Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

316results about How to "Guaranteed normal formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

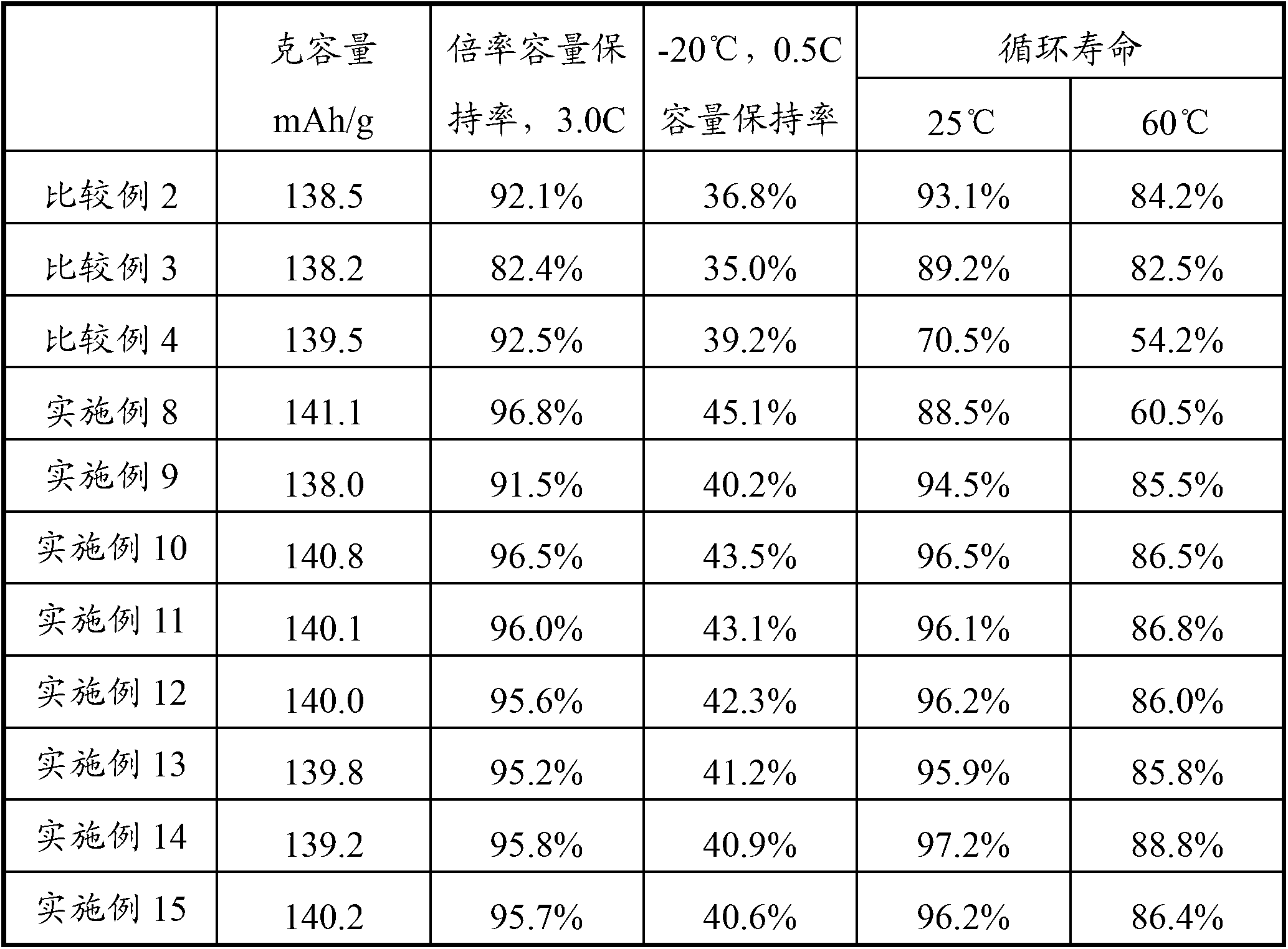

Lithium-ion secondary battery and electrolyte thereof

InactiveCN103078141AFacilitated DiffusionImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesMethyl carbonateCarbonate

The invention discloses a lithium-ion secondary battery and an electrolyte thereof. The electrolyte comprises a solvent, lithium salt and a film forming additive, wherein the solvent comprises a first solvent and a second solvent; the first solvent comprises linear carboxylic ester and ethylene carbonate; the second solvent is one or more of ethyl methyl carbonate, diethyl carbonate, dimethyl carbonate and propylene carbonate; and the film forming additive is one or more of fluoroethylene carbonate, vinylene carbonate, 1,3-propane suhone, succinonitrile, adiponitrile, lithium bis(oxalato)borate, and lithium oxalyldifluoroborate. Due to the collocation of linear carboxylic ester and ethylene carbonate, a solvent system with a higher dielectric constant and low viscosity is obtained; the film forming additive improves poor compatibility between linear carboxylic ester and graphite; and finally the lithium-ion secondary battery adopting the electrolyte presents high-power discharge capacity, excellent high-temperature cycling stability and low-temperature charge and discharge properties.

Owner:NINGDE AMPEREX TECH

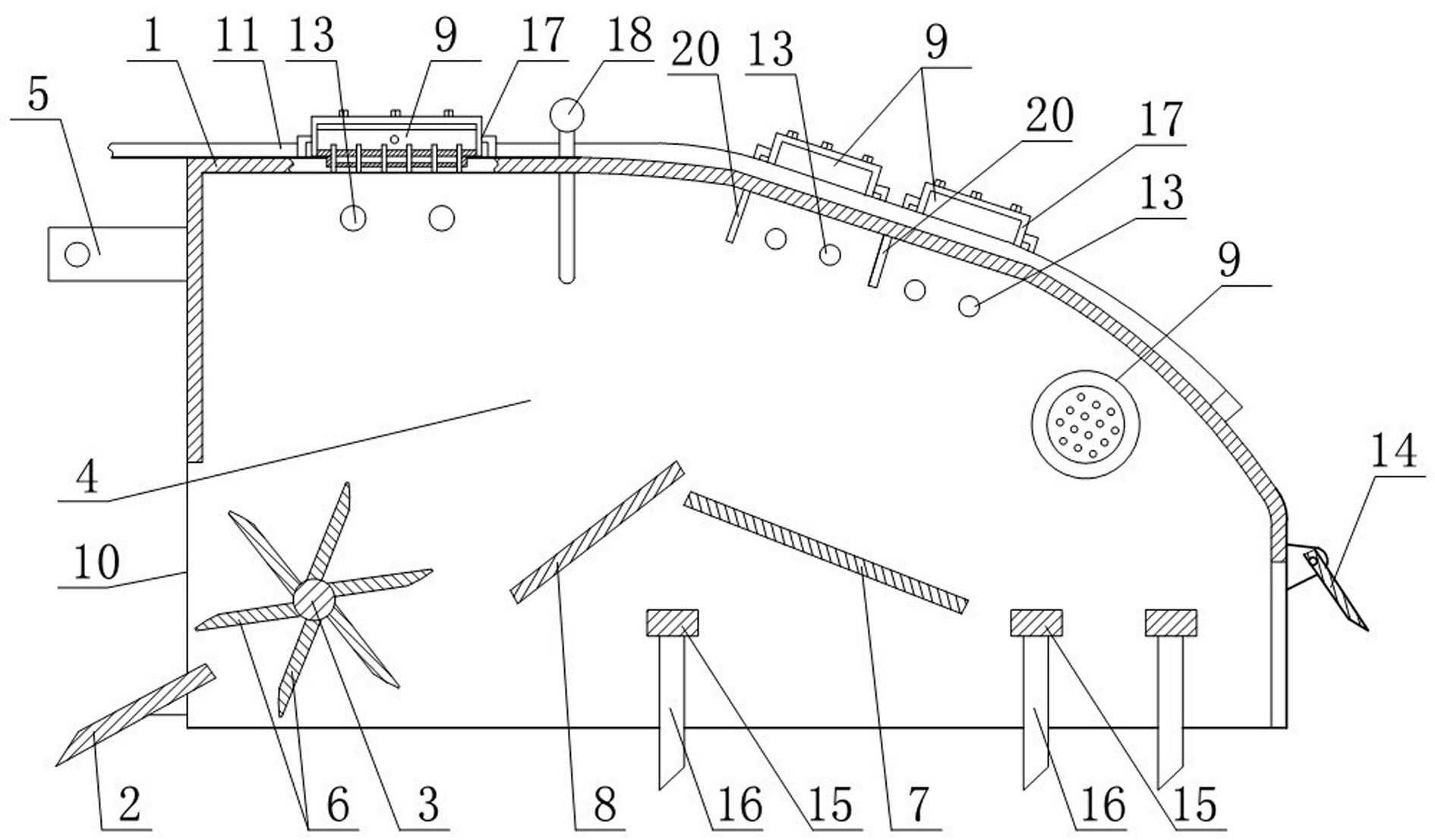

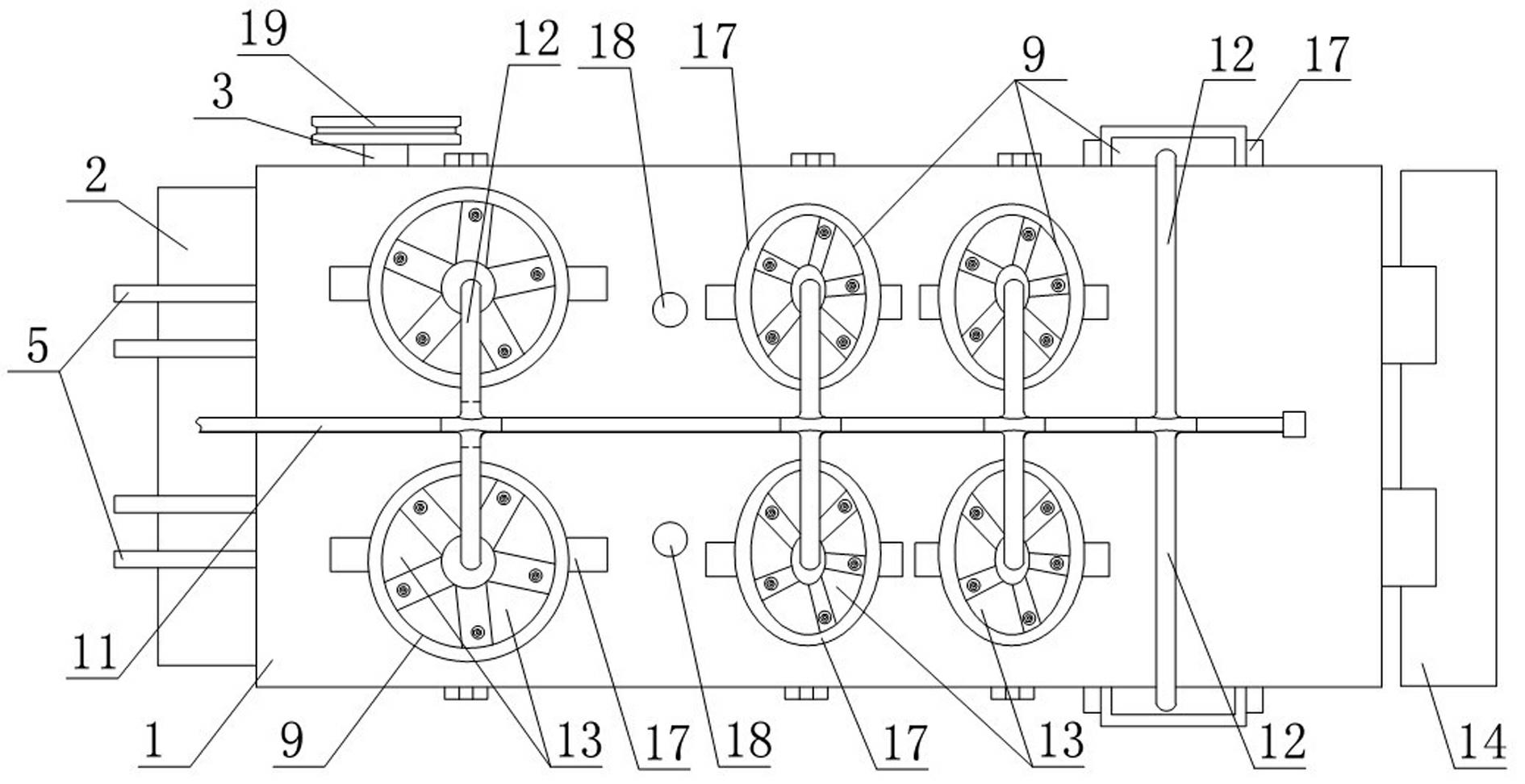

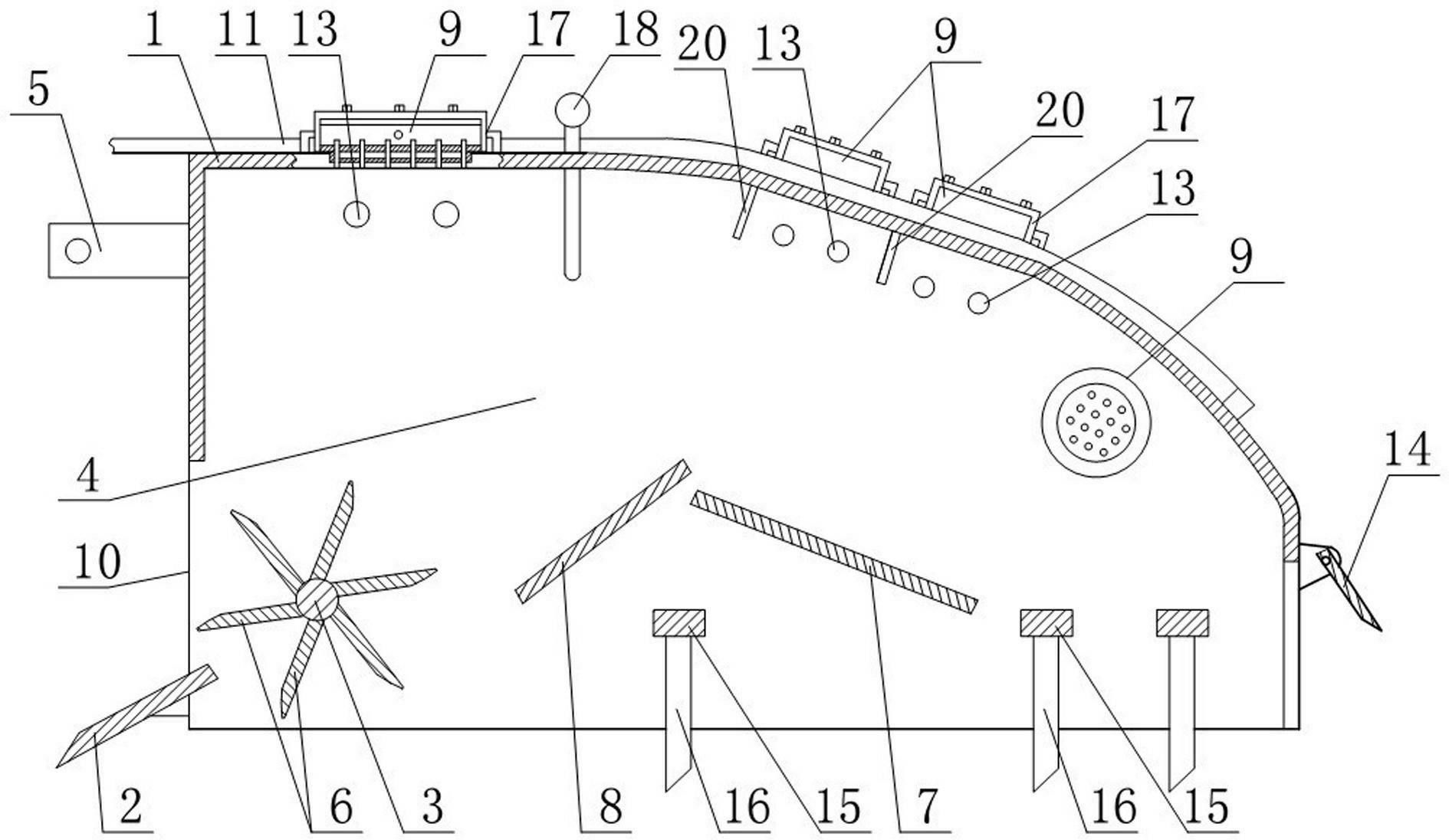

Method for killing soil bacteria and insects and improving soil and special device for killing bacteria and insects

InactiveCN102428778ABreak through the problems that cannot be preventedAchieve eradicationFlame throwersSoil-working methodsMicroorganismDrive shaft

The invention discloses a method for killing soil bacteria and insects and improving soil and a special device for killing bacteria and insects, wherein the method for killing soil bacteria and insects and improving soil comprises the following steps: first, rotatably plowing the surface soil, where the rotary plowing depth is not less than 35 cm; second, shoveling the surface soil from the land, and lifting the shoveled surface soil and then baking the surface soil by flame; and third, complementing microorganism, compost and trace element; the special device comprises a box, wherein a shoveling plate is arranged in the front of the box body; a soil inlet is arranged on the front wall of the box body; a transmission shaft is arranged above the back of the shoveling plate; soil-lifting blades are distributed on the transmission shaft annularly; a first tilting plate is arranged on the middle lower part of the box body; a gas pipe is arranged at the top of the box body; and a flame stove is arranged on the box body. When the special device and the method disclosed by the invention are used for killing bacteria and insects, the cost is low, the insect-killing effect is good and the organic activity and microorganism activity in the soil are ensured.

Owner:王丹妮

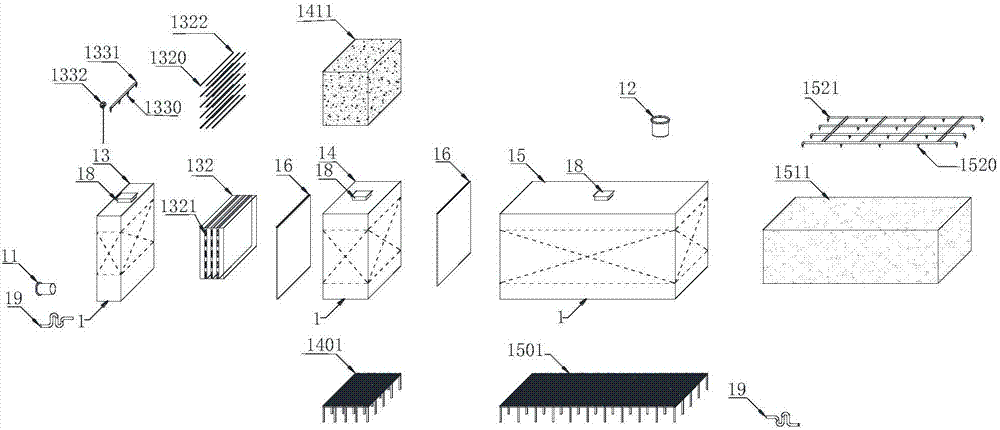

Ceramic composite material and preparation method thereof

ActiveCN102234187AImprove thermal conductivityGuaranteed normal formationCeramic compositeHeat conducting

The invention provides a ceramic composite material, comprising porous ceramic, wherein adhesive is filled in the pore space of the porous ceramic. The invention also provides a preparation method of the ceramic composite material, comprising the steps of: adhesive dipping: dipping the porous ceramic into the adhesive, and pressing the adhesive into the pore space of the porous ceramic; and curing: curing the adhesive in the porous ceramic to obtain the ceramic composite material. According to the preparation method provided by the invention, the ceramic composite material is obtained by filling the adhesive in the pore space of the porous ceramic; the porous ceramic is adopted as a substrate for the ceramic composite material, therefore, the forming of heat conductive paths is ensured, and compared with high molecular heat conducting composite material, the ceramic composite material has an excellent heat conducting performance; synchronously, because the porous ceramic is subjected to the adhesive dipping treatment, the ceramic composite material has a better bonding performance with heating elements and heat radiating devices compared with the single ceramic material; and the ceramic composite material is simple in production process and low in cost.

