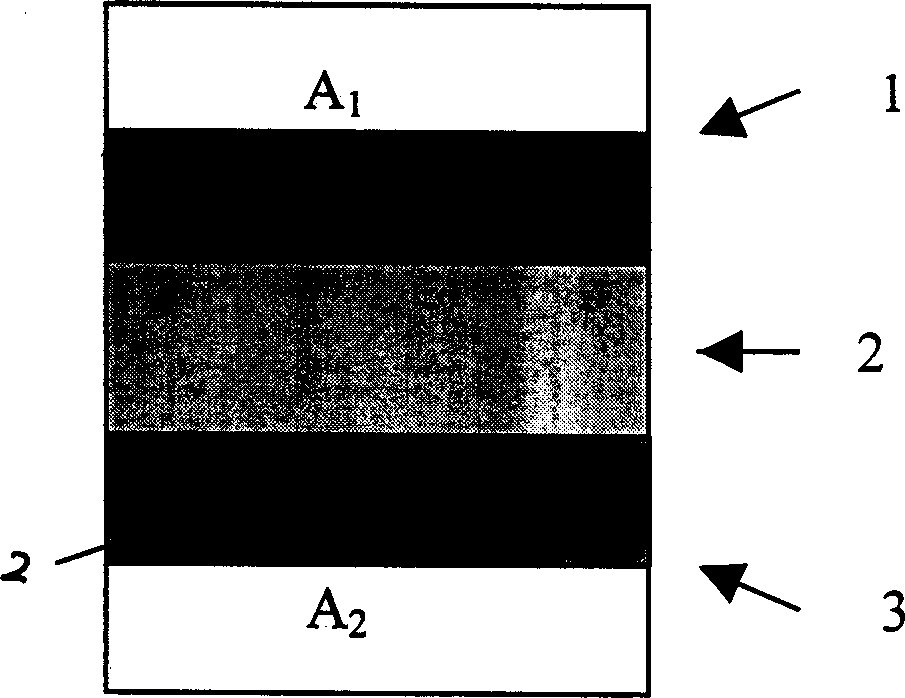

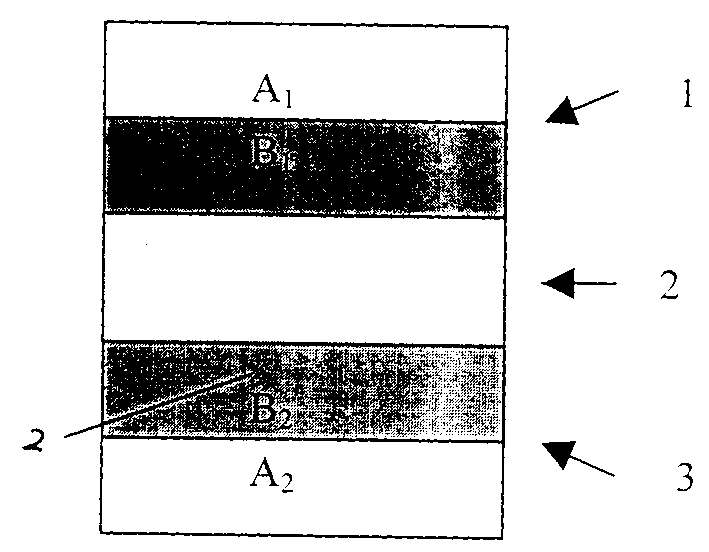

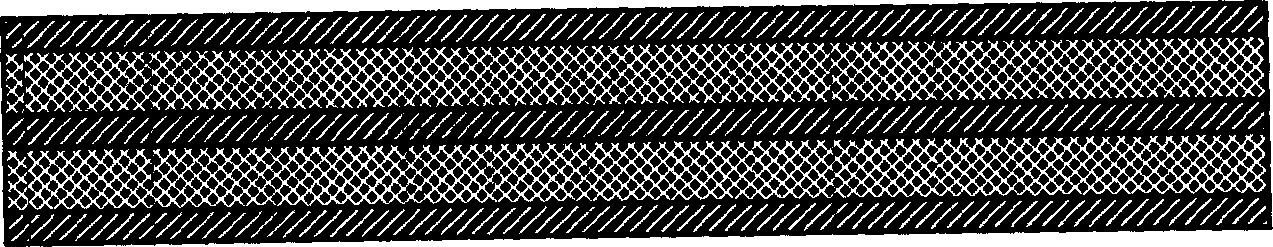

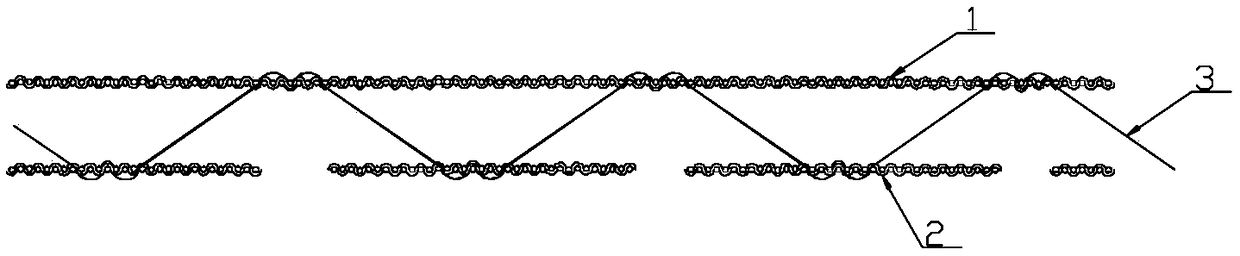

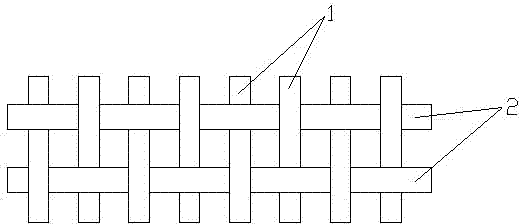

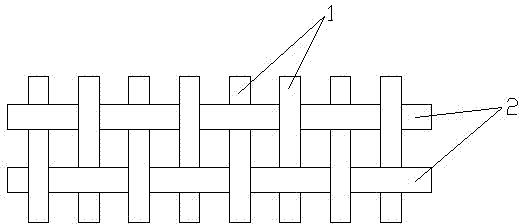

Design and preparing method of double-layer functional fabric

ActiveCN109371529AImprove antistatic performanceImproves UV protectionProtective fabricsMulti-ply fabricsSurface layerSkin surface

The invention discloses a design and preparation method of a double-layer functional fabric. The double-layer functional fabric is good in ultraviolet prevention and air permeability of surface layertextile and adopts colorful segment dyed silk so that the fabric can be more fashionable; inner layer textile is provided with permeable hole organization, resists bacteria, absorbs moisture, allows air to penetrate through, discharges sweat and dissipates heat; ATY silk is adopted for a connection layer of the fabric, is good in elasticity and fluffy and can have a certain supporting effect on the surface and inner layers to form a space with elasticity. The fabric adopts the double-layer design, the inner layer adopts the permeable hole organization and has good air permeability and heat dissipation performance, the situation is avoided that the fabric is tightly attached to the body after absorbing sweat of a wearer, and the space formed by the ATY silk is arranged between the surface layer and the inner layer and is utilized as a micro environment for adjusting the comfort degree of the skin surface; warp and weft of the surface layer adopt the colorful segment dyed filament yarn,so that the fabric has unique variety and fashion sense and also has good ultraviolet prevention and air permeability.