Owner:BYD CO LTD

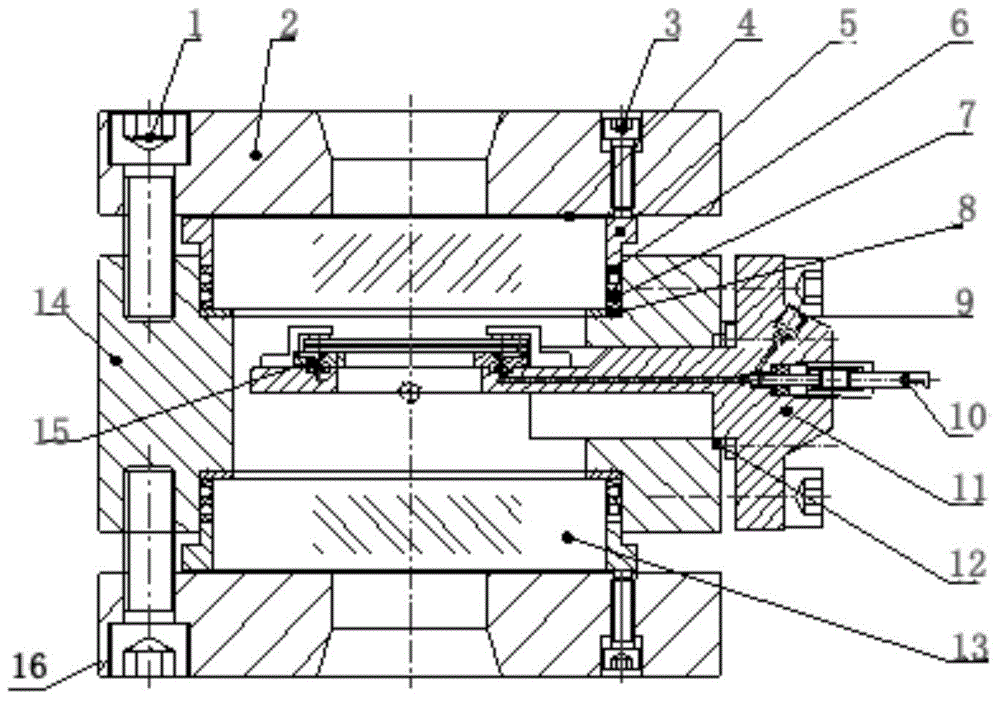

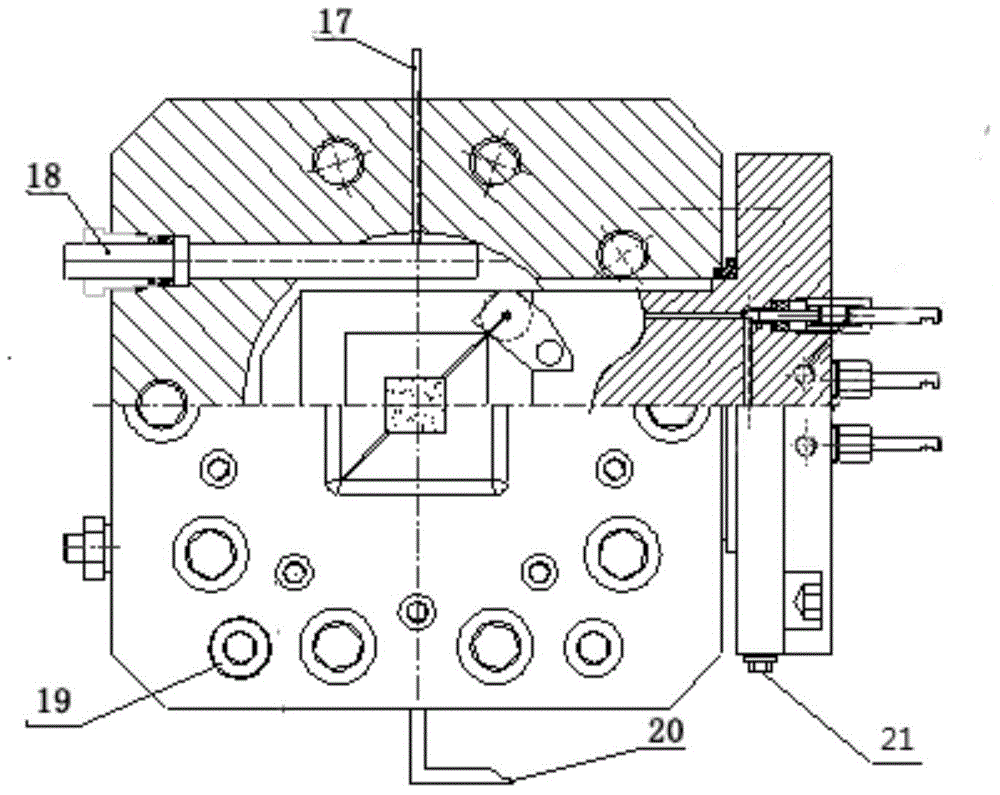

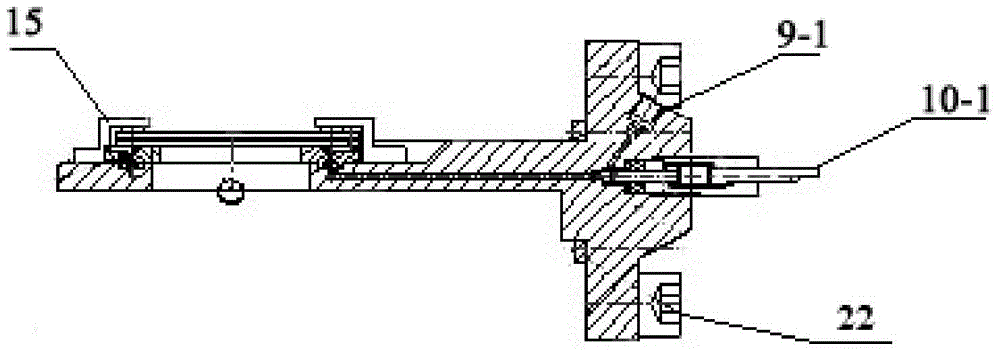

High-temperature high-pressure glass micro model gripper used for heavy oil thermal recovery

The invention discloses a high-temperature high-pressure glass micro model gripper used for heavy oil thermal recovery. The high-temperature high-pressure glass micro model gripper comprises a high-temperature high-pressure bin and high-pressure glass visual windows and further comprises a drawer type micro model support, upper pressing plates and lower pressing plates. The high-temperature high-pressure bin is a square-cylinder-shaped bin body. The upper portion and the lower portion of the inner wall of the bin body are each provided with an annular step. One high-pressure glass visual window is fixed to each annular step. The upper pressing plates and the lower pressing plates are arranged on the outsides of the high-pressure glass visual windows correspondingly. The high-temperature high-pressure bin is provided with a heater leading to an inner cavity of the bin body. The side face of the bin body is further provided with a model support inlet. The drawer type micro model support is pushed into the bin body from the model support inlet. Through the drawer type high-temperature high-pressure gripper, operation is simple, fast and convenient, and the problem of the unreliability of the leakproofness of the bin body due to repeated disassembly and assembly of the visual windows is avoided. A plurality of injection openings and control valves, bull plugs and back-pressure valves of the injection openings are adopted, so that noninterference between injection fluid is achieved, and meanwhile, the continuity of the injection fluid and pressure is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

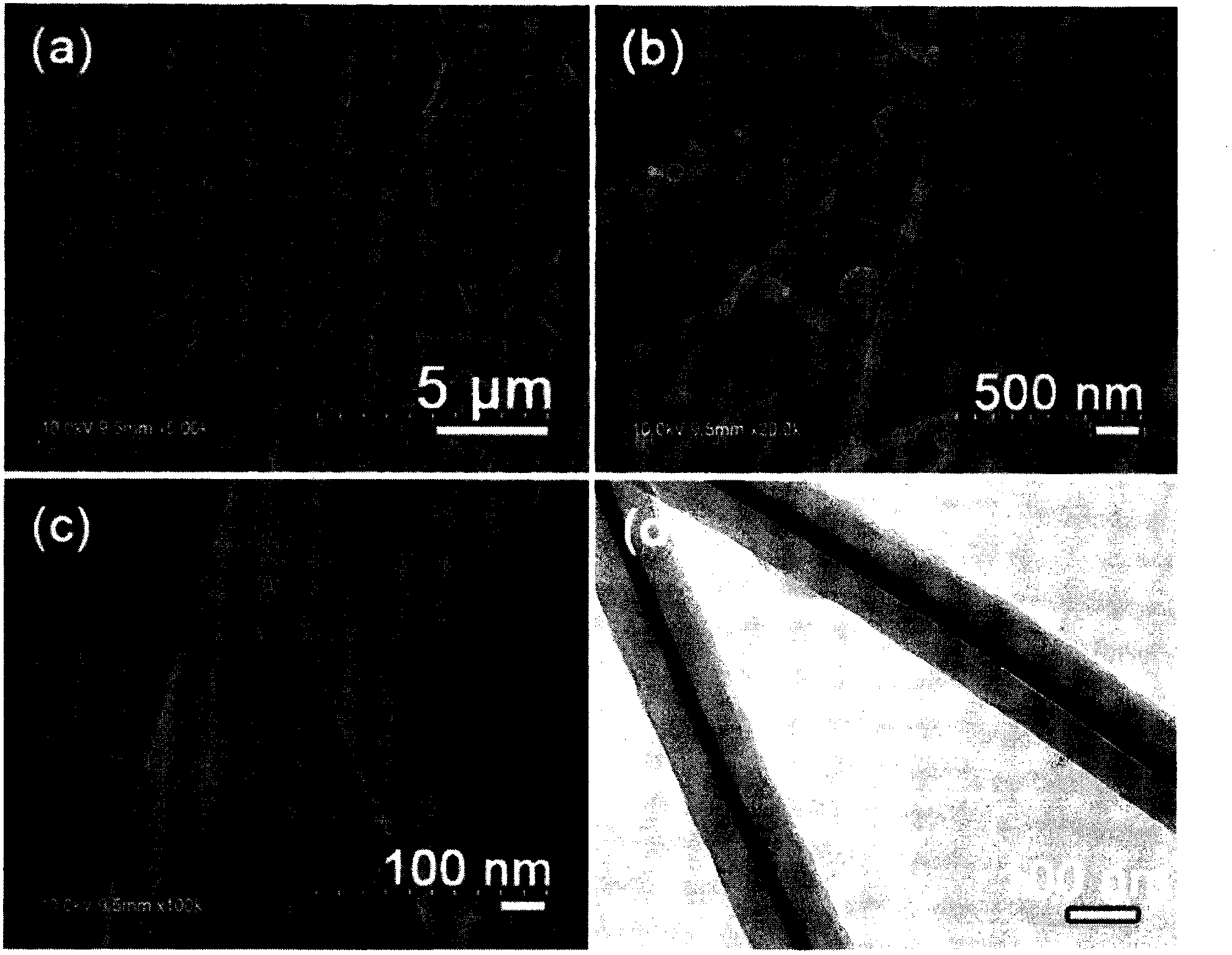

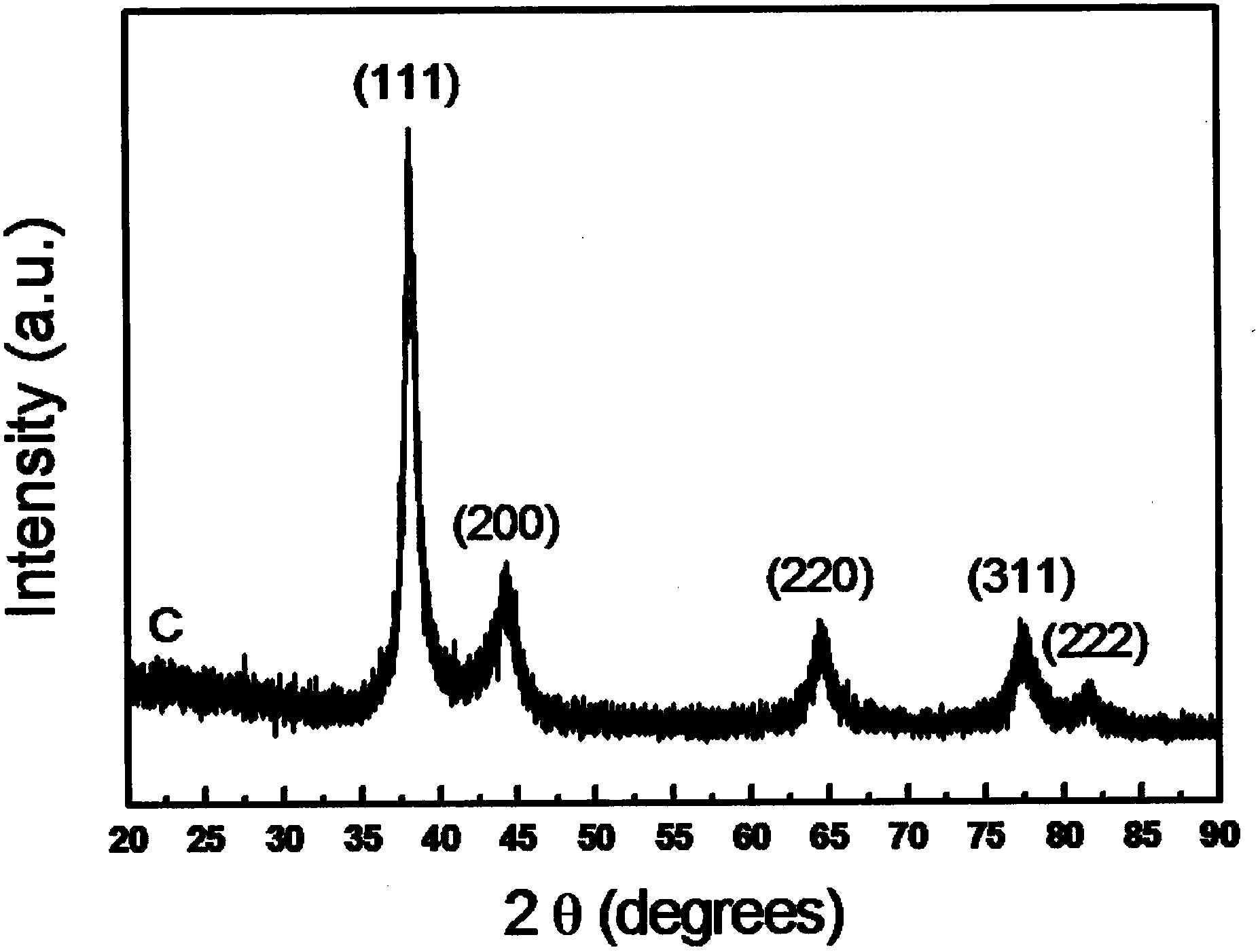

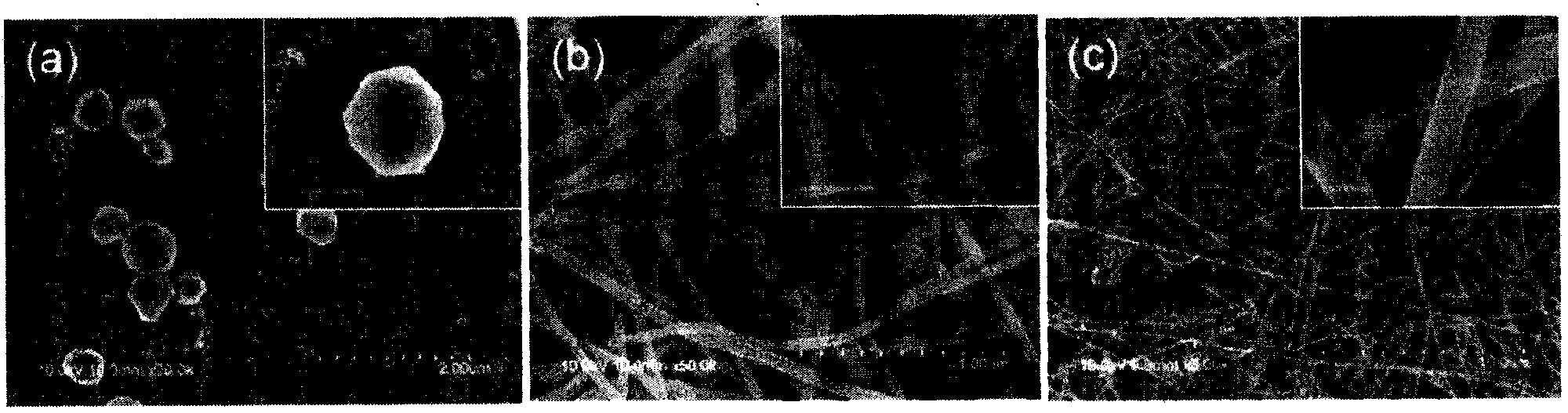

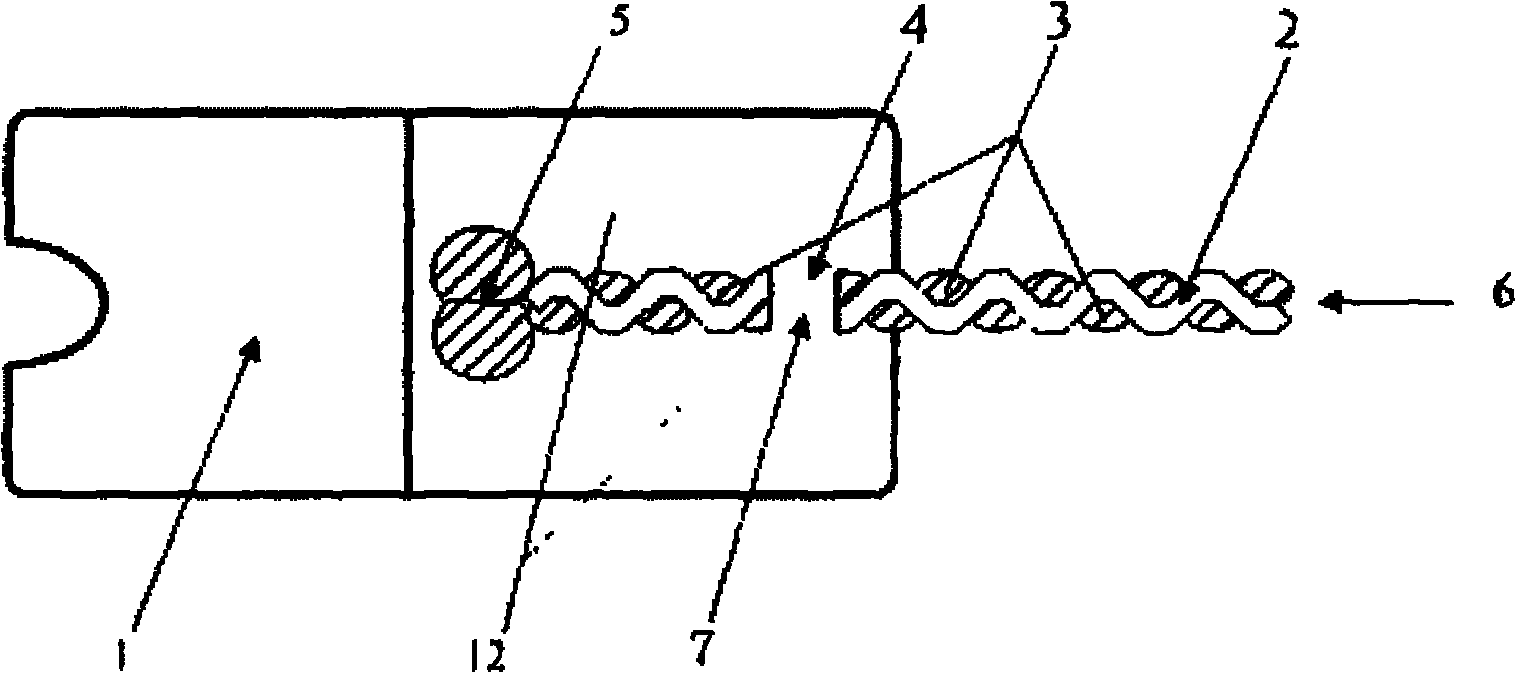

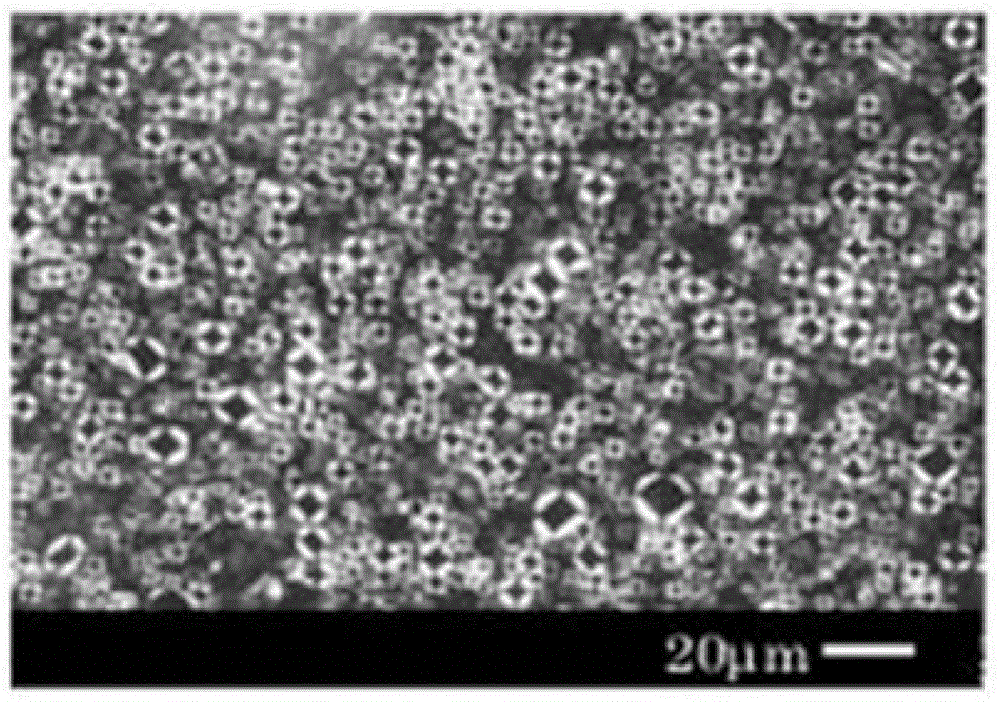

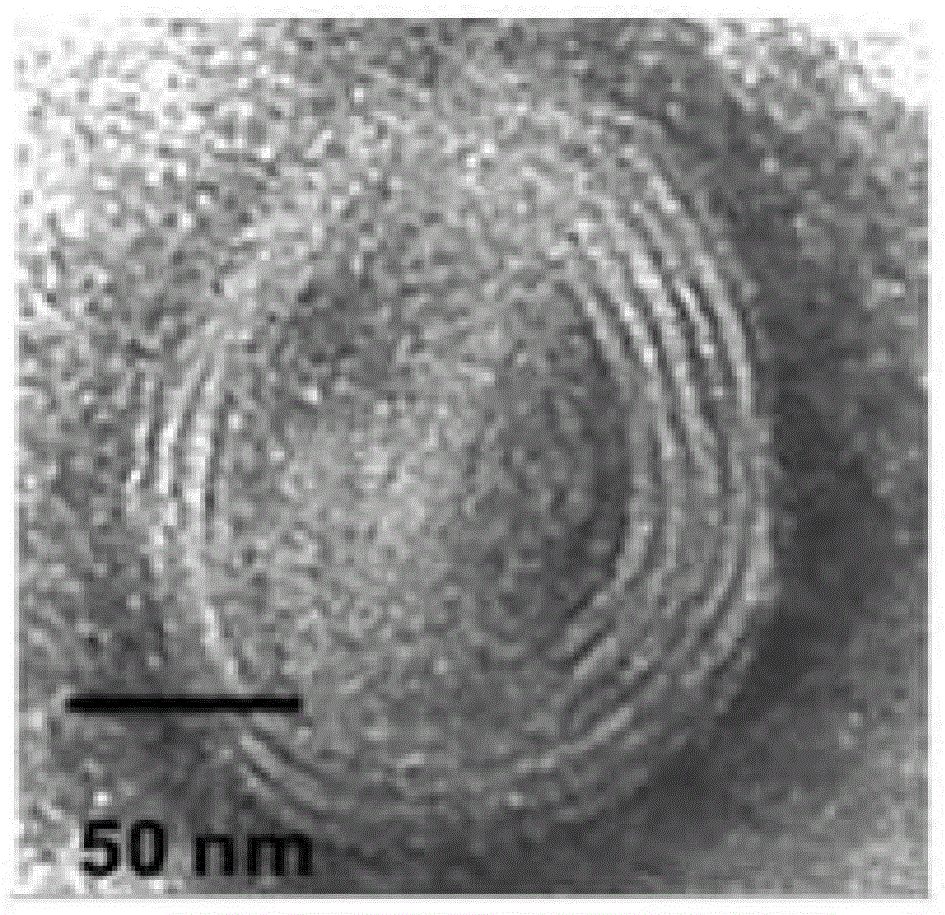

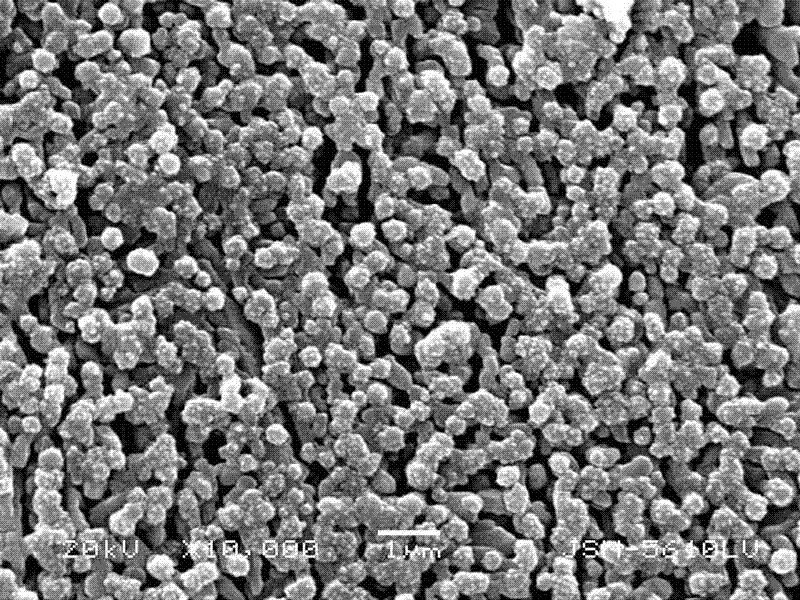

Method for manufacturing Ag/C nano interconnecting wire in coaxial-cable structure

InactiveCN103447546AUniform size distributionControllable section shapePolycrystalline material growthFrom normal temperature solutionsCarbon coatingChemical reaction

The invention discloses a Ag / C nano interconnecting wire in a coaxial-cable structure and a method for manufacturing the Ag / C nano interconnecting wire in the coaxial-cable structure. The method is based on the one-step hydrothermal reaction, glucose serves as a reducing agent and a carbon source, cetyltrimethyl ammonium bromide (CTAB) serves as a morphological control agent for metallic silver growth, and the best reaction time is in the range of 4-8h. A product is composed of Ag nano wires (cores) with diameters of 30+ / -5nm and surface nano carbon layers (shells), and the length can reach hundreds of micrometers; cross section appearances, dimensions and thicknesses (10-120nm) of carbon coating layers of the core Ag wires are controllable. Prevention of oxidization and corrosion of the nano silver cores is facilitated by carbon coating, so that the chemical reactivity and the heat stability of the nano silver cores are improved. According to the manufacturing method, no template is required, large-scale manufacturing of the interconnecting wires is achieved in one step, and the defects that other template methods (such as electrochemical deposition and chemical vapor deposition) are complicated in step and expensive in price are overcome. Besides, according to the method, devices are simple, the controllability is good, large-scale production can be achieved easily, and the method can be popularized to controllable manufacturing of other metal / carbon nano functional materials in the coaxial-cable structures.

Owner:NANJING UNIV

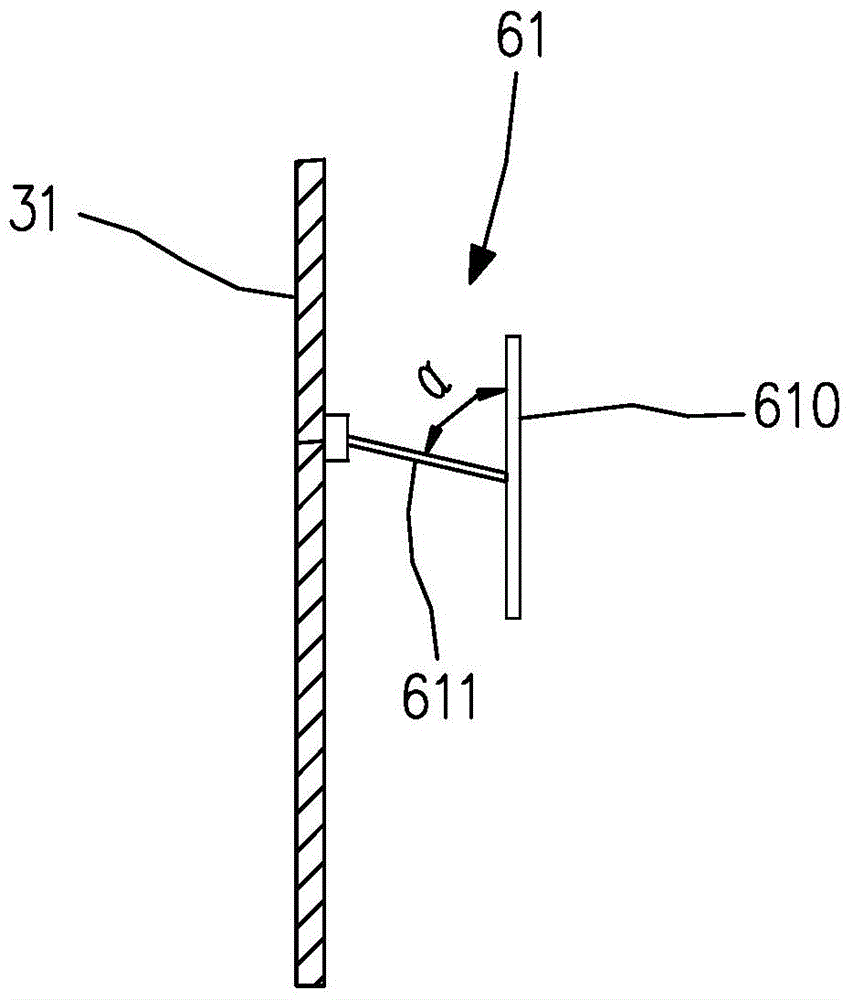

Production method for seamless nickel sheet with microprism array

InactiveCN103009016AAvoid pollutionImprove stitching accuracyElectroforming processesElectroformingNickel plate

The invention relates to a production method for a seamless nickel sheet with a microprism array. The production method includes the steps of manufacturing unit nickel sheets of required amount; performing finish machining to and removing burrs of the unit nickel sheets, and cutting two sides of a front surface of each unit nickel sheets to form a cut surface with certain angle; arranging the machined nickel plates as required, and welding the unit sheets from reverse surfaces to be sequentially connected to form a required large nickel sheet matrix; bending the welded large nickel sheet matrix, selecting a plastic cylinder with smooth inner wall, and fixing the bent large nickel sheet matrix on the smooth inner wall of the plastic cylinder; and placing the plastic cylinder with the large nickel sheet matrix adhered into an electroforming groove for electroforming, and forming the required seamless nickel sheet on the front surface of the large nickel sheet matrix. Cutting precision and splicing precision of the unit nickel sheets are controlled strictly, the surface of a die for producing the large nickel sheet matrix of the nickel sheet is seamless by the aid of the cylinder, and accordingly production of the seamless nickel sheet is truly achieved.

Owner:CHANGZHOU HUA R SHENG REFLECTIVE MATERIAL

Matt release film

ActiveCN105348946ASolve technical problems caused by residuesHigh residual adhesionCoatingsPolymer scienceAcrylic resin

The invention relates to a matt release film. The matt release film comprises a base film and a matt release coating layer arranged at one side of the base film; and the matt release coating layer is formed by coating a fluorine-containing thermosetting coating, and the coating comprises fluorine series resin, acrylic resin, aldehyde ketone resin, a curing agent system, an assistant, a delustering agent and a mixed solvent. The matt release film has the advantages of low surface tension, good adhesiveness and overcoatability, excellent heat and solvent resistance, and high residual adhesion rate and excellent matt effect after peeling when the matt release film is used in the field of electron manufacturing.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

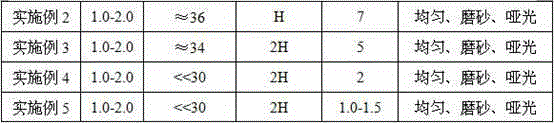

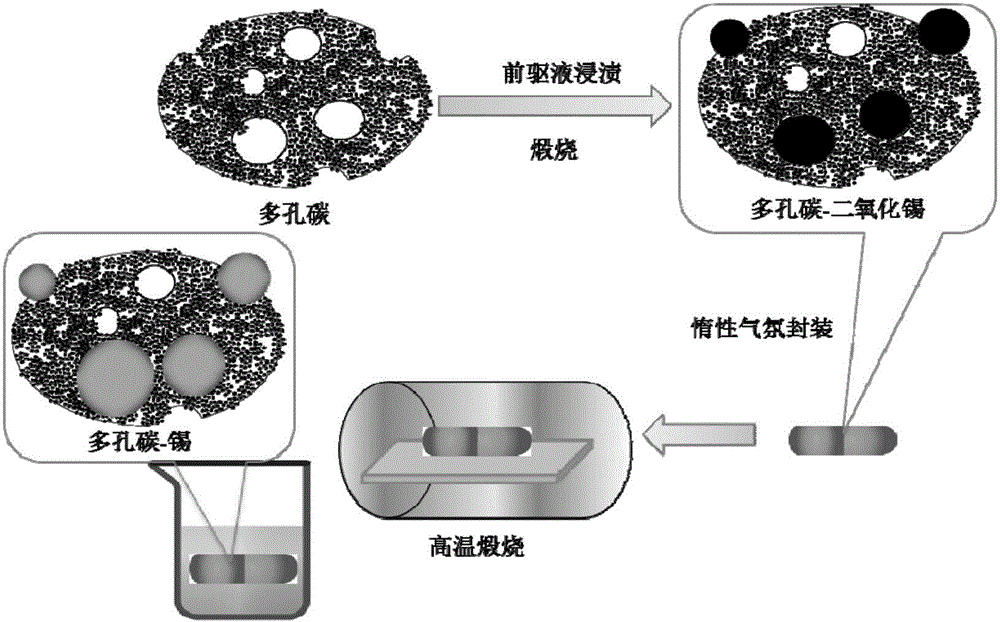

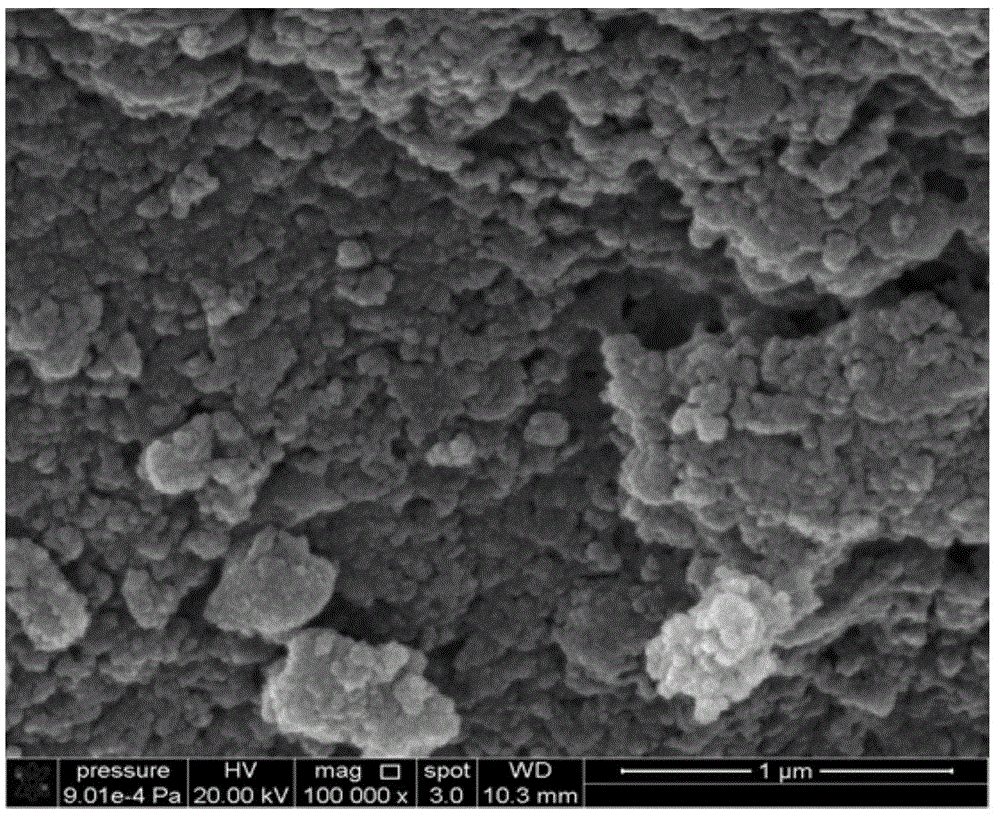

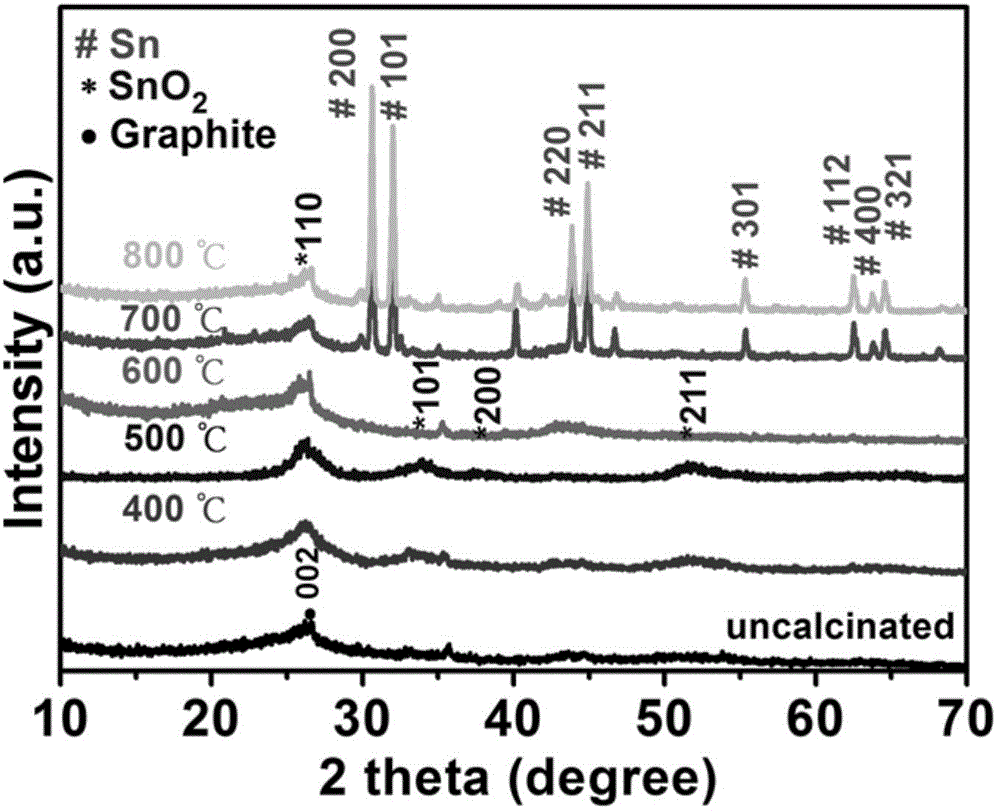

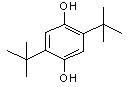

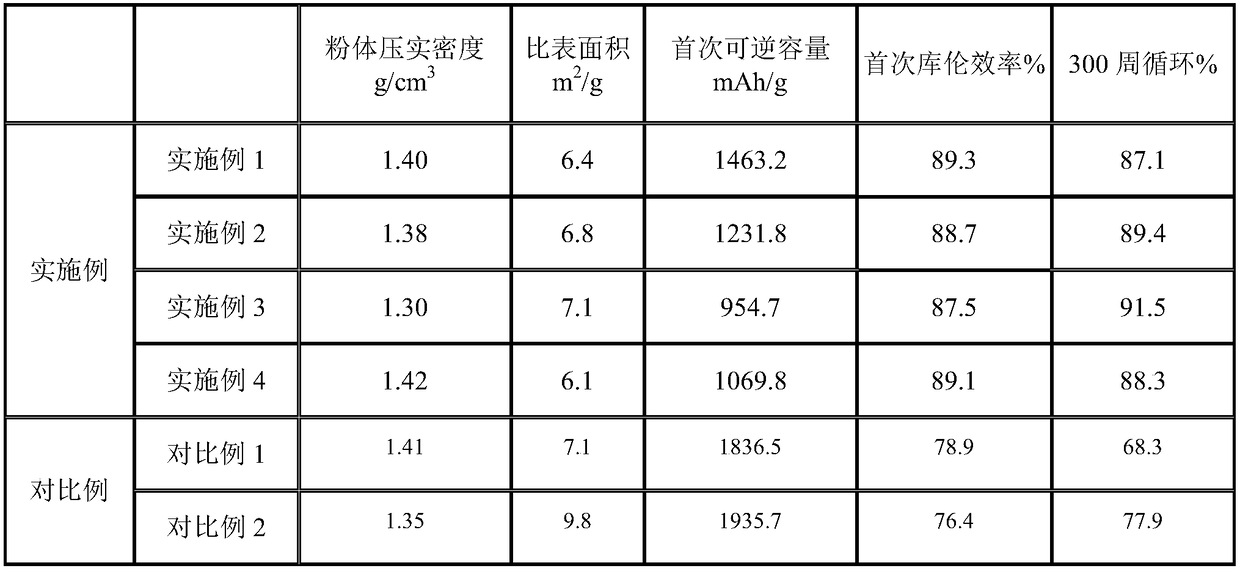

Preparation method of porous carbon-tin nanocomposite material for lithium battery cathode