Owner:修武县虹纬纺织有限公司

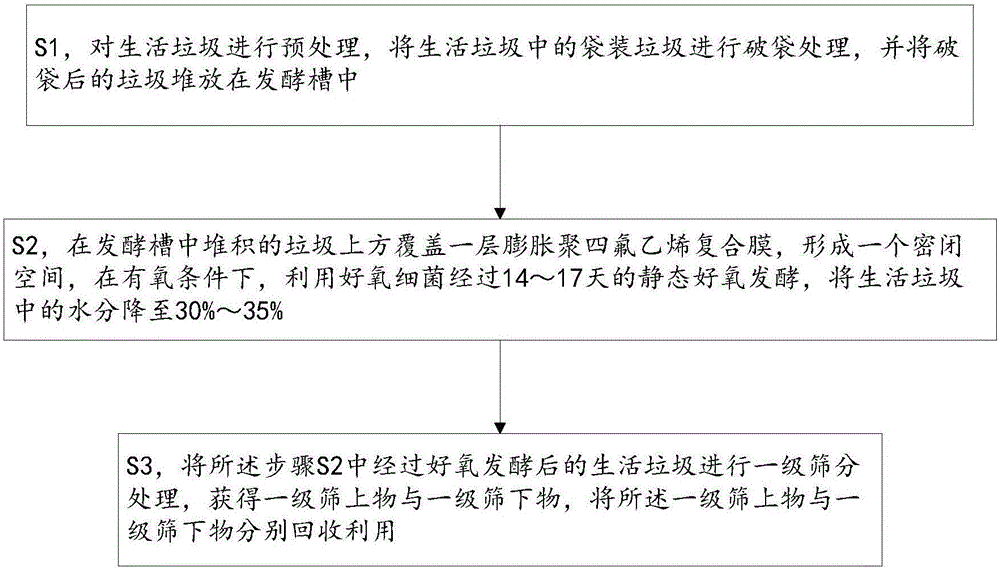

Household waste handling method

The invention discloses a domestic garbage treatment method and relates to the technical field of solid waste disposal. The domestic waste treatment method includes the following steps: S1, pretreating the domestic waste, breaking the bagged waste in the domestic waste, and stacking the broken bag in a fermentation tank; S2, fermenting The garbage accumulated in the tank is covered with a layer of expanded polytetrafluoroethylene composite film to form a closed space. Under aerobic conditions, aerobic bacteria are used for 14 to 17 days of static aerobic fermentation to reduce the moisture in domestic garbage. to 30% to 35%; S3, performing primary sieving treatment on the domestic garbage after aerobic fermentation in the step S2 to obtain the first-level sieve and the first-level sieve, and the first-level sieve The material and the undersize of the primary sieve are recycled separately. The beneficial effect of the invention is that the domestic waste can be decomposed and dried at low cost, the water content in the domestic waste can be reduced, the process is simplified, and the system investment and operation cost are reduced.

Owner:HUNAN VARY TECH

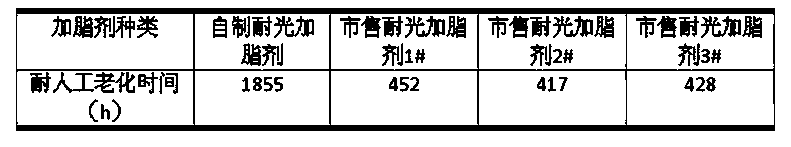

Method for preparing nano TiO2 composite leather greasing agent with ultraviolet protecting function

The invention discloses a method for preparing a nano TiO2 composite leather greasing agent with an ultraviolet protecting function. At present, the research on the application of nano TiO2 and hydrogenated ricinoleic acids to the leather greasing agent has been rarely reported at home. Rutile nano TiO2 with an excellent anti-ultraviolet capability is prepared by adopting a chemical precipitation method, and is modified with the hydrogenated ricinoleic acids, and modified rutile nano TiO2 and maleic anhydride react to obtain the TiO2 composite leather greasing agent with the ultraviolet protecting function. The ultraviolet protecting performance is realized by the hydrogenated ricinoleic acids and rutile nano TiO2. The hydrogenated ricinoleic acids are ricinus oil derivates, and the greasing agent manufactured in such a way that double bonds in molecules of the hydrogenated ricinoleic acids are subjected to hydrotreating is excellent in ultraviolet protecting performance. An electron hole formed in the surface of the rutile nano TiO2 has the advantages of relatively high recombination speed and relatively high UV-shielding capability, and the leather is provided with the ultraviolet protecting function.

Owner:SHAANXI UNIV OF SCI & TECH

Nanometer polypropylene modifier and its prepn process

The present invention relates to one kind of nanometer polypropylene modifier and its preparation process. The nanometer polypropylene modifier is prepared with nanometer completely vulcanized rubber powder in 40-50 %, antioxidant 168 in 10-15 %, antioxidant 1010 in 10-15 %, dispersant in 3-5 %, antistatic agent in 3-5 %, couplant in 3-5 % and calcium stearate in 3-5 %. The preparation process includes the following steps: 1. dispersing and mixing the components in a stirrer; 2. further dispersing in a ball mill; and 3. extruding to pelletize in an extruder while further dispersing. The nanometer polypropylene modifier as one multifunctional product has functions of strengthening, toughening, resisting heat, etc.

Owner:南京淳达科技发展有限公司

Fiber knitted fabric

The invention discloses fiber knitted fabric comprising a fabric body, wherein the fabric body is interwoven by warps and wefts, the warps are made of fiber interwoven by cotton fiber and silver fiber, the wefts are made of fiber interwoven by one or more than one of Tencel fiber or bamboo charcoal fiber or hemp fiber, the warp density of the fabric is 200-300 per inch, and the weft density of the fabric is 150-180 per inch. In such a way, the fiber knitted fabric disclosed by the invention has good air permeability and the effects of blocking ultraviolet rays, preventing radiation and keeping warm.