ActiveCN104157876AShort preparation timeGuaranteed normal formationCell electrodesSecondary cellsPorous carbonLithium electrode

The invention relates to a preparation method of a porous carbon-tin nanocomposite material for lithium battery cathode, and belongs to the technical field of inorganic nano materials. A matrix of porous carbon is immersed in a tin precursor solution, and then the matrix is calcined twice and subjected to in situ reduction to prepare the porous carbon-tin nanocomposite material. Compared with the prior art, the nanocomposite material prepared by the invention can be used in the field of cathode material for lithium ion batteries, and can obtain high capacity and good cycle performance.

Owner:SHANGHAI JIAO TONG UNIV

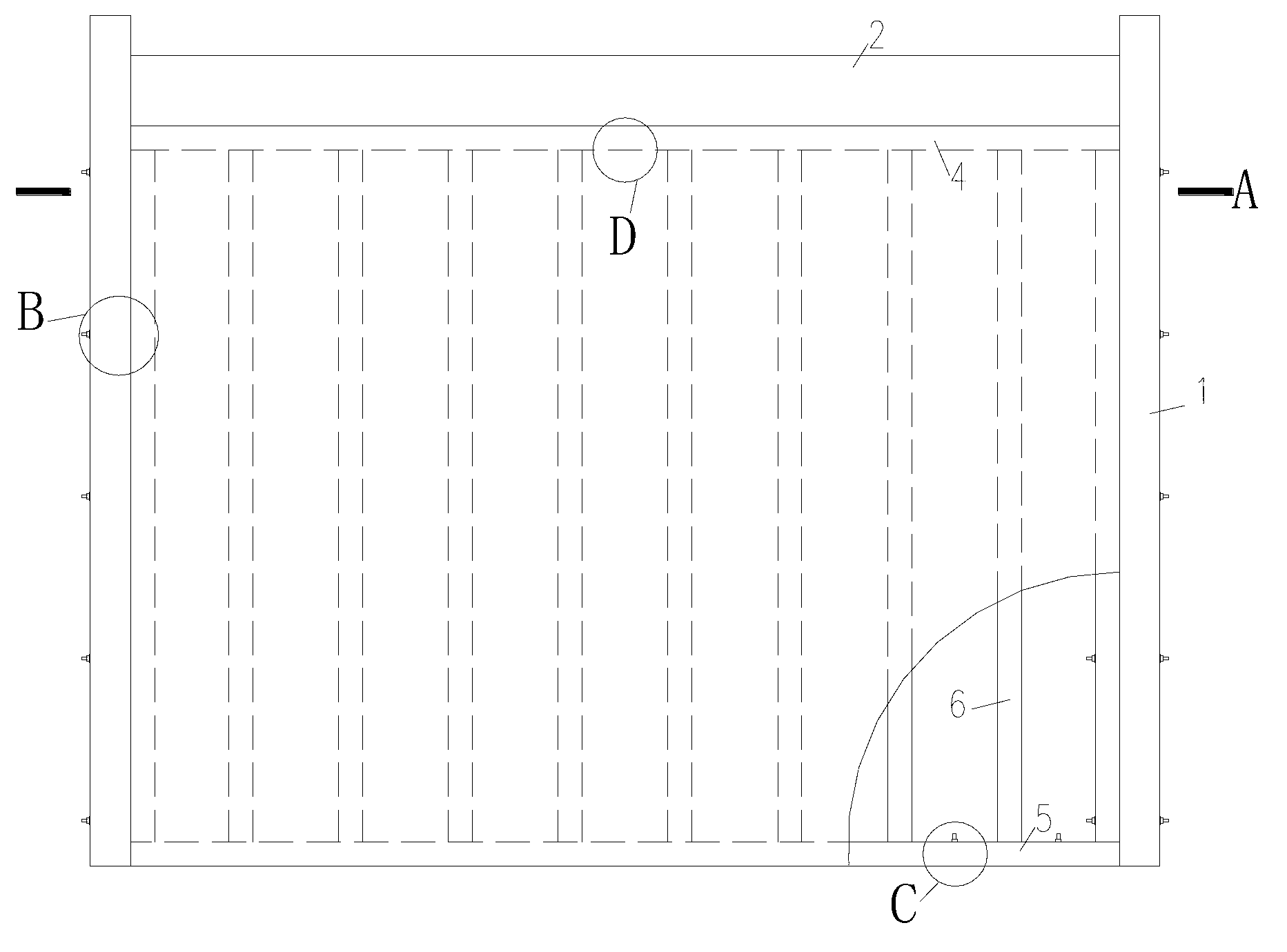

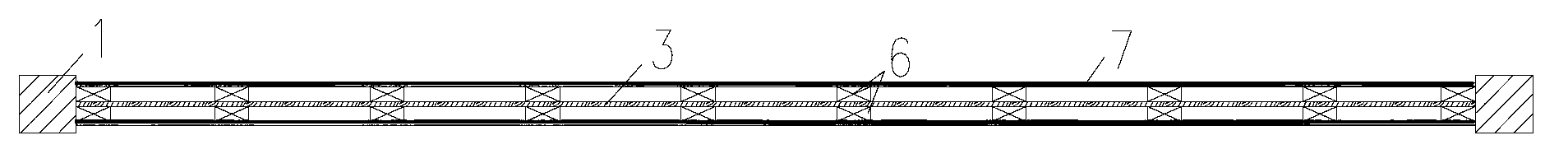

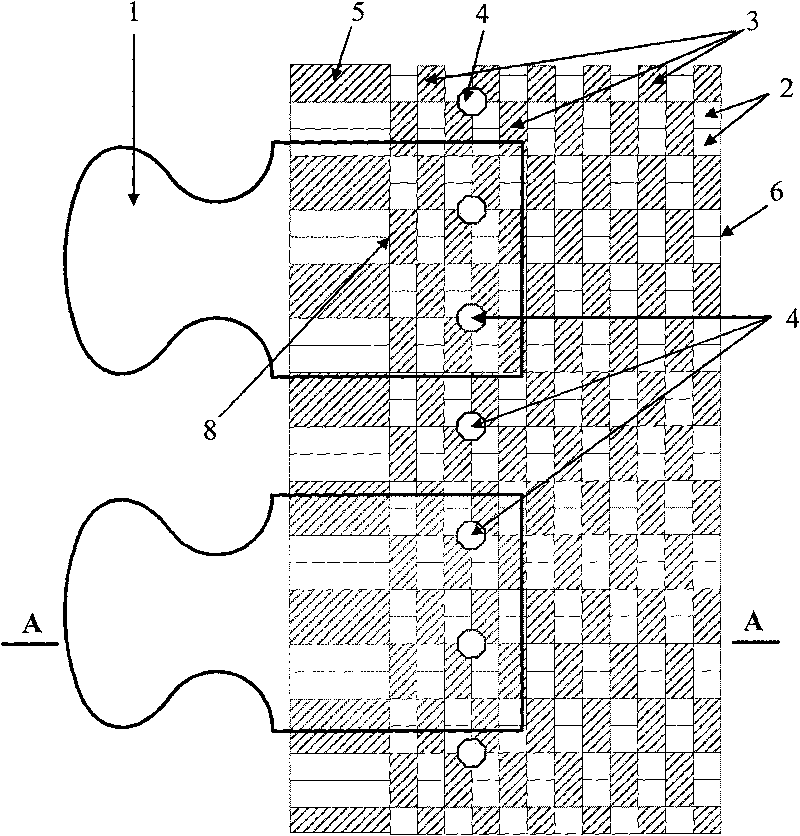

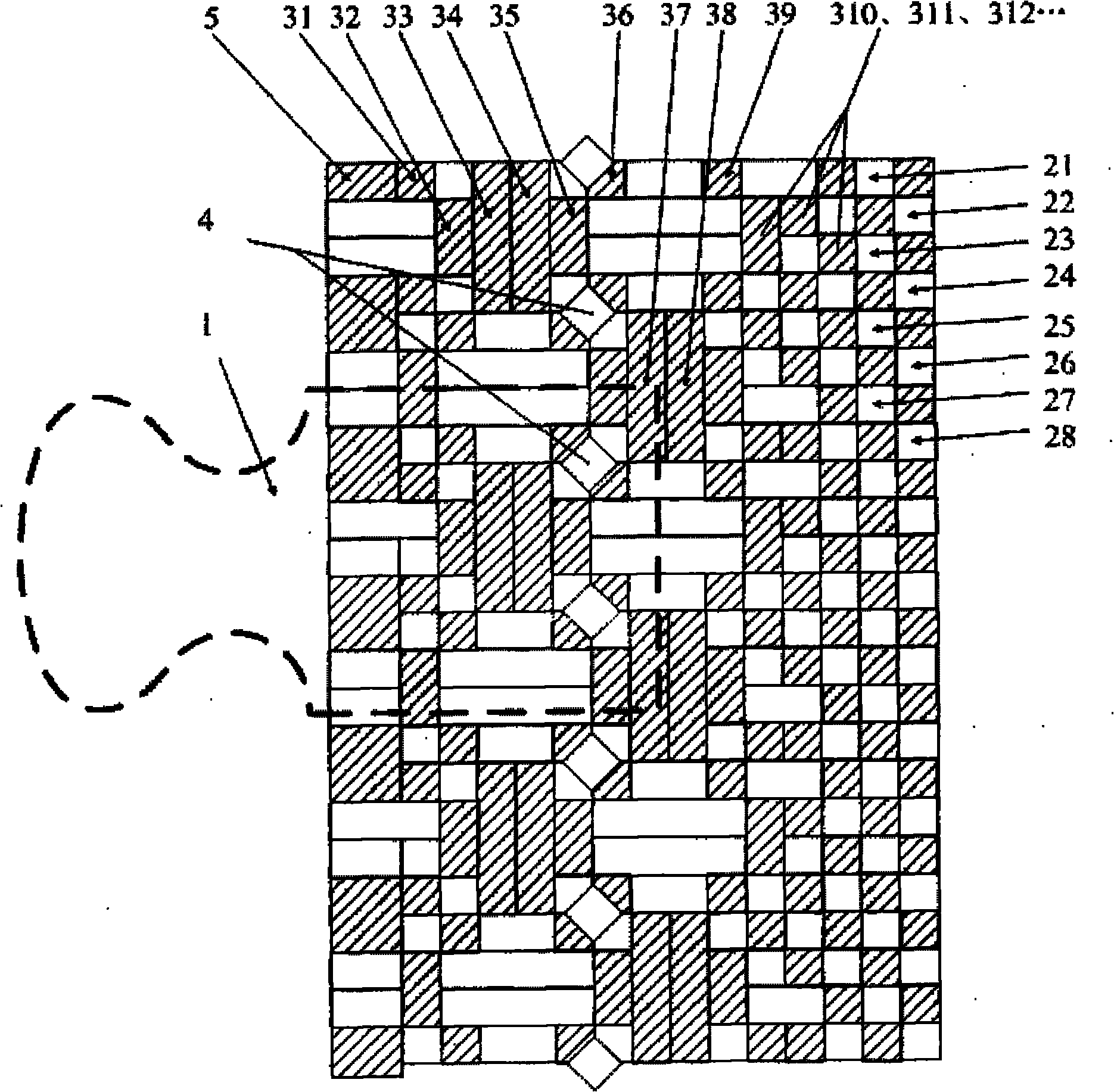

Wood frame shear wall

The invention discloses a wood frame shear wall which comprises a wood frame column, a wood frame beam, a wood-base structural slab, a top beam plate, a bottom beam plate, studs and a gypsum board, wherein the wood-base structural slab is arranged in the middle of the wall; the plurality of studs are respectively arranged between the top beam plate and the bottom beam plate, thus forming stud frames; the stud frames are symmetrically arranged at the two sides of the wood-base structural slab; the peripheries of the stud frames are connected with the wood frame beam and the wood frame column through bolts; and the gypsum board is arranged at the outer sides of the stud frames, and the edge of the gypsum board is parallel and level to the outer sides of the stud frames. According to the wood frame shear wall, a shingle and the studs are integrated into a whole. The wood frame shear wall is large in lateral rigidity resistance and good in ductility, has high lateral resistance and energy-dissipating capacity, can favorably make breakthrough in height and span of a timber architecture. The wood frame shear wall is wide in application prospect, can be applied to multi-floor and medium and high-rise wood frame structure buildings, and remarkably improves the lateral resistance of the whole structure.

Owner:南京工业大学建筑设计研究院有限公司

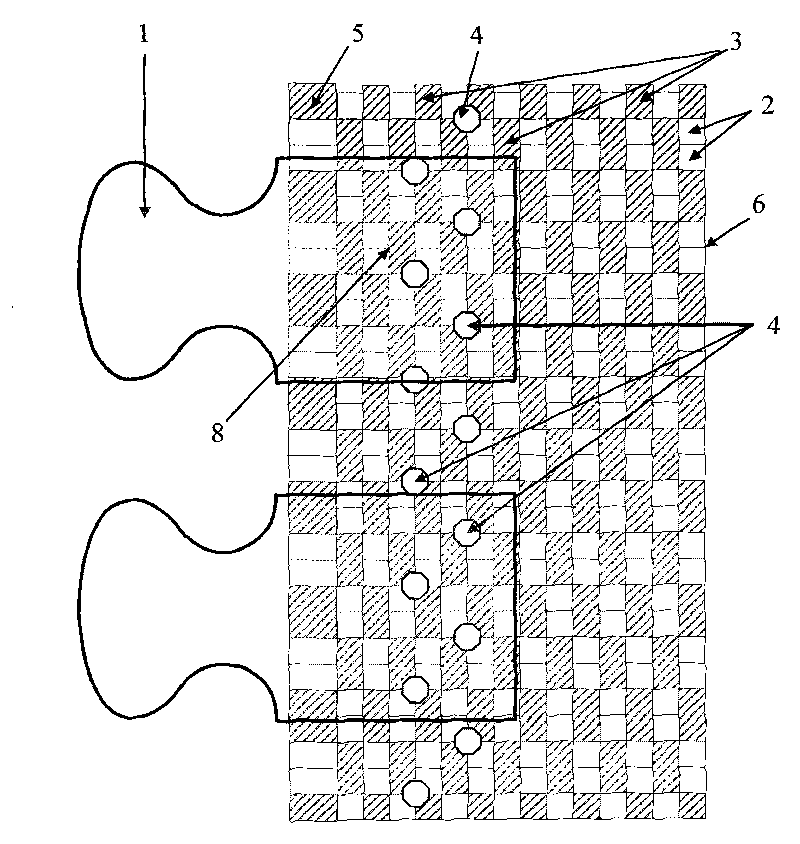

Injection molding zipper

InactiveCN101721019ALarge double-teaming forceImprove bindingSlide fastenersEngineeringInjection moulding

The invention aims to overcome the defect of insufficient binding force between the zipper teeth and the strap of the injection molding zipper in the prior art, and provides an injection molding zipper in a novel structure. In the injection molding zipper of the invention, the strap in the binding face region between the zipper teeth and the strap is provided with a small hole, at least one small hole or more than more small holes is / are arranged in the binding face region between the strap and each single zipper tooth, and the small holes are uniformly distributed in the arrangement direction of the zipper teeth. The small holes can ensure the injection molding material liquid, which is melted by the injection molding machine, to pass through in the production process of the injection molding zipper, so that the injection molding material liquid forms molding upright posts in the small holes after being cooled, and the molding upright posts and the zipper teeth can form an integral body. The injection molding zipper of the invention fundamentally changes the binding mode between the zipper teeth and the zipper strap of the injection molding zipper, which means to change the mode of the injection molding material wrapping the central line in the binding face region of the zipper strap, thereby obviously enhancing the binding force between the zipper teeth and the zipper strap of the injection molding zipper.

Owner:崔逸泉

High temperature self compensatiojn lubrication wear resistance material and its preparing method

InactiveCN1586770ARealize high temperature self-compensating lubrication functionOvercome the defects of matrix performance damageCeramicwareEngine lubricationLubricationWear resistant

The high temperature self-compensating lubricating wear resistant material includes substrate and solid lubricating particle compounded to the substrate. The substrate is mixed alloy, ceramic and RE element sintered body with sweat gland type structural micropores. The sweat gland type structural micropore has diameter of 0.05-8 micron and consists of internal micropore and penetrating micropore to the surface of the substrate, and the solid lubricating particle is compounded into the sweat gland type structural micropore. The present invention ensures the formation of wear resistant hard phase in the substrate material, and the composite material has its lubricant inside the substrate driven by the friction heat to diffuse toward the friction surface via the sweat gland micropores to realize the self compensating lubrication of the wear resistant material at high temperature.

Owner:WUHAN UNIV OF TECH

Rolling method of pipeline steel and stainless steel composite plate

InactiveCN104550234AGuaranteed normal formationGuaranteed mechanical performance indexTemperature control deviceMetal rolling arrangementsComposite plateHigh pressure

The invention discloses a rolling method of pipeline steel and a stainless steel composite plate. The rolling method comprises the step of a heating step, a rolling step, a cold control step, a straightening step and a stack cooling step. According to the rolling method, the rolling process is adjusted and researched, the low-temperature long heat preservation and heating process is adopted, a high-temperature low-speed high-pressure pressing process is adopted at the roughing rolling stage, the uniformity of the tissue of the steel plate before the cold control is guaranteed by controlling the thickness of an intermediate blank and controlling the finish rolling starting temperature, final rolling temperature, the pressing rate in the step before the final rolling and the like at the finish rolling stage, the particle size is relatively small, and the formation of the final steel plate needle-shaped ferritic structure is guaranteed by adopting a given cooling speed and controlling the start cooling temperature and the return red temperature by virtue of the cooling control process, so that the indexes of mechanical properties of the steel plate can be guaranteed.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

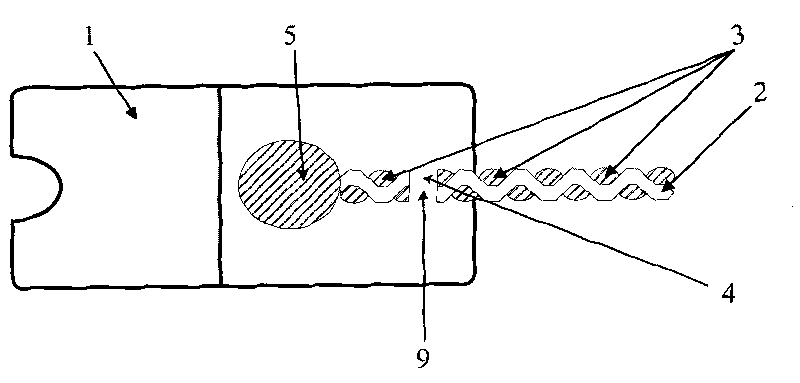

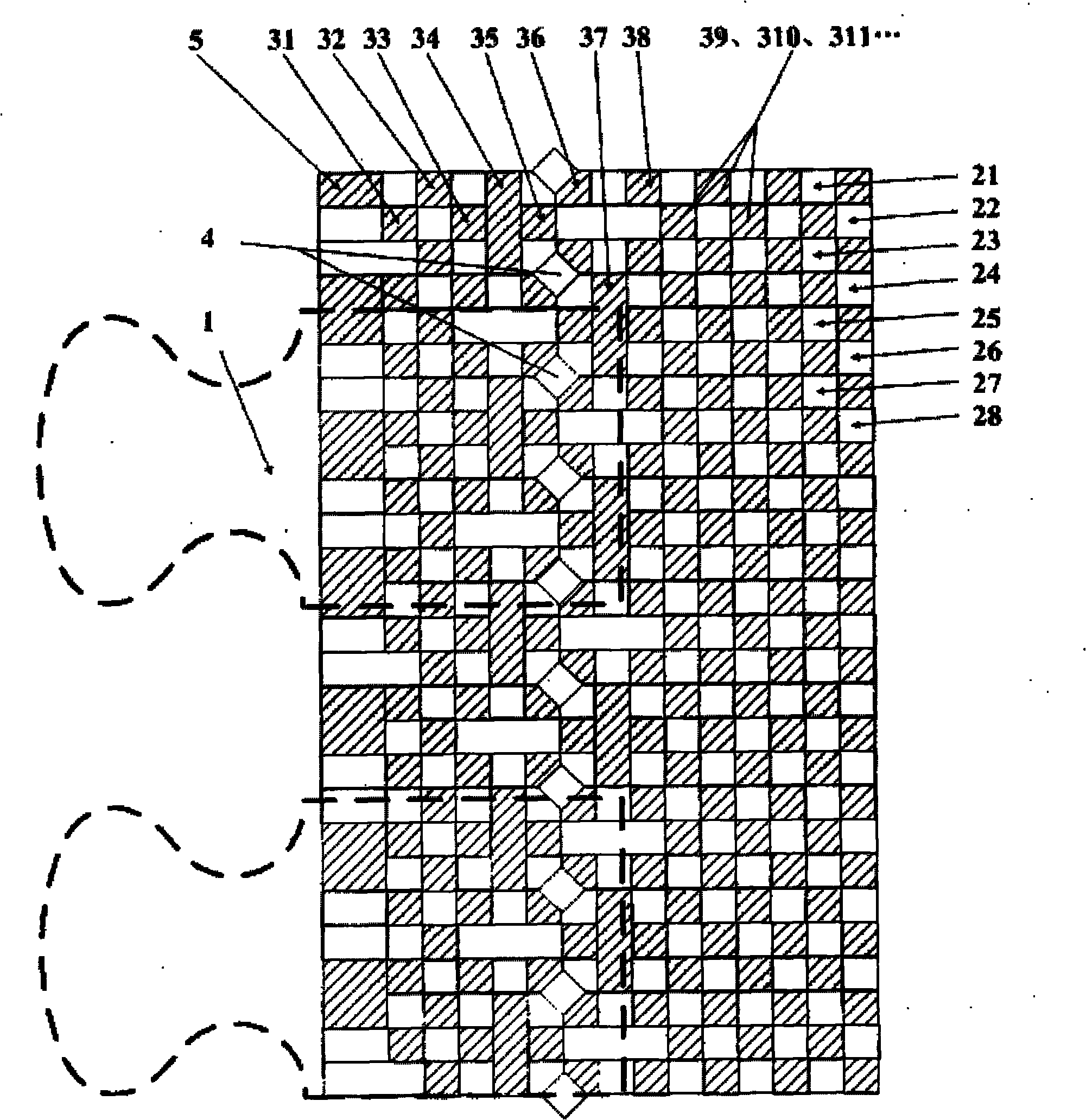

Cloth strap

InactiveCN101933692AImprove bindingPrecise positioningSlide fastenersWoven fabricsEngineeringUltimate tensile strength

The invention discloses a novel injection zipper cloth strap comprising a central line (5) at the edge of the cloth strap, a group of warp (3) and continuous wept (2). Continuous and alternately-arranged small holes (4) are arranged in a joint surface zone of the cloth strap and the injection zipper teeth and formed by setting the structural tissue of the warp of the cloth strap through the mutual influence of tension between the warp and the wept while braiding. The holes in the injection zipper cloth strap are formed without special tools, special procedures or special materials, and the warp and the wept of the cloth strap are kept to be integral with uninfluenced appearance and strength. The invention has the advantages of convenient and simple production and can enhance the binding force between the zipper cloth strap and the zipper teeth, and the like.

Owner:SHANGHAI ZEPU ZIPPER TECH SERVICES

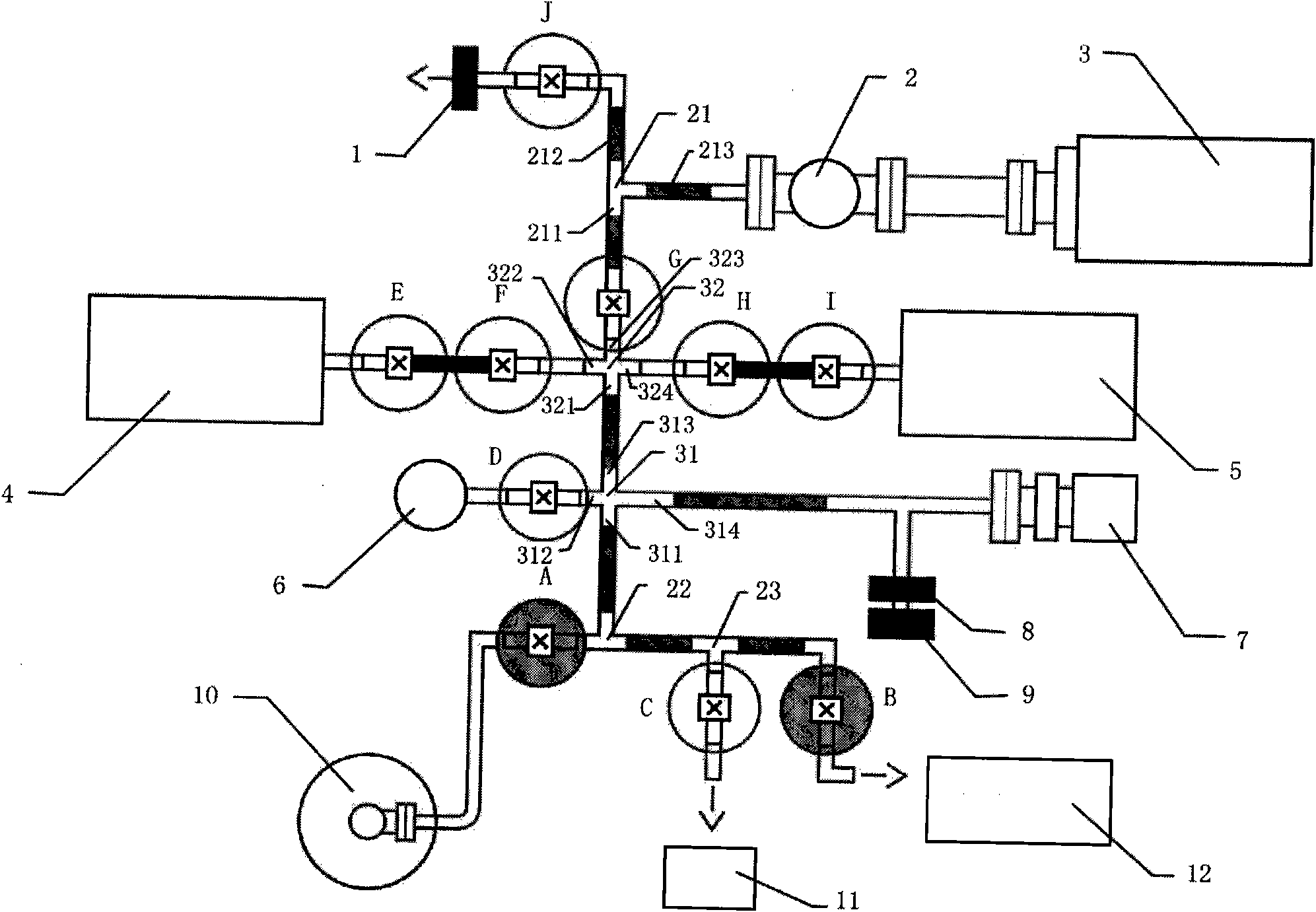

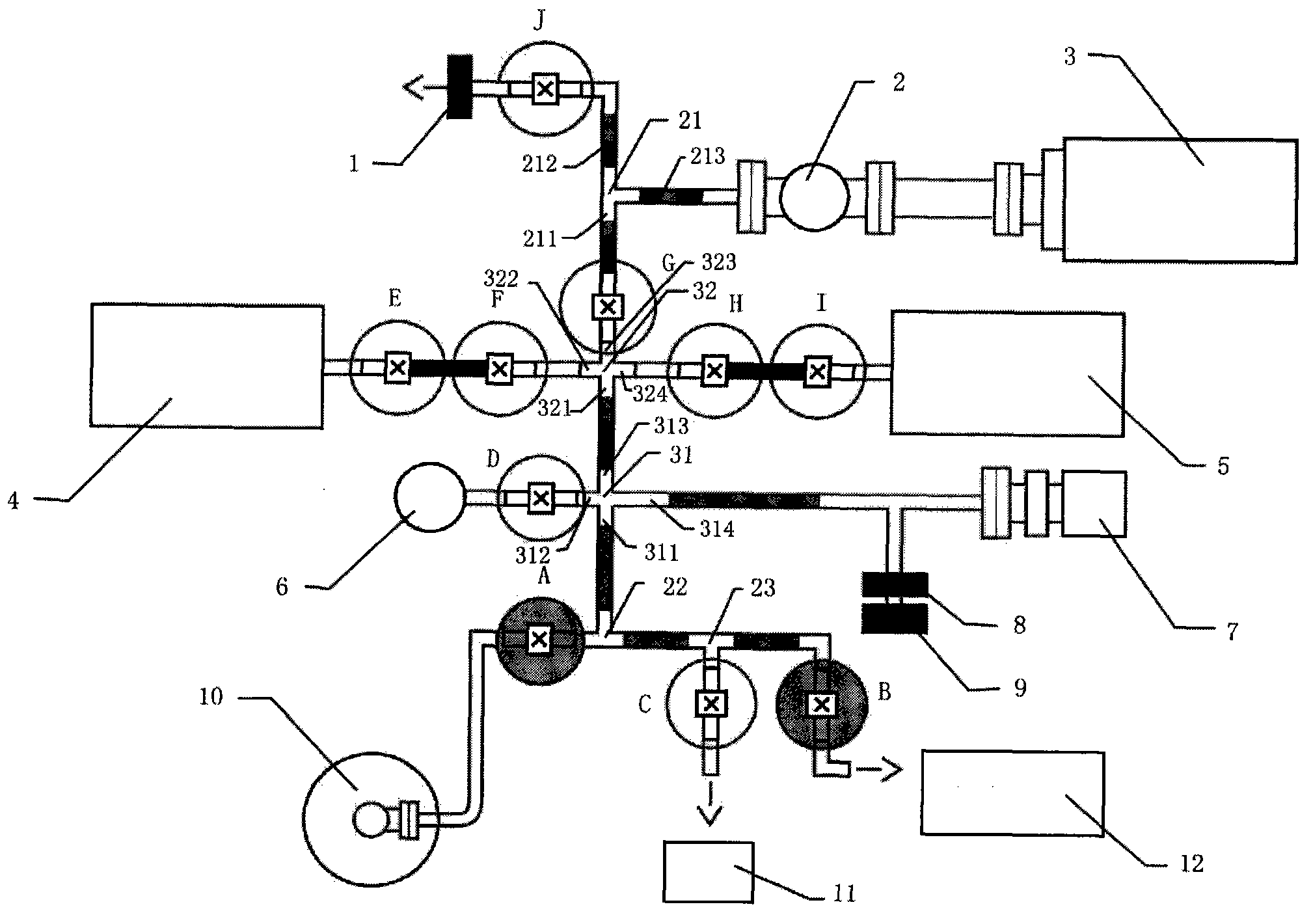

Rare gas determination system based on quadrupole mass spectrometer

InactiveCN101963596ASimple structureLow costMaterial analysis by electric/magnetic meansNoble gasEngineering

The invention discloses a rare gas determination system based on a quadrupole mass spectrometer. A laser sample room of the system is connected with a first port of a first four-way pipe through a valve B, a second port of the first four-way pipe is connected with a first impurity absorber through a valve D, a third port is connected with a first port of a first three-way pipe through a valve G, and a fourth port is connected with a molecular vacuum pump and a mechanical pump in sequence; a vacuum gage is installed between the molecular vacuum pump and the fourth port of the first four-way pipe, and a rare gas standard tank is connected between the valve G and the third port of the first four-way pipe; a second port of the first three-way pipe is connected with an ion pump through a valve J, and a third port is connected with a second impurity absorber and the quadrupole mass spectrometer in sequence. The components and the connecting pipes are connected by metal interfaces, and electric heater bands are installed on the outer surfaces of the connecting pipes of the components. The system can realize rare gas mass spectrometry under the premise of ensuring identical precision and accuracy, and has the advantages of low cost and high cost performance.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

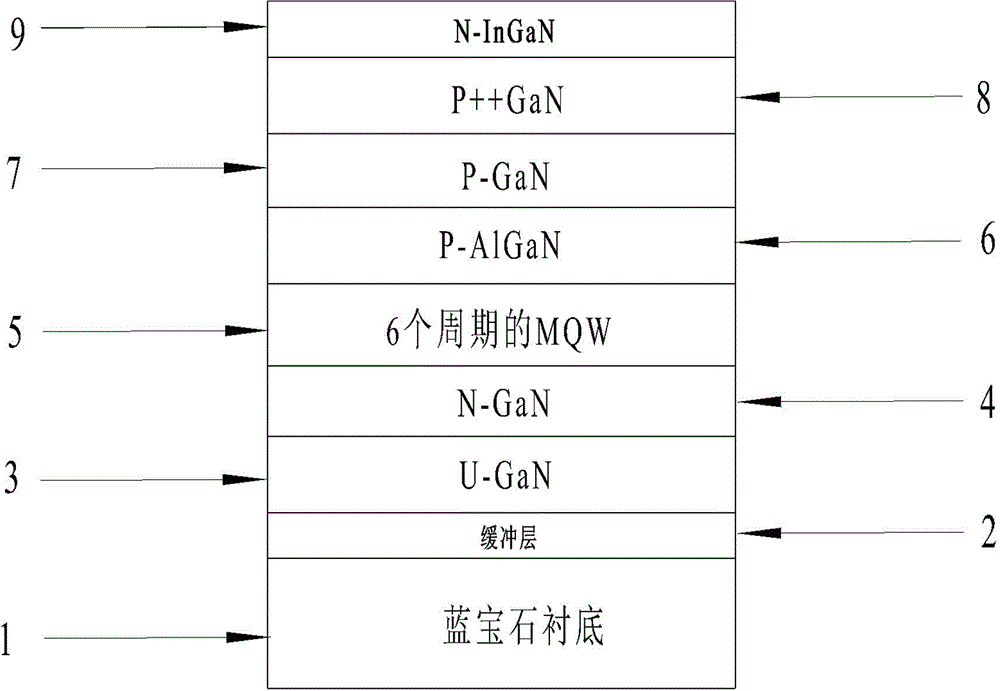

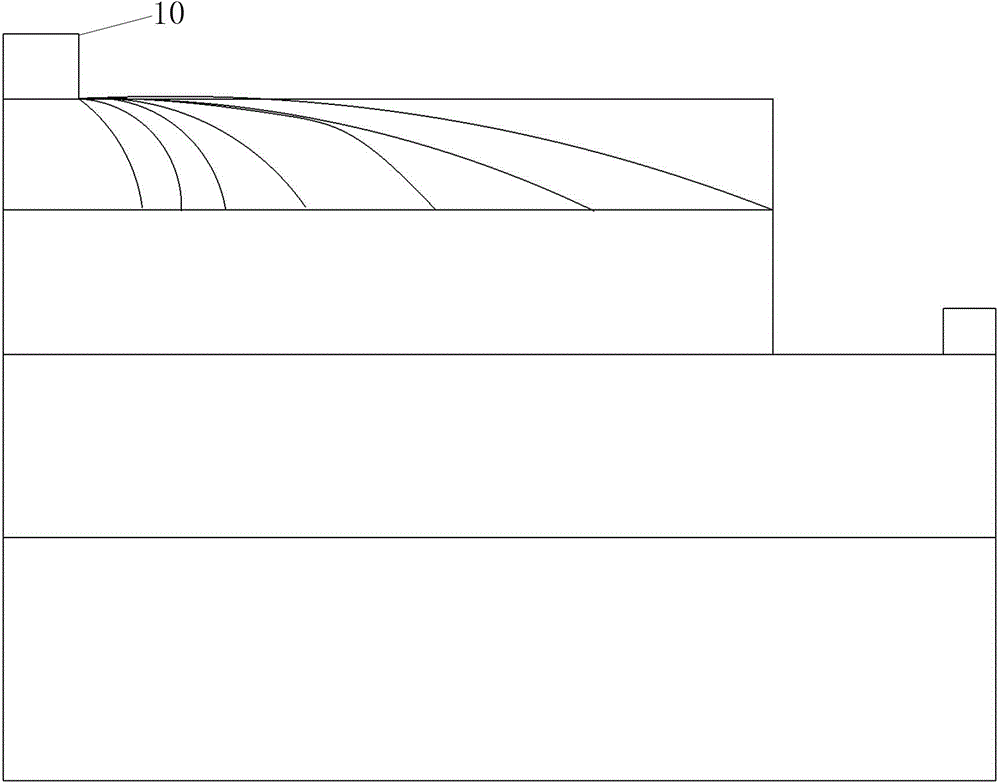

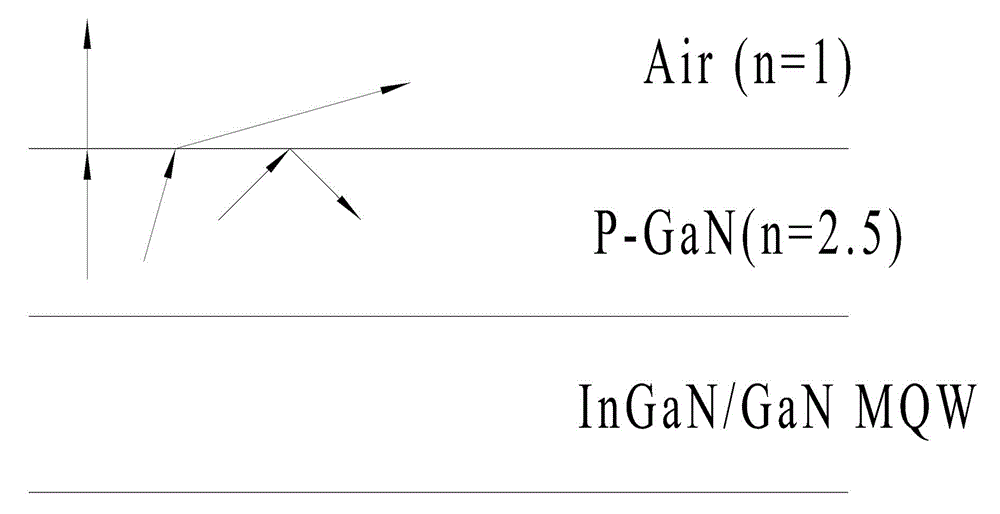

GaN-based light-emitting diode structure improving light extraction rate and preparation method

ActiveCN104157761AIncrease the carrier concentrationImprove acceleration performanceSemiconductor devicesNon dopedLead structure

The invention belongs to the field of photoelectric devices, and particularly relates to a GaN-based light-emitting diode structure improving the light extraction rate and a preparation method. The GaN-based light-emitting diode structure improving the light extraction rate and the preparation method solve the technical problems that the carrier concentration of a P-type area of an existing LED structure is not high, currents are distributed unevenly, and the light emitting efficiency is low. The GaN-based light-emitting diode structure improving the light extraction rate comprises a substrate, a GaN buffer layer growing on the substrate, a non-doped GaN layer growing on the GaN buffer layer, a Si-doped GaN layer growing on the non-doped GaN layer, multiple-quantum well structures, growing on the Si-doped GaN layer, of six periods, a p-AlGaN electronic blocking layer growing on the multiple-quantum well structures, a Mg-doped p-type GaN layer growing on the p-AlGaN electronic blocking layer, a heavily-doped p-type GaN layer growing on the Mg-doped p-type GaN layer, and an n-type InGaN layer growing on the heavily-doped p-type GaN layer. According to the GaN-based light-emitting diode structure improving the light extraction rate and the preparation method, the currents are distributed evenly, the light emitting efficiency is high, and the preparation process is simple.