Owner:CHANGSHU MEILI TOWN BINLI GARMENT & CLOTHING FACTORY

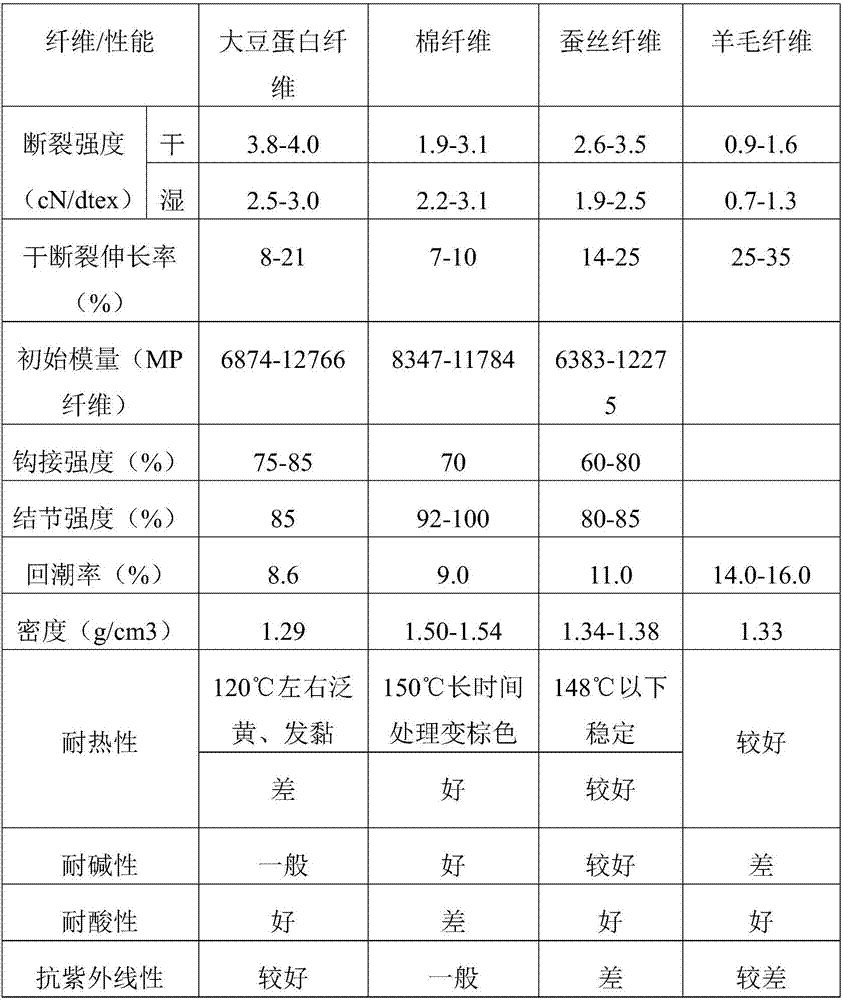

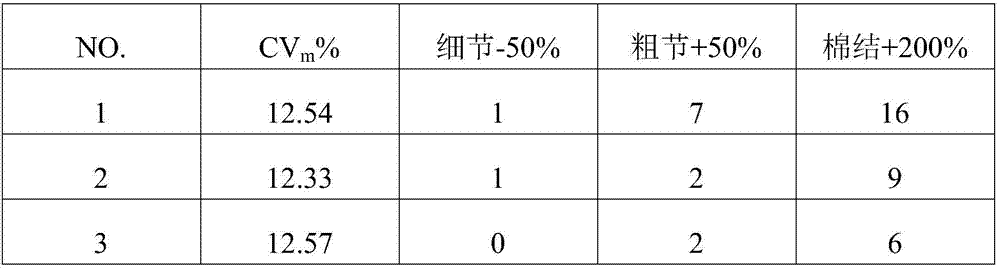

Four-component blended yarn product and spinning method thereof

InactiveCN107964706AGreat functionalityMeet the needs of the high-end marketFibre mixingYarnYarnCotton fibre

Provided is a four-component blended yarn product. The product is prepared from, by mass, 15-30% of soybean protein fibers, 10-30% of graphene fibers, 25-50% of viscose and 10-30% of cotton fibers. The soybean protein fibers, the graphene fibers, the viscose and the cotton fibers are subjected to drawing and spinning after being processed separately to prepare the four-component blended yarn product. The functions of all the four components are fully exerted, and functional yarn truly fitting with the upper class is prepared.

Owner:SHANDONG YANGGU SHUNDA TEXTILE

Waterborne anti-rust heat insulating coating

InactiveCN101298538AGood anti-rust and heat insulation effectExcellent anti-rustFireproof paintsAnti-corrosive paintsWater basedSoft water

The invention discloses a water-based anti-rust and heat insulation coating which is characterized in that the coating mainly consists of materials with following weight percentage: 10-30 percent of soft water, 0.1-0.3 percent of hydroxyethyl cellulose, 0.1-0.2 percent of preservative, 0.2-0.4 percent of anti-mildew agent, 0.2-0.5 percent of amine salt dispersant, 0.02-0.1 percent of low foam wetting agent, 0.1-0.3 percent of defoamer, 1-4 percent of glycol, 3-13 percent of coarse whiting, 3-20 percent of saponite, 18-25 percent of titanium pigment, 0.1-0.6 percent of organic amine, 3-6 percent of calcined kaolin, 28-43 percent of silicone-acrylate emulsion above Tg 35 DEG C, 1.3-2.8 percent of lauryl alcohol ester, 3-13 percent of hollow sodium silicate particle with the average grain size of about 10 to 30 Mum, 0.1-0.6 percent of thickener, 3-12 percent of wollastonite powder, and adjusting pH 10-pH 11. The invention is used for iron roofs and exterior walls etc., and has the advantages of good anti-rust and heat insulation effect, good durability, being easy for storage and coating, low cost and water environmental protection.

Owner:胡月祖

Soybean fiber knitting face fabric and manufacture technology thereof

The invention relates to a composite fiber blended multilayer knitting face fabric, and relative production, wherein said soybean protein fiber three-layer knitting face fabric is formed by face layer, middle layer and inner layer, while the face layer contains 8-30% cashmere and 60-95% wool; the middle layer contains polyester hollow fiber and Lycra; and the inner layer is the blended yarn which contains 30-70% soybean protein fiber and 30-70% cotton. The invention has beautiful appearance and better mechanical property.

Owner:马鞍山海狮织造有限公司

Blended fibriia composite fabric

The invention discloses a blended fibriia composite fabric. The blended fibriia composite fabric comprises a hygroscopic and breathable layer which is a surface layer and an antibiotic and radiation-proof layer which is an internal layer, the hygroscopic and breathable layer is obtained through blending braiding of 15-22wt% of sisal fibers and 78-85wt% of pina fibers, and the antibiotic and radiation-proof layer is obtained through blending braiding of 45-51wt% of hemp fibers and 49-55wt% of kendir fibers. The blended fibriia composite fabric has a double-layer structure design, the hygroscopic and breathable layer which is the surface layer has the characteristics of tough texture, wear resistance, acid and alkali resistance, and good hygroscopic and breathable properties, and the hygroscopic and breathable layer which is the internal layer has the characteristics of antibiosis, deodorization, ultraviolet resistance and healthcare, so the fabric has the characteristics of cooling, comfortableness, unlikely damage, and maintenance of the cleanness and health of human bodies.

Owner:SUZHOU TANXI TEXTILE TECH CO LTD

Method for preparing nano-TiO2 nylon 66 resin and fibre having anti-ultraviolet function

InactiveCN104629042AWith UV shielding functionWith sun protection and heat insulationMelt spinning methodsMonocomponent polyamides artificial filamentPolyesterYarn

The invention discloses a method for preparing nano-TiO2 nylon 66 resin and fibre having an anti-ultraviolet function, belonging to the technical field of fibre and textiles. The method disclosed by the invention comprises the following steps: injecting TiO2 suspension into a polymer melt at the outlet of a flash evaporation pump in the condensation polymerization process of nylon 66 at first, and then, carrying out post condensation polymerization of the polymer melt injected with the TiO2 suspension so as to obtain nano-TiO2 nylon 66 resin; and then, carrying out melt spinning of the nano-TiO2 nylon 66 resin so as to obtain nano-TiO2 nylon 66 fibre. The nylon 66 fibre having excellent properties and the anti-ultraviolet protection function can be manufactured from the nylon 66 resin manufactured by the invention through a POY-DTY (Polyester Pre-Oriented Yarn-Draw Texturing Yarn) spinning technology; and the fibre can be processed into high-quality clothes or costume materials having gentle lustre, soft hand feeling and comfort, good air permeability, abrasion resistance and easy rinsing property and having anti-ultraviolet and nursing functions.