Owner:太原理工大学建筑设计研究院有限公司

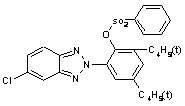

Anti-ultraviolet transparent hard coating film for in-mold decoration (IMD)

ActiveCN101955699AGuaranteed normal formationMeet the molding tensile performance requirementsSynthetic resin layered productsCoatingsPolyesterUltraviolet

The invention relates to an anti-ultraviolet transparent hard coating film for in-mold decoration (IMD), which is formed by coating a transparent hard coating on a transparent substrate. The transparent hard coating comprises the following components in part by weight: 20 to 40 parts of polyester acrylate oligomer, 10 to 30 parts of organic-inorganic hybrid oligomer, 0.5 to 5 parts of ultraviolet absorption precursor, 1.0 to 10 parts of hydrogen proton donor, 0.5 to 7 parts of photoinitiator, 0.5 to 7 parts of active amine, 0.05 to 2 parts of leveling agent and 30 to 70 parts of solvent, wherein the thickness of the hard coating is 2 to 6mu m. The anti-ultraviolet transparent hard coating film solves the problems of ageing, yellowing, embrittlement and the like of a product irradiated by ultraviolet rays, solves the problems of oxygen inhibition and hydrogen proton consumption and ensures the formation of an ultraviolet absorbent; and the film meets the requirements of the IMD on forming and stretching by combining raw materials and controlling the thickness of the hard coating, and the stretching and forming height of the film can be 7 to 8mm at most but the film cannot be embrittled.

Owner:CHINA LUCKY FILM CORP

Green domestic porcelain

InactiveCN101555126AIncrease the amount addedGood light transmissionClaywaresLithiumSodium Bentonite

The invention provides green domestic porcelain, a porcelain body of which comprises the following components in terms of weight percentage: 18-22% of Hunan feldspar, 9-13% of riped quartz, 8-12% of Zijin silica, 3-5% of bentonite, 18-24% of kaolin braying and 33-37% of weathering potash feldspar; porcelain glaze thereof comprises the following components in terms of weight percentage: 21-23% of waste porcelain powder, 9-11% of Hunan feldspar, 4-6% of lithium porcelain stone powder, 24-26% of quartz, 9-11% of kaoline, 4-6% of zinc oxide, 10-12% of dolomite and 11-13% of calcite. The green domestic porcelain has subtle glaze, crystal and transparent texture and white and green color, and presents the impression of glass colors. The green domestic porcelain adds assortment of the domestic porcelains, solves the problem of dull coloring and conforms to the consumption concept of consumers.

Owner:CHAOZHOU XINYUE CERAMICS MFG

Hollow-structure carbon and silicon negative pole material used for lithium ion battery, and preparation method of hollow-structure carbon and silicon negative pole material

ActiveCN108258230AImprove volume expansionImprove performanceNegative electrodesSecondary cellsCarbon coatingTransmission channel

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a hollow-structure carbon and silicon negative pole material used for a lithium ion battery. The inner side of the negative pole material is of a hollow structure, and a wall layer of the negative pole material comprises an inner wall and an outer wall; the inner wall is subjected to homogeneous phase compounding by nanometer silicon and a low carbon residue carbon source; the outer wall is a carbon coating layer formed by an original pyrolysis carbon source; the particle size of the nanometer silicon is 5-300nm; the softening point of the low carbon residue carbon source is less than 200DEG C, and a carbon residue rate is less than 40%; the thickness of the outer wall is 0.1-10 microns; thethickness of the inner wall is 1-8 microns. The invention designs the large hollow-structure carbon and silicon negative pole material used for the lithium ion battery, a large hollow part is reservedfor the volume expansion of silicon, the volume expansion problem of a silicon negative pole can be obviously solved, the formation of the large hollow structure is guaranteed by the low carbon residue carbon source, meanwhile, the nanometer silicon is subjected to homogeneous phase dispersion, a transmission channel and rate of electrons and lithium ions can be guaranteed, and the carbon coatinglayer coats the outmost layer so as to form a protection shell for isolating electrolyte.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD

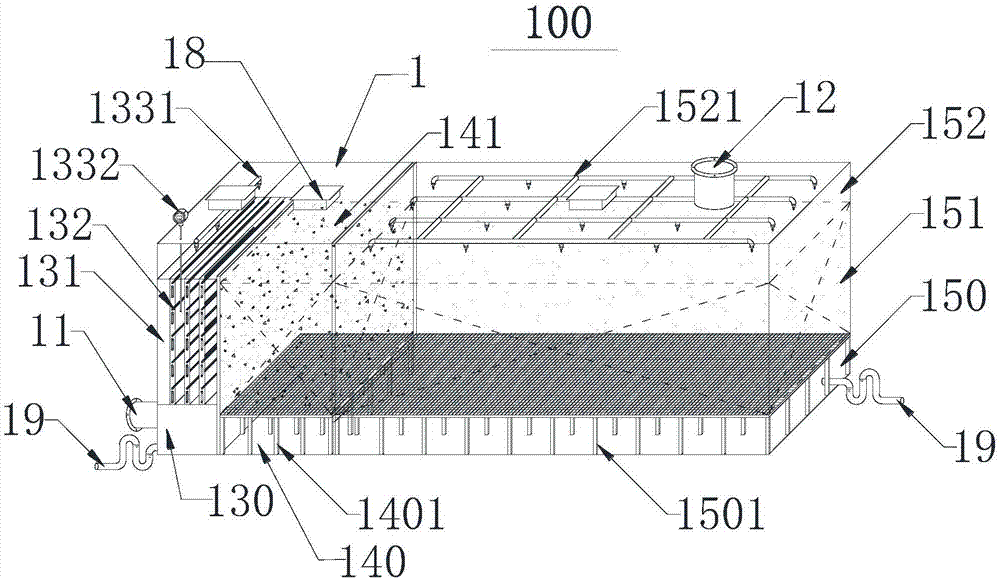

Organic waste gas treatment device

PendingCN107349767AImprove processing efficiencyImprove the degree of purificationGas treatmentDispersed particle separationCatalytic oxidationOxidation zone

The invention provides an organic waste gas treatment device which comprises a reaction cavity, wherein the reaction cavity is provided with an air inlet and an exhaust port at two ends in the left-right direction respectively, and the reaction cavity is divided into three reaction zones including a photo-oxidation zone, an ozone catalytic oxidation zone and a bio-trickling zone communicated with each other in sequence from the air inlet to the exhaust port. The organic waste gas treatment device for treating organic waste gas by adopting a photo-oxidation and biodegradation coupling method improves the organic waste gas treatment efficiency, realizes deep treatment, avoids the problem that organic small molecular intermediate products with toxicity are produced due to low mineralization degree of organic pollutants when organic waste gas of volatile organic compounds (VOCs) is treated by a single technology, is suitable for treating the organic waste gas of most industrial VOCs, and is beneficial to solving the urgent problem of atmospheric pollution at present in China.

Owner:SHENZHEN POLYTECHNIC

Method for preparing high-purity aluminium oxide

The invention discloses a method for preparing high-purity aluminium oxide. The method comprises the following several steps of: (1) reacting butyl alcohol and metal aluminium; (2) carrying out reduced-pressure distillation; (3) hydrolyzing; (4) calcining for the first time; (5) ball milling; and (6) calcining for the second time. According to the method, the aluminium butoxide is prepared, and then the hydrolysis and the calcining are carried out, so that a few steps are needed; butanol can be recycled for multiple times, and the prepared aluminium oxide is high in purity and reaches 5N after being detected by adopting ICP-MS; the average particle diameter is small and 0.01-0.03 micrometers; the specific area is 3-6 m<2> / g. The method disclosed by the invention can enhance the purity of the aluminium butoxide through the reduced-pressure distillation, thereby enhancing the purity of aluminium oxide; the method disclosed by the invention ensures the formation of aluminium oxide crystal grains and enhances the purity of the aluminium oxide by adopting ion exchange resin for further removing impurities; and the preparation process is pollution-free, low in energy consumption, environmental-friendly and suitable for industrial production.

Owner:浙江格洋新材料股份有限公司

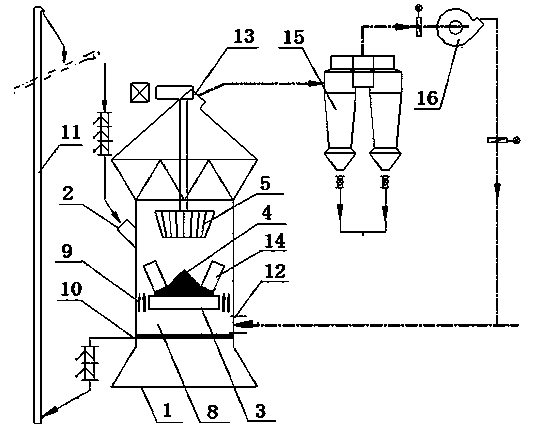

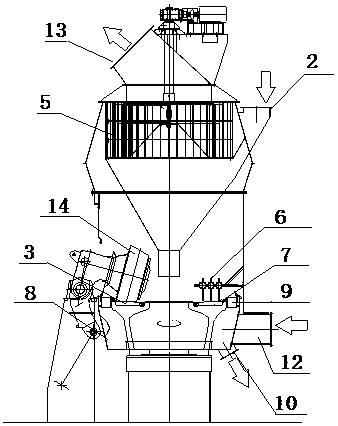

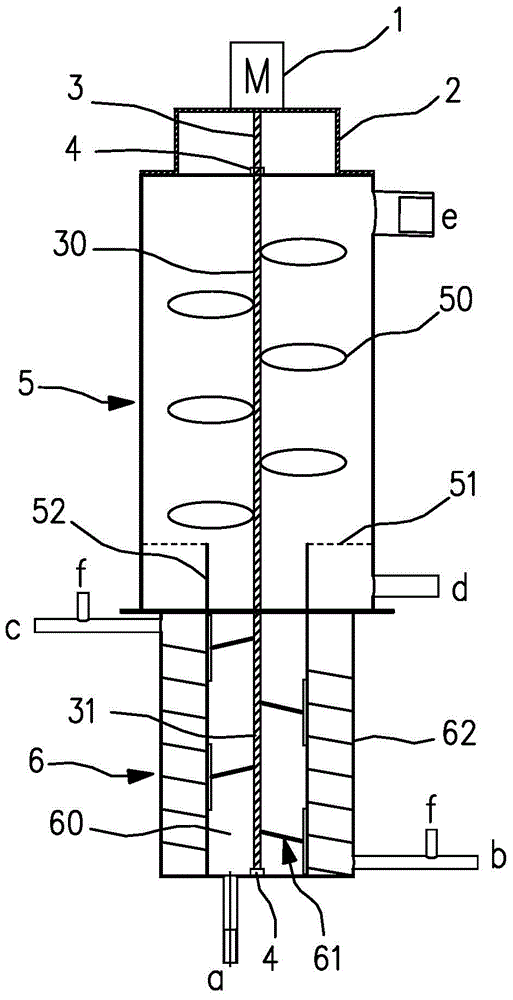

Technology and device for baking and grinding high-moisture chalk through vertical mill

The invention discloses a technology for baking and grinding high-moisture chalk through a vertical mill and belongs to the field of cement raw materials prepared by adopting high-moisture chalk raw materials. Clammy chalk with the moisture more than 25% is fed onto an inner refiner plate of the vertical mill from a feeding mouth of the vertical mill; hot wind passes through a wind chamber, a wind ring and a chamber above the refiner plate from a hot wind inlet and discharges out of the vertical mill from a hot wind outlet; zone control is performed on the moisture of materials inside the mill; the moisture of the materials is dried step by step; a powder selecting machine, the feeding mouth and the hot wind outlet are arranged at the upper part of the vertical mill; the refiner plate and mill grinding rollers are arranged inside the vertical mill; a cloth scraping plate is arranged above the refiner plate; a retaining ring is arranged at the edge of the refiner plate; the height of the retaining ring exceeds 150 mm; the wind chamber is arranged below the refiner plate; the wind chamber is communicated with the chamber above the refiner plate through the wind ring; the hot wind inlet of the mill, a material scraping device and a feeding back port are arranged in the wind chamber, the feeding back port is connected with the feeding mouth through an outer circulating system of the mill. The invention provides a simpler and energy-saving preparation technology and device for preparing the cement raw materials by adopting the high-moisture chalk raw materials.

Owner:成都建筑材料工业设计研究院有限公司 +1

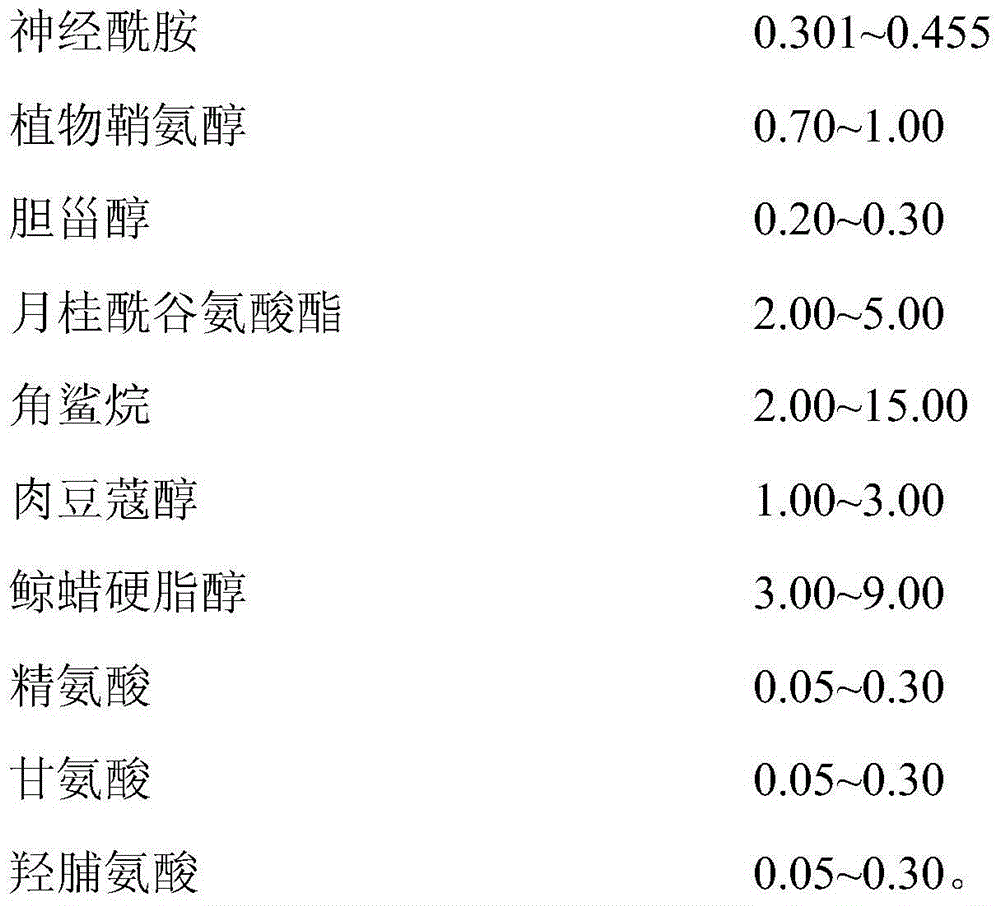

Moisturizing and repairing composition and epidermis biomimetic membrane liquid crystal complex constructed therefrom

ActiveCN104814881AExert moisturizing and repairing functionHigh affinityCosmetic preparationsToilet preparationsHydroxyprolineCholesterol

The invention belongs to the technical field of daily care products and discloses a moisturizing and repairing composition and an epidermis biomimetic membrane liquid crystal complex constructed therefrom. The core components of the moisturizing and repairing composition and the epidermis biomimetic membrane liquid crystal complex include ceramide, phytosphingosine, cholesterol, lauryl glutamate, squalane, myristyl alcohol, cetostearyl alcohol, arginine, glycine and hydroxyproline. In the invention, by means of combination of various raw materials and through a layered liquid crystal forming mechanism, the special epidermis biomimetic membrane is developed, by which a lamellar liquid crystal body, which likes a keratinocyte intercellular lipid layer, can be formed, so that an effect of protecting skin and improving skin can be achieved.

Owner:HUAANTANG BIOTECH GRP CO LTD

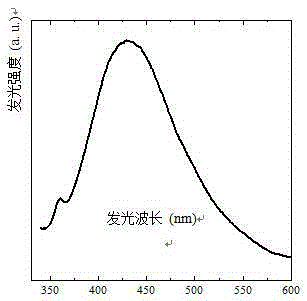

Light-emitting amorphous silicon carbide nanoparticle preparation method

ActiveCN105236410AGuaranteed normal formationSmall diameterMaterial nanotechnologyNanoparticleCarbide

The present invention relates to a light-emitting amorphous silicon carbide nanoparticle preparation method, and belongs to the technical field of photoelectric materials. The method is mainly characterized in that the silicon carbide polycrystalline ceramic sheet surface is subjected to a polishing treatment, focusing is performed onto the polycrystalline ceramic sheet immersed in deionized water by using excimer pulse laser, and during the irradiation process, a three-dimensional controllable platform carries a beaker to slowly translate so as to make the laser irradiation position on the ceramic sheet be continuously changed, such that finally the amorphous silicon carbide nanoparticles suspended in the deionized water and having the diameter of about 10 nm is obtained, wherein the surface is hydrophilic so as to ensure that the amorphous nanoparticles can be stably suspended in the ionized water and do not produce settling. In addition, the amorphous silicon carbide nanoparticles have strong and stable blue light emission, and have good application prospects in the fields of photoelectricity and biomedicine.

Owner:YANGZHOU UNIV

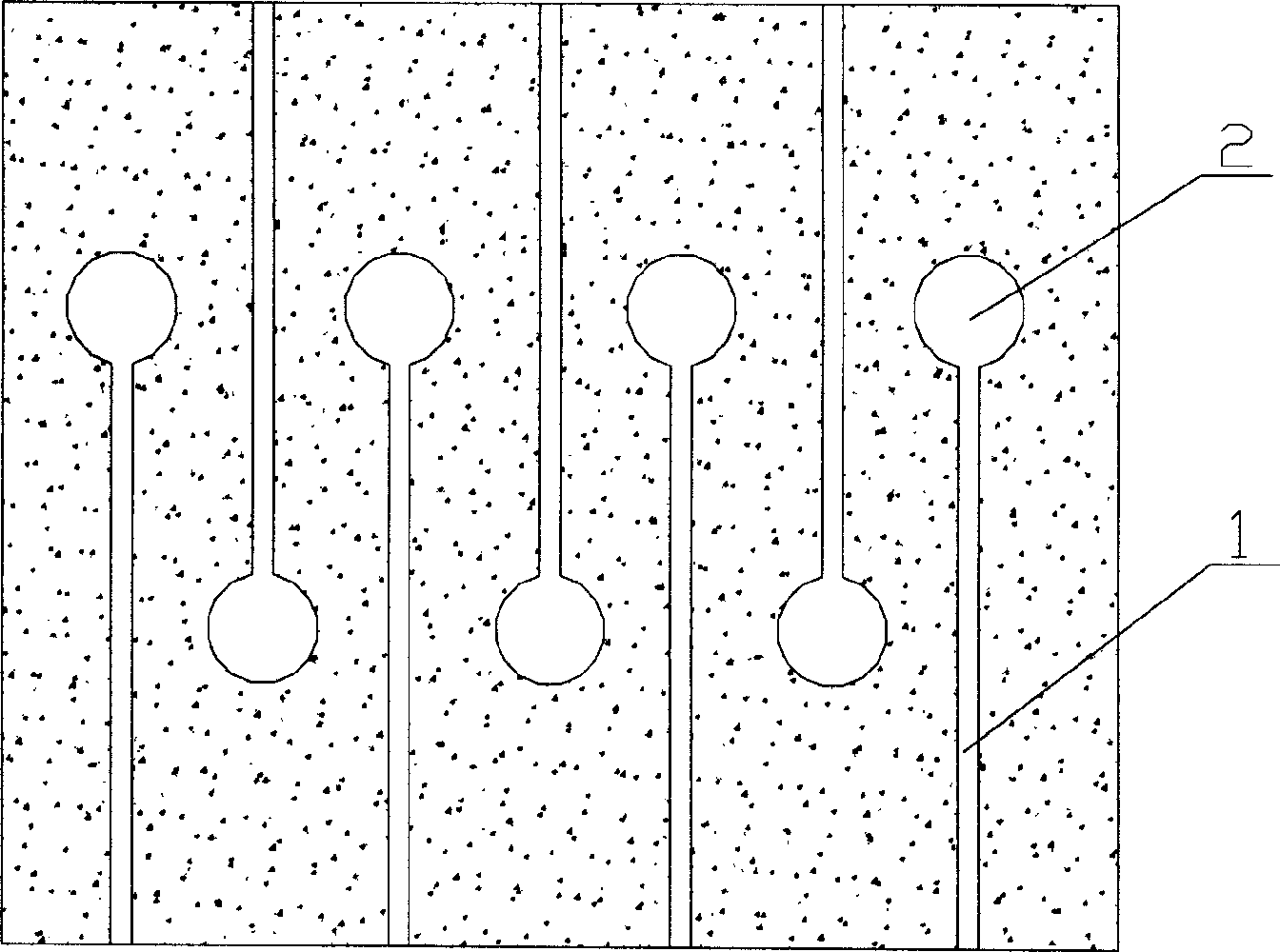

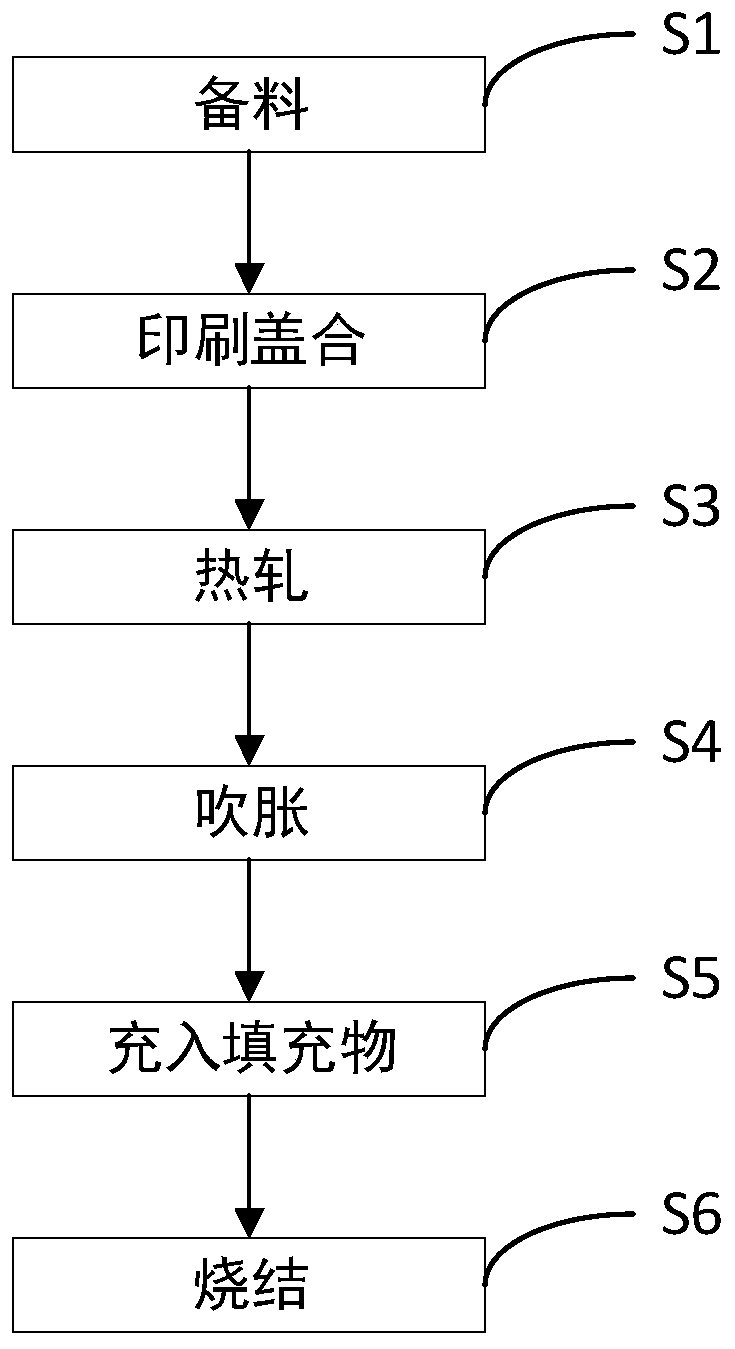

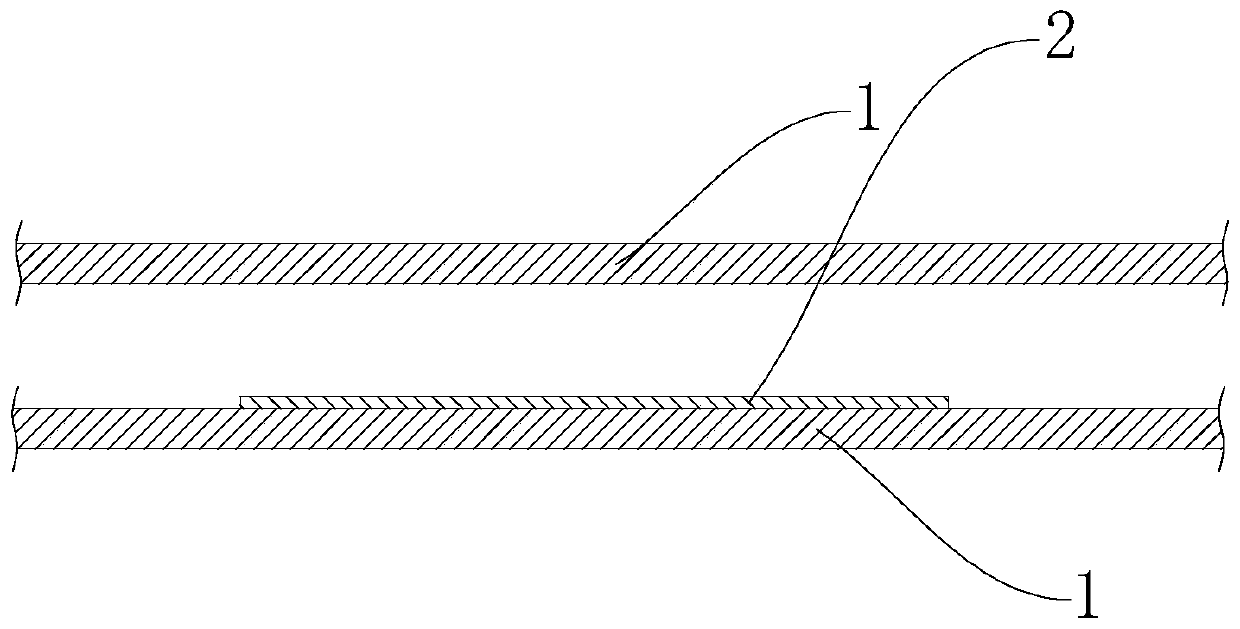

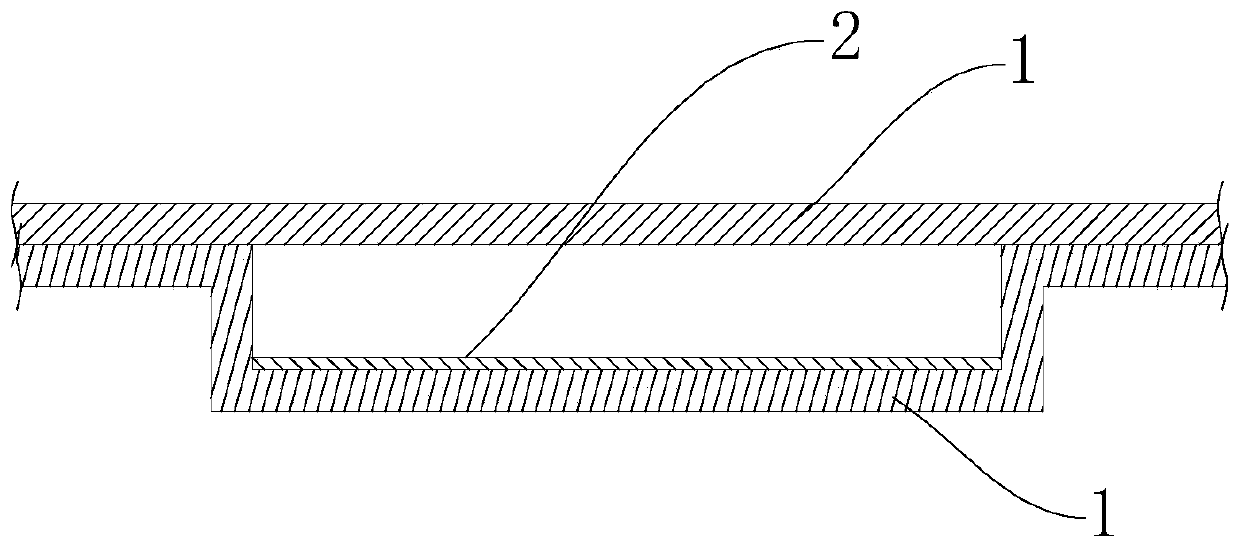

Processing method for blowing type soaking plate with capillary structure

ActiveCN110360861AAvoid deformationImprove cooling effectIndirect heat exchangersHigh pressureMelting point

The invention discloses a processing method for a blowing type soaking plate with a capillary structure. The processing method specifically comprises the following steps of 1, preparing materials, specifically, two substrates are prepared; 2, printing and capping, specifically, a blocking agent is printed on the substrates, and the two substrates are capped, wherein the blocking agent is positioned between the two substrates; 3, hot rolling, specifically, the double-layer substrate is rolled and synthesized into a composite plate; 4, blowing, specifically, high-pressure gas is introduced intothe composite plate, so that a part printed with the blocking agent is expanded to form a cavity; 5, filling filler, specifically, filler is filled into the cavity of the composite plate, wherein thefiller comprises particles, and the melting point of the particles is higher than that of the substrates; and 6, sintering, specifically, the composite plate is heated, and the filler is sintered on the composite plate to form the capillary structure. The filler is filled after a blowing process and sintered in the cavity to form the capillary structure, so that the situation that the filler is deformed or even broken due to extrusion is avoided, the formation of the capillary structure is guaranteed, and the heat dissipation effect of the soaking plate is improved.

Owner:常州恒创热管理有限公司

Preparation method for inorganic nanoparticle/graphene three-dimensional porous composite material

InactiveCN105932258APore Size ControlImprove conductivityMaterial nanotechnologyCell electrodesHigh energyMicrosphere

The invention provides a preparation method for an inorganic nanoparticle / graphene three-dimensional porous composite material. According to the preparation method, the inorganic nanoparticle / graphene three-dimensional porous composite material is prepared by the steps of uniformly mixing polystyrene microspheres pre-loaded with inorganic nanoparticles with a graphene oxide solution, then removing a solvent, and packaging and compounding the mixture; and next, removing a polystyrene template through thermal treatment, carrying out thermal reduction on graphene, and keeping the inorganic nanoparticles. The preparation method has the beneficial effects as follows: the polystyrene microspheres are taken as the carrier of the inorganic nanoparticles, so that agglomeration of the inorganic nanomaterial and the graphene lamination can be effectively avoided in the regulation and control process of the porous structure; when the porous composite material is used as the negative electrode of a lithium battery, the inorganic nanoparticles with high theoretical specific capacity supplies possibility for implementation of the high energy density of the material; the three-dimensional conductive network formed by graphene supplies possibility for implementation of the high power density; and in addition, due to the three-dimensional porous structure, the volume change caused by lithium intercalation / deintercalation of the active particles can be effectively relieved, so that the cyclic stability of the material is improved.

Owner:TIANJIN POLYTECHNIC UNIV

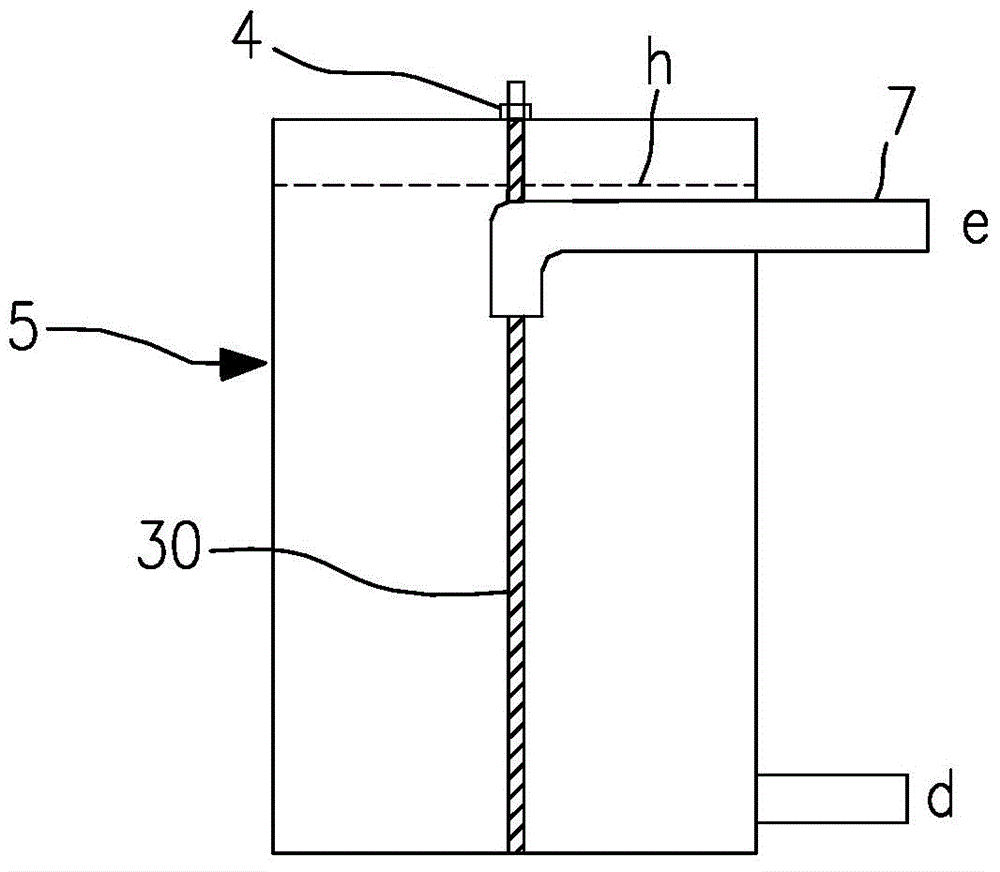

Crystal growth tank used for freezing and concentration

ActiveCN104689596ASmooth dischargeAvoid energy consumptionSolution crystallizationWhole bodyEngineering

The invention relates to a crystal growth tank used for freezing and concentration. The crystal growth tank comprises a barrel-shaped crystal tank body and a growth tank body, wherein a feeding hole is formed in the bottom of the crystal tank body; a cold medium water inlet located at the bottom end of the crystal tank body and a cold medium water outlet located at the top end of the crystal tank body are formed in the two symmetrical side edges of the crystal tank body; the crystal tank body is located on the lower side of the growth tank body, and the crystal tank body and the growth tank body are connected to form a communicated whole body, and a rotary shaft penetrates through the centers of the crystal tank body and the growth tank body; and the rotary shaft is rotationally and fixedly sealed between the top of the growth tank body and the bottom of the crystal tank body through sealing bearings at the two ends. A rotary shaft section in a material barrel of the crystal tank body, namely a scraping knife shaft, is movably connected with mutually-staggered scraping knives; a rotary shaft section in the growth tank body, namely a stirring shaft, is fixedly provided with hollow annular stirrers which are uniformly distributed; and the part, which is close to the center of the top, of the growth tank body is further provided with an ice discharging hole in a manner of extending out of the tank. The crystal growth tank is simple in structure, low in energy consumption and stable to operate, and can effectively guarantee the concentration effect.

Owner:HEFEI GENERAL MACHINERY RES INST

Artificial bone biotic producing process based on quick forming and steoro weaving

InactiveCN1561931AGuaranteed suitabilityGuaranteed normal formationBone implantArtificial boneRapid prototyping

A bionic technology based on fast shaping and 3D braiding for preparing artificial bone features that the 3D braiding and coating are used to form a microchannel structure of artificial bone and the fast shaping is used for generating the integral shape of artificial bone to match with the bone of patient.

Owner:XI AN JIAOTONG UNIV

Microcrystalline domestic ceramic prepared by talcum

The invention relates to microcrystalline domestic ceramic prepared by talcum. By taking the raw material components and the component contents thereof take 100 g of microcrystalline ceramic body as reference, the mass in gram of each component is as follows: 55-65 g of talcum, 50-65 g of soda feldspar, 4-15 g of potassium feldspar and 0.2-1.8 g of barium carbonate. The microcrystalline domestic ceramic prepared by talcum disclosed by the invention has the following advantages that: 1) cost is low, and the problems of the process properties of common ceramic production process necessary for clay and the supply bottleneck of high-quality kaolin are thoroughly solved; 2) automatic production process for glass is used for replacing manual and semi-mechanized processes for domestic ceramic, so that production efficiency is greatly increased and quality is greatly stabilized; and 3) the various performances and appearance quality requirement of domestic ceramic are realized via special heat treatment method.