Owner:LIAONING YINZHU CHEMTEX GROUP

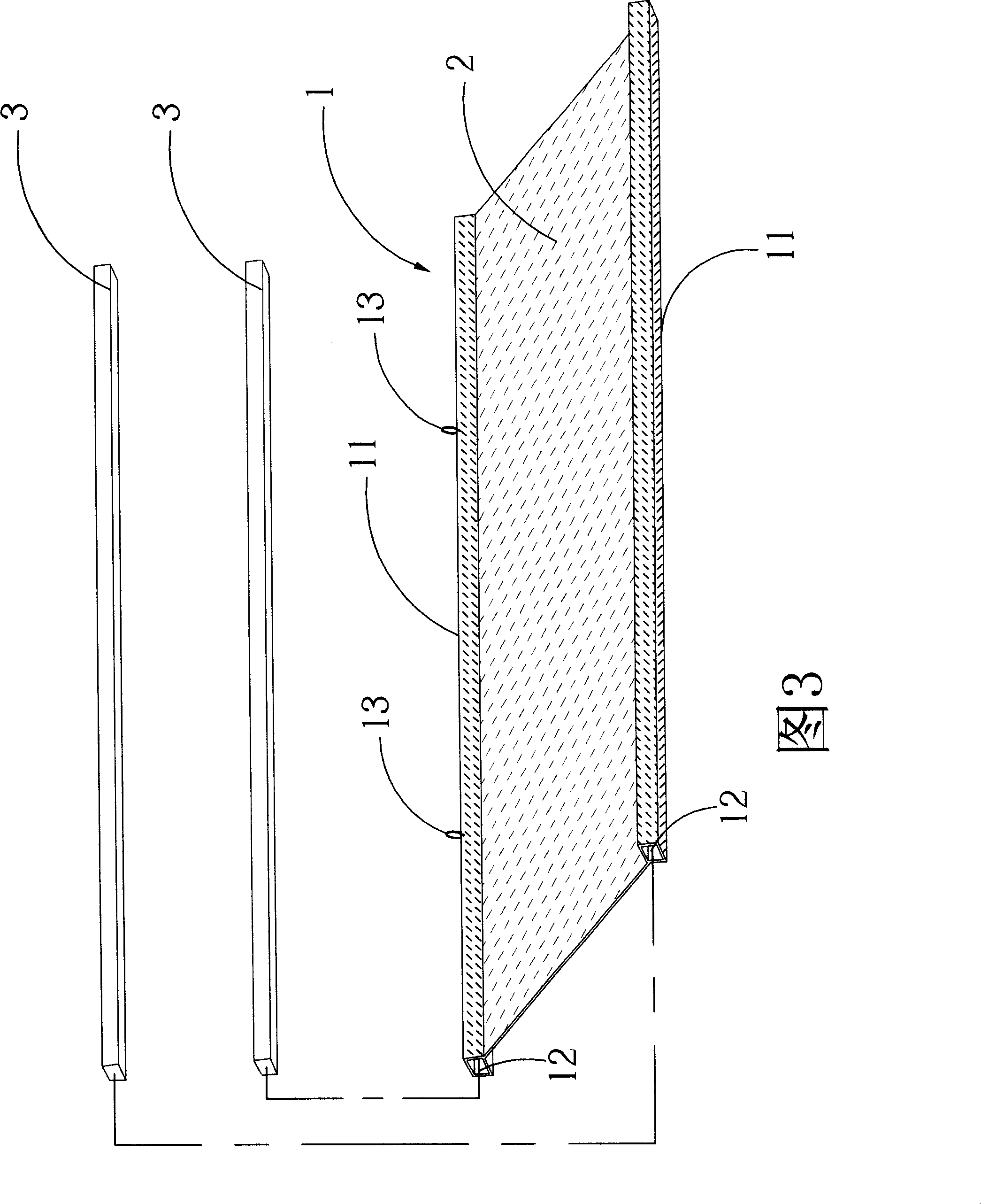

Blade of window-shades and manufacturing method of blade

ActiveCN103668986AEasy to store and transportEasy to processFibre treatmentInterior spaceEngineering

The invention provides a method of manufacturing a blade of window-shades. The method comprises the following steps: (a) weaving a strip-shaped textile fabric, wherein two long sides of the textile fabric are weaved as double layers to form a strip-shaped inner space; (b) immersing the strip-shaped textile fabric in a hardener, wherein the strip-shaped textile fabric passes through the hardener at a predetermined speed; (c) drying the textile fabric immersed by the hardener at high temperature; and (d) extruding the textile fabric dried at high temperature to set the fabric in a flat state, so that the textile fabric is used as the blade of window-shades.

Owner:LANGDE STRIP MFG RUI AN CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com