Owner:廉江红星陶瓷企业有限公司 +1

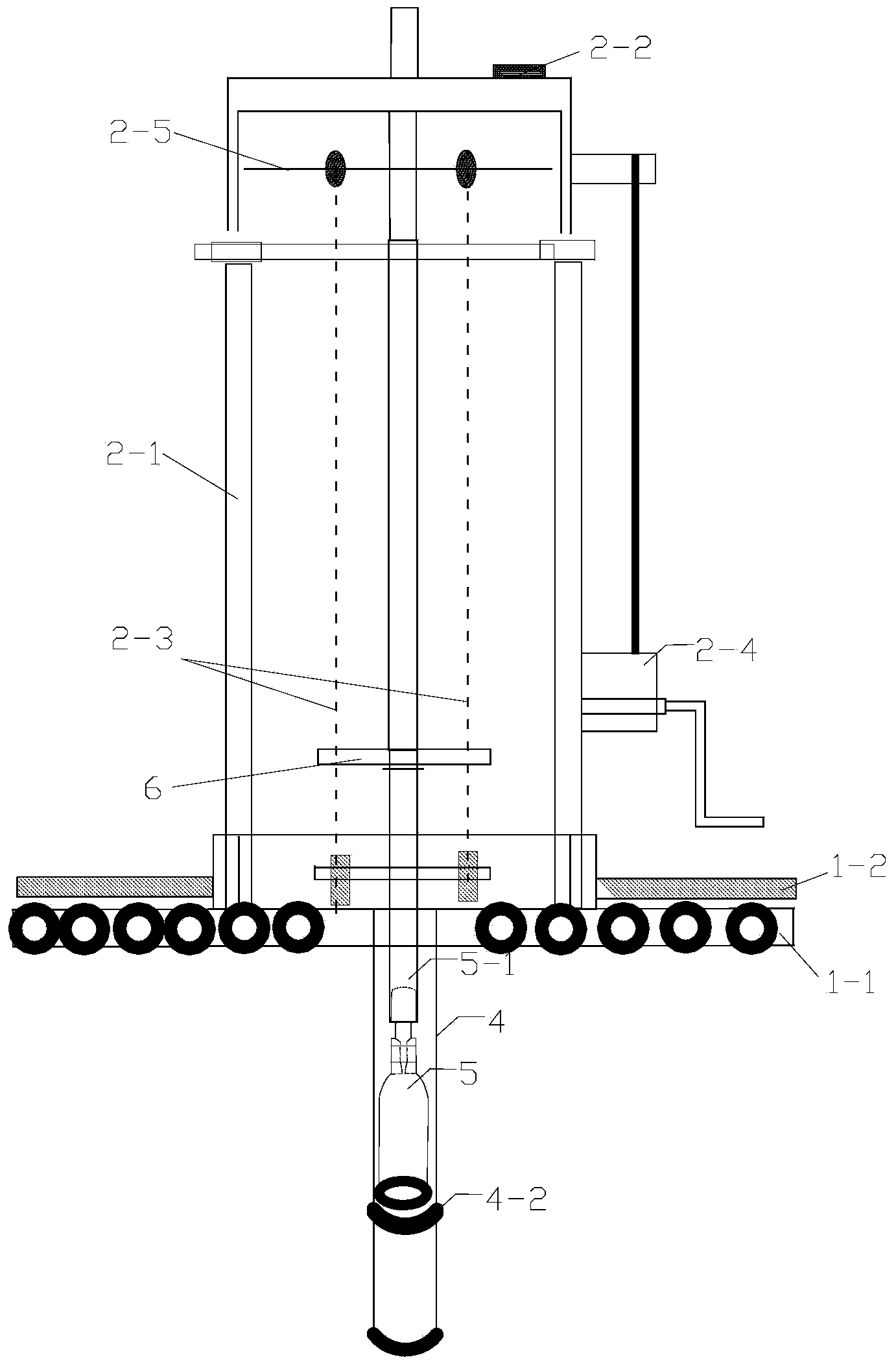

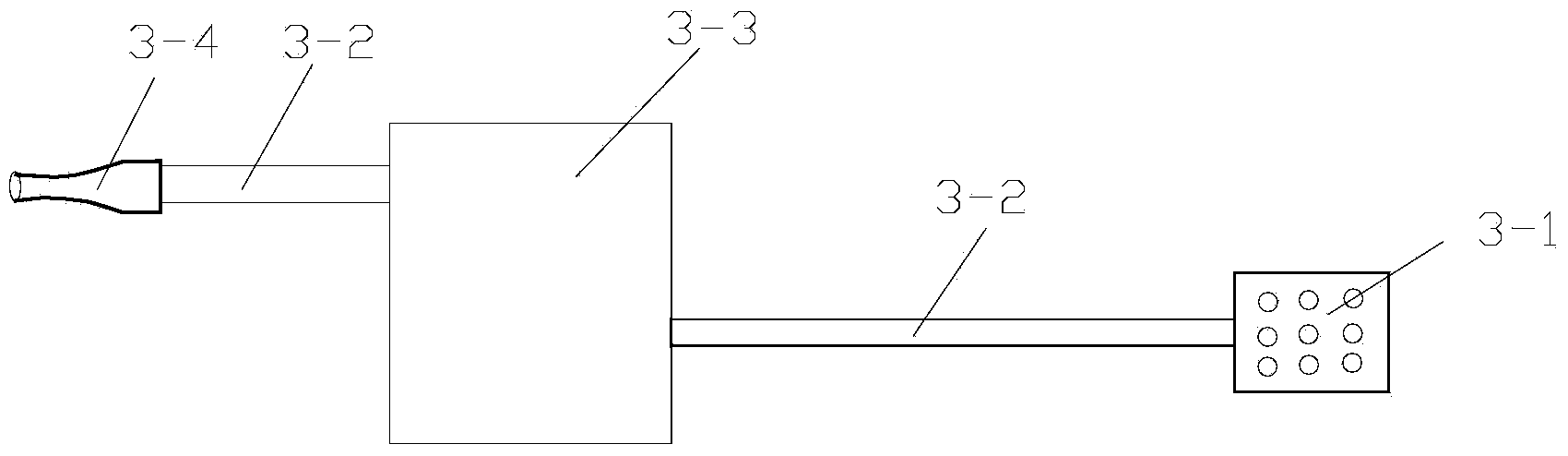

Equipment and method for reconnoitering and field sampling in soft soil region

InactiveCN103643669ASolve different difficultiesQuality improvementIn situ soil foundationEngineeringHigh water content

The invention discloses equipment for reconnoitering and field sampling in a soft soil region. The equipment comprises a bearing platform, a sampling power system, a sampling device, a hole-forming device, a hole-protecting device, a power generator and a transport device, wherein the transport device is used for transporting the bearing platform to a work place; the hole-forming device is used for forming a sampling hole in the bearing platform; the hole-protecting device is arranged in the hole formed by the hole-forming device; the sampling device is used for obtaining a soil sample in a position with the distance of 15-80 cm from the lower part of the bottom elevation of the sampling hole. The invention further discloses a method for sampling by the equipment for reconnoitering and field sampling in the soft soil region. According to the equipment and the method, the reconnoitering and sampling operations can be carried out in the soft soil region with very high water content and very low bearing capacity, and the high-grade undisturbed soil sample can be obtained.

Owner:TIANJIN SURVEY & DESIGN INST OF WATER TRANSPORT ENG +2

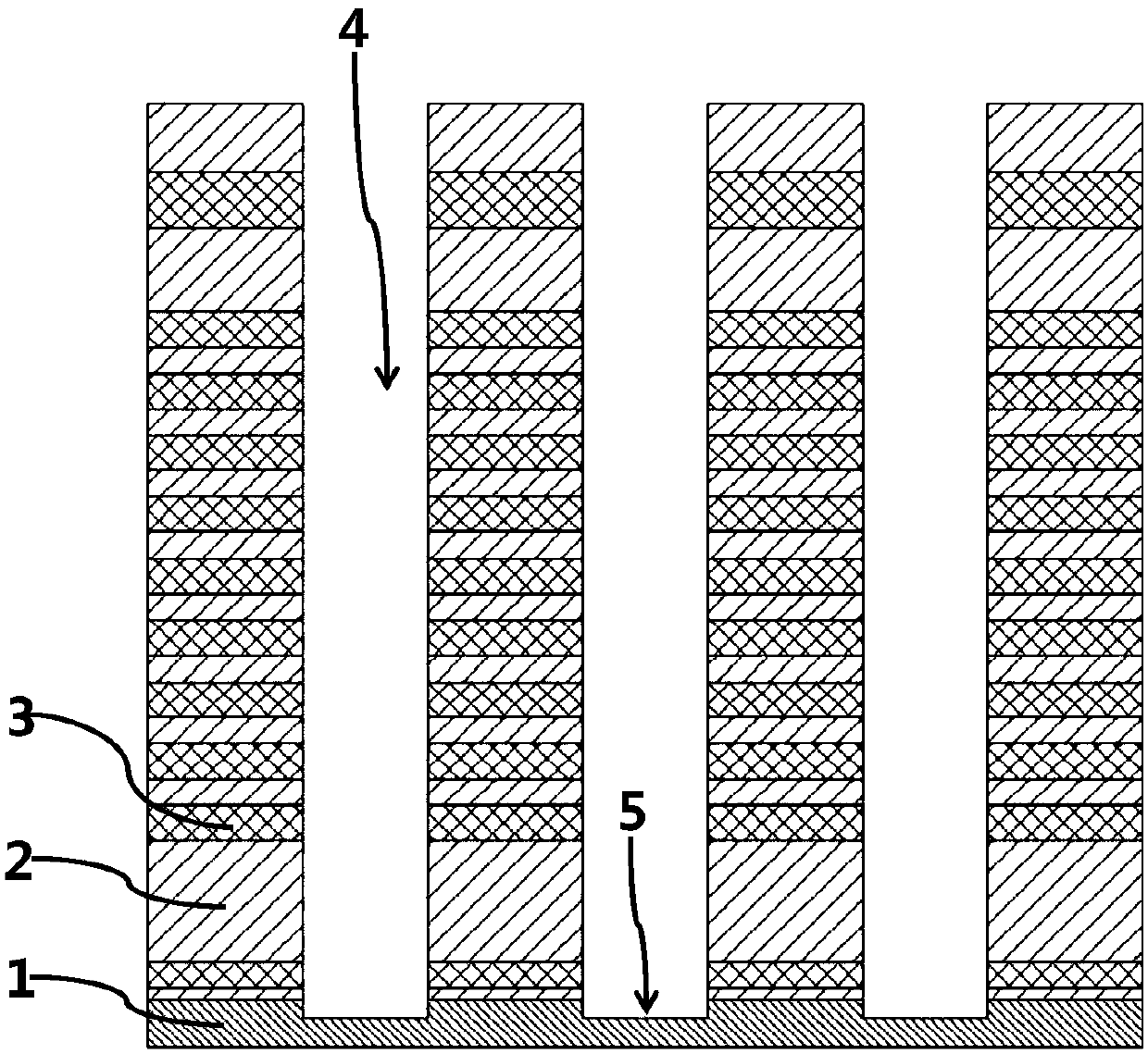

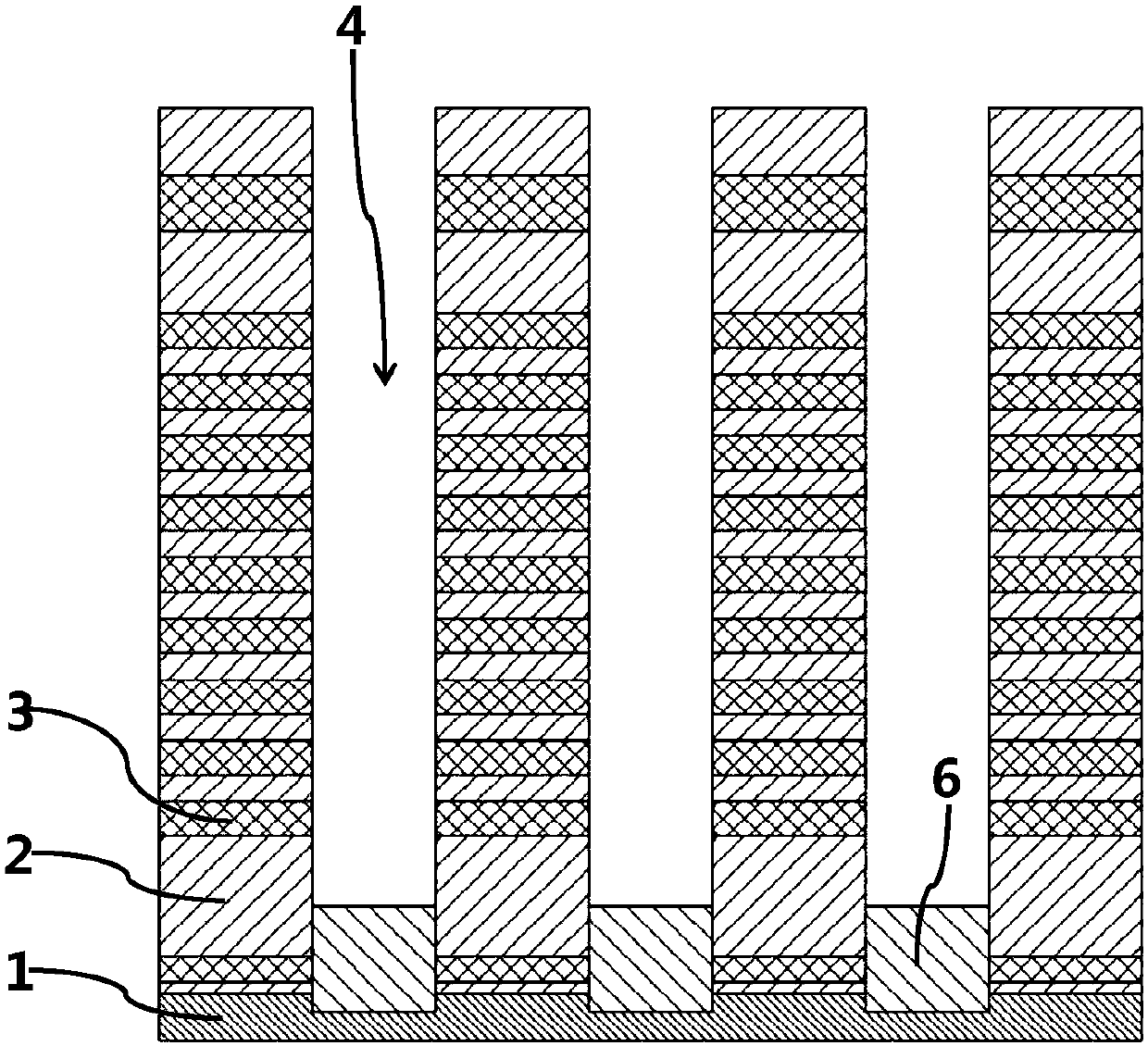

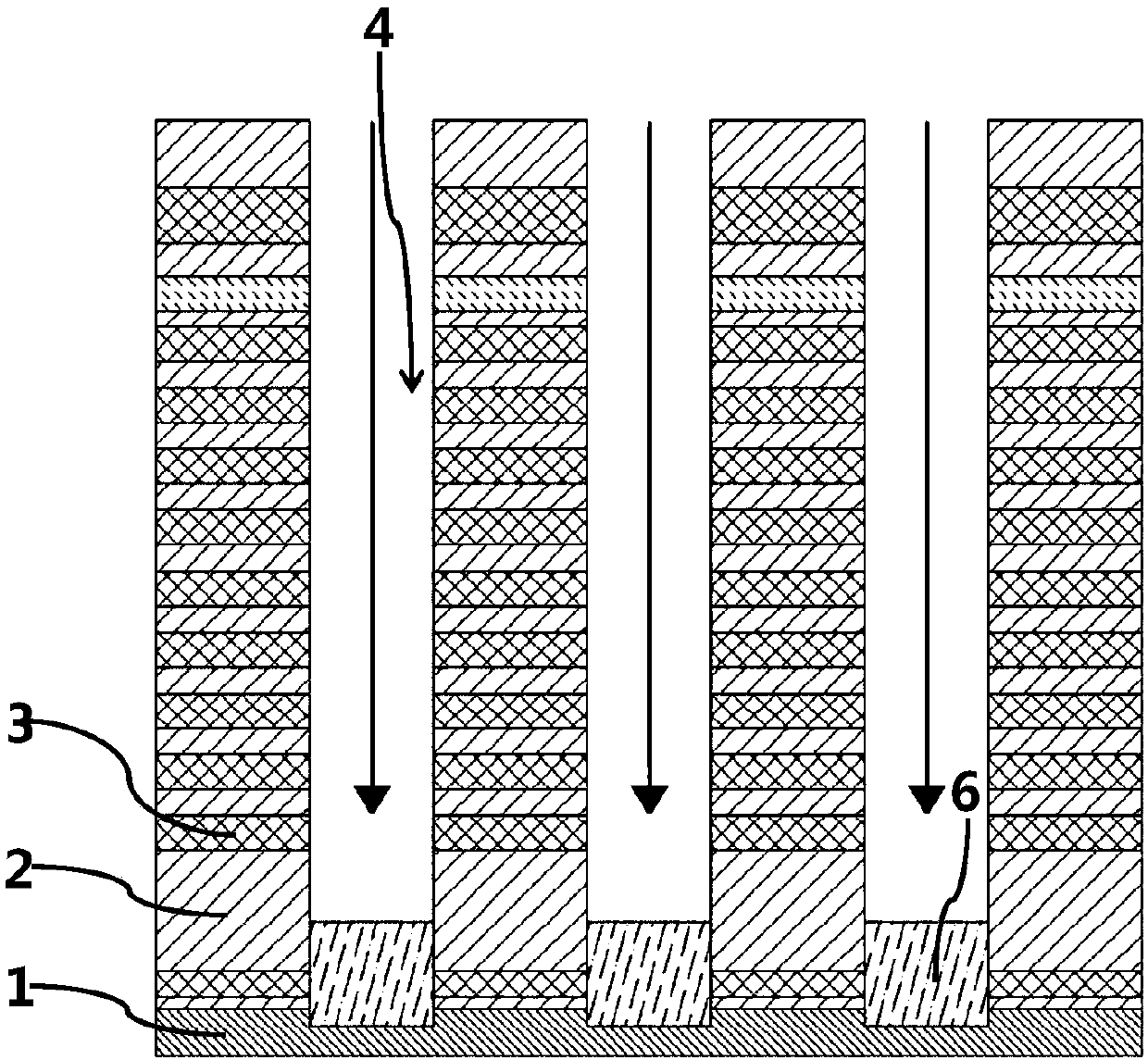

Technology of improving ion implantation and boron element diffusion in silicon epitaxial growth

ActiveCN107731671AInhibited DiffusionImproved threshold voltage (Vt) characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingAmorphous siliconBoron

The invention provides technology of improving ion implantation and boron element diffusion in silicon epitaxial growth in 3D NAND flash memory structure. Through adopting air having F and / or CI, plasma processing is conducted on a silicon groove interface in silicon epitaxial growth, and thereby monocrystalline silicon in silicon epitaxial growth interface can be effectively damaged and then willbe converted into amorphous silicon. As the epitaxial growing speed of the amorphous silicon interface is lower than that of the monocrystalline silicon interface, the forming of a vacancy (Void) between a silicon epitaxial layer and a substrate can be facilitated. The formed vacancy (Void) becomes a barrier of boron element interface diffusion, which effectively blocks the boron element doped during ion implantation from diffusing to the silicon substrate from the silicon epitaxial layer. Accordingly, the characteristic of the threshold-voltage (vt) of the silicon epitaxial layer can be improved, and the integral performance of the 3D NAND flash memory can be finally enhanced.

Owner:YANGTZE MEMORY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com